Patents

Literature

33 results about "N-propylbenzene" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

N-Propylbenzene (phenylpropane) is an aromatic hydrocarbon consisting of a propyl group as a substituent on a benzene ring. It is a colorless liquid. A more common structural isomer of this compound is cumene.

Production of diisopropylbenzene

A process for the disproportionation of cumene is disclosed which comprises the step of contacting a feed containing cumene, under disproportionation conditions, with a catalyst comprising a molecular sieve, preferably TEA-mordenite. The contacting step disproportionates at least part of the cumene in the feed to provide a disproportionation effluent containing benzene and a mixture of diisopropylbenzene isomers. The effluent is then recovered and contains, prior to any separation step, less 1% of ortho-diisopropylbenzene by weight of the total diisopropylbenzene content of said effluent, less than 1 wt % of n-propylbenzene, less than 5 wt % of triisopropylbenzenes and less than 5 wt % of disproportionation products other than benzene and diisopropylbenzenes.

Owner:EXXONMOBIL CHEM PAT INC

Catalyst for alkylation reaction of aromatic hydrocarbons and low-carbon alkanes and use thereof

A catalyst for the alkylation reaction of aromatic hydrocarbon and light alkane contains Mo element and ZSM-5 molecular sieve, wherein the weight ratio of the Mo element and the ZSM-5 molecular sieve is 1-16%. A binder of 5-40 wt% is added into the catalyst. In accordance with the embodiment of the catalyst in the alkylation reaction of aromatic hydrocarbon and light alkane, the reaction temperature is 250-450 DEG C, the material molar ratio of the aromatic hydrocarbon and light alkane is 0.5-3, the weight space-velocity is 0.2-5 h<-1>, accordingly, toluene, ethyl benzene, isopropyl benzene and n-propylbenzene can be prepared with high selectivity.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

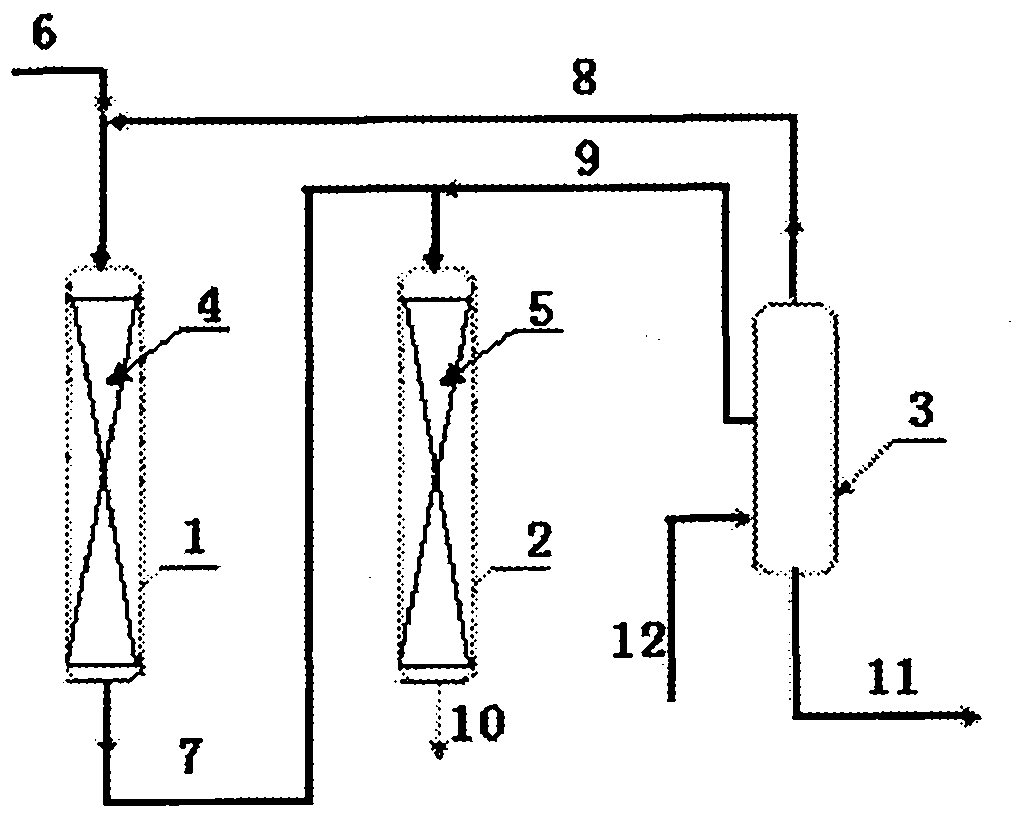

Method for producing isopropylbenzene by using benzene and propylene

ActiveCN102464565AImprove product qualityReduce contentHydrocarbonsHydrocarbon preparationAlkyl transferN-propylbenzene

