CPCI printed board test case

A technology for testing chassis and printed boards, used in printed circuit testing, electronic circuit testing, electrical measurement, etc., can solve problems such as increased workload, inaccurate positioning, reduced work efficiency, etc. Time, the structure of the chassis is simple, and the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described in detail through the accompanying drawings and specific embodiments below.

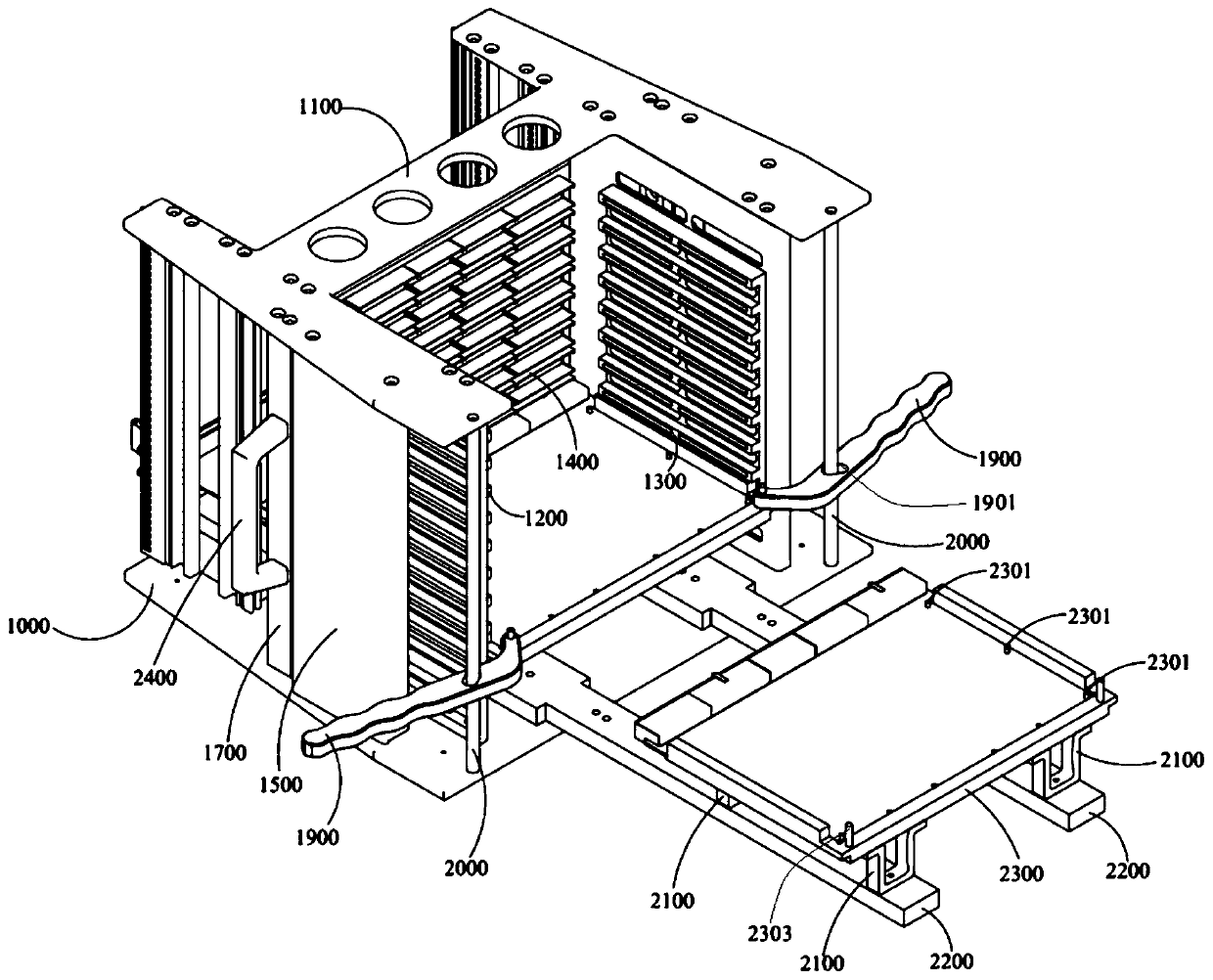

