Composite phase change heat exchanger for flue gas heat recovery of boiler

A composite phase-change heat and waste heat recovery technology, which is applied to feed water heaters, preheating, lighting and heating equipment, etc., can solve the problems of difficult layout of tubular phase-change heat exchangers, eliminate the risk of low-temperature corrosion, reduce The effect of dust accumulation and convenient arrangement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

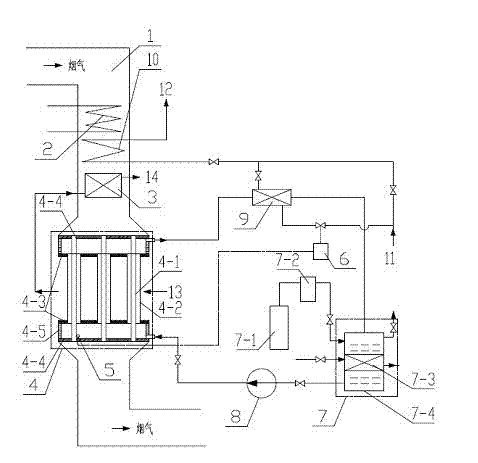

[0044] Composite phase change heat exchanger for waste heat recovery of boiler flue gas (see attached figure 1 and accompanying drawings), use air 13 and cold fluid 11 such as low-temperature water (or heat transfer oil) as working fluids for recycling waste heat, including boiler flue 1, internal and external equipment in the flue, and connecting pipes, control instrument valves . The flue 1 is equipped with a fluid heater 10, a composite phase change heat exchanger 4, the original economizer 2 of the boiler, an air preheater 3, and the dust removal and desulfurization equipment of the original boiler. Outside the flue, there are thermostat 7, heat exchanger 9, frequency modulation water pump 8 and its supporting pipes, instrument valves and so on.

[0045] The composite phase change heat exchanger 4 mainly includes an inner heat exchange tube 4-1, a casing 4-2, a first tube sheet 4-3, a second tube sheet 4-4 and a box 4 between the tube sheets -5. Among them, the air goe...

Embodiment 2

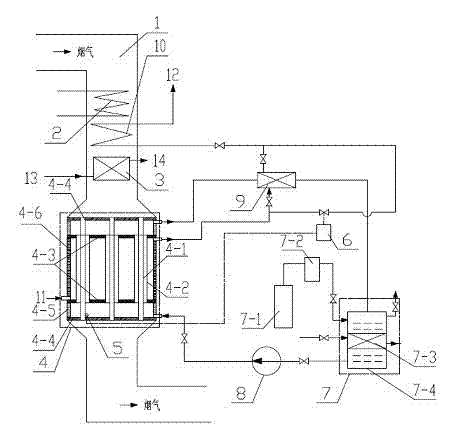

[0050] Composite phase change heat exchanger for waste heat recovery of boiler flue gas (see attached figure 2 and accompanying drawings), using cold fluid 11 such as low-temperature water (or heat transfer oil) as a working medium for recycling waste heat, including boiler flue 1, internal and external equipment of the flue, connecting pipes, and control instrument valves. The flue 1 is equipped with a fluid heater 10, a composite phase change heat exchanger 4, the original economizer 2 of the boiler, an air preheater 3, and the dust removal and desulfurization equipment of the original boiler. Outside the flue, there are thermostat 7, heat exchanger 9, frequency modulation water pump 8 and its supporting pipes, instrument valves and so on.

[0051] The composite phase change heat exchanger 4 mainly includes an inner heat exchange tube 4-1, a casing 4-2, a first tube sheet 4-3, a second tube sheet 4-4 and a box 4 between the tube sheets -5 and 4-6. Among them, the cold flu...

Embodiment 3

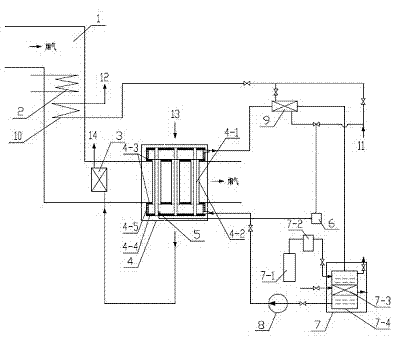

[0057] The composite phase change heat exchanger 4 of the present invention can also be arranged in a horizontal flue, such as image 3 shown. The flue gas passes through the shell side outside the casing, and the cold fluid to be heated passes through the tube side of the inner heat exchange tube. The specific implementation method is the same as above.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com