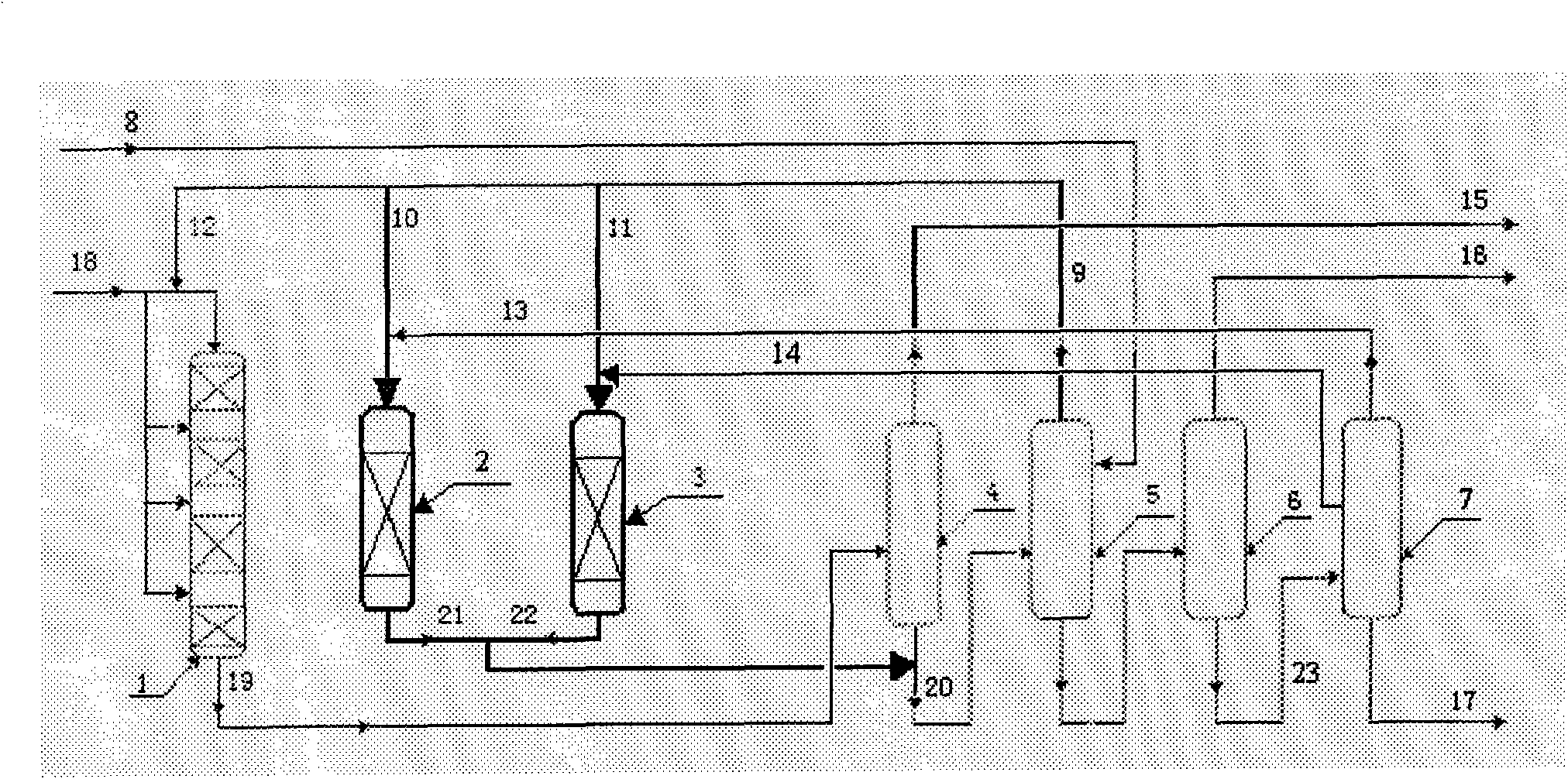

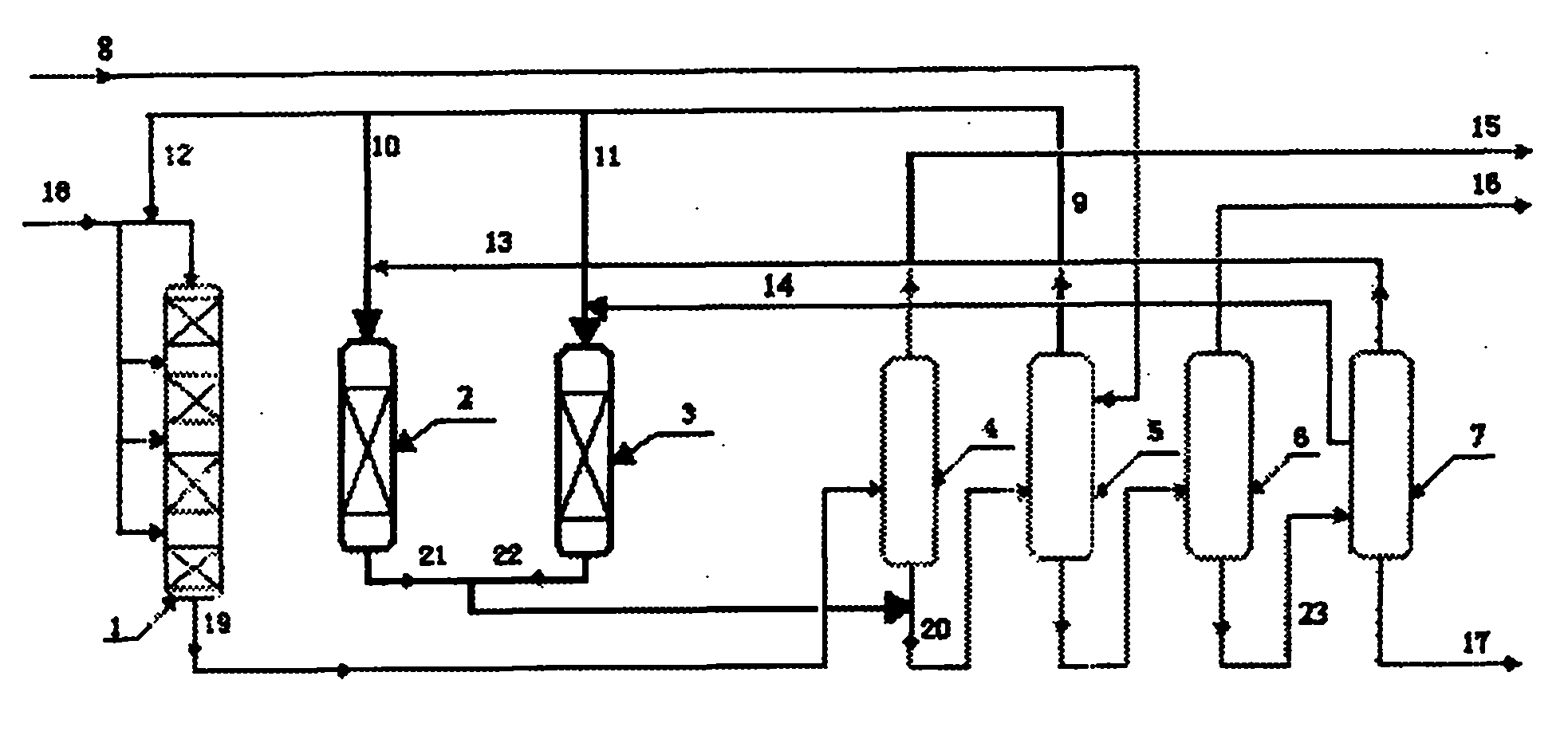

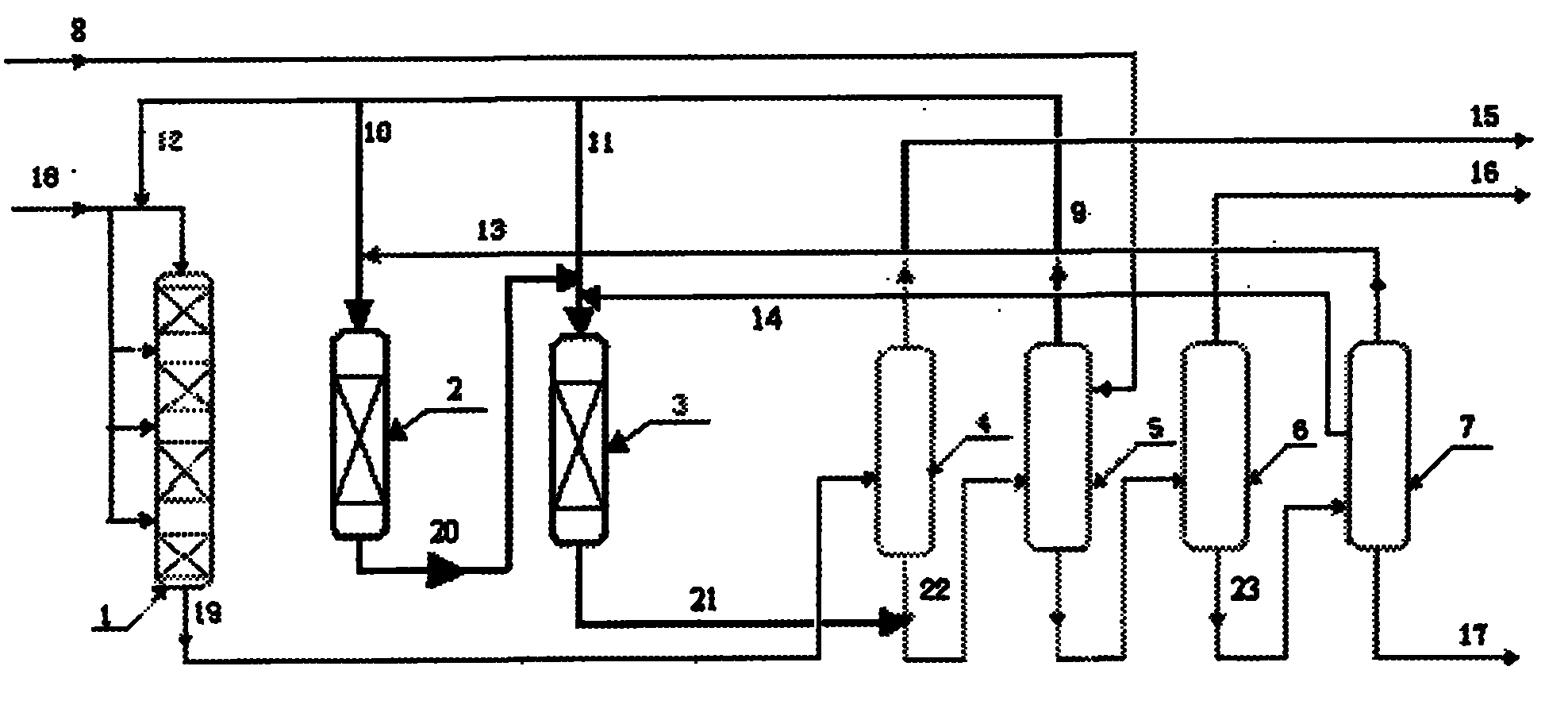

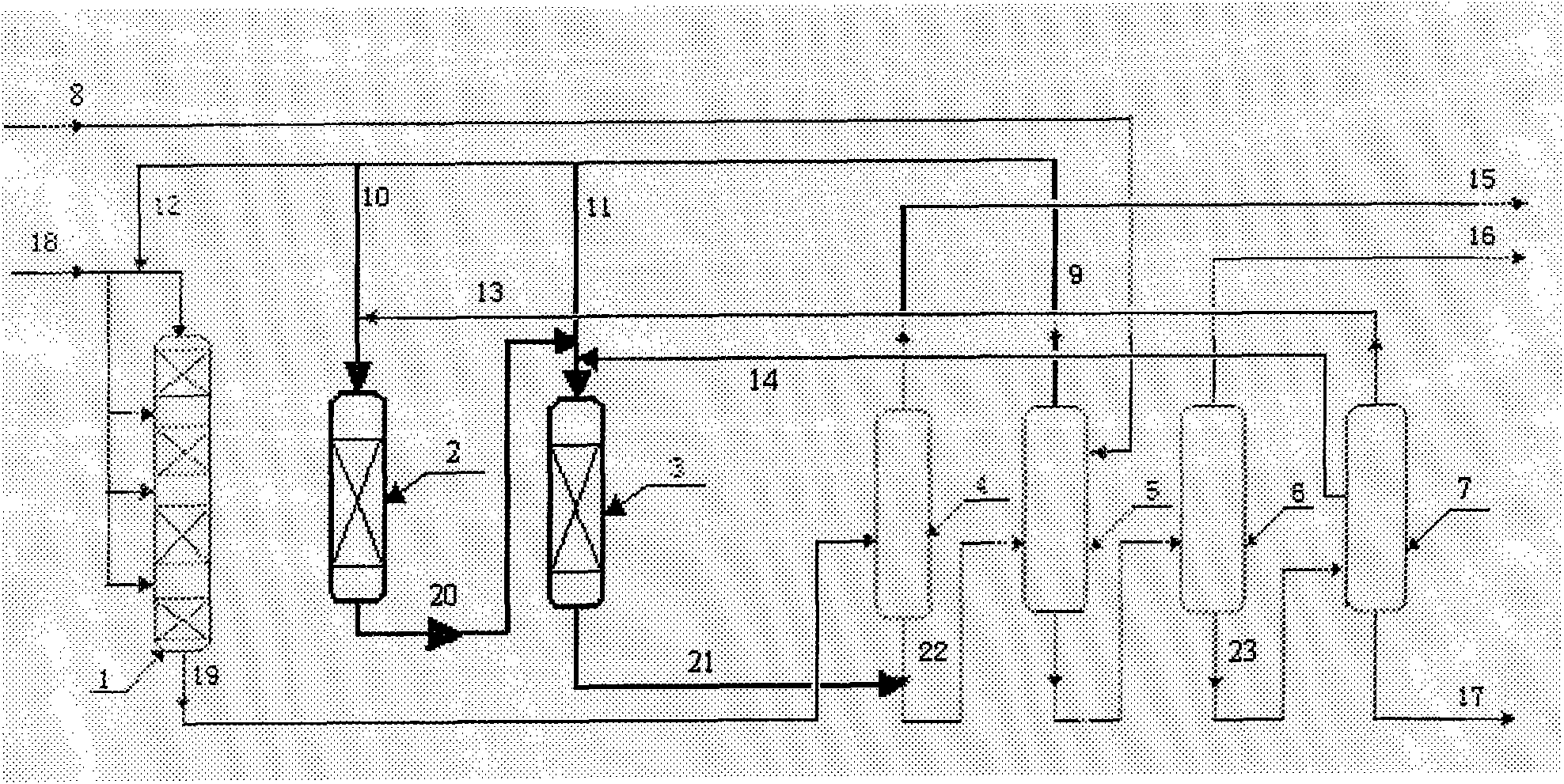

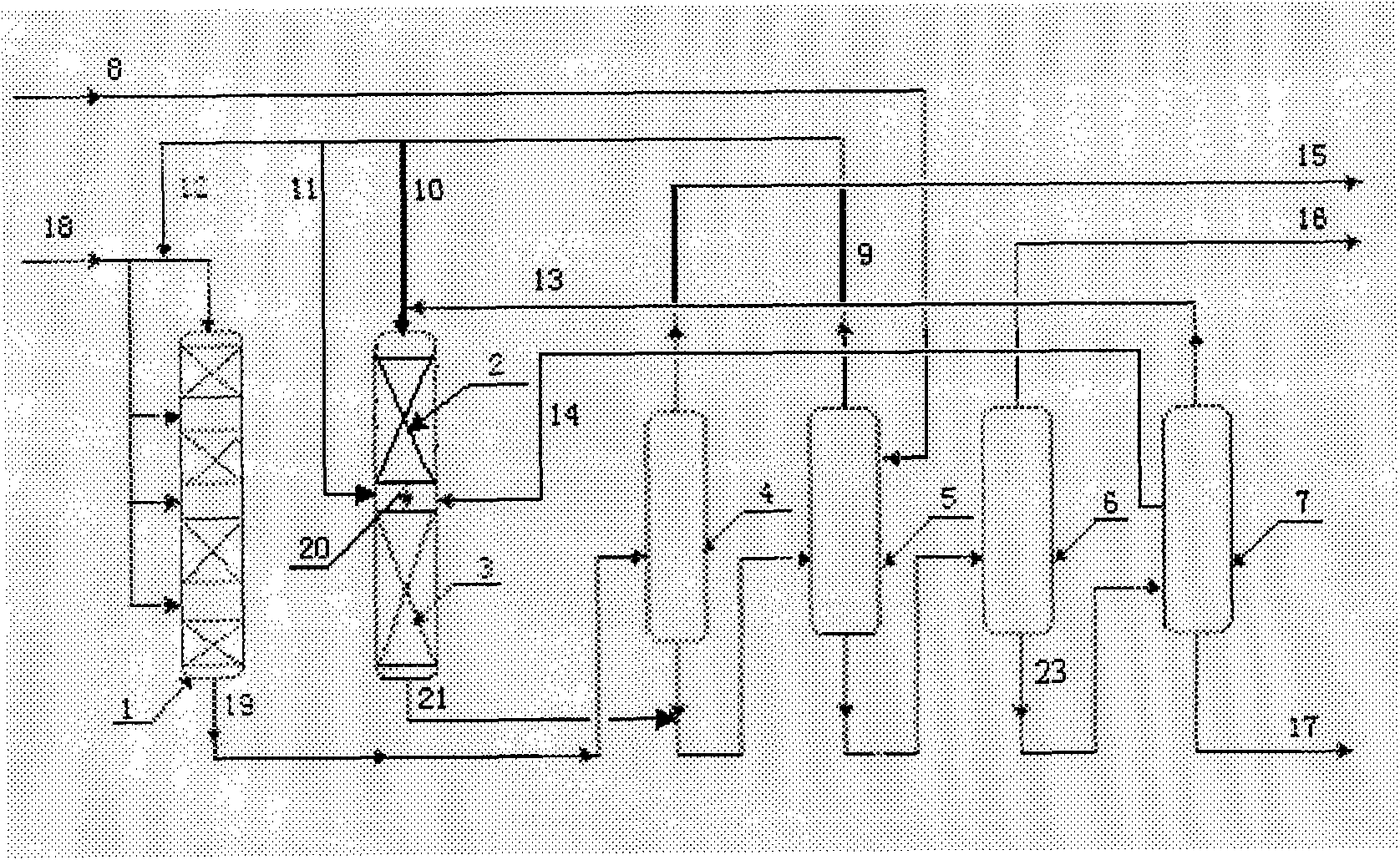

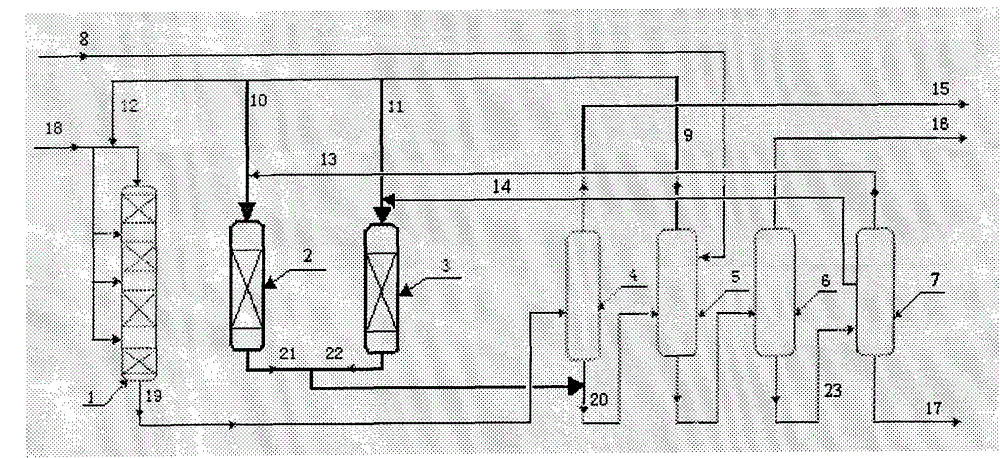

The invention relates to a method for producing isopropylbenzene by using benzene and propylene and mainly solves the problem of high content of n-propylbenzene existing in an isopropylbenzene product of the prior art. The method better solves the problem and can be applied to the industrial production of isopropylbenzene by adopting the technical scheme which comprises the following steps of: (1) a first stream of benzene material flow 12 and propylene enter an alkylation reactor to react, thereby a material flow 19 comprising the benzene, propylene, isopropylbenzene and polyisopropylbenzene is obtained; (b) the material flow 19 is separated to obtain material flow 23 containing polyisopropylbenzene; (c) after the material flow 23 is separated by a rectifying tower, material flow 13 is obtained at the tower top, and material flow 14 is obtained in the middle part of the tower; (d) a second stream of material flow 10 and the material flow 13 enter a first a first alkyl group transfer reaction zone for carrying out alkyl group transfer reaction to obtain material flow 21; and a third stream of material flow 11 and the material flow 14 enter a second alkyl group transfer reaction zone for carrying out alkyl group transfer reaction to obtain material flow 22; and (e) the material flow 21 and the material flow 22 enter the follow-up refining process, thereby the isopropylbenzene product is obtained.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for producing isopropylbenzene by using benzene and propylene

ActiveCN102464566AImprove product qualityReduce contentHydrocarbonsHydrocarbon preparationAlkyl transferTower

The invention relates to a method for producing isopropylbenzene by using benzene and propylene and mainly solves the problem of high content of n-propylbenzene existing in an isopropylbenzene product of the prior art. The method better solves the problem and can be applied to the industrial production of isopropylbenzene by adopting the technical scheme which comprises the following steps of: (1) a first stream of benzene material flow 12 and propylene enter an alkylation reactor to react, thereby material flow 19 comprising benzene, propylene, isopropylbenzene and polyisopropylbenzene is obtained; (b) the material flow 19 is separated to obtain material flow 23 containing polyisopropylbenzene; (c) after the material flow 23 is separated by a rectifying tower, material flow 13 is obtained at the tower top, and material flow 14 is obtained in the middle part of the tower; (d) a second stream of material flow 10 and the material flow 13 enter a first alkyl group transfer reaction zone for carrying out alkyl group transfer reaction to obtain a material flow 20; the material flow 20, a third stream of material flow 11 and the material flow 14 enter a second alkyl group transfer reaction zone for carrying out alkyl group transfer reaction to obtain material flow 22; and the material flow 21 enters the follow-up refining process, thereby the isopropylbenzene product is obtained.

Owner:CHINA PETROLEUM & CHEM CORP +1

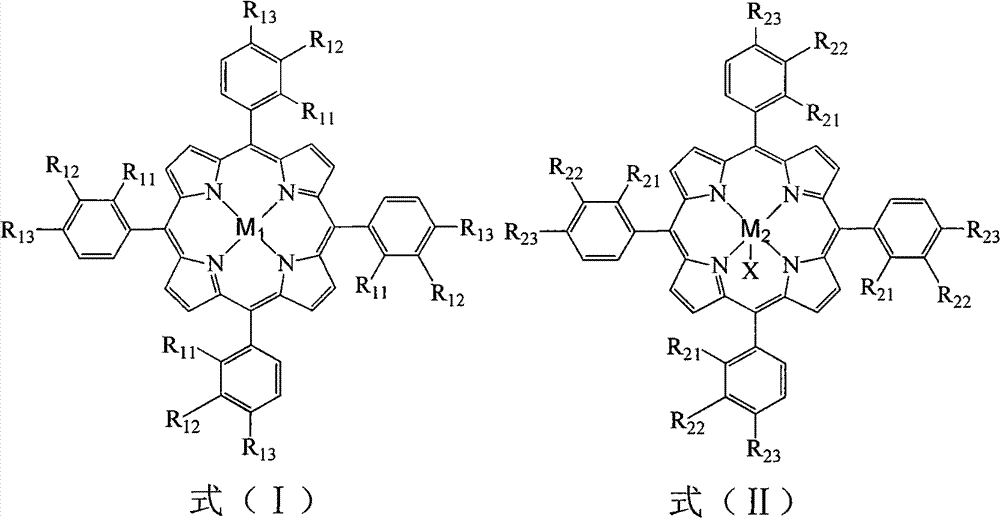

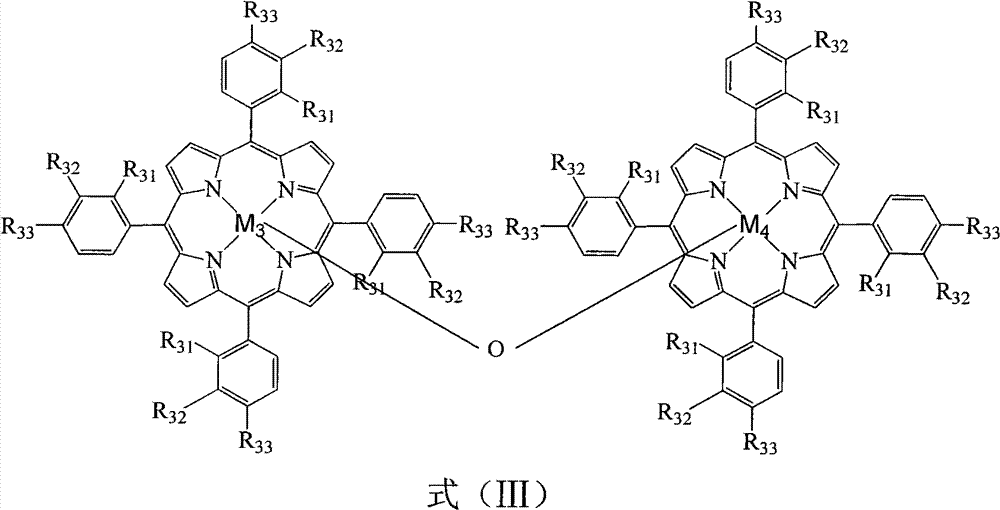

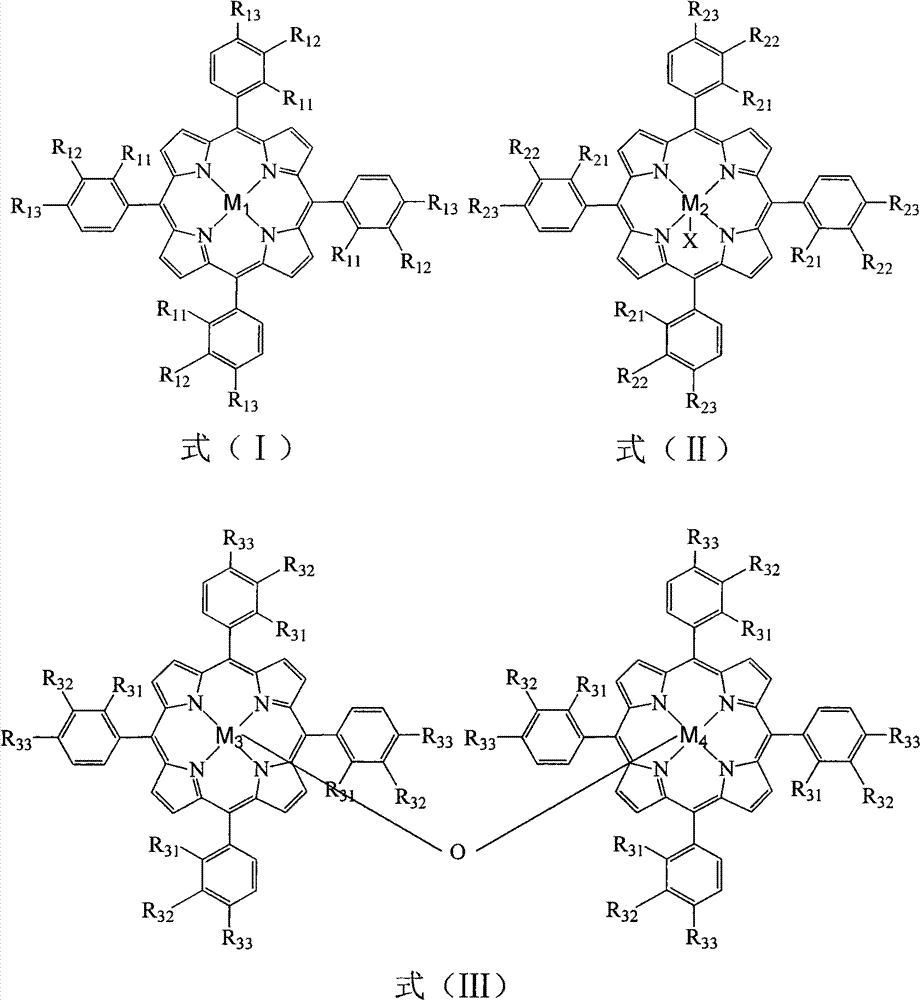

Method for preparing propiophenone by biomimetic catalytic oxidation of n-propylbenzene with oxygen

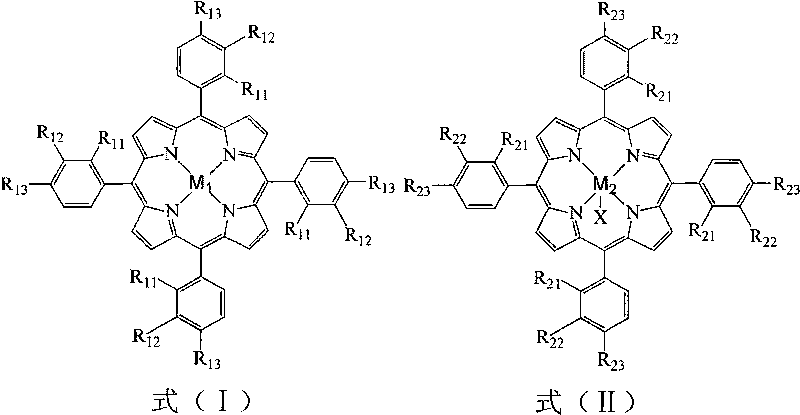

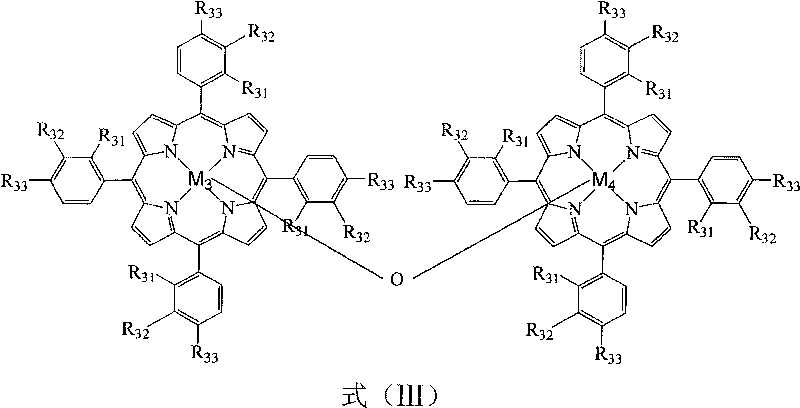

InactiveCN101759540AReduce pollutionReduce manufacturing costOrganic compound preparationOrganic-compounds/hydrides/coordination-complexes catalystsCatalytic oxidationPorphyrin

The invention relates to a method for preparing propiophenone by biomimetic catalytic oxidation of n-propylbenzene with oxygen, comprising the following steps: taking n-propylbenzene as the raw material, selecting any one of 1-30ppm of mononuclear metalloporphyrin and mu-oxo-dinuclear metalloporphyrin or the composition of the two substances as the catalyst under normal pressure and in the absence of solvents, introducing oxygen at the flow rate of 10-60mL / min, initiating reaction at 140-160 DEG C and then carrying out reaction at 70-110 DEG C for 4-10h, thus obtaining the propiophenone. In the method, the way of high temperature quick initiation and low temperature reaction is adopted, thus minimizing the reaction initiation time, greatly shortening the reaction time, improving the reaction efficiency, reducing the energy consumption, lowering the operation cost and improving the reaction safety.

Owner:BEIJING UNIV OF TECH

Production of diisopropylbenzene by disproportion of cumene in the presence of a TEA-mordenite catalyst

A process for the disproportionation of cumene is disclosed which comprises the step of contacting a feed containing cumene, under disproportionation conditions, with a catalyst comprising a molecular sieve, preferably TEA-mordenite. The contacting step disproportionates at least part of the cumene in the feed to provide a disproportionation effluent containing benzene and a mixture of diisopropylbenzene isomers. The effluent is then recovered and contains, prior to any separation step, less 1% of ortho-diisopropylbenzene by weight of the total diisopropylbenzene content of said effluent, less than 1 wt % of n-propylbenzene, less than 5 wt % of triisopropylbenzenes and less than 5 wt % of disproportionation products other than benzene and diisopropylbenzenes.

