Winding drum with cable guide grooves

A reel and guide rope technology, applied in the direction of the hoisting device, the spring mechanism, etc., can solve the problems of high equipment manufacturing cost, shortened cable life, large cable exit angle, etc., and achieves simple structure and reasonable design. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in combination with specific embodiments.

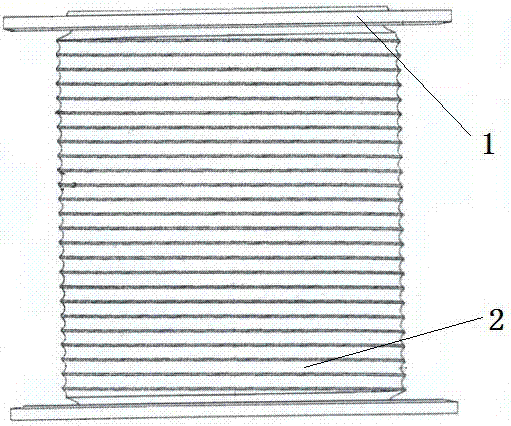

[0017] Such as figure 1 As shown, a rope guide drum mainly includes an I-shaped shaft 1 and a threaded track 2. The surface of the I-shaped shaft 1 has a neatly arranged threaded track 2, and the threaded track 2 is a groove-shaped structure. The width of the groove matches the diameter of the cable, and the depth of the groove matches the radius of the cable.

[0018] The I-shaped shaft 1 is a hollow cylindrical structure, and the wing plate is a flat circular plate structure. The wing plate of the I-shaped shaft 1 has a number of round holes, and a number of steel balls are placed inside the round holes. The steel balls The diameter is larger than the diameter of the circular hole.

[0019] The surface of the I-shaped shaft 1 is coated with an anti-corrosion coating, and the thickness of the anti-corrosion coating is in the range of 1-3mm.

[0020] Inspired by the abov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com