Lightweight rigid self-lubricating composite rope and preparation method thereof

A composite rope and self-lubricating technology, applied in the rope field, can solve the problems of chemical fiber ropes such as poor wear resistance and scratch resistance, easy to cause accidents, fiber rope breakage, etc., to reduce operating strength and industrial energy consumption, and reduce friction The effect of low power and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

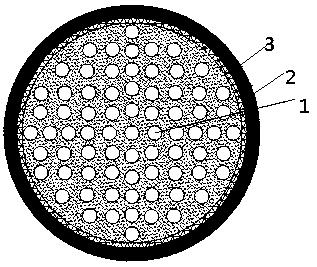

[0032] To make a lightweight rigid self-lubricating composite rope with a breaking strength of 180kN and a diameter of 24mm, it can be realized through the following steps:

[0033] 1) Rope design: the diameter of the rope is 24mm, the plastic coating layer is 2mm, the diameter of the rope before plastic coating is 20mm, the aromatic braided sheath is 2mm, and the diameter of the rope core is 16mm. Calculated according to the HMPE yarn accounting for 80%, the diameter sum of the yarn is 12.8mm, and the number of yarns is designed to be 30;

[0034] 2) Preparation of rope yarn: add 20-in-1500D ultra-high molecular weight polyethylene fiber multifilament with 15 twists / m, half of it is forward and half is reverse;

[0035] 3) Preparation of rope core: thread 30 rope yarns from the inner layer to the outer layer on the twisting rope machine according to the structure of 3+6+9+12, the first layer of 3 rope yarns rotates in the forward direction, and the second layer The 6 rope ya...

Embodiment 2

[0040] To make a lightweight rigid self-lubricating composite rope with a breaking strength of 198kN and a diameter of 20mm, it can be realized through the following steps:

[0041] 1) Rope design: the diameter of the rope is 20mm, the plastic coating layer is 1mm, the diameter of the rope before plastic coating is 18mm, the aromatic braided sheath is 1mm, and the diameter of the rope core is 16mm. Calculated according to the HMPE yarn accounting for 70%, the diameter of the yarn is 13.3mm, and the number of yarns is designed to be 36;

[0042] 2) Preparation of rope yarn: add 10 twists / m to 20-in-1500D ultra-high molecular weight fiber multifilament;

[0043]3) Prepare the rope core: thread 36 rope yarns on the twisting machine from the inner layer to the outer layer according to the structure of 3+6+12+15, the first layer of 3 rope yarns rotates in the forward direction, and the second layer The 6 ropes rotate in the reverse direction, the 12 ropes in the third layer rotate...

Embodiment 3

[0048] To make a lightweight rigid self-lubricating composite rope with a breaking strength of 33kN and a diameter of 10mm, it can be achieved through the following steps:

[0049] 1) Rope design: the diameter of the rope is 10mm, the plastic coating layer is 1mm, the diameter of the rope before plastic coating is 8mm, the aromatic braided sheath is 1mm, and the diameter of the rope core is 6mm. Calculated based on 90% of HMPE yarns, the diameter sum of the yarns is 5.8mm, and the number of yarns is designed to be 11;

[0050] 2) Preparation of rope yarn: add 10-in-1500D ultra-high molecular weight fiber multifilament with 20 twists / m;

[0051] 3) Preparation of rope core: thread 11 rope yarns from the inner layer to the outer layer on the twisting rope machine according to the structure of 3+8, the first layer of 3 rope yarns rotates in the forward direction, and the second layer of 8 rope yarns According to reverse rotation, the rope output speed is 0.2m / min, the rotating s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Breaking strength | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Breaking strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com