Cyclonic and electrostatic coupling high-efficiency dust and mist removal apparatus and its application

A technology of electrostatic coupling and demisting device, applied in electrostatic separation, external electrostatic separator, electrode structure, etc., can solve the problems of unstable electric field voltage, reduce dust removal efficiency, and dust accumulation in cathode lines, and achieve increased turbulent flow, The effect of improving the removal efficiency and the large area of the dust collecting plate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

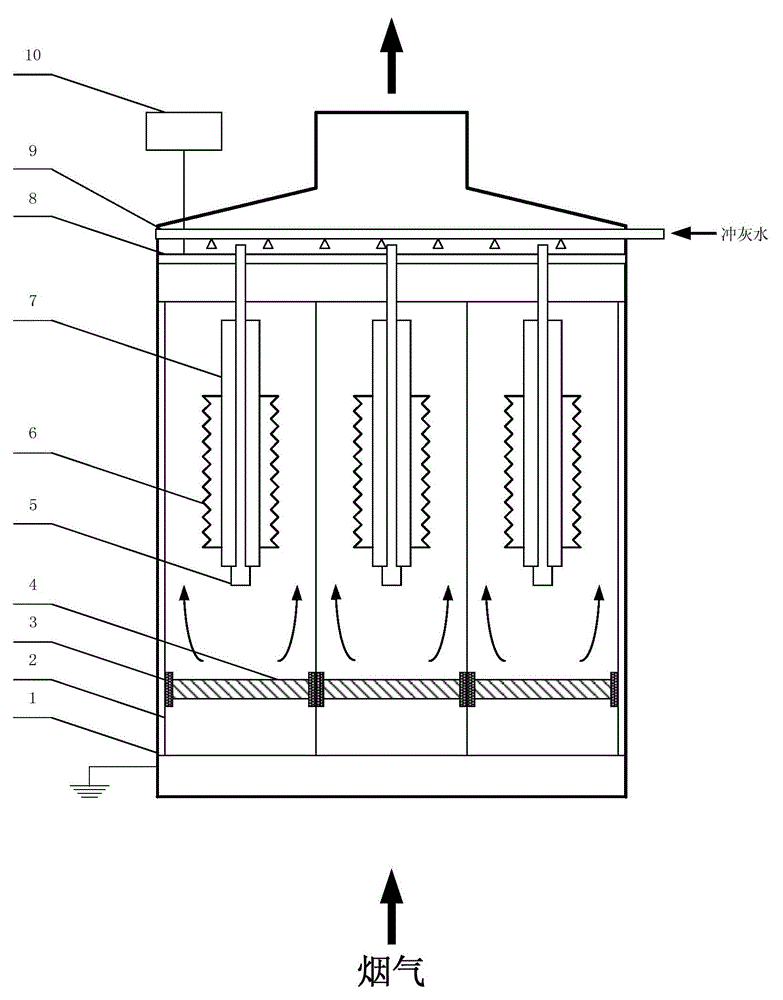

[0039] Using a hexagonal stainless steel cylinder with a side length of 400mm, press figure 1 The cyclone electrostatic dust and mist removal unit is built as the test device as shown. The amount of flue gas used in the test is 100m 3 / h, flue gas temperature is 90°C, inlet flue gas SO 3 The concentration is 50mg / Nm 3 , soot content 1400mg / Nm 3 . In the case of no voltage applied, the measured SO 3 The removal efficiency is about 35%, and the dust removal efficiency is 40%. Then, the electrostatic voltage was adjusted to 40kV, and the measured SO 3 The removal efficiency is about 60%, and the dust removal efficiency is 70%. It can be seen that the combination of the inward injection plate, the bottom swirl plate and spraying technology can significantly improve the purification degree of flue gas.