Owner:EXXONMOBIL CHEM PAT INC

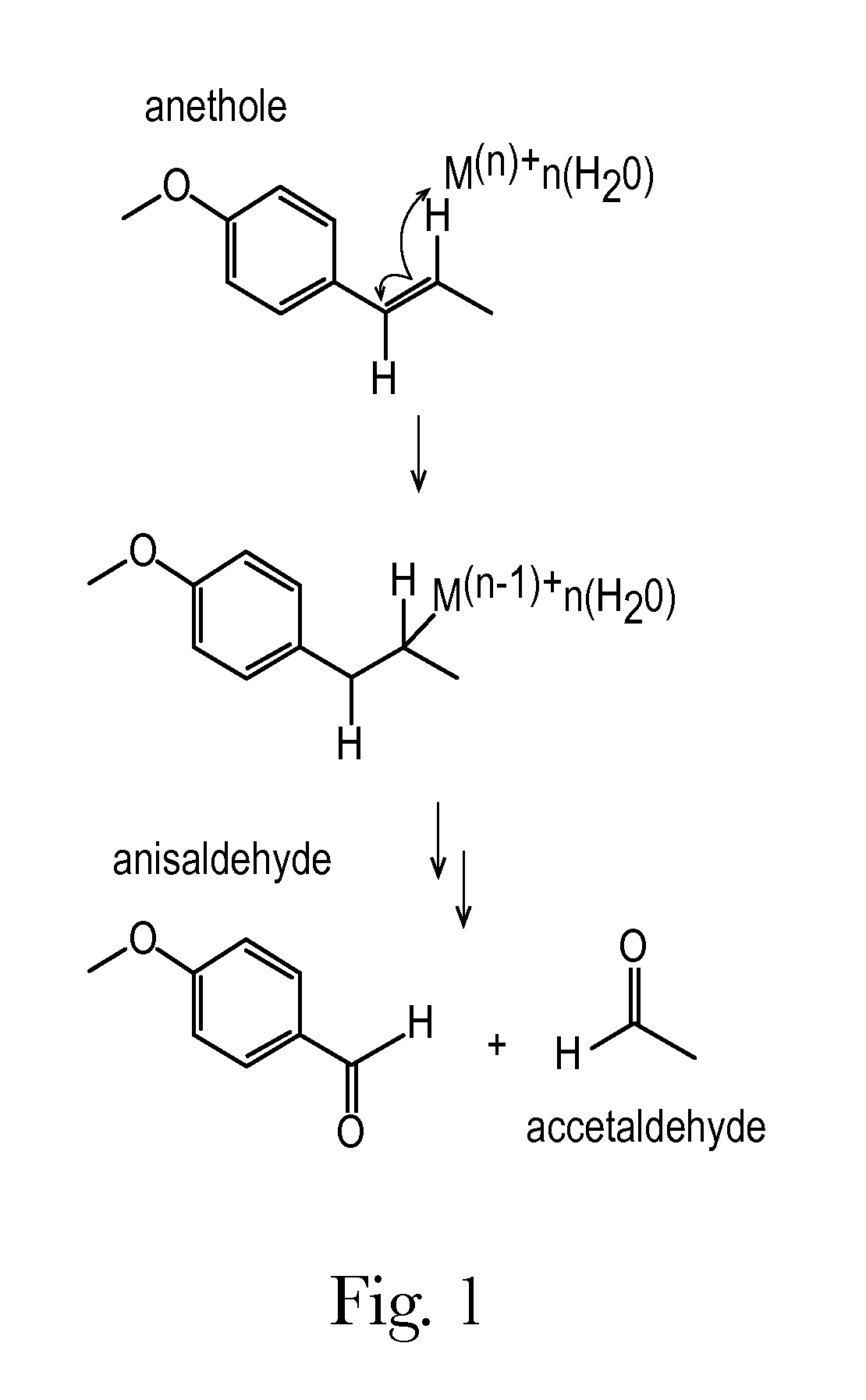

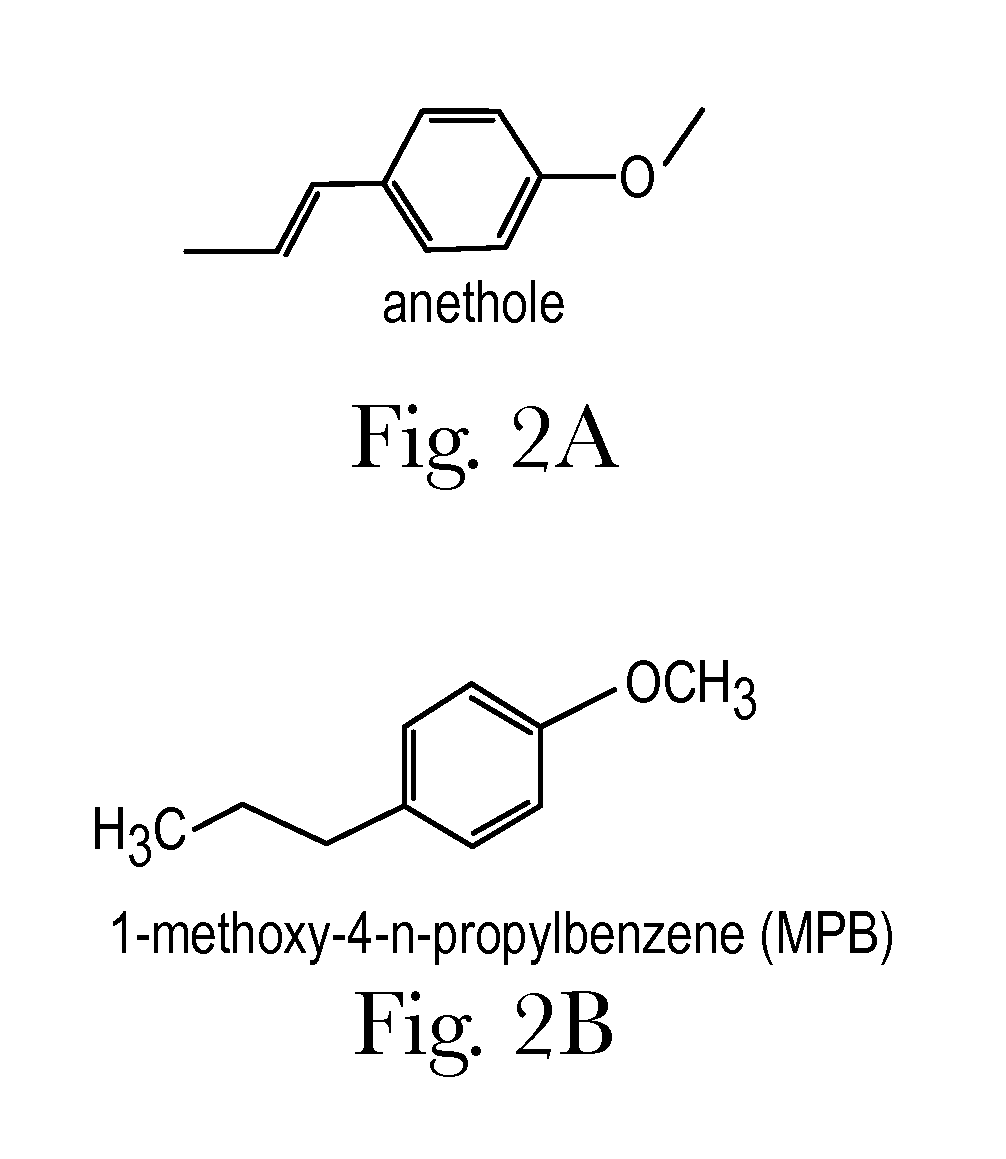

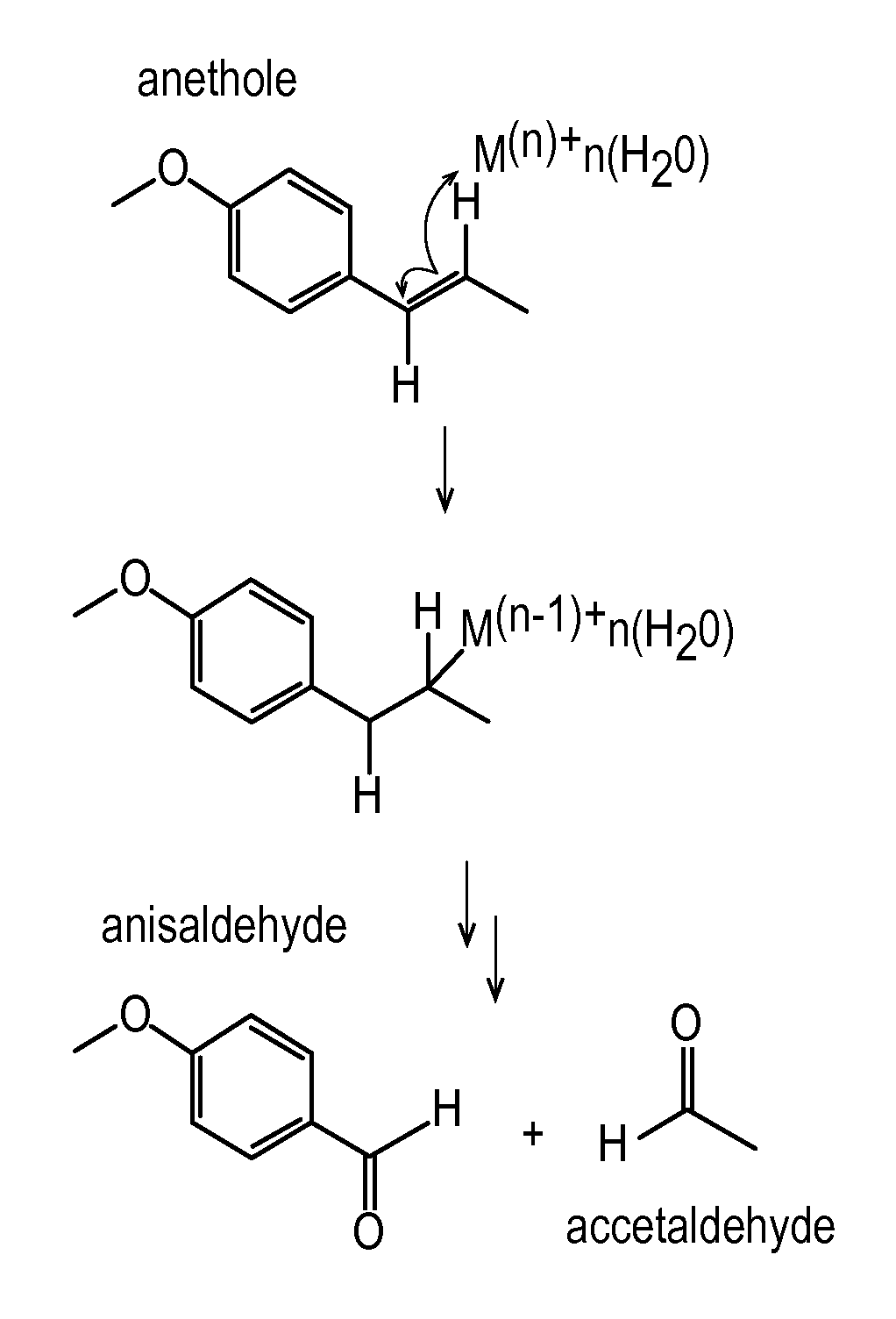

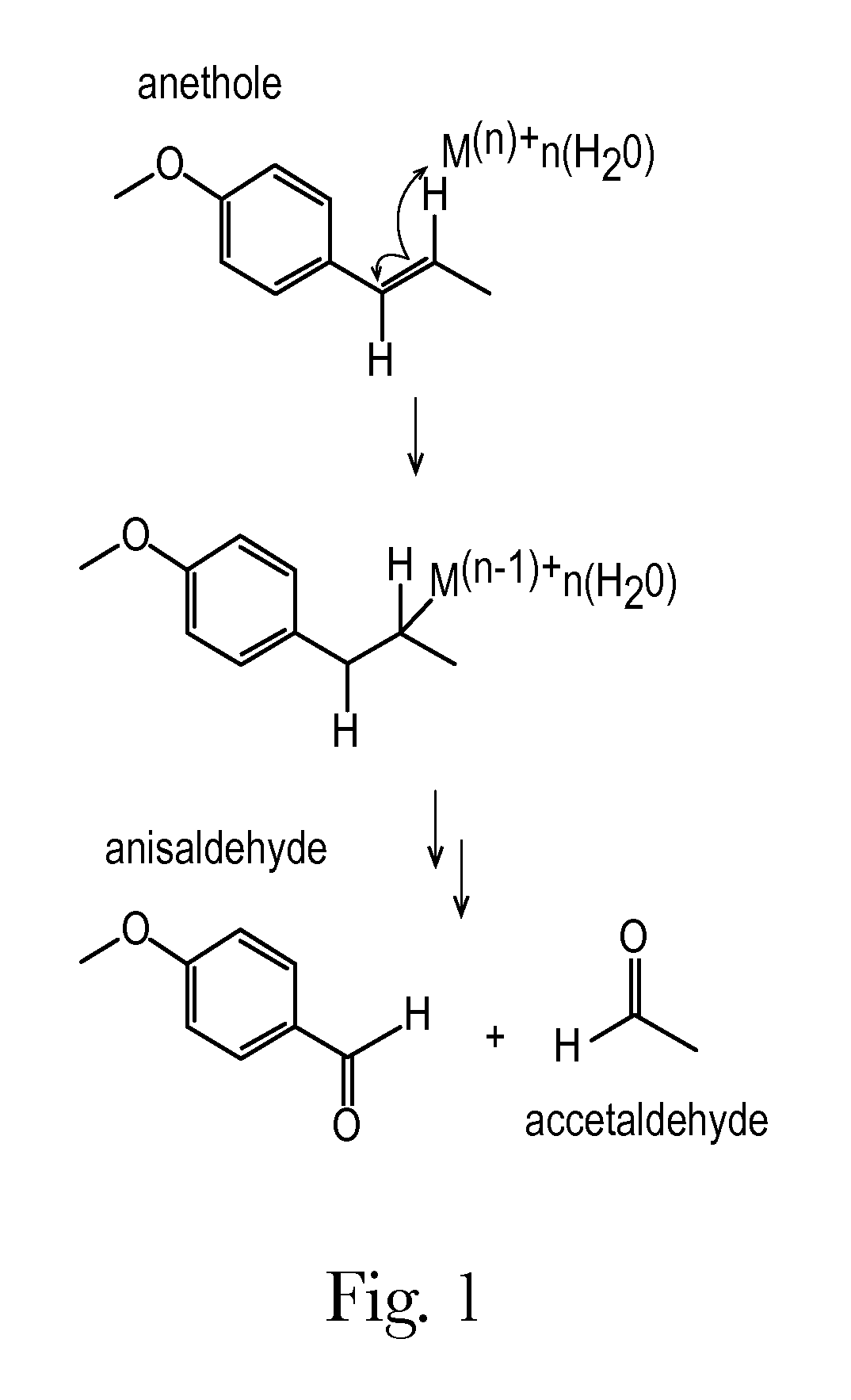

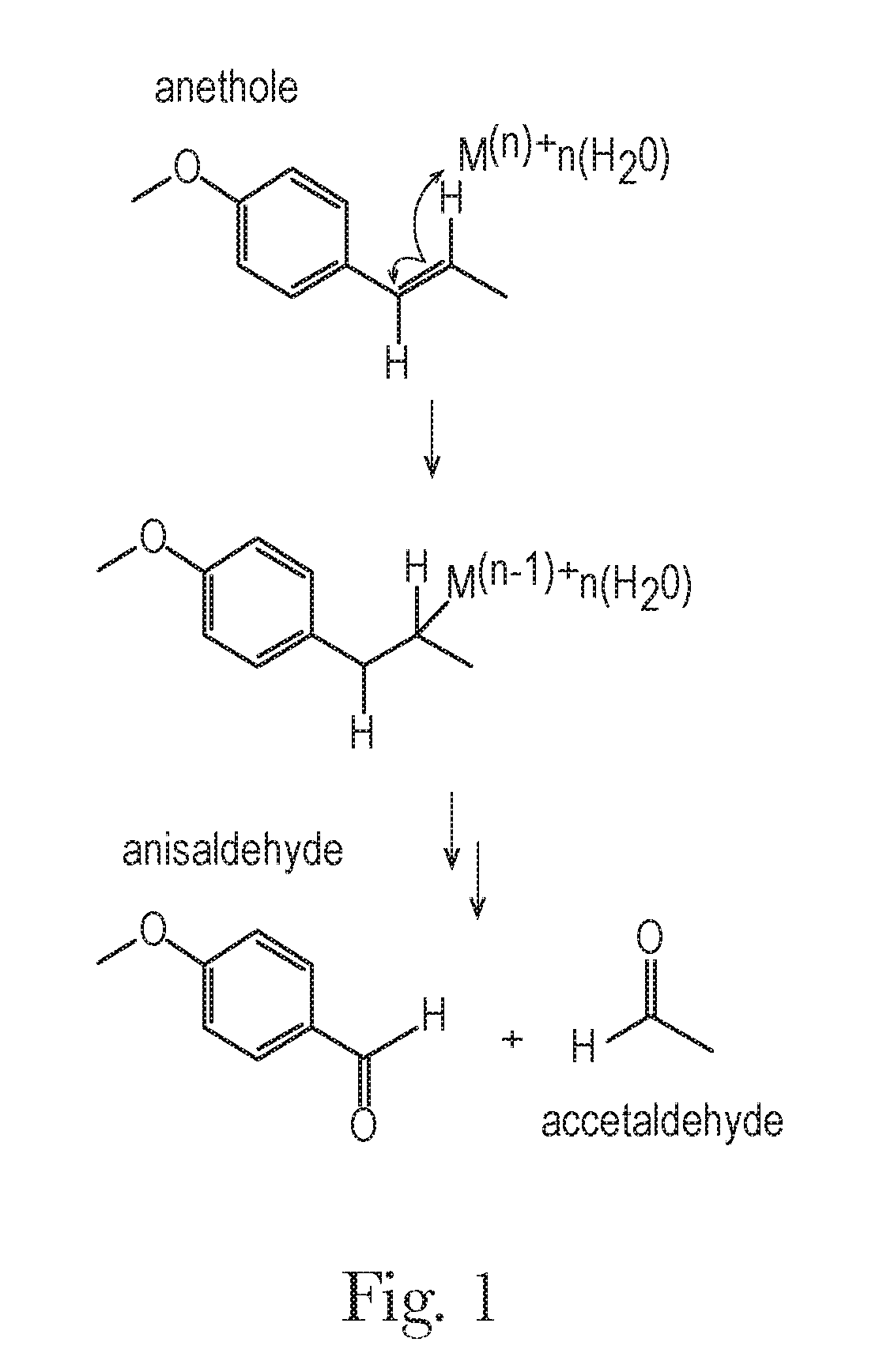

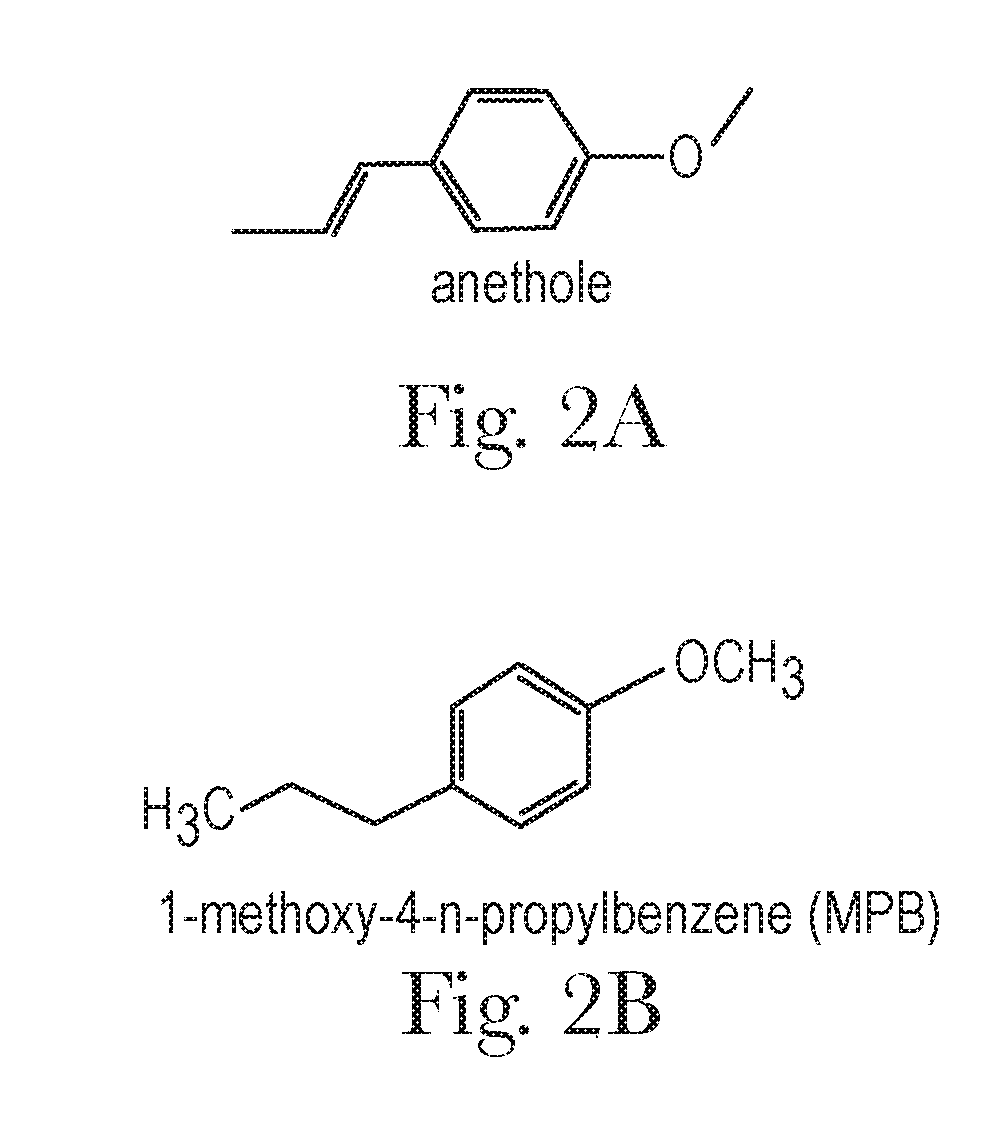

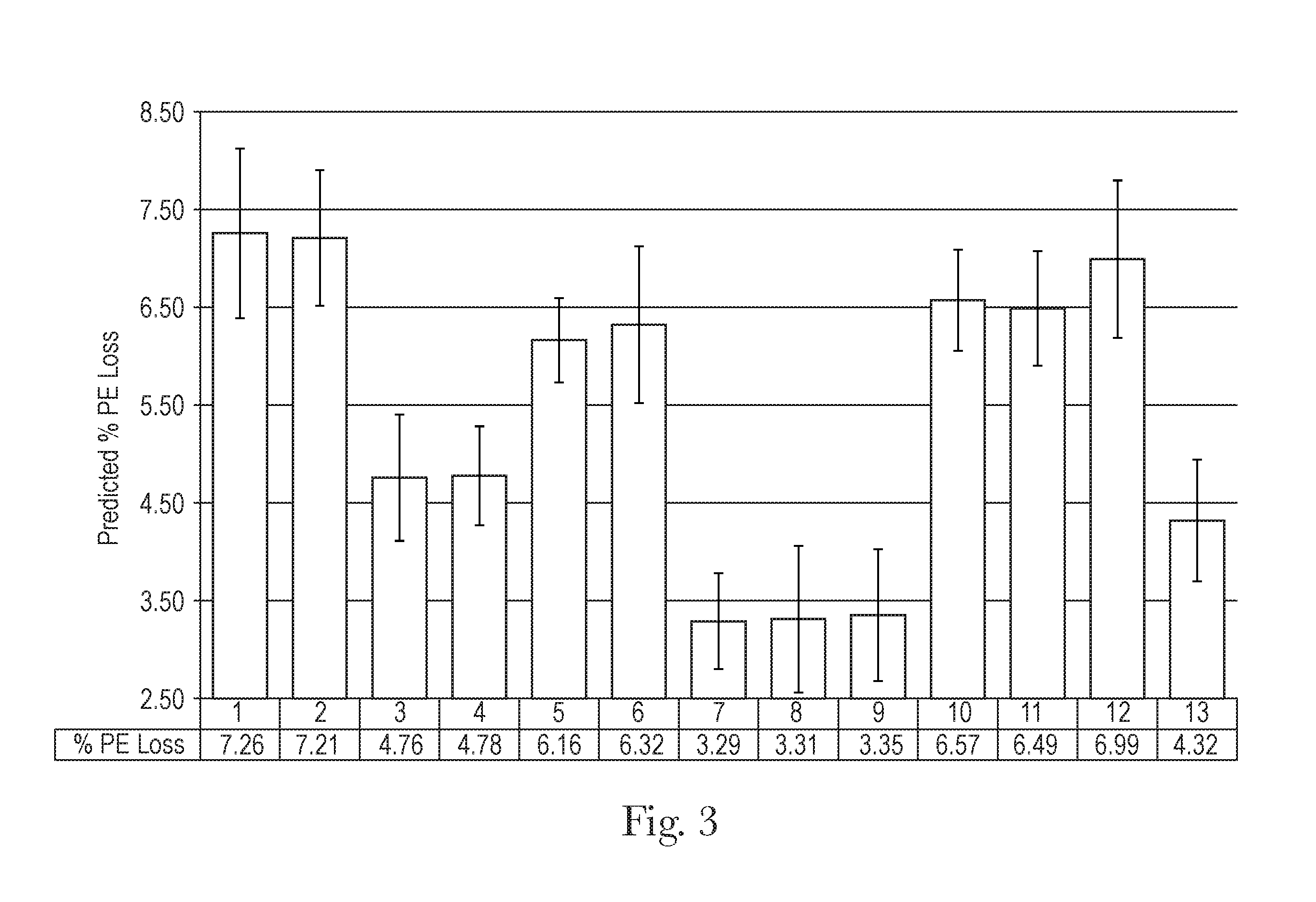

Anise Flavored Medication

An anise flavored liquid medication. The liquid medication contains phenylephrine and an anethole analog that is substantially free of aldehyde groups. In one example, the anethole analog can be 1-methoxy-4-n-propylbenzene.

Owner:THE PROCTER & GAMBLE COMPANY

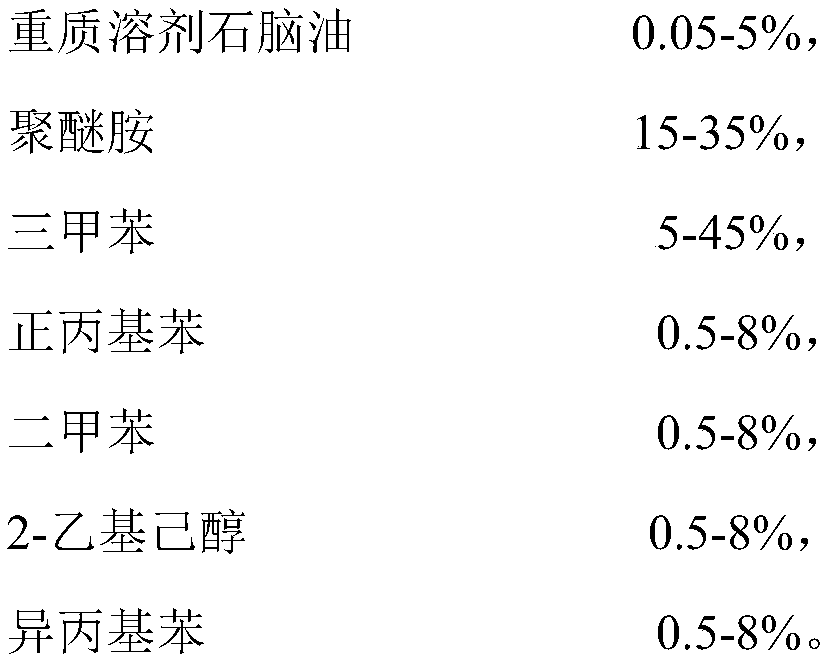

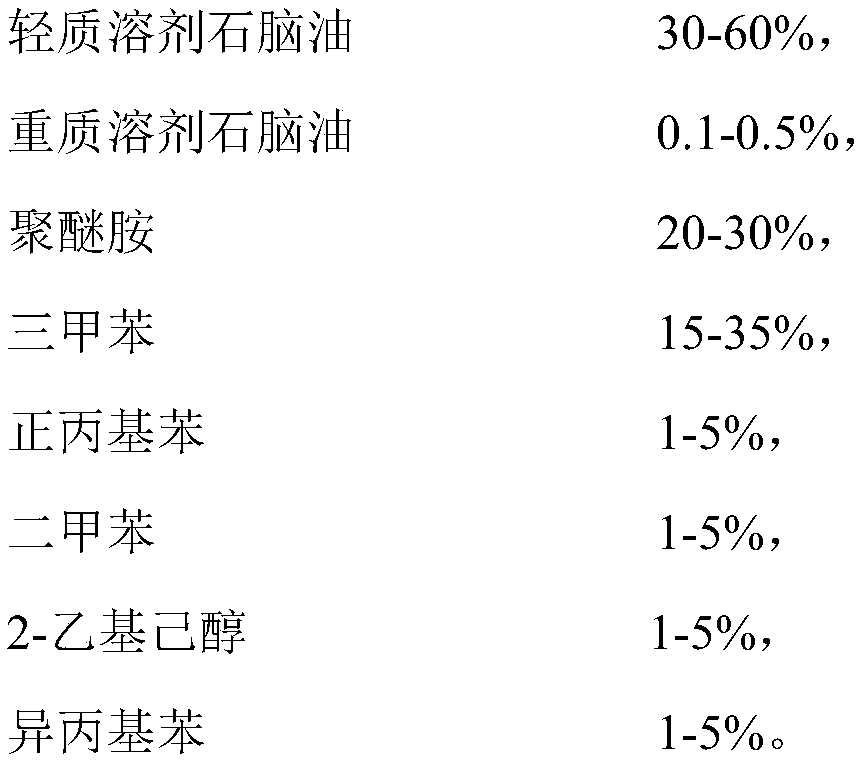

Gasoline detergent and application and preparation method thereof

InactiveCN109337723AEasy to cleanImprove cleaning efficiencyLiquid carbonaceous fuelsFuel additivesAlcoholNaphtha

The invention discloses a gasoline detergent and application and a preparation method thereof. The gasoline detergent is prepared from the following components in percentage by mass: 30 to 60 percentof light solvent naphtha, 0.05 to 5 percent of heavy solvent naphtha, 15 to 35 percent of polyetheramine, 5 to 45 percent of trimethylbenzene, 0.5 to 8 percent of n-propylbenzene, 0.5 to 8 percent ofxylene, 0.5 to 8 percent of 2-ethylhexanol and 0.5 to 8 percent of isopropyl benzene. The detergent and the modifier of the invention contain polar activating factors which can adsorb, permeate and peel off colloidal sludge and carbon deposit and are discharged along exhaust gas after being burned at a high temperature, thereby cleaning an entire fuel system; the problems of difficult cold start,unstable idling, unsmooth acceleration and the like which are caused by the carbon deposit are solved. The gasoline detergent is safe and environmentally friendly, does not contain alcohol substancesand cannot corrode or damage an engine part.

Owner:开平保驰捷汽车用品科技有限公司

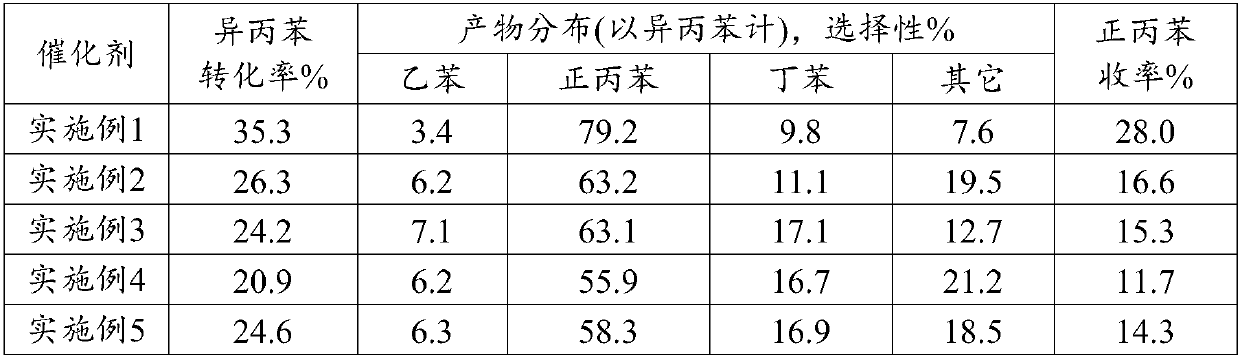

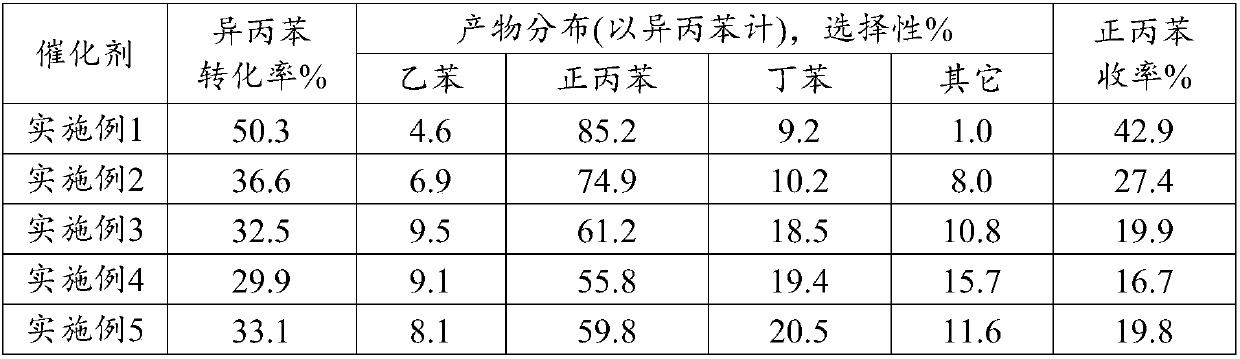

Use of catalyst for alkylation reaction of aromatic hydrocarbons and low-carbon alkanes

