A kind of transparent ceramic orthodontic bracket and preparation method thereof

A technology of orthodontic brackets and transparent ceramics, which is applied in the field of ceramics, can solve the problems of long deglue time, low light transmittance of transparent ceramics, and low green strength, so as to avoid rearrangement and agglomeration, facilitate automatic production, and feed smooth surface effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

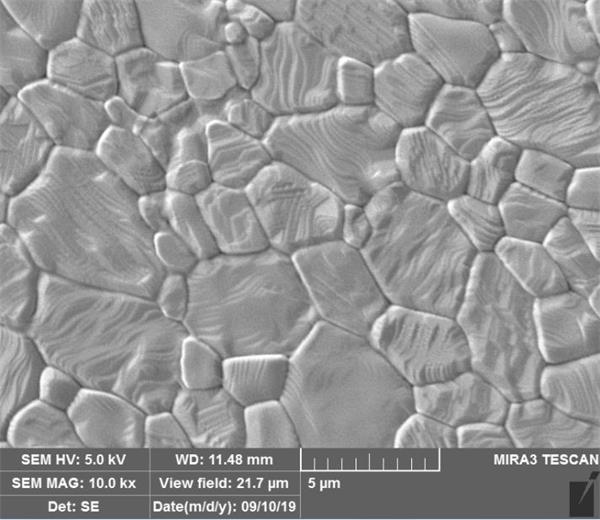

Image

Examples

Embodiment 1

[0064] a. The specific surface area of alumina powder is 20g / m 2 , with a particle size of 1 μm, high-purity alumina.

[0065] b. The binder ratio is: 73 parts of polyoxymethylene, 5 parts of paraffin wax, 5 parts of EBS wax, 7 parts of EVA, 7 parts of PP, 1.5 parts of DOP, 1.5 parts of dispersant-polyether modified heptamethyltrisiloxane .

[0066] 1. On the internal mixer, the injection molding feedstock was first banburyed at a temperature of 190 degrees for 2 hours, then cooled to 50 degrees, and kneaded for 0.5 hours. The content of high-purity nano-alumina powder in the feed was: 80.5 parts, the binder The content of 19.5 parts.

[0067] 2. Add the mixture in step 1 into a screw extruder granulator, the temperature is 180 degrees, the screw speed is 400 rpm, and the transparent alumina feed particles are prepared after dicing.

[0068] 3. The feed particles in step 2 are injection-molded on a ceramic injection molding machine to prepare ceramic brackets.

[0069] 4...

Embodiment 2

[0074] a. The specific surface area of alumina powder is 10g / m 2 , the particle size is 0.5μm, high-purity alumina.

[0075] b. The binder ratio is: 65 parts of polyoxymethylene, 5 parts of paraffin wax, 7 parts of EBS wax, 10 parts of EVA, 10 parts of PP, 1.5 parts of DOP, 1.5 parts of dispersant-polyether modified heptamethyltrisiloxane .

[0076] 1. On the internal mixer, the injection molding feedstock was first banburyed at a temperature of 190 degrees for 2 hours, then cooled to 50 degrees, and kneaded for 0.5 hours. The content is 18.5 parts.

[0077] 2. Add the mixture in step 1 into a screw extruder granulator, the temperature is 180 degrees, the screw speed is 400 rpm, and the transparent alumina feed particles are prepared after dicing.

[0078] 3. The feed particles in step 2 are injection-molded on a ceramic injection molding machine to prepare ceramic brackets.

[0079] 4. Put the ceramic bracket in step 3 in an oxalic acid catalytic degreasing furnace at a...

Embodiment 3

[0083] a. The specific surface area of alumina powder is 7g / m2 , the particle size is 0.5μm, high-purity alumina.

[0084] b. The binder ratio is: 60 parts of polyoxymethylene, 5 parts of paraffin wax, 10 parts of EBS wax, 10 parts of EVA, 10 parts of PS, 2 parts of DOP, and 3 parts of dispersant-polyether modified heptamethyltrisiloxane.

[0085] 1. On the internal mixer, the injection molding feedstock is first banburyed at a temperature of 190 degrees for 2 hours, then cooled to 50 degrees, and kneaded for 0.5 hours. The content of high-purity nano-alumina powder in the feed is 83 parts, and the amount of the binder The content is 18 servings.

[0086] 2. Add the mixture in step 1 into a screw extruder granulator, the temperature is 190 degrees, the screw speed is 400 rpm, and the transparent alumina feed particles are prepared after granulation.

[0087] 3. The feed particles in step 2 are injection-molded on a ceramic injection molding machine to prepare ceramic bracke...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com