Embodiment 2

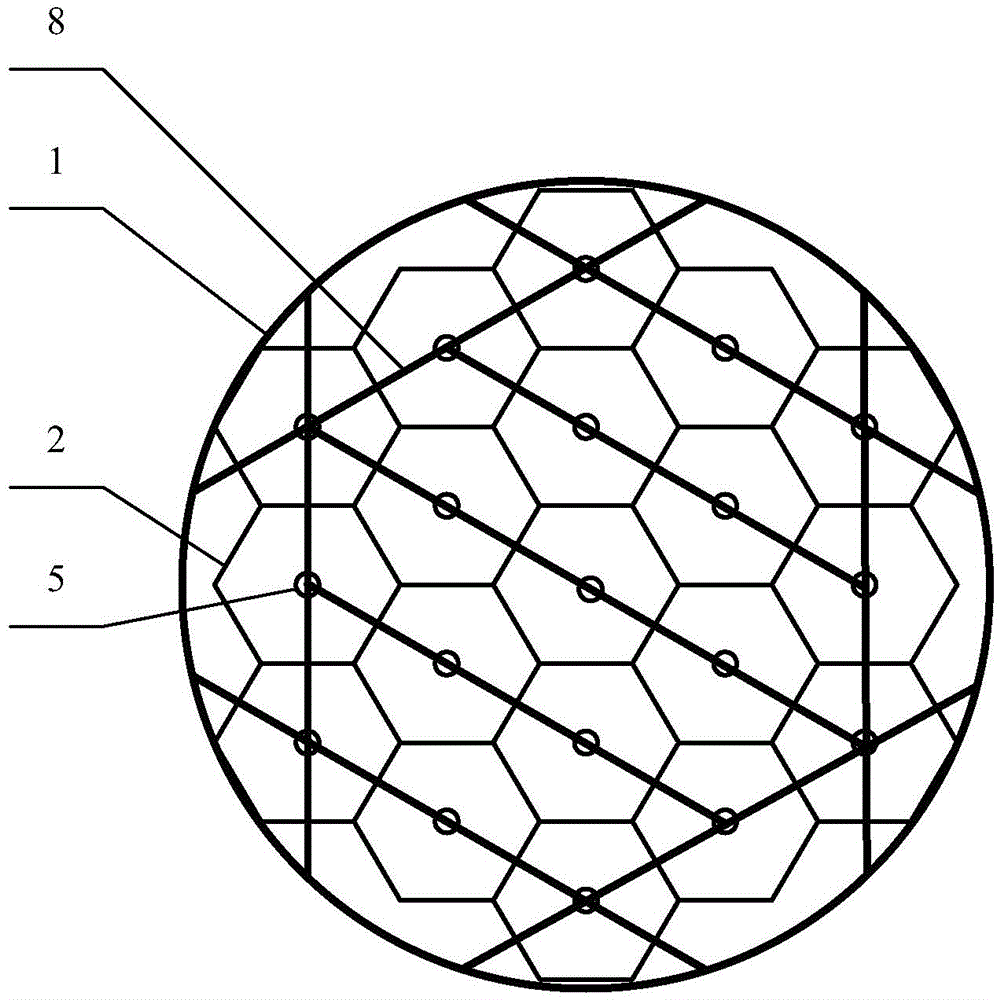

[0041] For a coal-fired boiler with a coal consumption of 10t / h, the designed flue gas volume is 20000Nm 3 / h, flue gas temperature is 140°C, inlet flue gas SO 3 Concentration up to 100mg / Nm 3 , soot content 4000mg / Nm 3 . The device of the present invention adopts the figure 1 The device shown uses 7 towers with an inner diameter of 2200mm. Sodium-calcium double-alkali flue gas desulfurization process is adopted. The vane elevation angle of the bottom swirl plate is 28°, and the opening ratio is 32%; the elevation angle of the inward jet plate is 32°, and the opening ratio is 36%.

[0042] When the boiler load is 90%, the measured desulfurization efficiency is 96.3% and the dust removal efficiency is greater than 97% (the dust concentration in the outlet flue gas is lower than 50mg / Nm3) when the liquid-gas ratio is 1.8L / m3. The airflow resistance of the whole tower is only about 800Pa.

Embodiment 3

[0044] The same structure as in Example 1 is used to treat the coal-fired flue gas of a 40t / h coal-fired boiler. The flue gas is pre-dusted by a multi-tube dust collector, and desulfurized and further dusted by a magnesium oxide desulfurization process. The amount of flue gas treated is 120000m3 / h, and the concentration of sulfur dioxide is 3500mg / Nm 3 . The diameter of the absorption tower is 3500mm. The results show that when the liquid-gas ratio is 2.2L / m 3 , the desulfurization rate was 97%. No fouling and clogging occurred during the continuous operation of the equipment for 6 months.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com