The invention relates to application of a catalyst in the alkylation reaction of aromatic hydrocarbon and light alkane. The catalyst contains Mo element and ZSM-5 molecular sieve, wherein the weight ratio of the Mo element and the ZSM-5 molecular sieve is 1-16%. The catalyst contains 5-40 wt% of binder. The reaction temperature in the alkylation reaction of the aromatic hydrocarbon and the light alkane is 250-450 DEG C; the mole ratio of the feeding aromatic hydrocarbon and the light alkane is 0.5-3, and the weight air speed is 0.2-5 / h. When the catalyst is applied to the alkylation reaction of benzene and propane, toluene, ethyl benzene, isopropyl benzene and n-propylbenzene can be prepared with high selectivity.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Production of diisopropylbenzene

A process for the disproportionation of cumene is disclosed which comprises the step of contacting a feed containing cumene, under disproportionation conditions, with a catalyst comprising a molecular sieve, preferably TEA-mordenite. The contacting step disproportionates at least part of the cumene in the feed to provide a disproportionation effluent containing benzene and a mixture of diisopropylbenzene isomers. The effluent is then recovered and contains, prior to any separation step, less 1% of ortho-diisopropylbenzene by weight of the total diisopropylbenzene content of said effluent, less than 1 wt % of n-propylbenzene, less than 5 wt % of triisopropylbenzenes and less than 5 wt % of disproportionation products other than benzene and diisopropylbenzenes.

Owner:EXXONMOBIL CORP (US)

Anise flavored medication

An anise flavored liquid medication. The liquid medication contains phenylephrine and an anethole analog that is substantially free of aldehyde groups. In one example, the anethole analog can be 1-methoxy-4-n-propylbenzene.

Owner:PROCTER & GAMBLE CO

Anise Flavored Medication

Owner:PROCTER & GAMBLE CO

Method for preparing propiophenone by biomimetic catalytic oxidation of n-propylbenzene with oxygen

InactiveCN101759540BReduce pollutionReduce manufacturing costOrganic compound preparationOrganic-compounds/hydrides/coordination-complexes catalystsPorphyrinCatalytic oxidation

