Method for separation of m/4-ethyltoluene from aromatic hydrocarbon mixture

A technology of p-toluene and ethyl benzene and mixture, applied in the separation room, p-ethyl benzene field, can solve the problems of high theoretical plate number and reflux

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

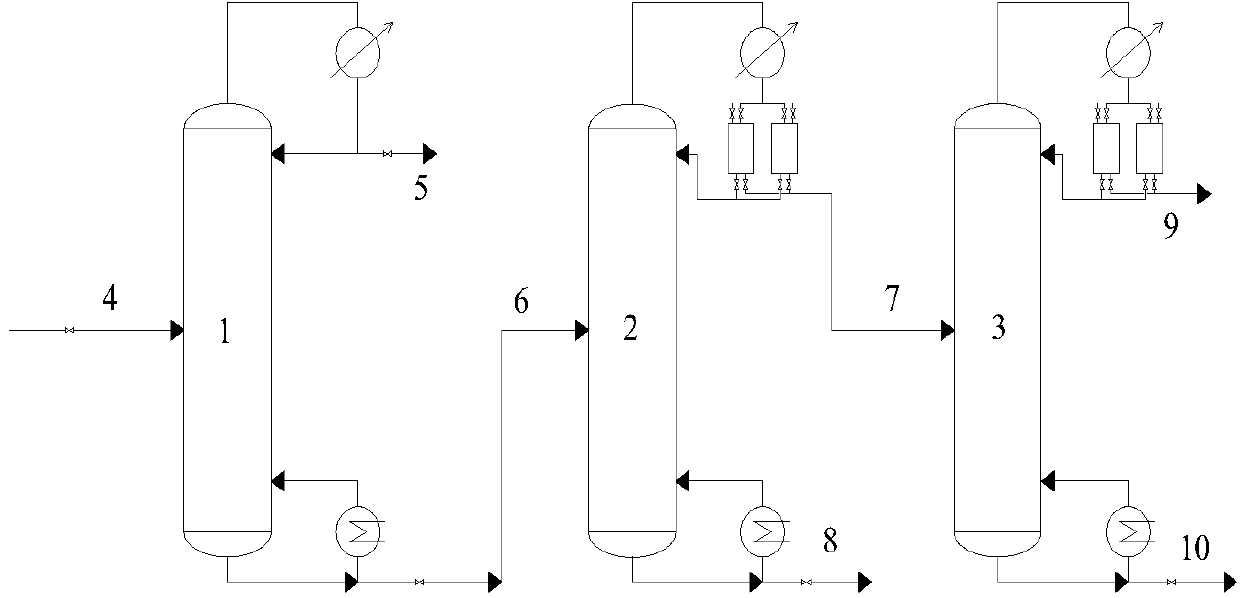

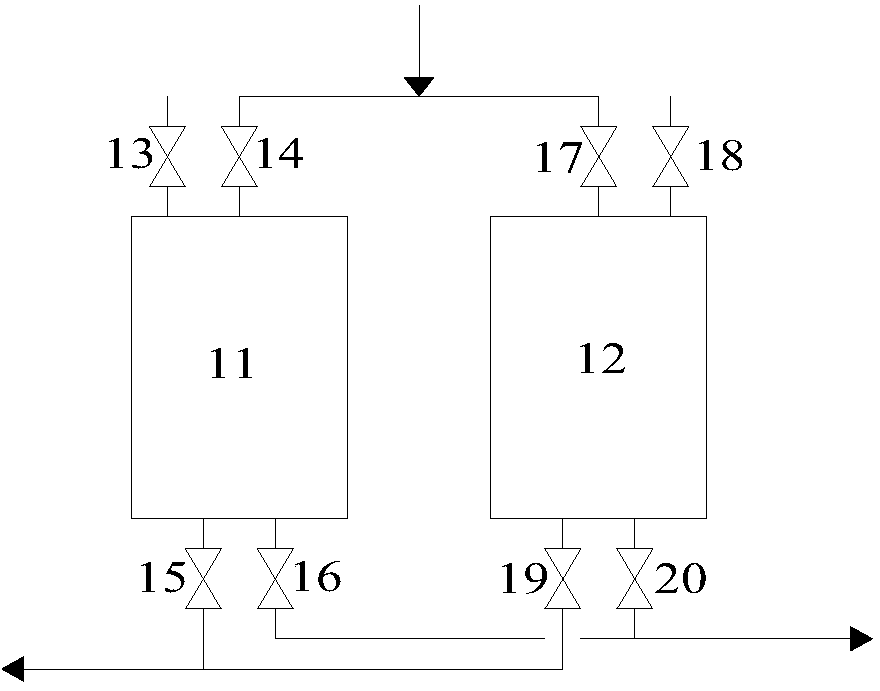

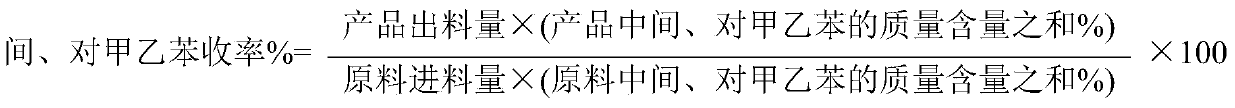

[0034] according to figure 1 As shown, 3000g of aromatics mixture is introduced into the crude fractionation tower, and carbon eight and carbon eight components are extracted from the top of the crude fractionation tower, and the bottom liquid of the crude fractionation tower is introduced into the first fractionation column for intermittent rectification. The stream containing m- and p-methylethylbenzene is drawn from the top of the sub-column to enter the second fractionating column for intermittent rectification, and m- and p-methylethylbenzene products are obtained from the bottom of the second fractionating column. The first fine fractionation tower and the second fine fractionation tower are respectively provided with double accumulation tanks. Based on the total mass of the aromatic hydrocarbon mixture, in the aromatic hydrocarbon mixture, the mass percentage of toluene is 71.71%, the mass percentage of n-propylbenzene is 0.77%, the mass percentage of m-methylethylbenze...

Embodiment 2

[0036] according to figure 1 As shown, 3000g of aromatics mixture is introduced into the crude fractionation tower, and carbon eight and carbon eight components are extracted from the top of the crude fractionation tower, and the bottom liquid of the crude fractionation tower is introduced into the first