Palm fruit sterilization system

A technology of palm fruit and sterilizing machine, which is applied in the direction of fat production, fat oil/fat production, etc. It can solve the problems of high accumulation of palm fruit clusters, high labor intensity, complex system, etc., and achieves easy automatic control, saves manual operation, and kills leaven simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

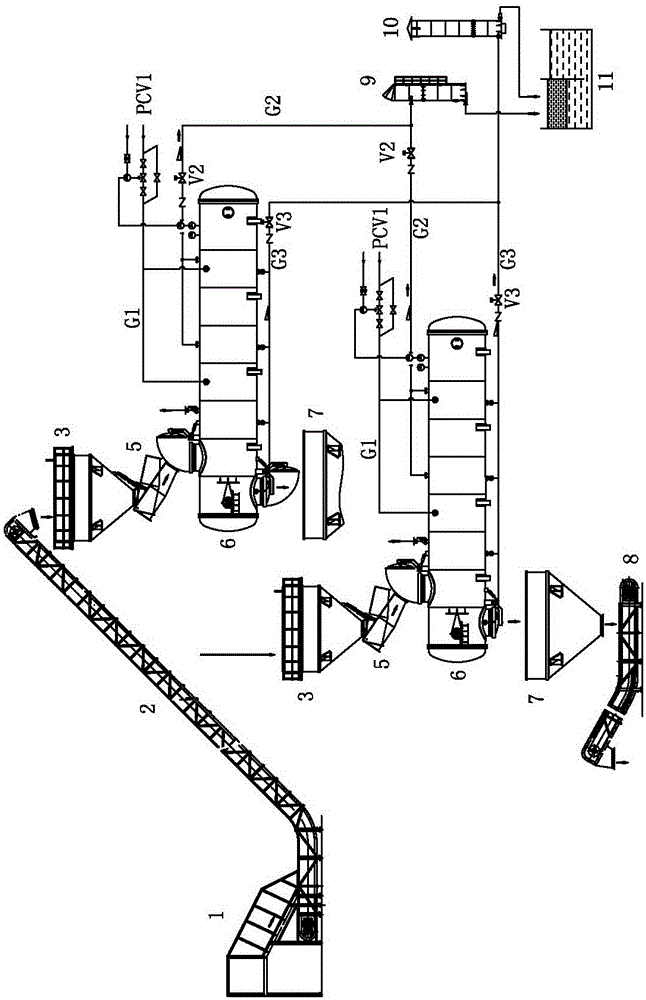

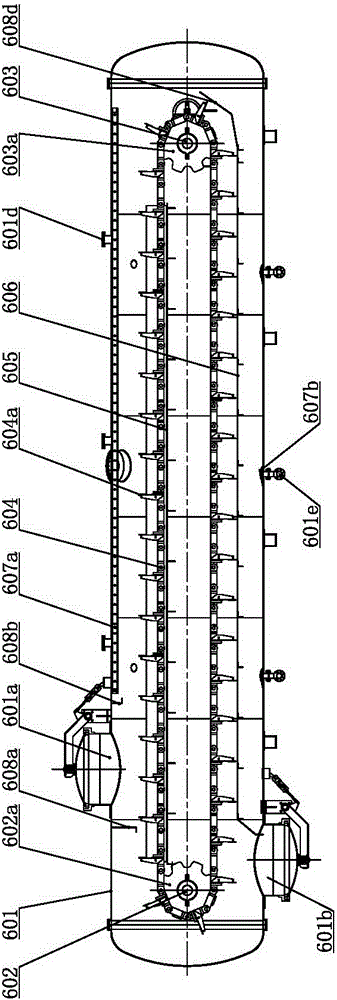

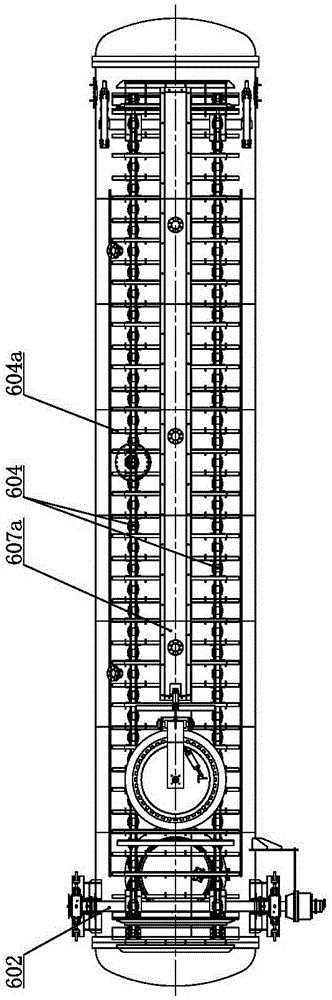

[0044] like figure 1 As shown, the brown fruit sterilization system of the present invention includes a fresh fruit string ramp 1, a fresh fruit scraper conveyor 2, a fresh fruit temporary storage feeding device, a brown fruit sterilization machine 6, a ripe fruit hopper 7 and a ripe fruit scraper conveyor 8 , the exit of the fresh fruit string ramp 1 is connected to the entrance of the fresh fruit scraper conveyor 2, the exit of the fresh fruit scraper conveyor 2 is connected to the entrance of the fresh fruit temporary storage feeding device, and the outlet of the fresh fruit temporary storage feeding device is connected to the palm fruit killer. The sterilizing machine feed port 601a of the fermentation machine 6 is connected, and the sterilizing machine discharge port 601b of the palm fruit sterilizing machine 6 is connected with the entrance of the ripe fruit hopper 7.

[0045] The fresh brown fruit slides down from the fresh fruit string ramp 1 and enters the fresh fruit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com