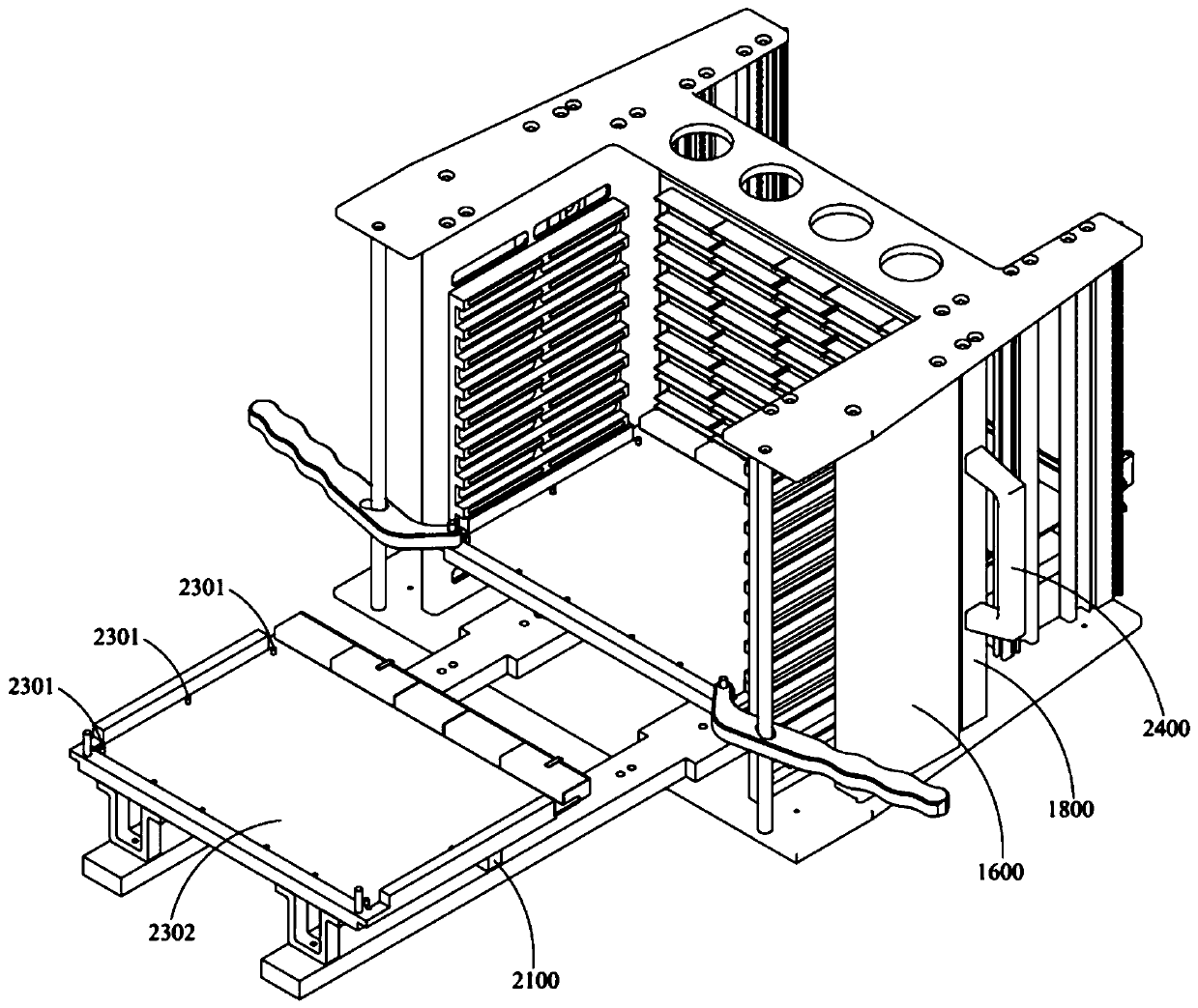

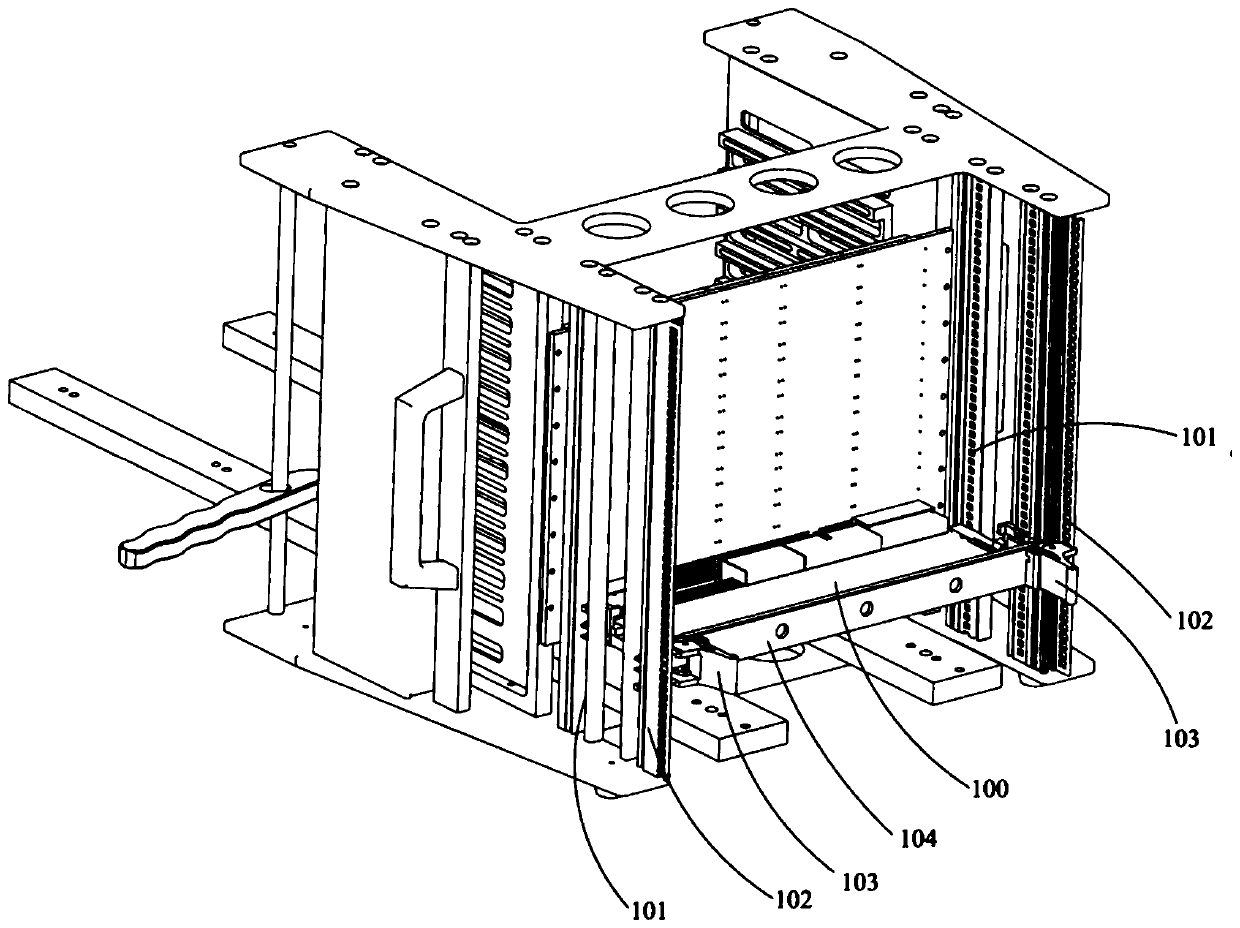

[0025] Such as Figure 1-3 A kind of CPCI printed board test case shown, comprises frame, the CPCI bottom plate printed board 1400 that is vertically arranged in the frame, and the CPCI bottom plate printed board divides the frame into a front board installation area and a rear side In the wiring area, the rack includes a bottom plate 1000, a top plate 1100, and a left side plate 1200 and a right side plate 1300 arranged on both sides of the installation area and connecting the bottom plate and the top plate; a structural cold plate is arranged in front of the installation area 2300, the bottom of the cold plate of the structural part is connected with a pair of linear guide rails, the linear guide rails are arranged on the bottom plate, and the cold plate of the structural part can slide into the installation area on the linear guide rails.

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com