Steel wire rope rolling-up device of bridge type crane

A bridge crane and wire rope technology, applied in the direction of hoisting device, spring mechanism, etc., can solve the problems of wire rope winding disorder, fast wire wear, large economic consumption, etc. effect of life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

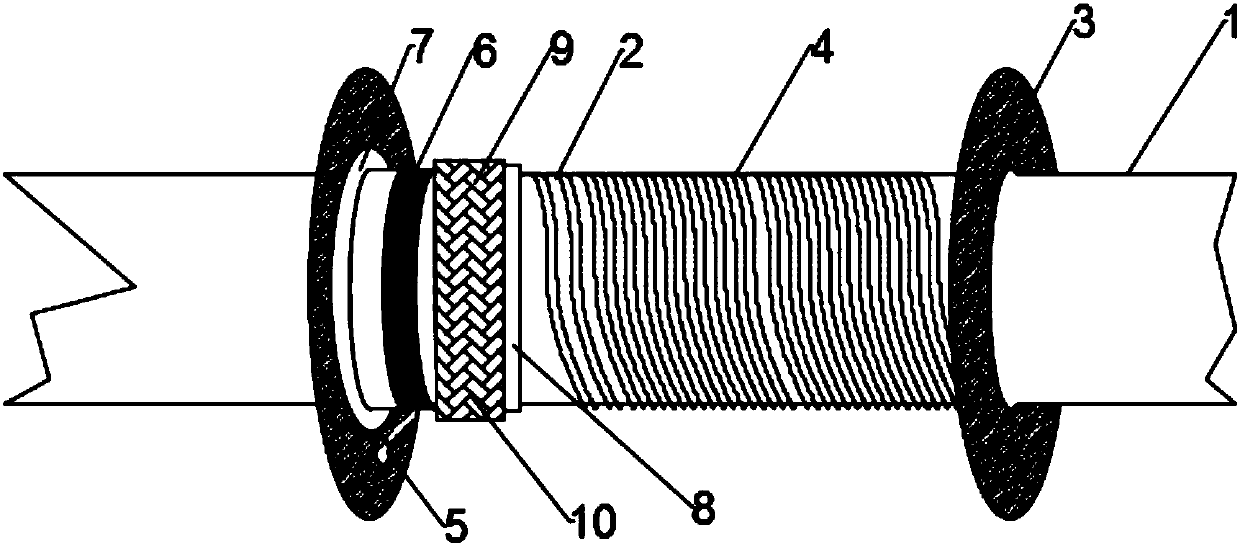

[0017] Such as figure 1 and figure 2 As shown, the present invention provides a wire rope winding device for a bridge crane, comprising a reel 1, the reel 1 is provided with a rope groove 2 around its periphery, and both ends of the rope groove 2 are provided with a Lan 3, thread 4 is engraved on the rope groove 2, and the thread 4 is directly engraved on the drum, which can reduce the use of materials, and the distance between the thread 4 is equal to the diameter of the steel wire rope. One of the flanges 3 is provided with a fixing hole 5, and the fixing hole 5 is installed on the flange 3 below the rope groove 2, and the function of the fixing hole 5 and the thread 4 is to fix one end of the wire rope , it is beneficial to guide the steel wire rope to be neatly wound on the reel 1 to avoid damage to the steel wire rope.

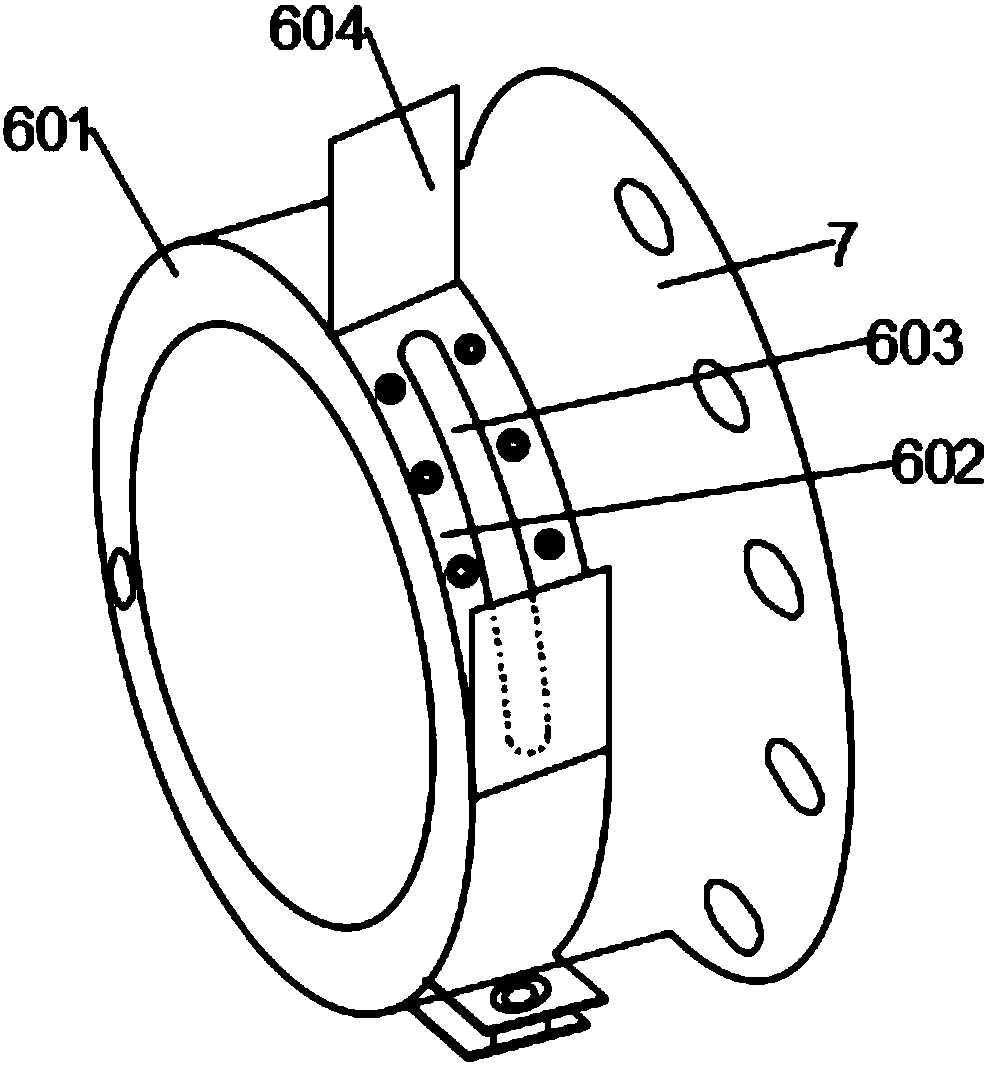

[0018] A rope guide 6 is provided between one of the flanges 3 and the rope groove 2. The function of the wire rope 6 is to make the wire ropes neatly...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com