Intelligent optical distribution frame

A technology of optical fiber intelligence and distribution frame, which is applied in the direction of light guide, optics, optical components, etc., can solve the problems of single function, small pigtail storage capacity, inconvenient deployment and connection operation, etc., and achieve simple and compact structure, space saving, and easy operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

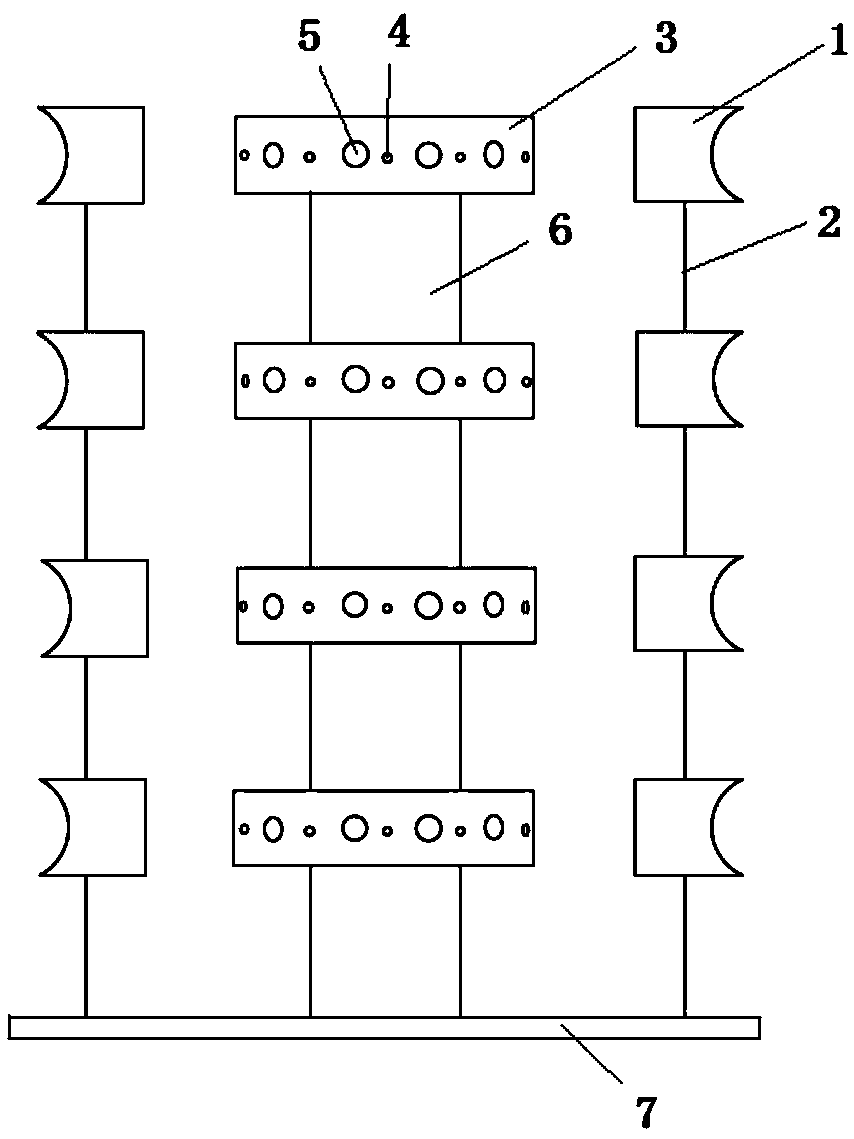

[0029] An optical fiber intelligent distribution frame of the present invention comprises a horizontally arranged bottom plate 7, a hollow cylindrical frame 6 vertically arranged on the bottom plate 7, and four wiring rings sleeved on the cylindrical frame 6 at intervals 3 and the fiber coil frame 1 for coiling optical fibers arranged on the periphery of the junction ring 3; the cylindrical frame 6 is used to pass through the optical fiber when in use; 24 optical fibers are penetrated on the ring wall of the junction ring 3 Flange head 5, these 24 fiber optic flange heads 5 are evenly spaced, and the inner end of described fiber optic flange head 5 (the end near cylindrical frame 6) communicates with the inside of described cylindrical frame 6, so that from cylindrical frame 6 The passing optical fiber can pass through the fiber optic flange head 5 smoothly; a monitoring assembly for monitoring the real-time status of the optical fiber is arranged in the junction ring 3, and a ...

