Palm fruit bundle transfer method

A technology of palm fruit bundles and fruit cages, which is applied in the field of oil production in palm fruit pressing plants, and can solve the problems of steel structure workshops covering a large area and investment, difficult automatic control, and large investment in equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

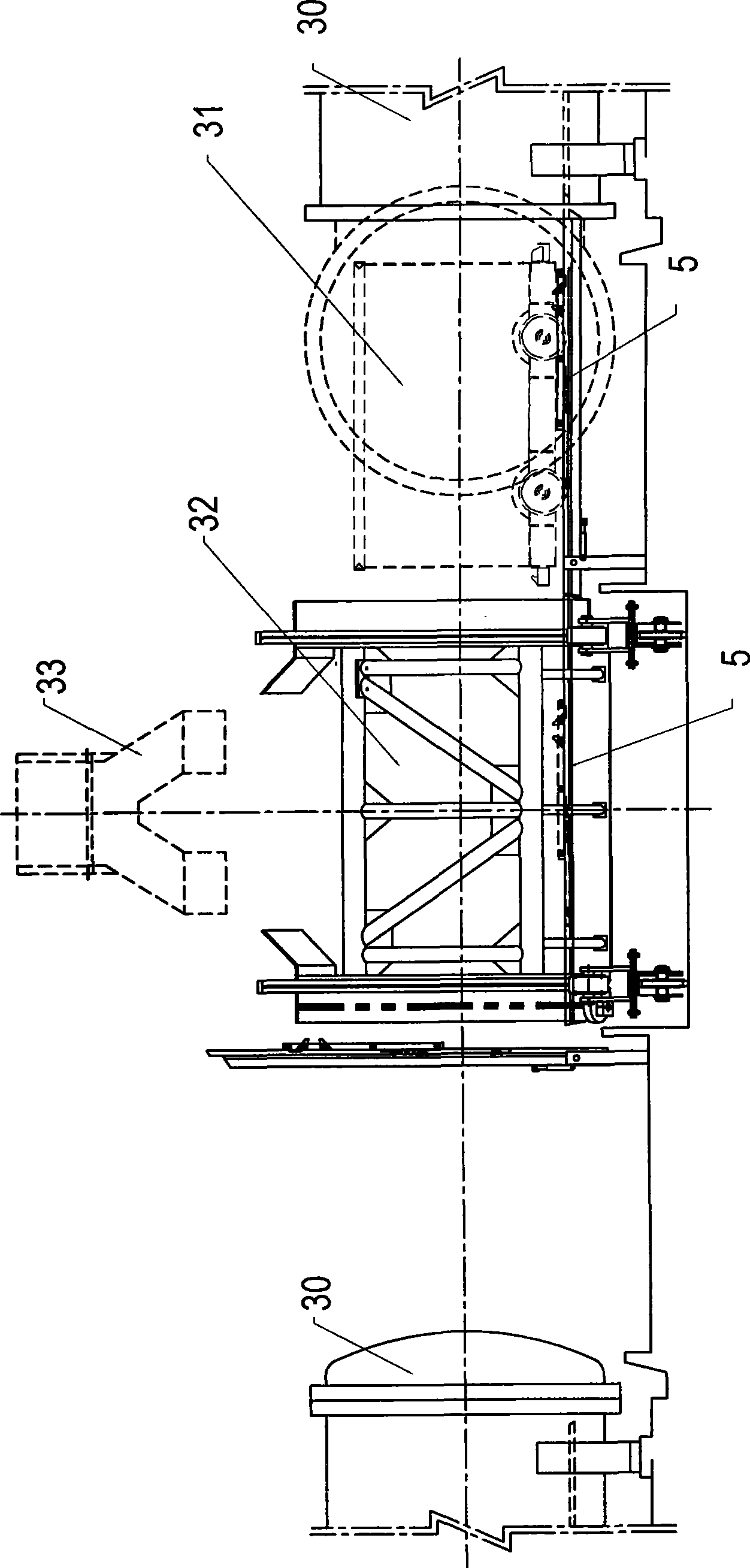

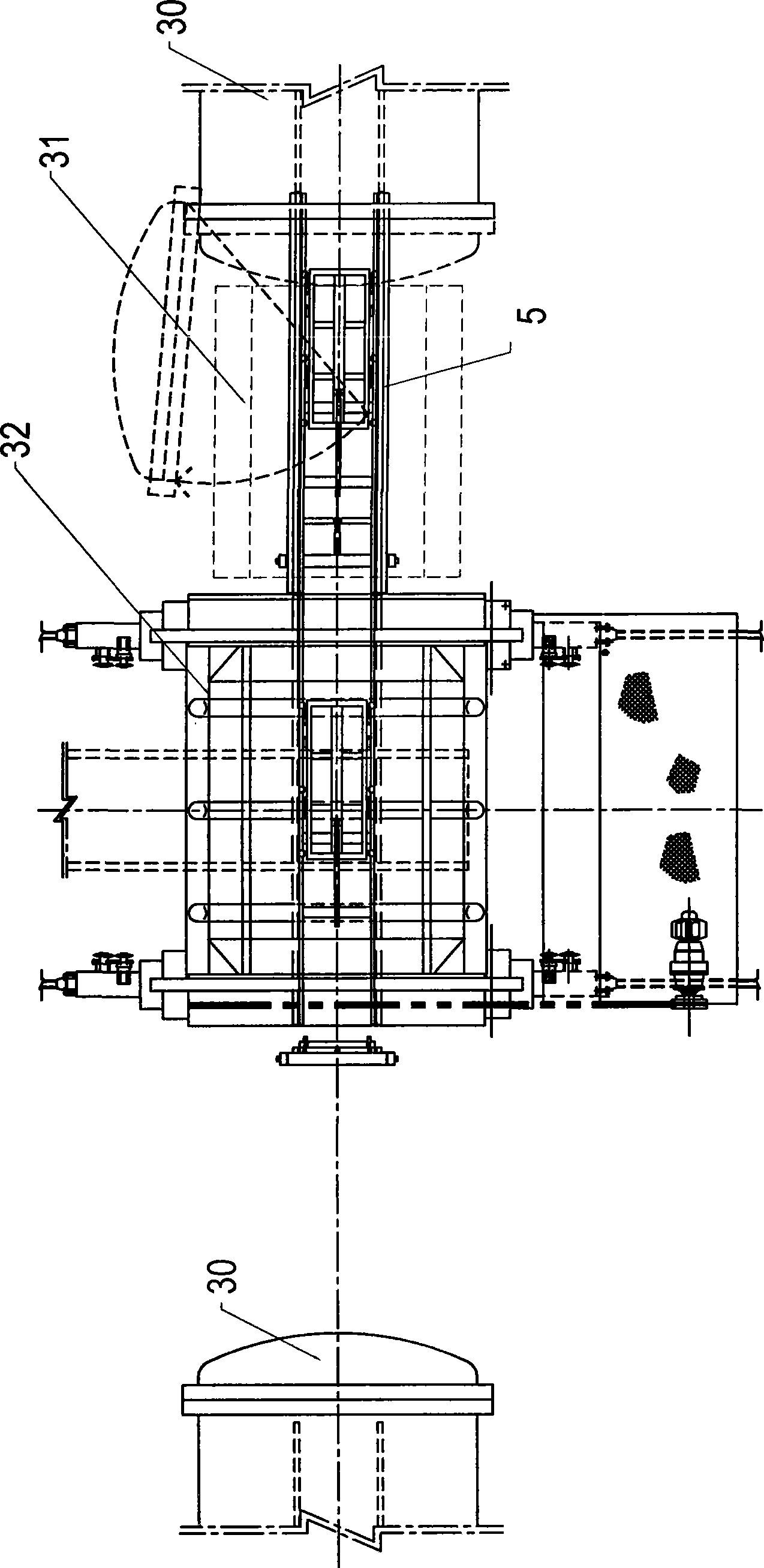

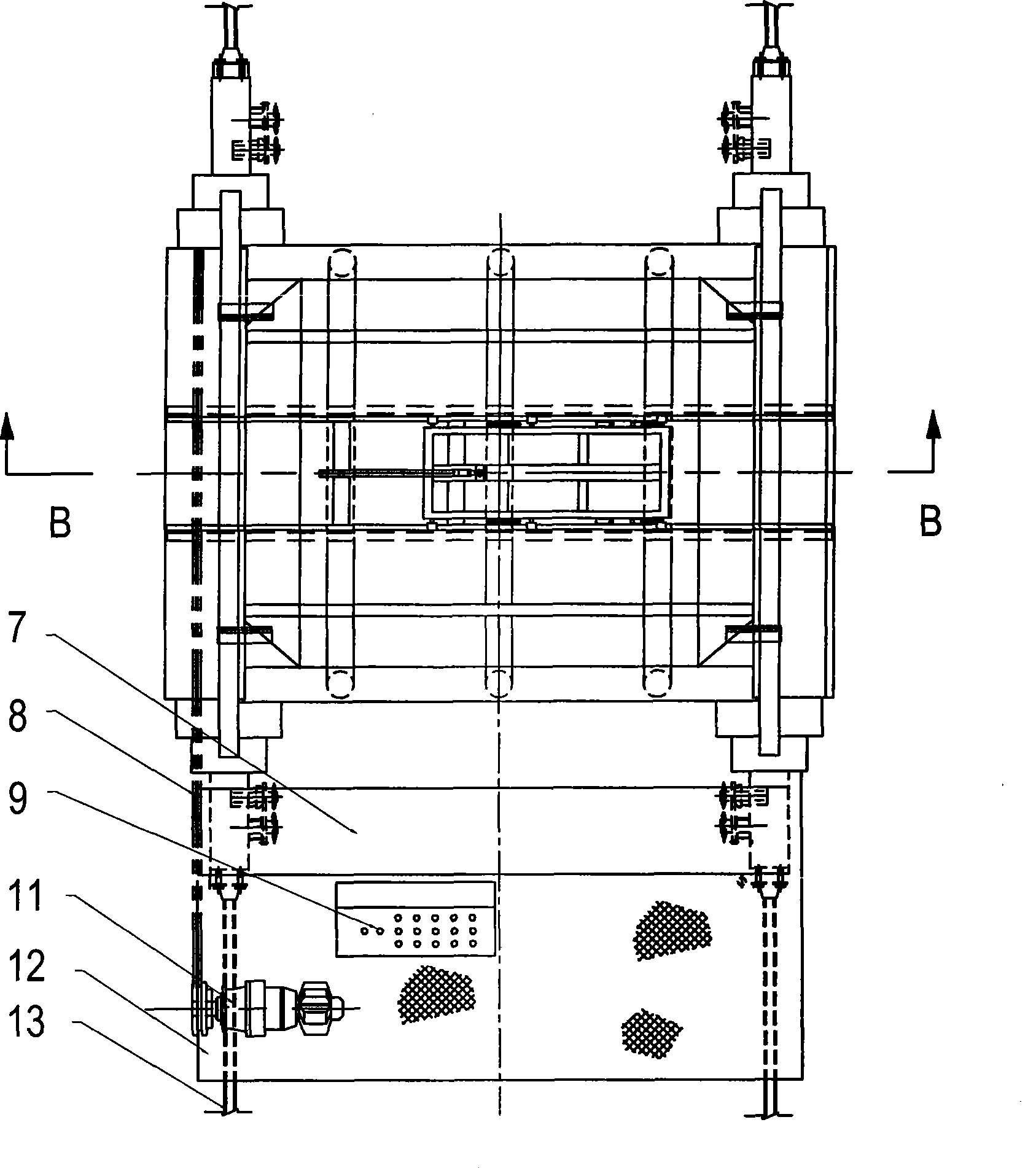

[0019] Such as figure 1 , 2 As shown, the palm fruit bunch transfer method comprises that the palm fruit bunch utilizes slope unloading to the feeding scraper 33 process, and then the feeding scraper 33 transports the fruit bunch to the empty fruit cage car 31 of the mobile transfer overturning car 32 Inside, then the push-pull mechanism 5 of the mobile transshipment dumper 32 pushes the fruit cage trolley 31 full of fruit bundles into the sterilization tank 30 along the track to carry out the sterilization process; The push-pull mechanism 5 of 32 pulls the fruit cage car 31 out of the sterilization tank 30, pulls it into the mobile transfer dumper 32, and then the mobile transfer dumper 32 is moved to the designated position by the walking aid mechanism to turn over and unload the material along the track, killing The fermented palm fruit bundles enter the next process for fruit removal; the empty fruit cage car 31 is reloaded by the feed scraper 33 to carry out cycle produc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com