Owner:BEIJING UNIV OF TECH

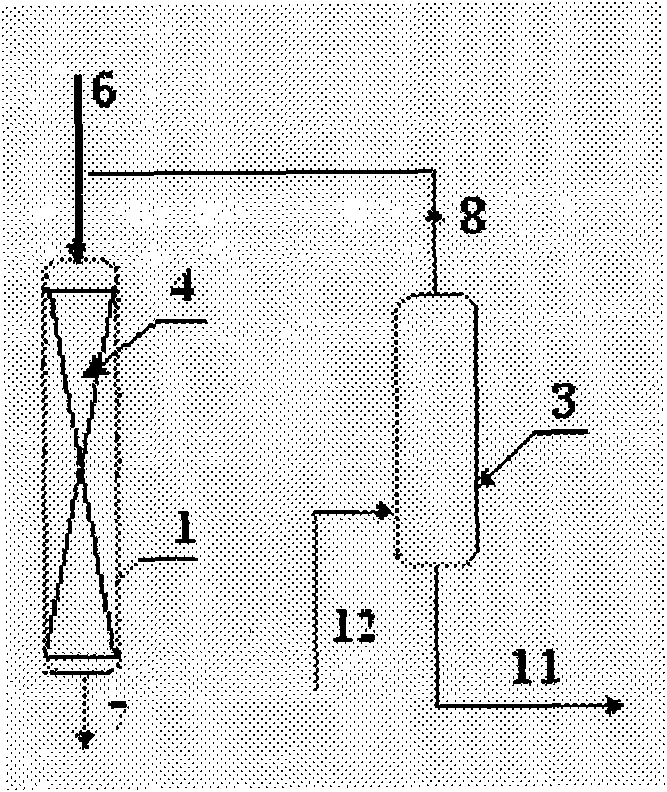

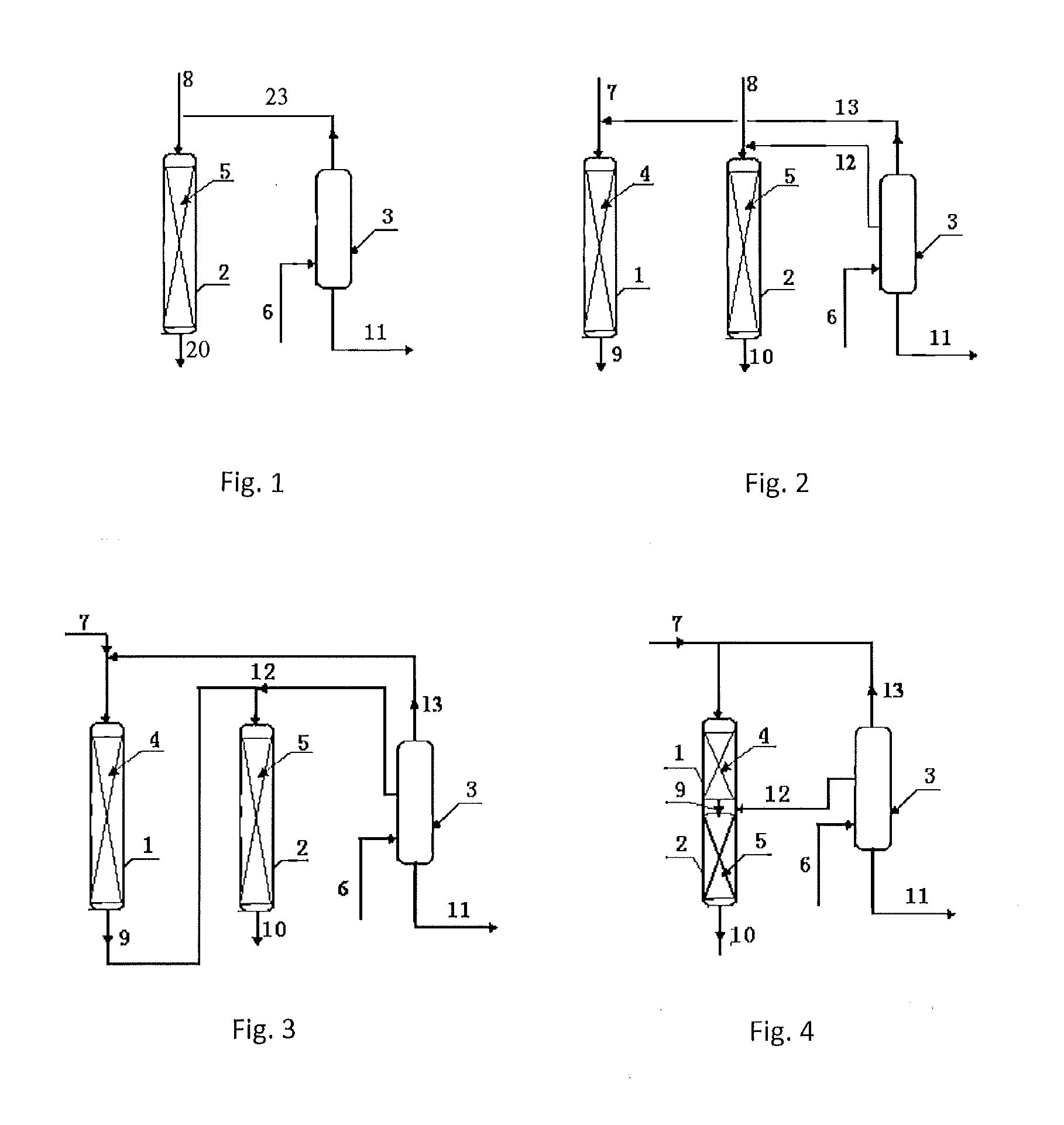

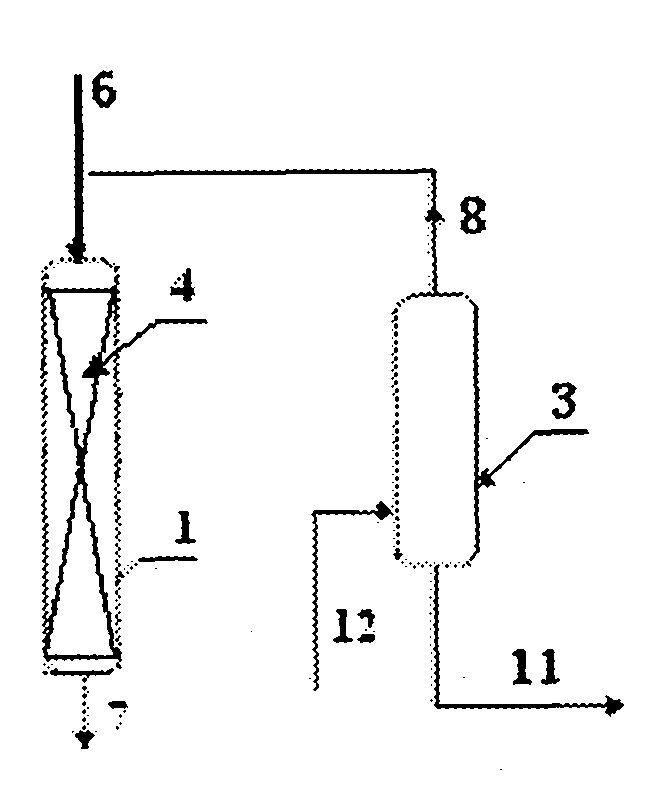

Method for producing isopropylbenzene

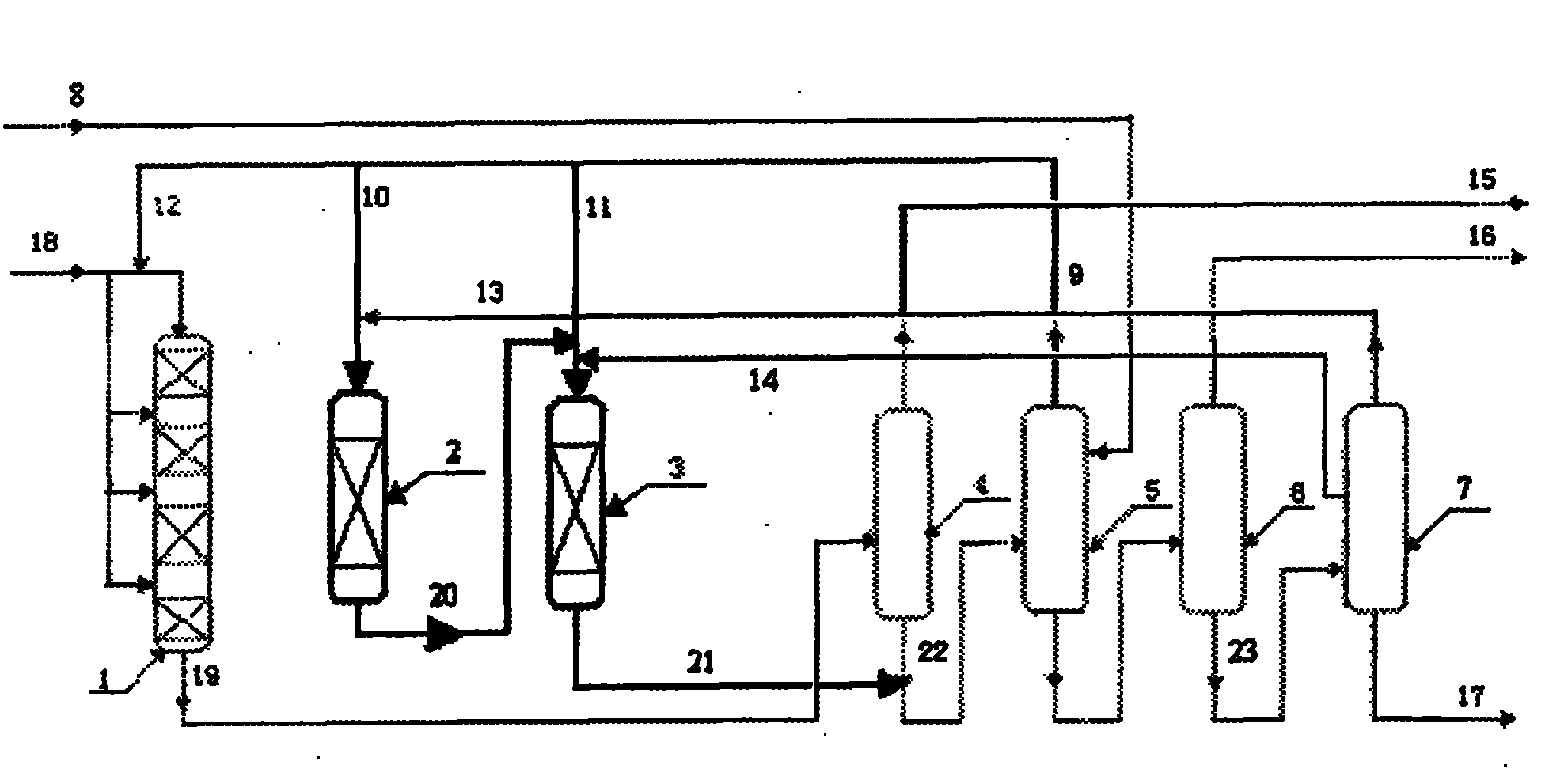

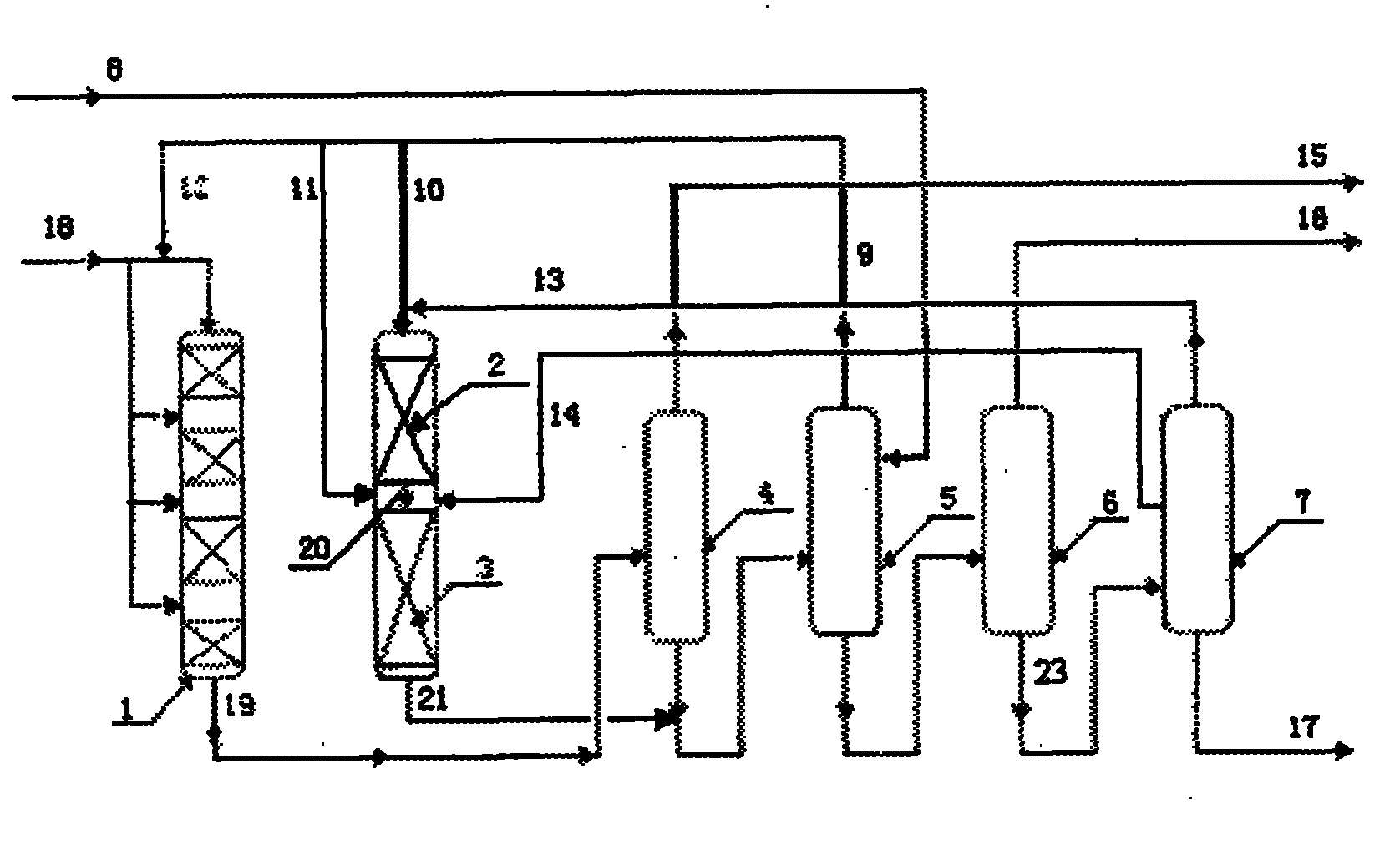

ActiveCN102464563AReduce contentImprove product qualityHydrocarbonsHydrocarbon preparationAlkyl transferDistillation

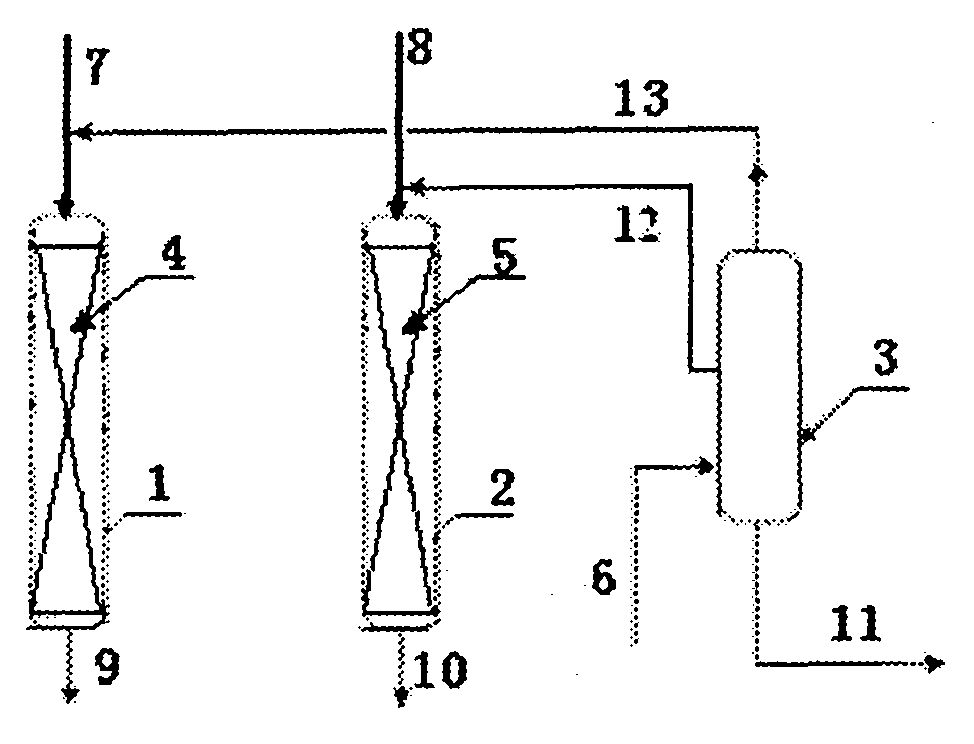

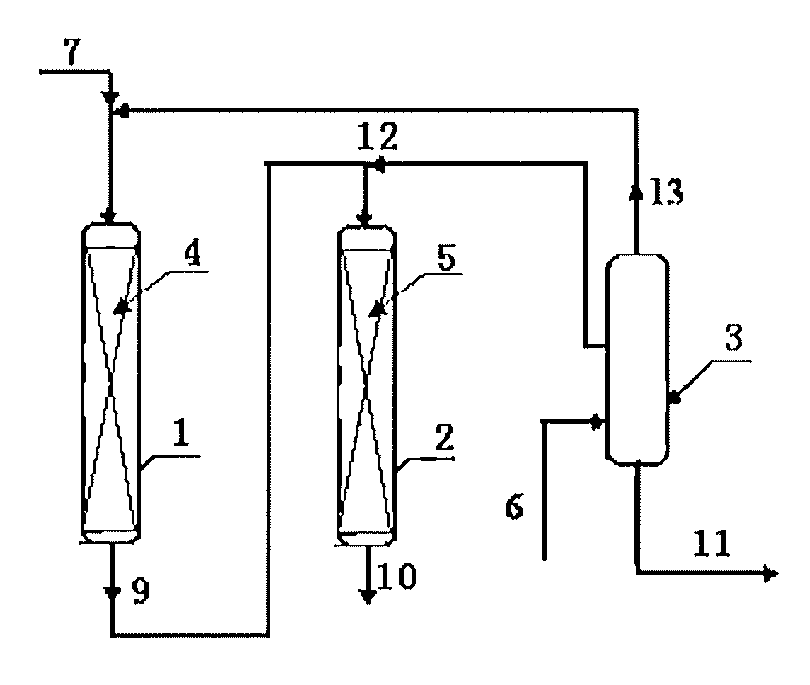

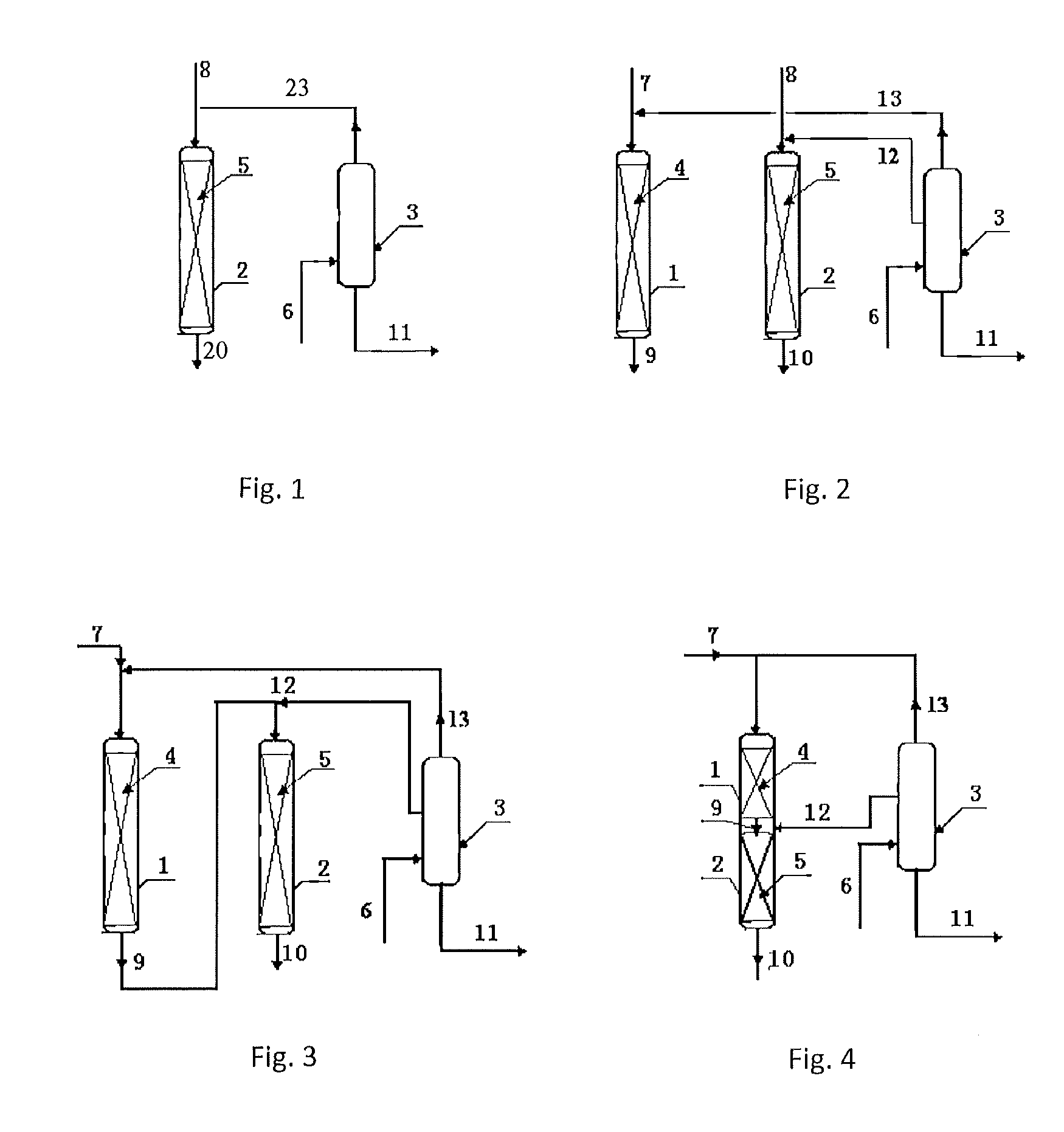

The invention relates to a method for producing isopropylbenzene. The problem that the content of n-propylbenzene is high in the prior art is solved. The method comprises the following steps that: a) a material flow which contains multi-substituted isopropylbenzene enters a multi-substituted isopropylbenzene tower, after distillation separation, a material flow 13 is obtained from the top of the tower, a material flow 12 is obtained from the middle part of the tower, and a heavy component material flow which contains tar is obtained from a tower kettle, wherein in the material flow 13, the content of diisopropylbenzene is at least more than 95 weight percent, and in the material flow 12, the content of triisopropylbenzene is at least more than 0.5 percent; b) a first benzene material flow and the material flow 13 enter a first alkyl transfer reactor from the top to be contacted with a catalyst to perform an alkyl transference reaction, and a material flow 9 which contains the isopropylbenzene is obtained at the bottom; c) a second benzene material flow and the material flow 12 enter a second alkyl transference reactor from the top to be contacted with a catalyst to perform an alkyl transference reaction, and a material flow 10 which contains the isopropylbenzene is obtained at the bottom; and d) the material flow 9 and the material flow 10 enter a subsequent refining process to produce the product, namely the isopropylbenzene. The problem is better solved through the technical scheme and the method can be applied to the industrial production of the isopropylbenzene.