Embodiment 2

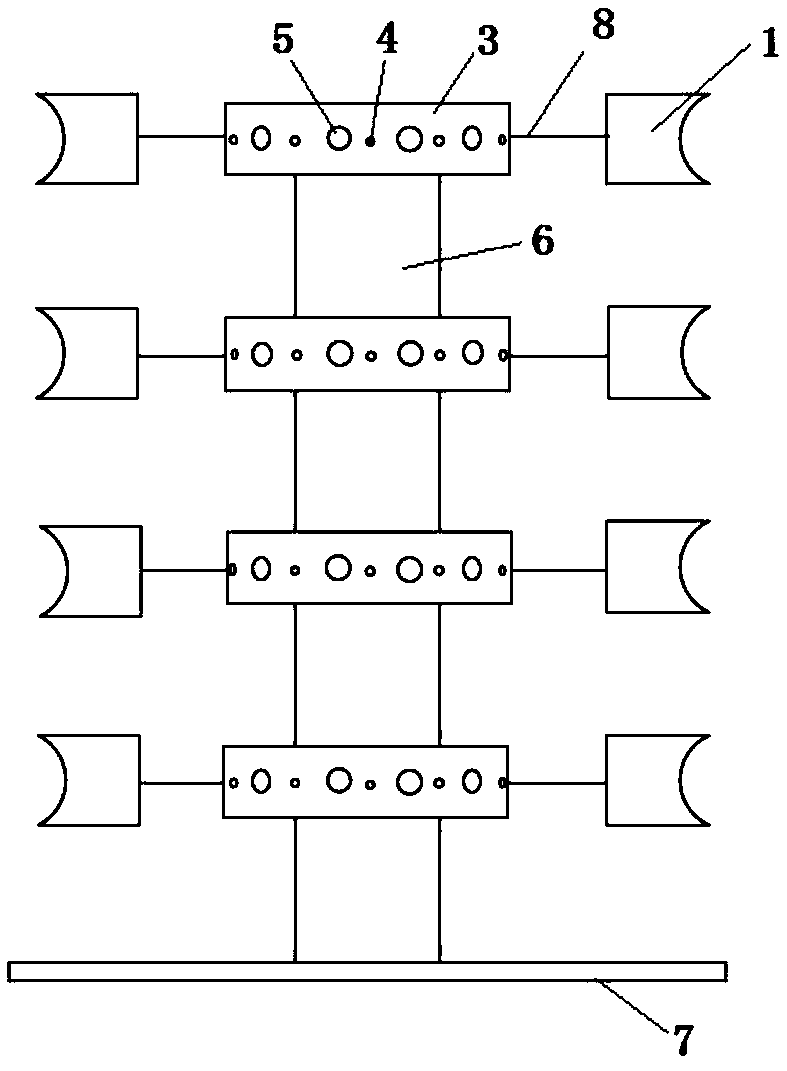

[0033] An optical fiber intelligent distribution frame of the present invention comprises a horizontally arranged bottom plate 7, a hollow cylindrical frame 6 vertically arranged on the bottom plate 7, and four wiring rings sleeved on the cylindrical frame 6 at intervals 3 and the coil frame 1 for coiling the optical fiber arranged on the periphery of the junction ring 3; the cylindrical frame 6 is used to pass the optical fiber during use; the ring wall of the junction ring 3 is provided with 48 optical fibers Flange head 5, these 48 fiber optic flange heads 5 are evenly spaced, and the inner end of described fiber optic flange head 5 (the end near cylindrical frame 6) communicates with the inside of described cylindrical frame 6, so that from cylindrical frame 6 The passing optical fiber can pass through the fiber optic flange head 5 smoothly; a monitoring assembly for monitoring the real-time status of the optical fiber is arranged in the junction ring 3, and a warning light...

