Bridge suspension and steel bar type stereo garage

A three-dimensional garage and steel beam technology, which is applied to buildings, building types, buildings, etc. where cars are parked, can solve the problems of oil leakage equipment failure rate, high production labor intensity, complex structure, etc., to reduce difficulty and improve safety. , the effect of large channel area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

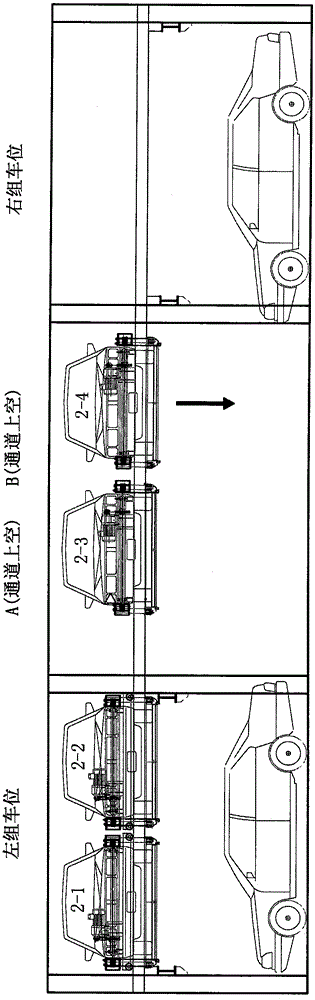

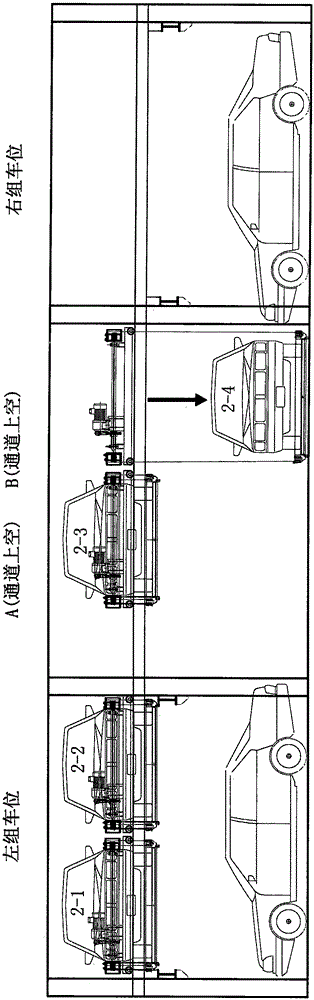

[0035] A suspension bridge steel girder type three-dimensional garage of the present invention comprises a traverse mechanism, a lifting mechanism, a car cutting board mechanism and a bridge steel frame structure.

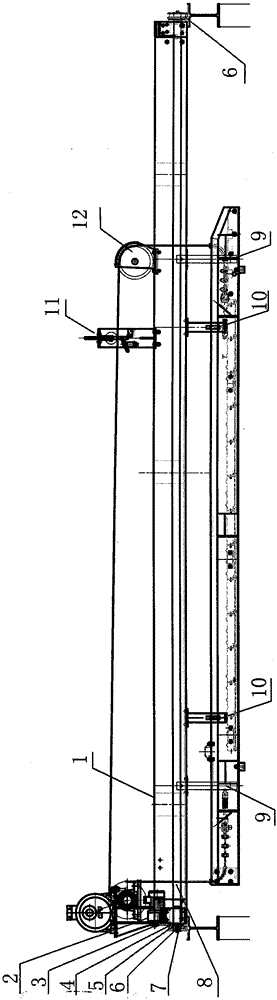

[0036] Described traversing mechanism sees figure 1Installed on the rails of the front and rear bridges on the upper floor, including: traversing frame 1, gear motor 2, driving sprocket 3, passive sprocket 4, chain 5, driving and passive rollers 6, bearing with seat 7, main and driven shafts 8. Guide seat 9 (built-in upper line and upper limit two line position switches), fall arrester device 10, rope loosening device 11 (built-in offline line and lower limit two line position switches), pulley 12 and other components. The reduction motor 2 is installed at the inner end of the outer side of the left longitudinal beam on the front side of the 1st side. Drive sprocket 3 is installed in the front end of reduction motor 2 shafts. The driven sprocket 3 is installed on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com