Owner:CHINA PETROLEUM & CHEM CORP +1

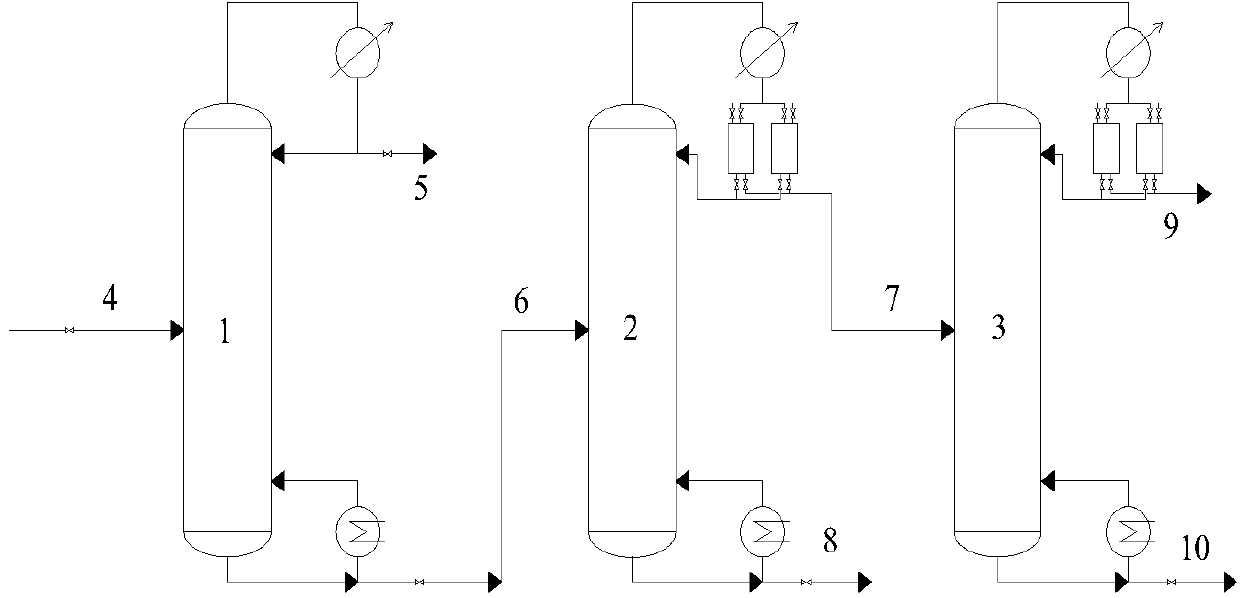

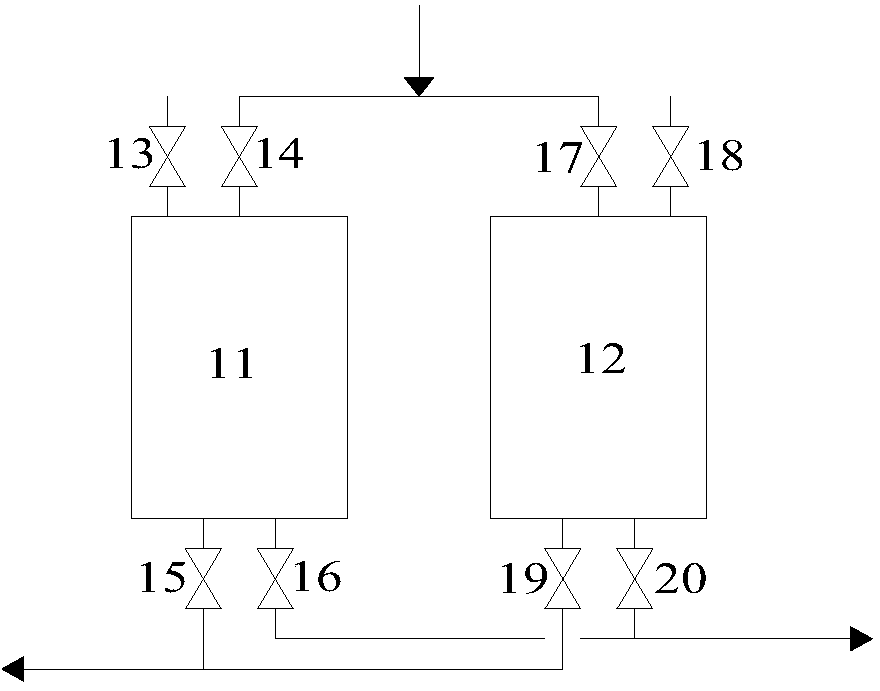

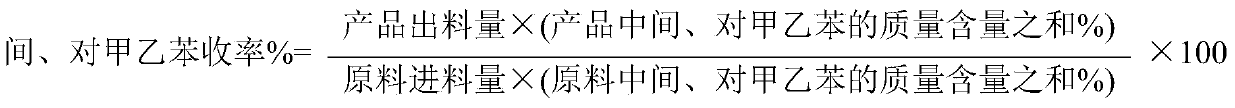

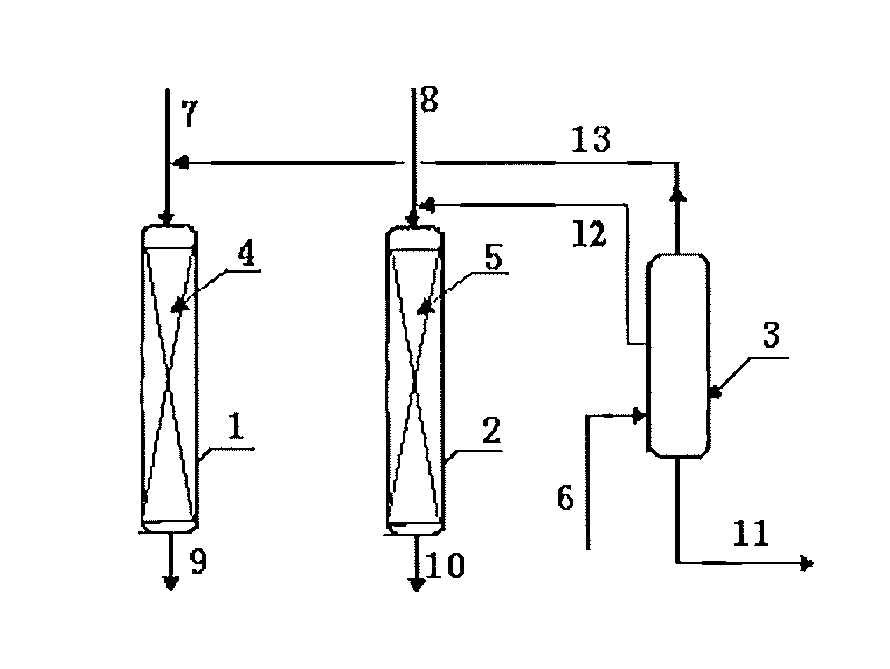

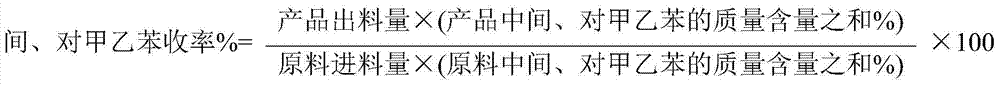

Method for separation of m/4-ethyltoluene from aromatic hydrocarbon mixture

ActiveCN105503507AThe number of theoretical boards is reducedRealize vacuum batch distillation operationDistillation purification/separationTheoretical plateN-propylbenzene

The invention relates to a method for separation of m / 4-ethyltoluene from an aromatic hydrocarbon mixture, and mainly solves the technical problem of difficult separation of m / 4-ethyltoluene from an aromatic hydrocarbon mixture. According to a technical scheme, the aromatic hydrocarbon mixture is introduced into a coarse separation tower, C8 and C8 pre-components are removed from the coarse separation tower top, the coarse separation tower bottom liquid is introduced into a first fine separation tower equipped with double liquid accumulation tanks at the top, a light component containing m / 4-ethyltoluene is led out from the first fine separation tower top into a second fine separation tower equipped with double liquid accumulation tanks, a n-propylbenzene and cumene mixture is led out from the second fine separation tower top, and the m / 4-ethyltoluene product is led out from the second fine separation tower bottom. The method provided by the invention well solves the technical problem, and can be applied to the aromatic hydrocarbon mixture separation field. With double tower top liquid accumulation tanks, batch rectification can be operated under the total reflux condition, thereby reducing the number of theoretical plates of the tower, and the alternating operation of the double liquid accumulation tanks can realize pressure reduced batch rectification.

Owner:CHINA PETROLEUM & CHEM CORP +1

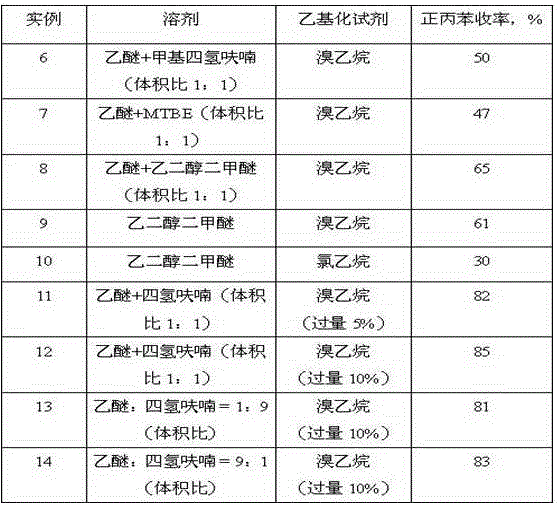

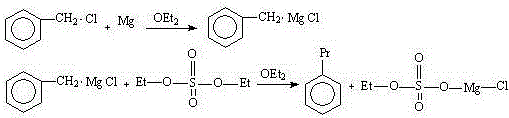

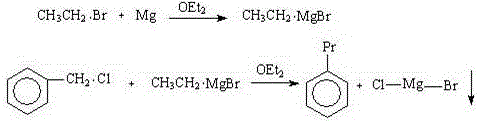

A kind of method of synthesizing n-propyl benzene

ActiveCN104892345BImprove responseEasy to operateHydrocarbonsHydrocarbon preparationGrignard reagentEvaporation

The invention relates to a method for synthesizing n-propylbenzene through a Grignard reagent method. The technical scheme comprises that in an ether solvent, benzyl chloride reacts with magnesium powder or magnesium strip to produce a benzyl magnesium chloride Grignard reagent, and the benzyl magnesium chloride Grignard reagent reacts with an ethylation reagent to produce n-propylbenzene. Compared with the method in the prior art, the method for synthesizing the n-propylbenzene by using the Grignard reagent method in the present invention has the following advantages that (1) the reaction is simple, the used reagents are less, and the operation is easy; (2) the pollutants are less, and the method does not produce a lot of aluminum-containing wastewater; (3) the reaction temperature is low and is usually not more than 100 DEG C, the energy consumption is low, and the method does not required the heating evaporation of a large amount of water in the F-C method; and (4) the raw materials are easy to obtain, the yield is high, the side effects are less, and the production cost is low.

Owner:山东东昌精细化工科技有限公司

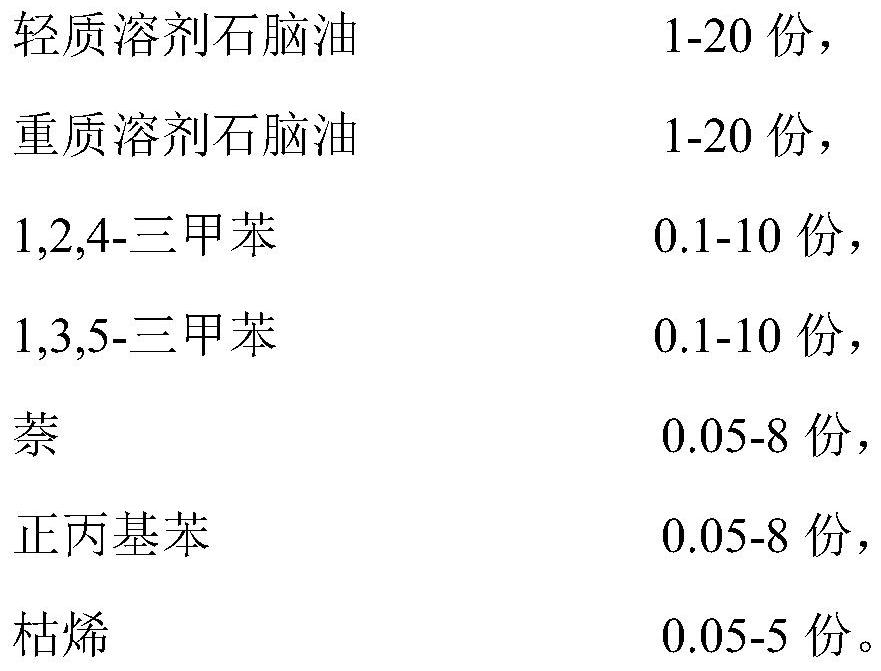

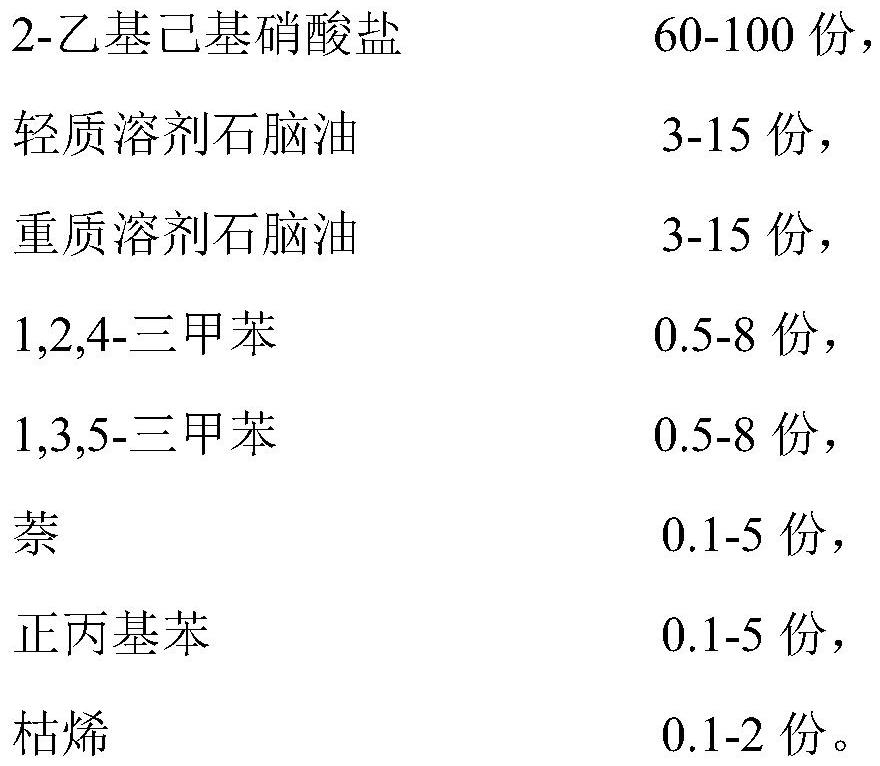

A kind of diesel oil additive and preparation method thereof

ActiveCN109294640BImprove utilization efficiencyBurn completelyLiquid carbonaceous fuelsFuel additivesBiodieselInjector nozzle

The invention discloses a diesel oil additive and a preparation method thereof. The diesel oil additive includes a multifunctional agent and aviation kerosene with a mass ratio of 1:1-5, in parts by mass, wherein the multifunctional agent includes the following components : 60-100 parts of 2-ethylhexyl nitrate, 1-20 parts of light solvent naphtha, 1-20 parts of heavy solvent naphtha, 0.1-10 parts of 1,2,4-trimethylbenzene, 1, 0.1-10 parts of 3,5-trimethylbenzene, 0.05-8 parts of naphthalene, 0.05-8 parts of n-propylbenzene, and 0.05-5 parts of cumene. The diesel additive of the present invention can clean the carbon deposits in the fuel injector, make the combustion more complete, improve the fuel utilization efficiency, increase the power, restore the good atomization effect of the fuel, improve the difficult condition of cold start, and can effectively improve the stability of diesel oil. Fully compatible.

Owner:开平保驰捷汽车用品科技有限公司

Oil-saving cleaning agent

InactiveCN110041973AReduce resistanceReduce running fuel consumptionLiquid carbonaceous fuelsCombustion chamberN-Butanol

The invention discloses an oil-saving cleaning agent. The oil-saving cleaning agent comprises the following components, by weight: 35-40 parts of polyetheramine, 2-3 parts of n-butanol, 5-8 parts of n-propylbenzene, 1-2 parts of methyl tert-butyl ether, 3-5 parts of isooctyl alcohol, 15-20 parts of polyisobutene amine, 0.2-0.5 part of isoamyl alcohol, 3-5 parts of xylene, 2-3 parts of isobutylbenzene, 8-10 parts of polyetheramine, 1-2 parts of di-tert-butyl-p-cresol, 10-15 parts of an auxiliary additive, 2-3 parts of apricot tree branches, 10-15 parts of honeysuckle flowers, and 3-5 parts of roots of slender dutchmanspipe. The oil-saving cleaning agent can reduce combustion chamber deposits, reduce engine resistance and reduce engine operating oil consumption through the synergistic effectof the components.