Embodiment 3

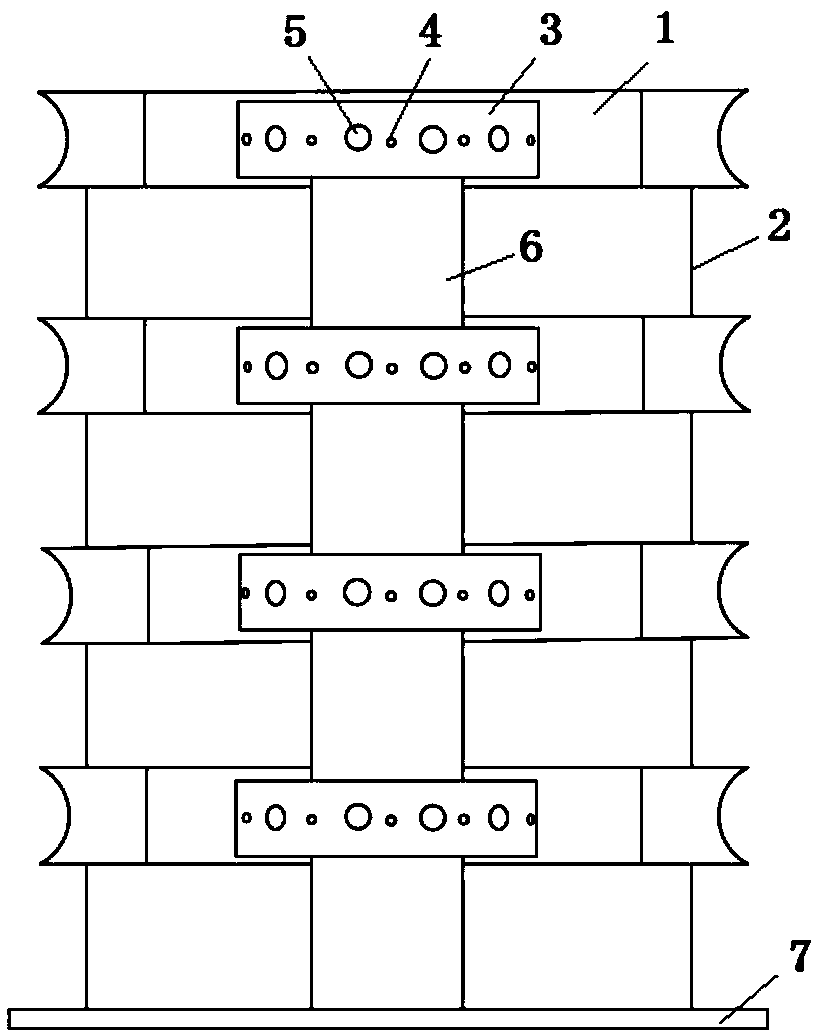

[0037]An optical fiber intelligent distribution frame of the present invention comprises a horizontally arranged bottom plate 7, a hollow cylindrical frame 6 vertically arranged on the bottom plate 7, and four wiring rings sleeved on the cylindrical frame 6 at intervals 3 and the coil frame 1 for coiling optical fibers arranged on the periphery of the junction ring 3; the cylindrical frame 6 is used to pass through the optical fibers during use; 72 optical fibers are penetrated on the ring wall of the junction ring 3 Flange head 5, these 72 fiber optic flange heads 5 are evenly spaced, and the inner end of described fiber optic flange head 5 (the end near cylindrical frame 6) communicates with the inside of described cylindrical frame 6, so that from cylindrical frame 6 The passing optical fiber can pass through the fiber optic flange head 5 smoothly; a monitoring assembly for monitoring the real-time status of the optical fiber is arranged in the junction ring 3, and a warning...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com