Phase transition combined air preheater

A technology of air preheater and phase change heat exchanger, applied in heat exchange equipment, lighting and heating equipment, combustion method, etc., can solve the problems of fouling, affecting the thermal efficiency of boilers, wasting heat sources, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

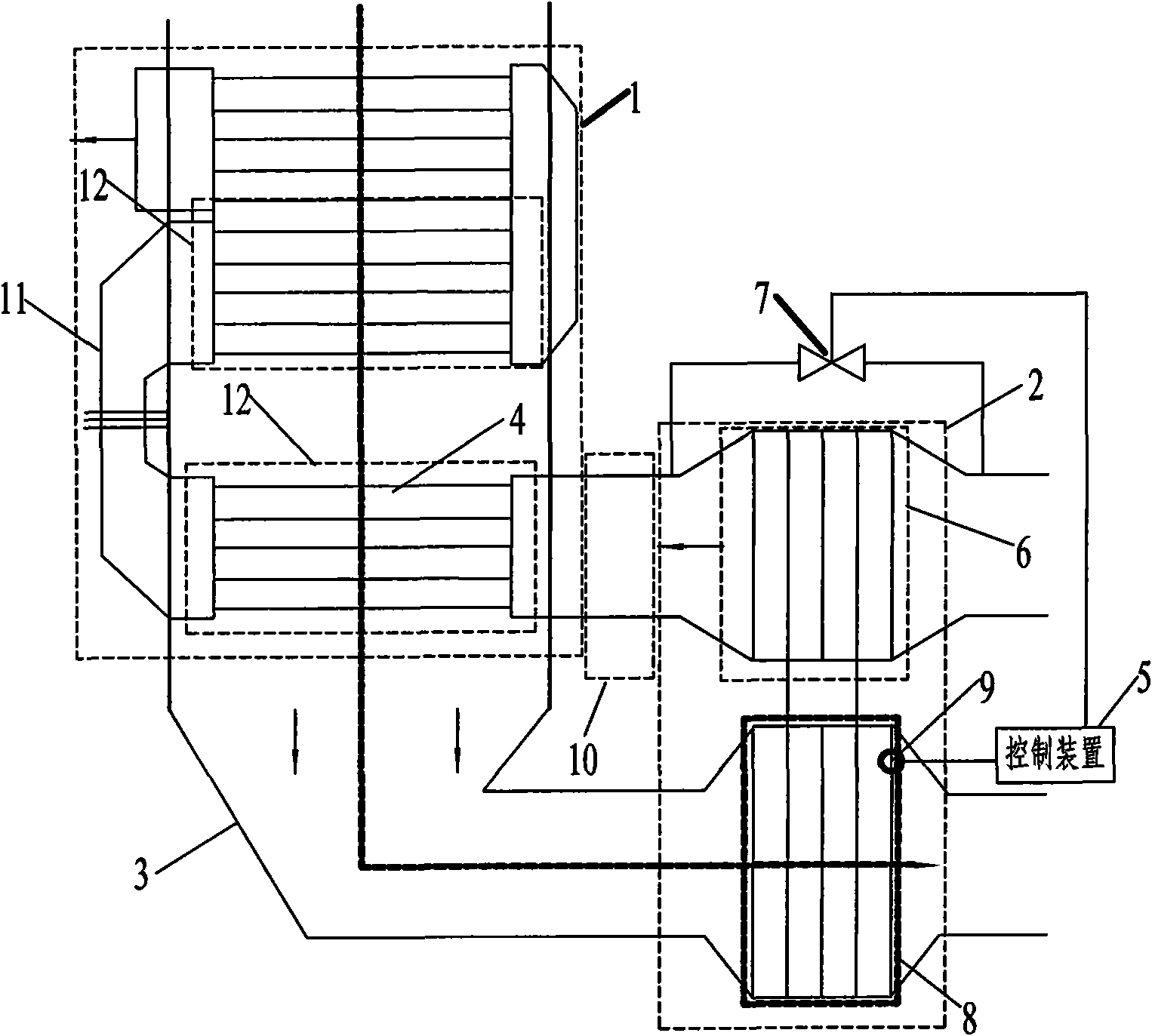

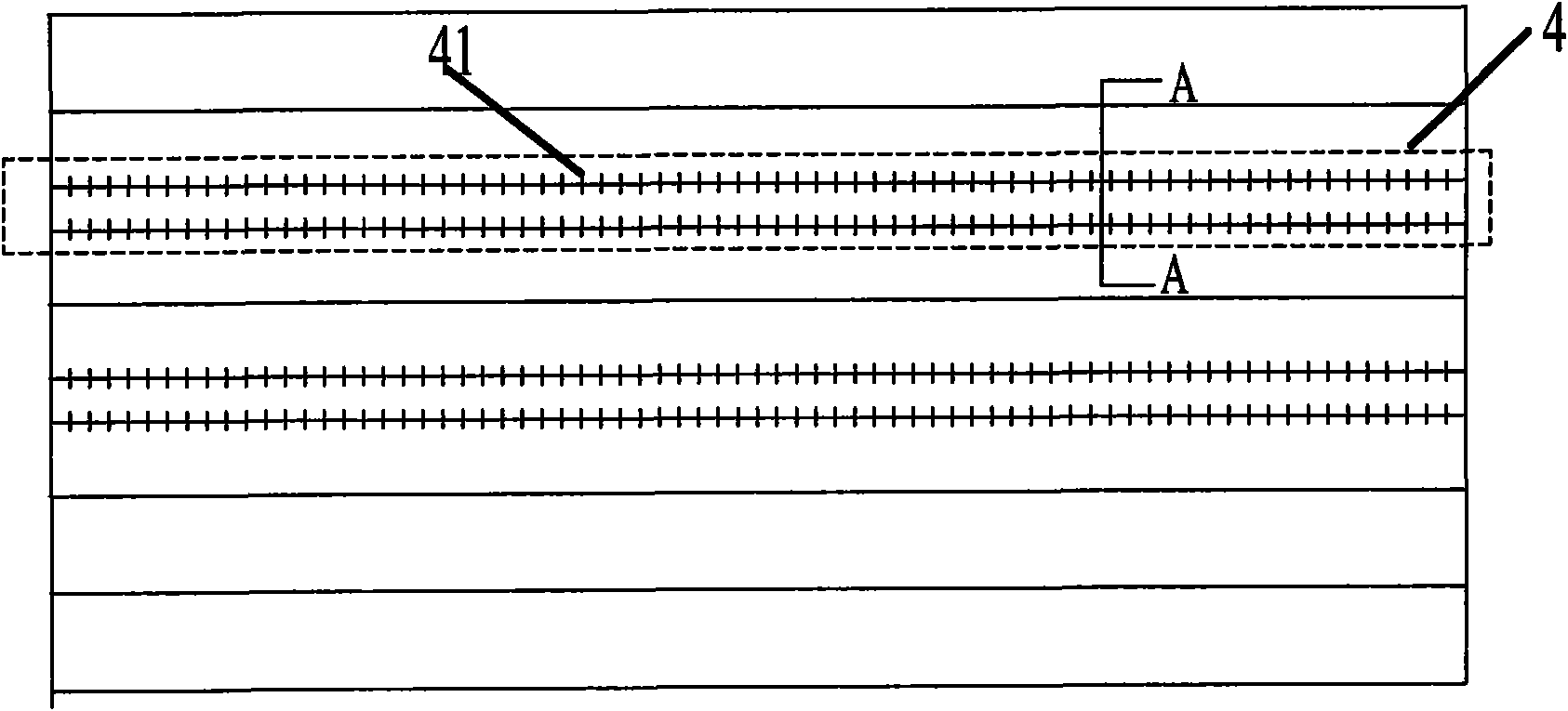

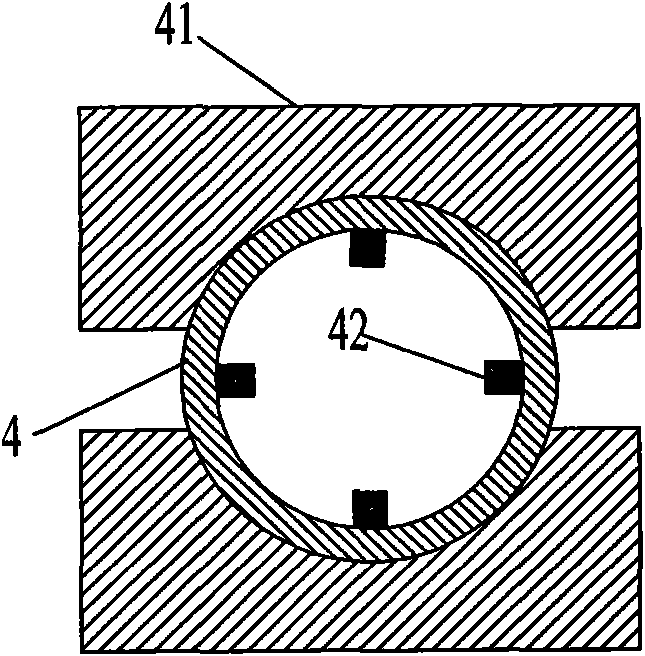

[0023] Such as figure 1 , figure 2 with image 3 As shown, the present invention proposes an implementation case of a phase change combined air preheater.

[0024] The combined phase change air preheater includes: a tubular air preheater 1 and a phase change heat exchanger 2, wherein the tubular air preheater 1 is connected to the upper section 6 of the phase change heat exchanger through an air duct 10, The upper section 6 of the phase change heat exchanger is provided with a flow valve 7 controlled by the control device 5 to flow through the phase change heat exchanger 2; the lower section 8 of the phase change heat exchanger is connected to the tail flue 3 of the boiler, and the A temperature collection module 9 electrically connected to the control device 5 is provided on the tube wall of the lower section 8 of the device. The control device 5 controls the opening of the flow valve 7 according to the wall surface temperature collected by the temperature collection module 9. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com