Owner:国久新能源科技有限公司

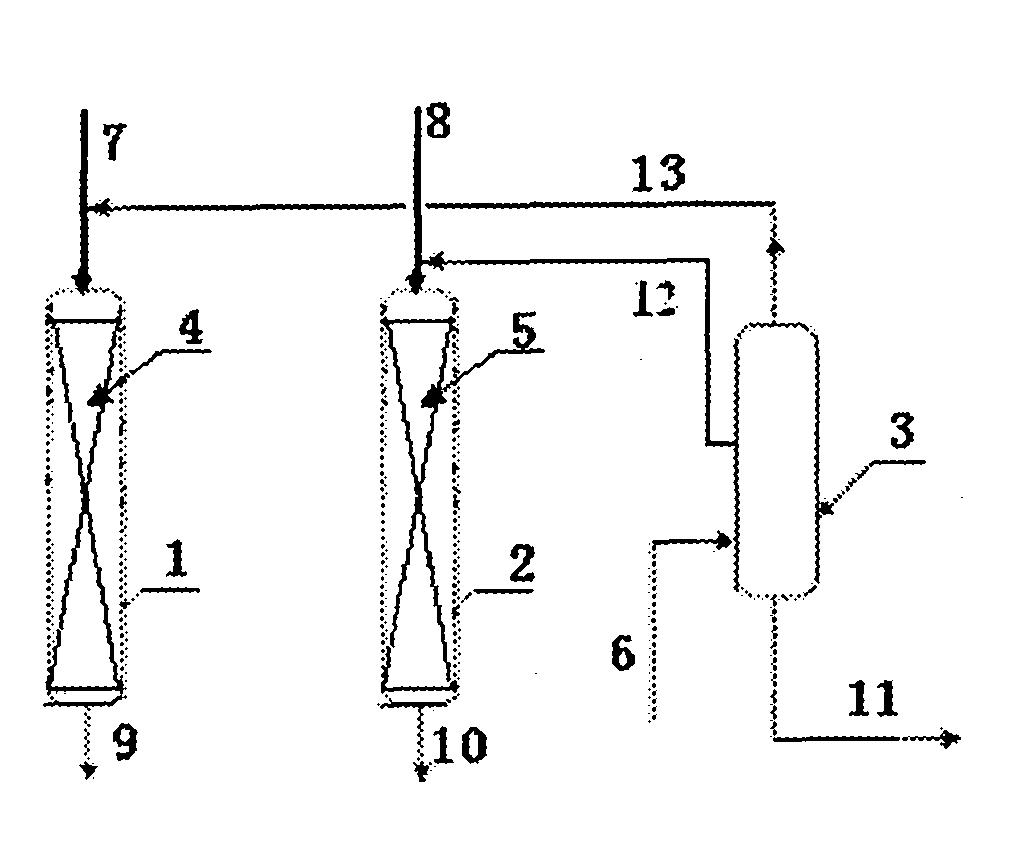

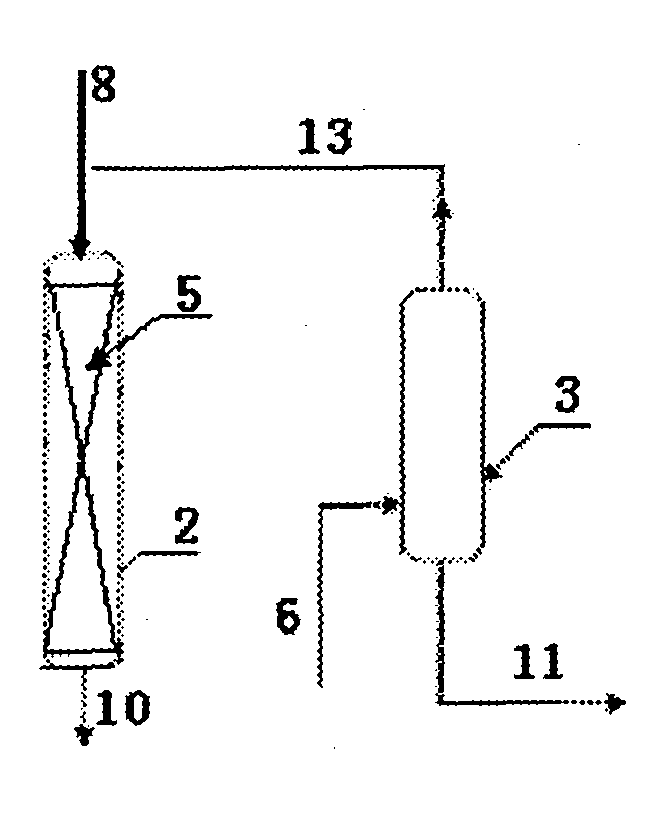

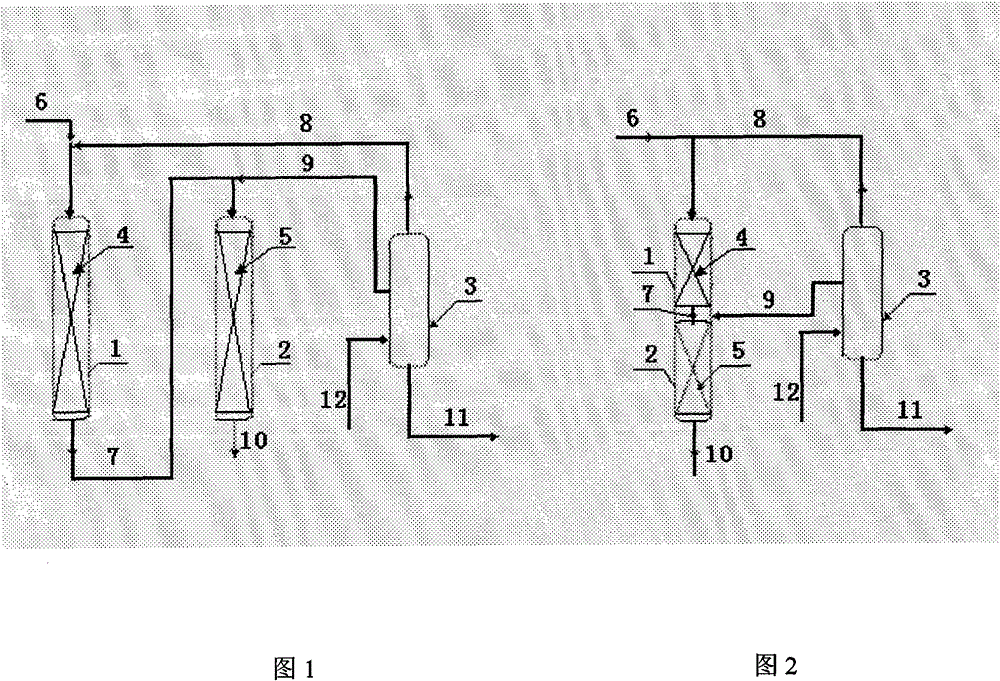

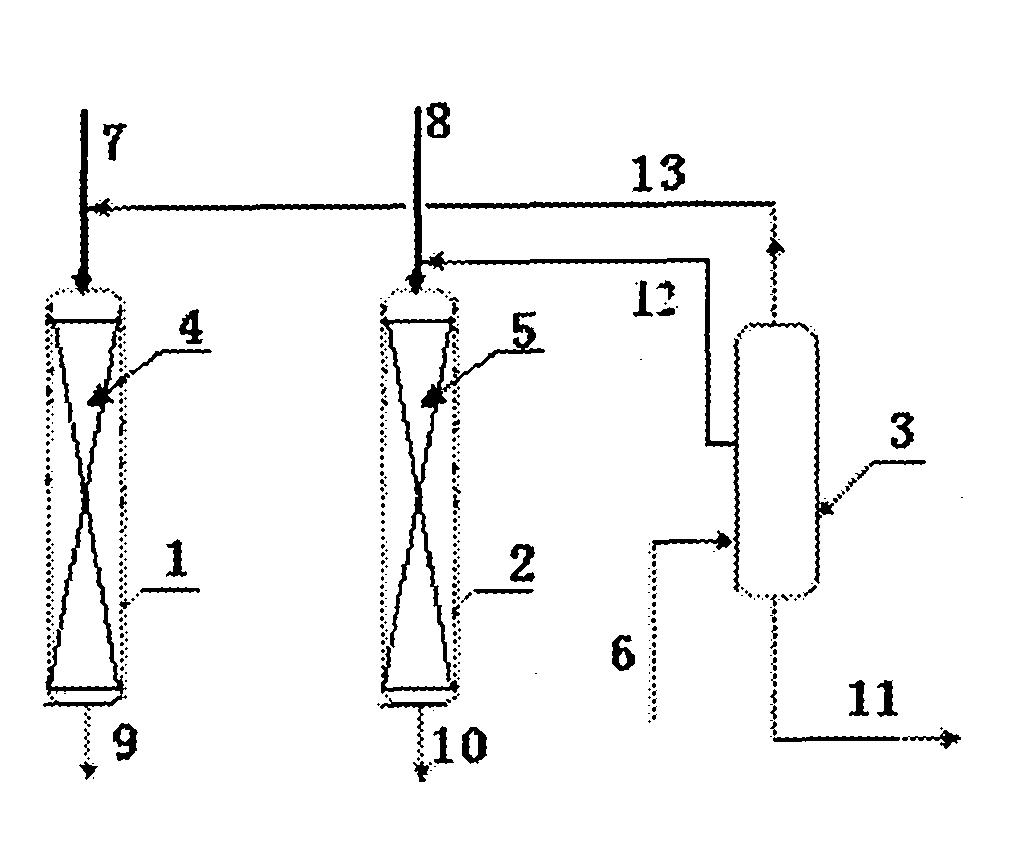

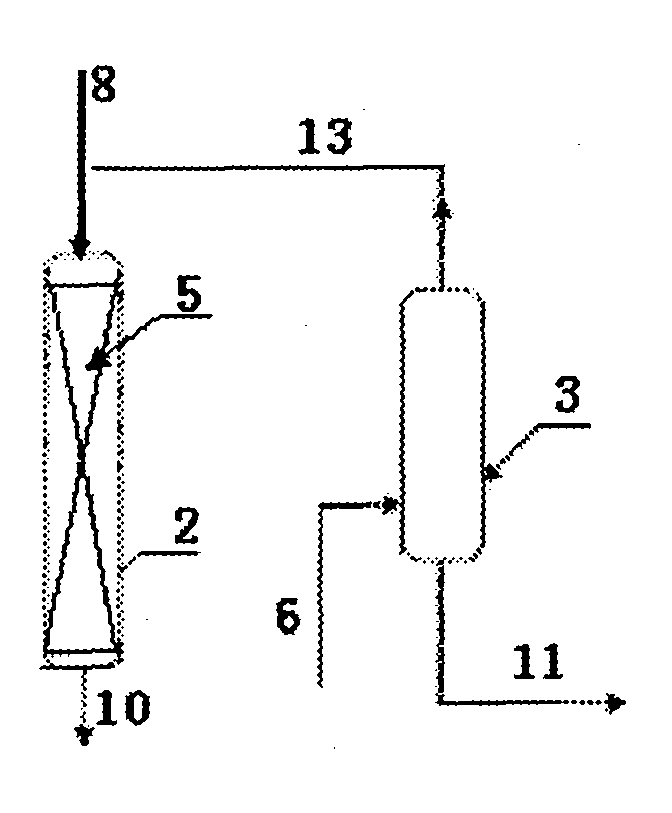

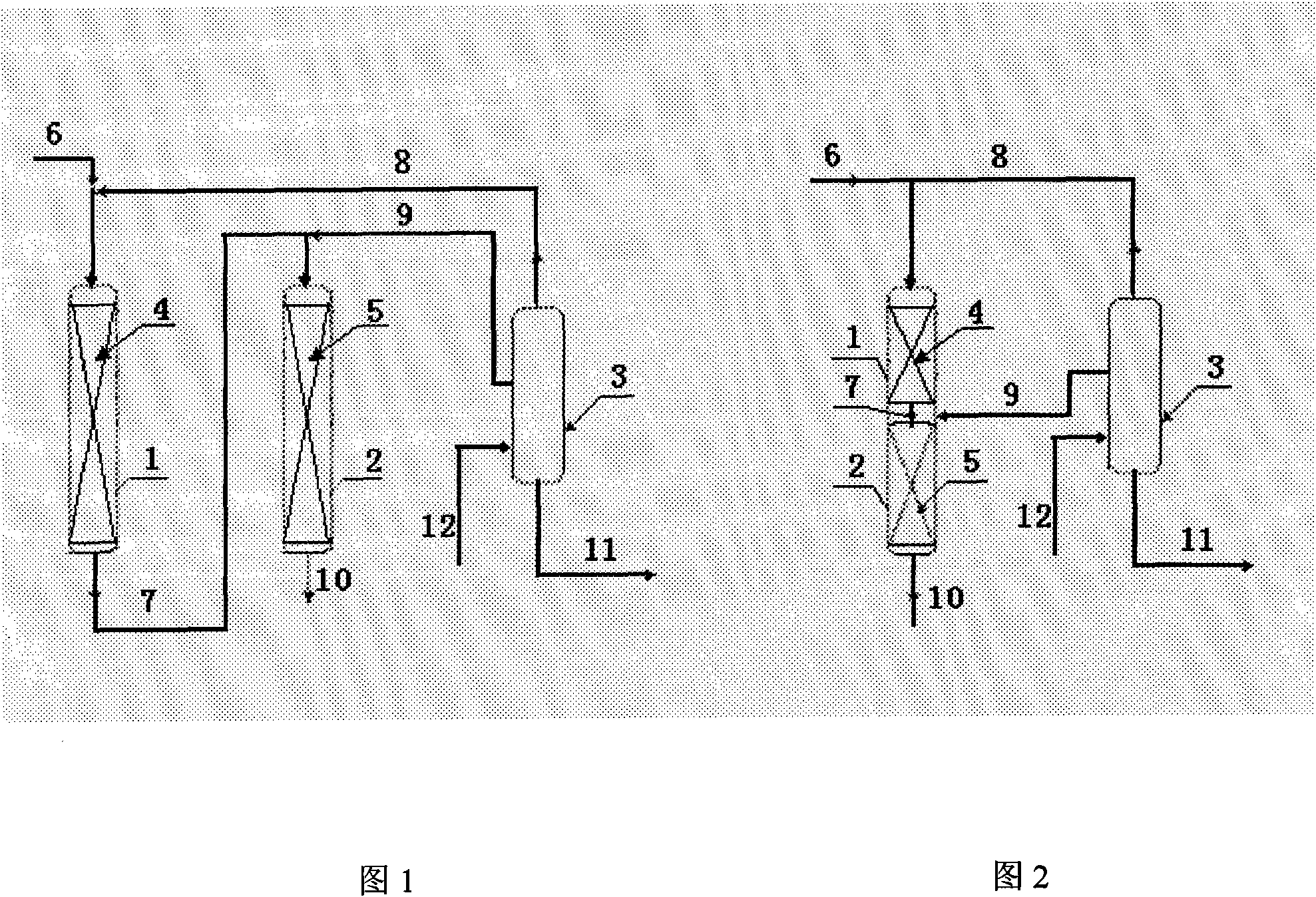

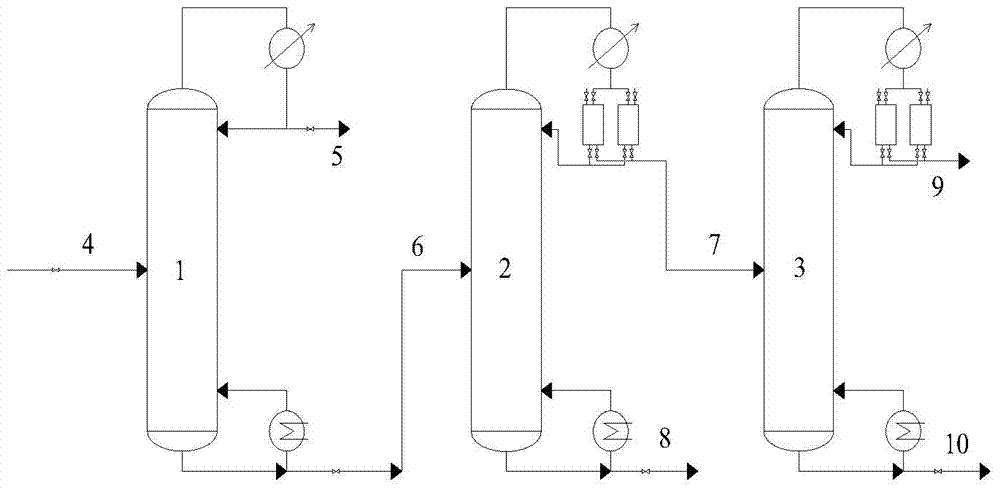

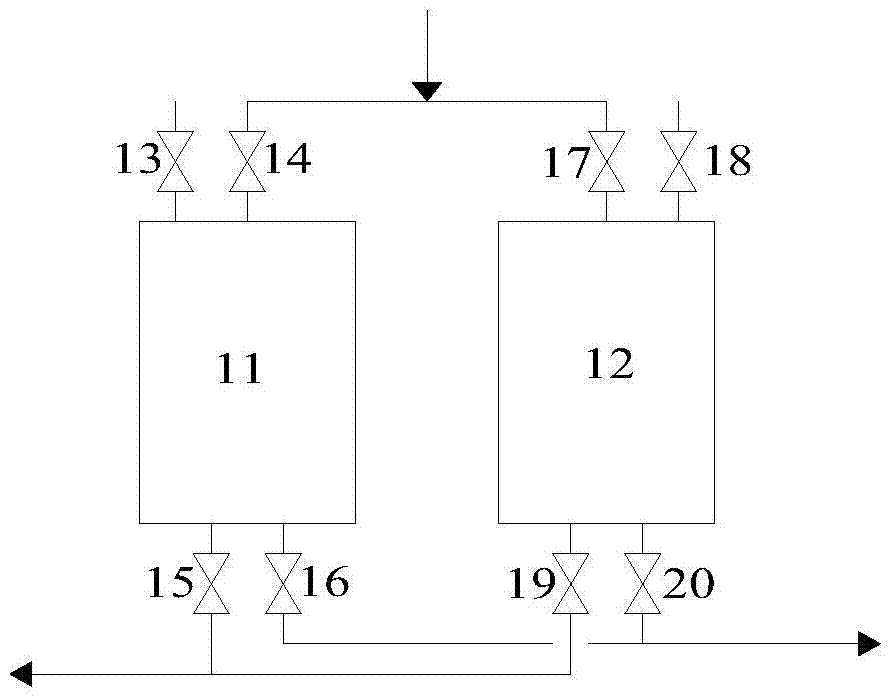

Method for producing isopropylbenzene

ActiveCN102464564BReduce contentImprove product qualityHydrocarbonsHydrocarbon preparationTarEngineering

The invention relates to a method for producing isopropylbenzene and mainly solves the problem of high content of n-propylbenzene existing in the prior art. The method better solves the problem and can be applied to the industrial production of isopropylbenzene by adopting the technical scheme which comprises the following steps of: (1) a material flow 12 containing polysubstituted isopropylbenzene enters a polysubstituted isopropylbenzene tower, after rectifying seperation is carried out on the material flow 12, a material flow 8 is obtained at the tower top, a material flow 9 is obtained in the middle part of the tower, and a heavy component material flow 11 containing oil tar is obtained in the tower bottom and enters a follow-up process; (b) a raw material benzene material flow 6 and the material flow 8 enter a first alkyl group transfer reaction zone from the top to contact with a catalytic agent for carrying out alkyl group transfer reaction, and a material flow 7 containing isopropylbenzene is obtained after reaction; (c) the material flow 7 and the material flow 9 enter a second alkyl group transfer reaction zone from the top to contact with the catalytic agent for carrying out alkyl group transfer reaction, and a material flow 10 containing isopropylbenzene is obtained after reaction; and the material flow 10 enters the follow-up refining process, thereby the isopropylbenzene product is obtained.

Owner:CHINA PETROLEUM & CHEM CORP +1

Process for producing cumene

ActiveUS20130237730A1Reduce contentImprove product qualityMolecular sieve catalystCatalystsN-propylbenzeneCumene

A process of producing isopropyl benzene which solves the problem of high amount of n-propyl benzene according to the prior art. The process separates the polyisopropyl benzene through a suitable rectification into two streams of relatively lighter and heavier components, wherein the content of diisopropylbenzene in the stream of relatively lighter components is controlled to be at least greater than 95 wt %, and the content of tri-isopropyl benzene in the stream of relatively heavier components is controlled to be at least greater than 0.5 wt %. Such a technical solution subjecting the two streams respectively to the transalkylation solves the problem raised from the prior art, and is useful for the industrial production of isopropyl benzene.