fractionation column for intermittent rectification. The stream containing m- and p-methylethylbenzene is drawn from the top of the sub-column to enter the second fractionating column for intermittent rectification, and m- and p-methylethylbenzene products are obtained from the bottom of the second fractionating column. The first fine fractionation tower and the second fine fractionation tower are respectively provided with double accumulation tanks. Based on the total mass of the aromatic hydrocarbon mixture, in the aromatic hydrocarbon mixture, the mass percentage of toluene is 79.47%, the mass percentage of n-propylbenzene is 0.65%, the mass percentage of m-methylethylbenze...

Embodiment 3

[0038] according to figure 1 As shown, 3000g of aromatics mixture is introduced into the crude fractionation tower, and carbon eight and carbon eight components are extracted from the top of the crude fractionation tower, and the bottom liquid of the crude fractionation tower is introduced into the first fractionation column for intermittent rectification. The stream containing m- and p-methylethylbenzene is drawn from the top of the sub-column to enter the second fractionating column for intermittent rectification, and m- and p-methylethylbenzene products are obtained from the bottom of the second fractionating column. The first fine fractionation tower and the second fine fractionation tower are respectively provided with double accumulation tanks. Based on the total mass of the aromatic hydrocarbon mixture, in the aromatic hydrocarbon mixture, the mass percentage of toluene is 75.78%, the mass percentage of n-propylbenzene is 0.89%, the mass percentage of m-methylethylbenze...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com