Plural-wire coiling device and plural-wire coiling method

A winding device and winding method technology, applied in the direction of electromechanical devices, coil manufacturing, motor generator manufacturing, etc., can solve problems such as difficulty in winding neatly, enlargement, etc., and achieve the effect of preventing the gap from expanding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] Next, the best mode for implementing the present invention will be described based on the drawings.

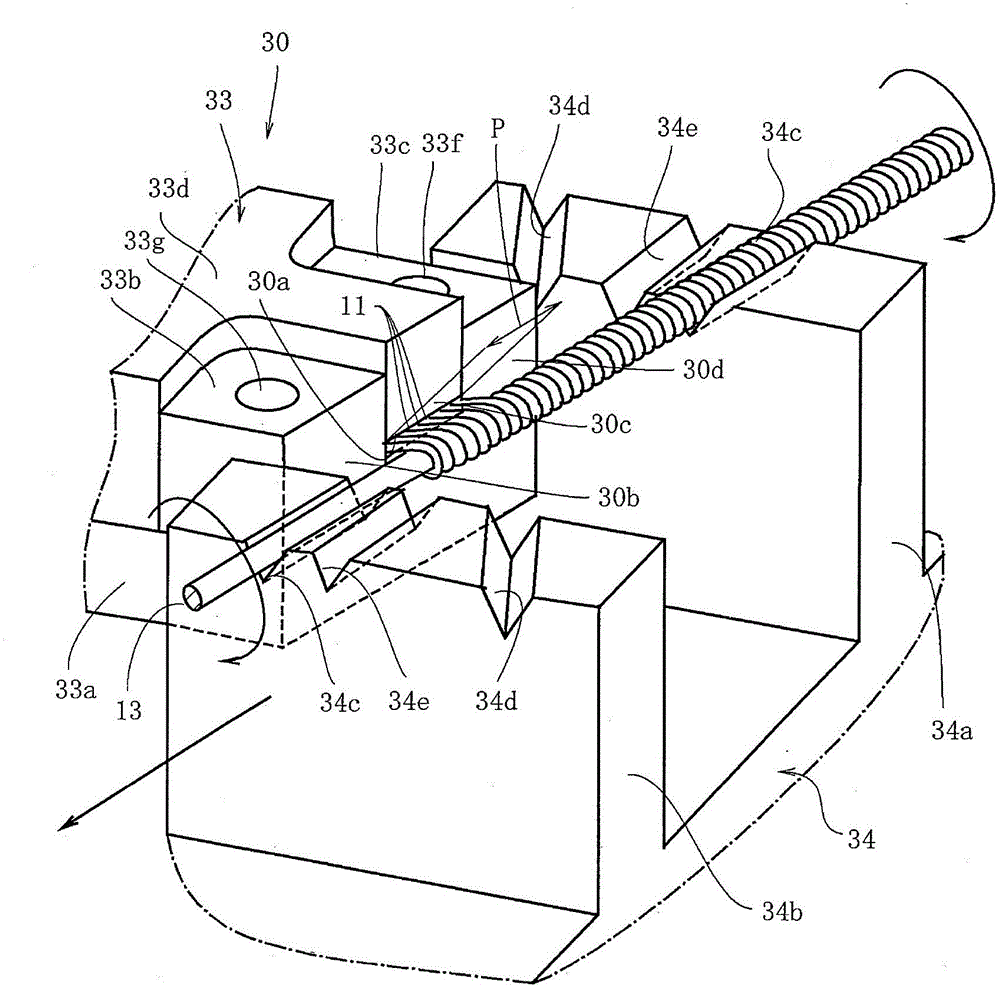

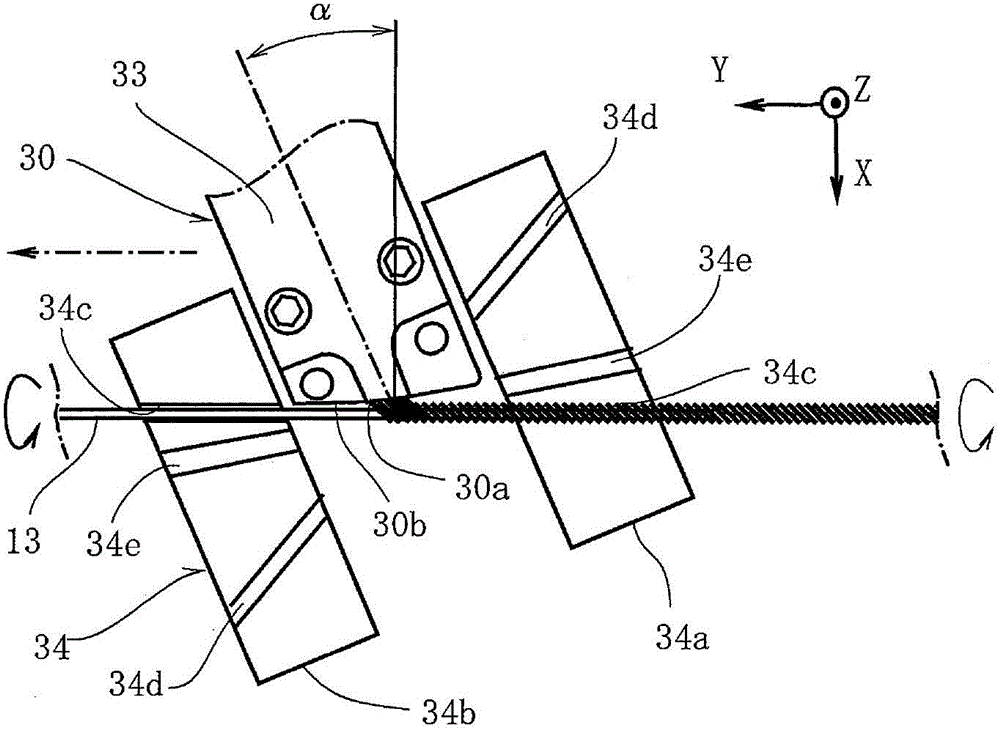

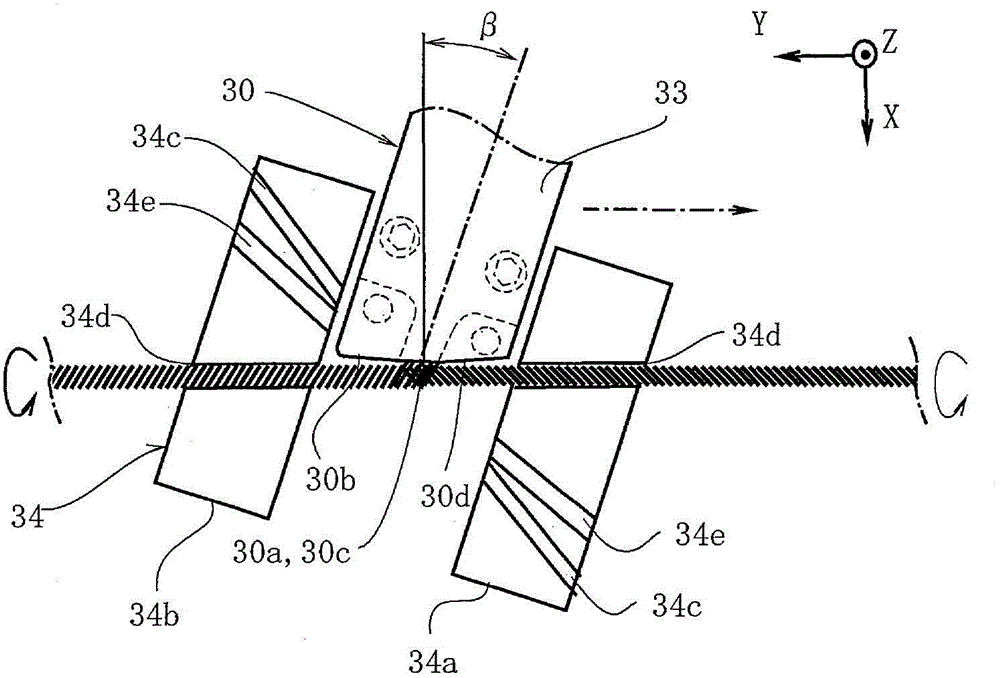

[0035] Such as Figures 12 to 14 As shown, the multi-wire winding device 10 of the present invention is a plurality of wires 11 ( Figure 14 ) is a device that is neatly wound on the outer periphery of the winding core 13 . As the winding core 13 in the figure, a case where a thin and long pin-shaped winding core having a circular cross section is used is shown. In addition, the winding core 13 is not limited to a winding core having a circular cross section, and may also be a winding core having a square cross section. Here, three axes X, Y, and Z that are orthogonal to each other are set. The X axis extends along the horizontal front and back direction, the Y axis extends along the horizontal horizontal direction, and the Z axis extends along the vertical direction. As for the device of the core 13, the multi-wire winding device 10 of the present invention will be d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com