Crane elevator for wind power generator repairing

A technology of wind power generators and cranes, which is applied in the direction of clockwork mechanism and hoisting device, etc. It can solve the problems of unstable lifting of heavy objects, wear of steel wire ropes, and steel wire ropes jumping out of the reel, so as to avoid cross-overlapping and lifting The effect of highly improving and prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

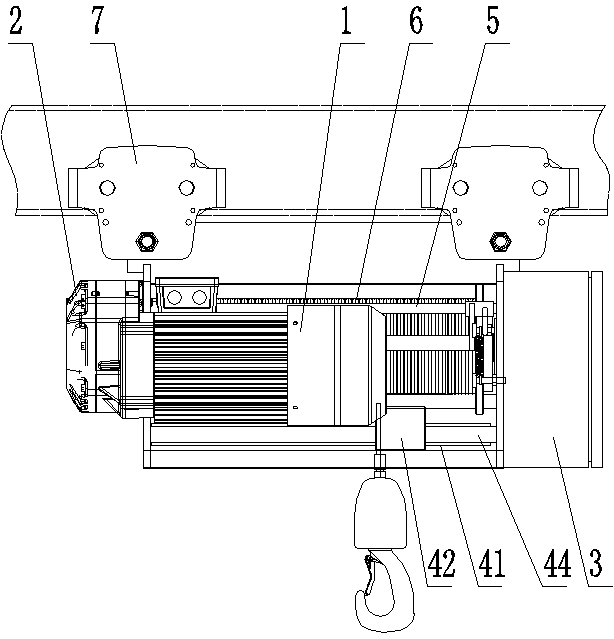

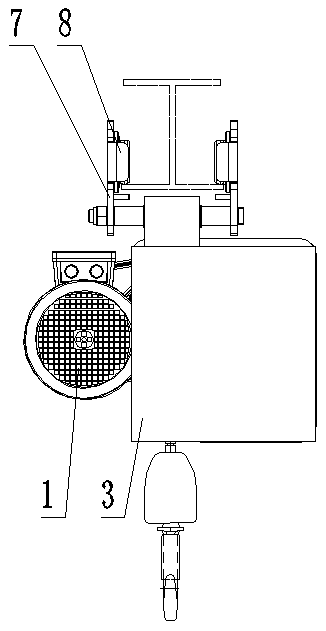

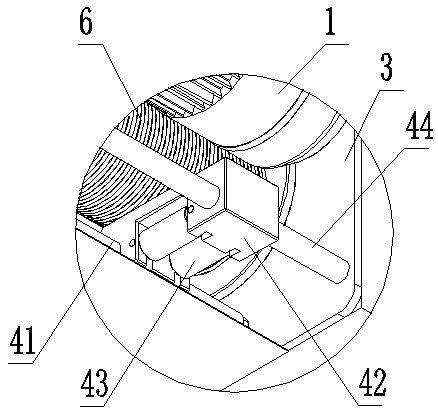

[0024] Such as Figure 1 to Figure 5 As shown, a crane hoist for wind power generator maintenance of the present invention includes a geared motor 1 and a reel driven by the geared motor 1, and a steel wire rope is wound on the reel, and also includes a first transmission box 2, a second transmission Box 3, reciprocating rope arrangement and rope pressing mechanism 5, the reel is a broken line reel 6, and the broken line reel 6, reciprocating rope arrangement and rope pressing mechanism 5 are all arranged on the first transmission box 2 and the second transmission box 3, the reduction motor 1 is connected to the folding reel 6 through the first transmission box 2.

[0025] The tops of the first transmission box 2 and the second transmission box 3 are fixedly connected with a mounting plate 7 on which a wheel 8 is mounted. The present invention can walk along suspension beam or beam by wheel 8.

[0026] The folding line reel 6 comprises a drum body, the two ends of the drum b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com