Owner:CHINA PETROCHEMICAL CORP +1

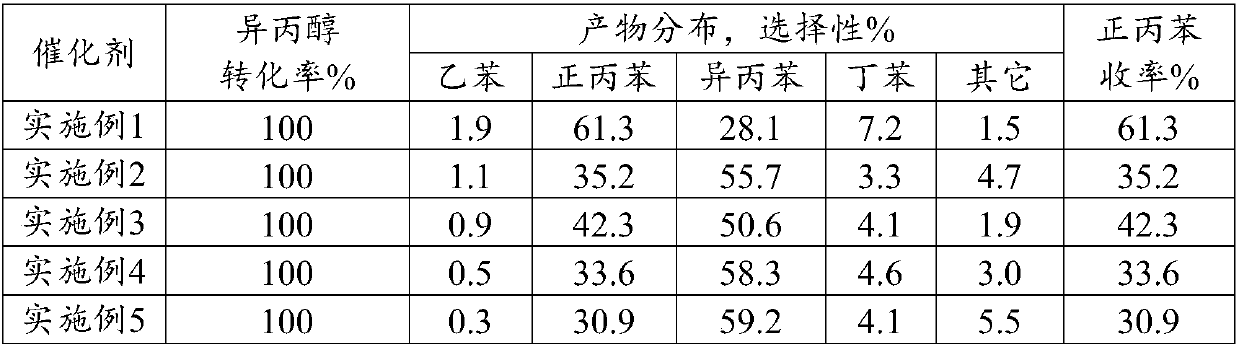

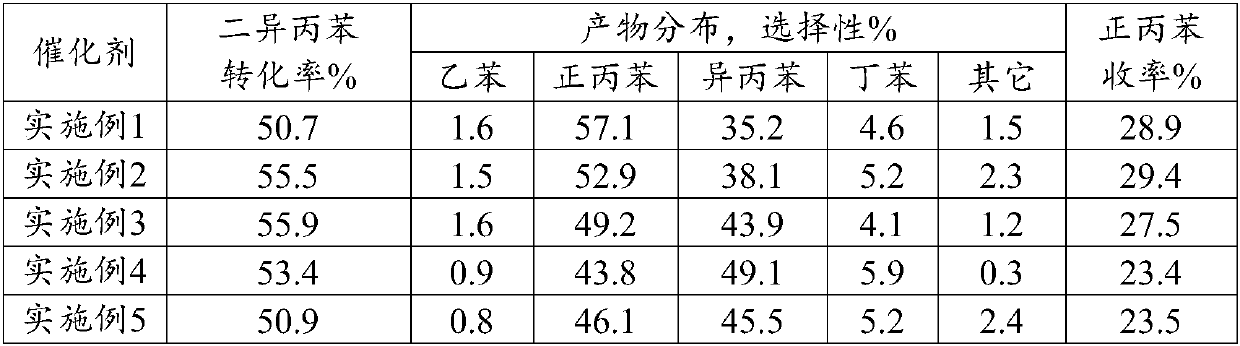

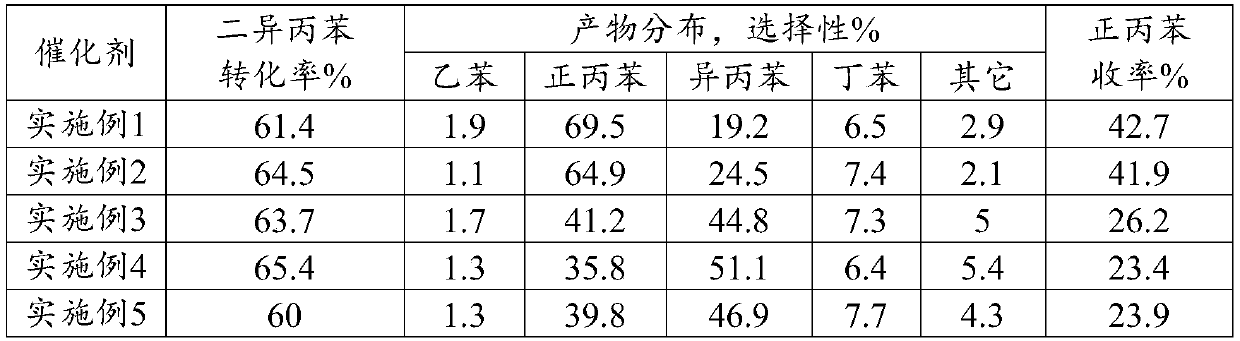

Method for producing n-propylbenzene by using benzene and isopropanol

ActiveCN108530245AHigh yieldAvoid rearrangementMolecular sieve catalystsHydrocarbon from oxygen organic compoundsN-propylbenzeneReaction conditions

The invention relates to a method for producing n-propylbenzene by using benzene and isopropanol. The method comprises the step of contacting benzene and isopropanol with a catalyst under the effective reaction condition to obtain the n-propylbenzene, and is characterized in that the effective reaction condition comprises that the temperature is at least more than 200 DEG C. The method can be applied to industrial production of the n-propylbenzene.

Owner:CHINA PETROLEUM & CHEM CORP +1

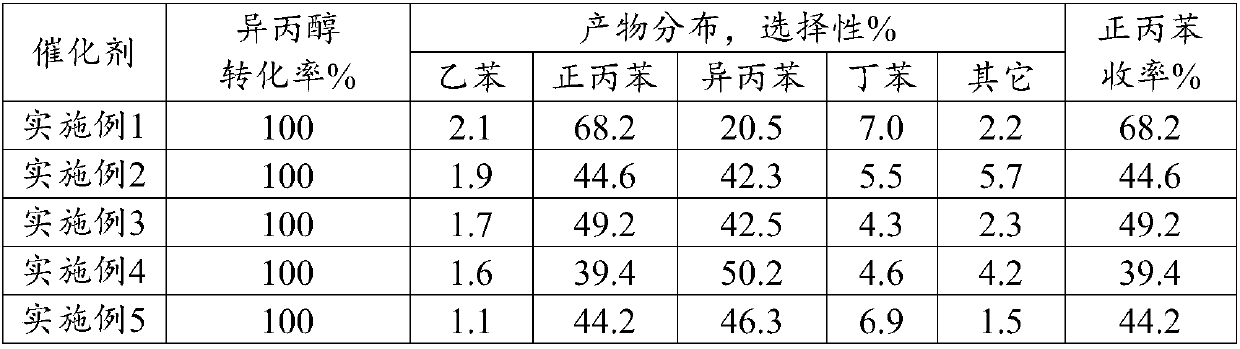

Method for producing n-propylbenzene by using benzene and isopropylbenzene

InactiveCN108530249AHigh yieldSimple processHydrocarbon by isomerisationMolecular sieve catalystsN-propylbenzeneReaction conditions

The invention relates to a method for producing n-propylbenzene by using benzene and isopropylbenzene. The method comprises the step of contacting benzene and isopropylbenzene with a catalyst under the effective reaction condition to obtain the n-propylbenzene, and is characterized in that the effective reaction condition comprises that the temperature is at least more than 200 DEG C. The method can be applied to industrial production of the n-propylbenzene.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for producing isopropylbenzene by using benzene and propylene

ActiveCN102464566BImprove product qualityReduce contentHydrocarbonsHydrocarbon preparationAlkyl transferTower

Owner:CHINA PETROLEUM & CHEM CORP +1

Process for producing cumene

ActiveUS9321705B2Reduce contentImprove product qualityMolecular sieve catalystCatalystsN-propylbenzeneCumene

A process of producing isopropyl benzene which solves the problem of high amount of n-propyl benzene according to the prior art. The process separates the polyisopropyl benzene through a suitable rectification into two streams of relatively lighter and heavier components, wherein the content of diisopropylbenzene in the stream of relatively lighter components is controlled to be at least greater than 95 wt %, and the content of tri-isopropyl benzene in the stream of relatively heavier components is controlled to be at least greater than 0.5 wt %. Such a technical solution subjecting the two streams respectively to the transalkylation solves the problem raised from the prior art, and is useful for the industrial production of isopropyl benzene.

Owner:CHINA PETROCHEMICAL CORP +1

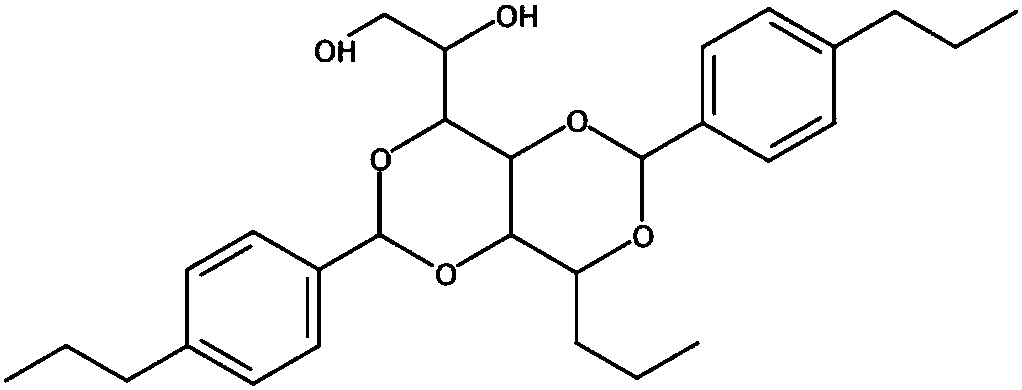

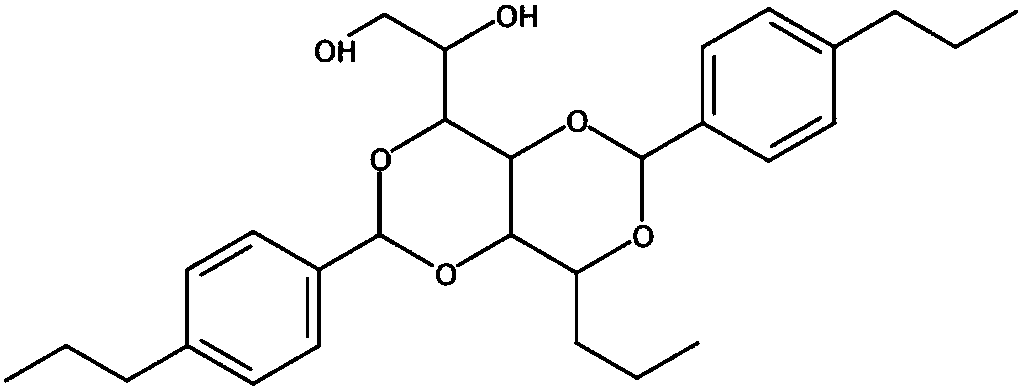

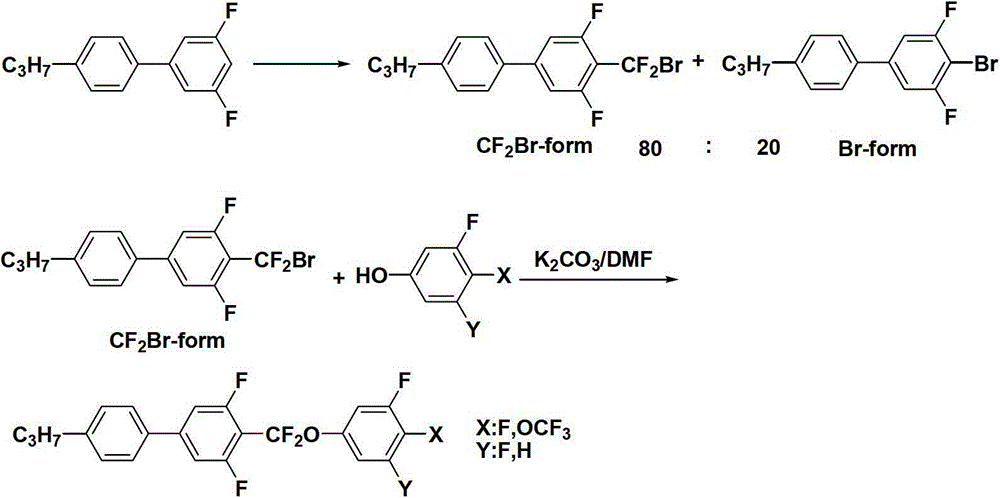

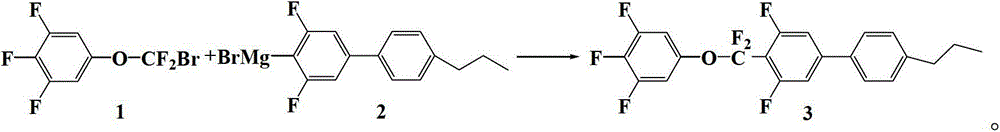

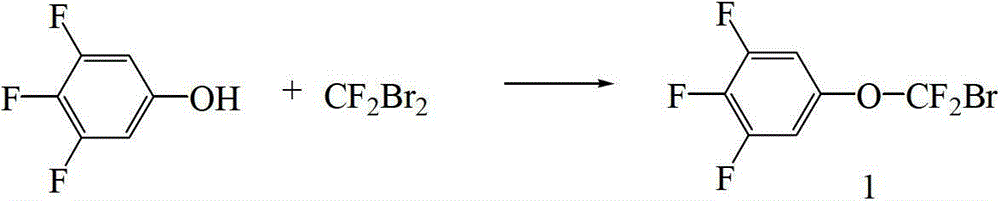

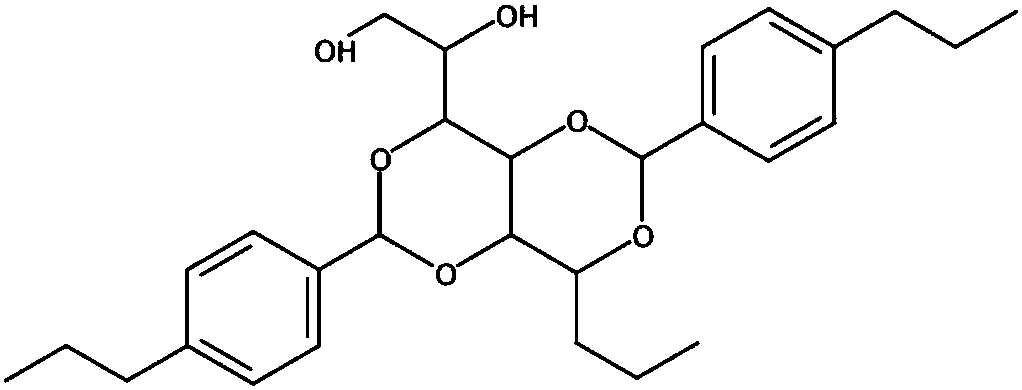

Preparation method of CF2O-containing compound, and intermediate compound and preparation method thereof

ActiveCN103086850BEasy to operateMild reaction conditionsOrganic compound preparationMagnesium organic compoundsGrignard reagentBromine

The invention discloses a preparation method of a CF2O-containing compound, and an intermediate compound and a preparation method thereof. The preparation method of a CF2O-containing compound, provided by the invention, comprises the following step: in solvent, in the presence of a catalyst, performing coupling reaction on 5-(bromo-difluoro-methoxy)-1,2,3-trifluorobenzene shown as Formula 1 and a Grignard reagent 3,5-difluoro-4'-propylbiphenyl-4-magnesium bromide shown as Formula 2, thus obtaining 4-(4-n-propyl)phenyl-3,5-difluoro-1',1'-difluorobenzyl-3,4,5-trifluorophenyl ether shown as Formula 3. The preparation method provided by the invention is simple to operate, mild in reaction conditions, convenient in posttreatment steps, high in reaction conversion rate, high in atom economy, friendly to environment, favorable in product purity and suitable for industrial production.

Owner:LIANHE CHEM TECH +4

Method for producing isopropylbenzene

ActiveCN102464563BReduce contentImprove product qualityHydrocarbonsHydrocarbon preparationAlkyl transferDistillation

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for producing isopropylbenzene

ActiveCN102464564AReduce contentImprove product qualityHydrocarbonsHydrocarbon preparationTarEngineering

The invention relates to a method for producing isopropylbenzene and mainly solves the problem of high content of n-propylbenzene existing in the prior art. The method better solves the problem and can be applied to the industrial production of isopropylbenzene by adopting the technical scheme which comprises the following steps of: (1) a material flow 12 containing polysubstituted isopropylbenzene enters a polysubstituted isopropylbenzene tower, after rectifying seperation is carried out on the material flow 12, a material flow 8 is obtained at the tower top, a material flow 9 is obtained in the middle part of the tower, and a heavy component material flow 11 containing oil tar is obtained in the tower bottom and enters a follow-up process; (b) a raw material benzene material flow 6 and the material flow 8 enter a first alkyl group transfer reaction zone from the top to contact with a catalytic agent for carrying out alkyl group transfer reaction, and a material flow 7 containing isopropylbenzene is obtained after reaction; (c) the material flow 7 and the material flow 9 enter a second alkyl group transfer reaction zone from the top to contact with the catalytic agent for carrying out alkyl group transfer reaction, and a material flow 10 containing isopropylbenzene is obtained after reaction; and the material flow 10 enters the follow-up refining process, thereby the isopropylbenzene product is obtained.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for producing n-propylbenzene by using benzene and diisopropylbenzene

InactiveCN108530250AHigh selectivitySimple processMolecular sieve catalystsMolecular sieve catalystN-propylbenzeneReaction conditions

The invention relates to a method for producing n-propylbenzene by using benzene and diisopropylbenzene. The method comprises the step of contacting benzene and diisopropylbenzene with a catalyst under the effective reaction condition to obtain the n-propylbenzene, and is characterized in that the effective reaction condition comprises that the temperature is at least more than 200 DEG C. The method can be applied to industrial production of the n-propylbenzene.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for separating m- and p-methylethylbenzene from aromatic hydrocarbon mixture

ActiveCN105503507BThe number of theoretical boards is reducedRealize vacuum batch distillation operationDistillation purification/separationTheoretical plateN-propylbenzene

The invention relates to a method for separating m- and p-methylethylbenzene from aromatic hydrocarbon mixtures, and mainly solves the technical problem that the intermediate and p-methylethylbenzene of aromatic hydrocarbon mixtures are difficult to separate. The present invention introduces the aromatic hydrocarbon mixture into the rough fractionation tower, removes carbon 8 and carbon 8 former components from the top of the rough fractionation tower, and introduces the bottom liquid of the crude fractionation tower into the first fine fractionation tower with double liquid accumulation tanks on the top of the tower. , the light components containing m- and p-methylethylbenzene are drawn from the top of the first fractionation column to enter the second fractionation column with double liquid accumulation tanks, and the mixture of n-propylbenzene and cumene is drawn from the top of the second fractionation column. The technical scheme of extracting m- and p-methylethylbenzene products from the tower kettle of the difinishing tower solves the above-mentioned technical problems well, and can be applied in the field of separating aromatic hydrocarbon mixtures. The advantage of the double liquid accumulation tanks on the top of the tower is that the batch rectification can always be operated under the condition of total reflux, thereby reducing the number of theoretical plates of the column, and the alternate operation of the double liquid accumulation tanks can realize the vacuum intermittent distillation.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for producing isopropylbenzene by using benzene and propylene

ActiveCN102464565BImprove product qualityReduce contentHydrocarbonsHydrocarbon preparationAlkyl transferN-propylbenzene

The invention relates to a method for producing isopropylbenzene by using benzene and propylene and mainly solves the problem of high content of n-propylbenzene existing in an isopropylbenzene product of the prior art. The method better solves the problem and can be applied to the industrial production of isopropylbenzene by adopting the technical scheme which comprises the following steps of: (1) a first stream of benzene material flow 12 and propylene enter an alkylation reactor to react, thereby a material flow 19 comprising the benzene, propylene, isopropylbenzene and polyisopropylbenzene is obtained; (b) the material flow 19 is separated to obtain material flow 23 containing polyisopropylbenzene; (c) after the material flow 23 is separated by a rectifying tower, material flow 13 is obtained at the tower top, and material flow 14 is obtained in the middle part of the tower; (d) a second stream of material flow 10 and the material flow 13 enter a first a first alkyl group transfer reaction zone for carrying out alkyl group transfer reaction to obtain material flow 21; and a third stream of material flow 11 and the material flow 14 enter a second alkyl group transfer reaction zone for carrying out alkyl group transfer reaction to obtain material flow 22; and (e) the material flow 21 and the material flow 22 enter the follow-up refining process, thereby the isopropylbenzene product is obtained.

Owner:CHINA PETROLEUM & CHEM CORP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com