Method for producing butadiene

A production method and technology of butadiene, which are applied in extraction and purification/separation, organic chemistry, hydrogenation to hydrocarbons, etc., can solve the problems of uneconomical delight tower, fluctuation of operating pressure of extraction tower, etc., to reduce risks and ease operating conditions. , the effect of reducing operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] The mixed C4 fraction is mixed with 24.58Kmol / h of hydrogen at a flow rate of 819.25Kmol / h, and enters the first-stage hydrogenation reactor. -1 63.11% of the alkynes are hydrogenated into the corresponding alkenes under the condition of Olefins, the remaining alkynes at the outlet of stage II reactor are less than 10ppm. The composition of the mixed C4 fraction is listed in Table 1. The hydrogenation reactors in stage I and stage II are filled with the catalyst disclosed in ZL00107257.9.

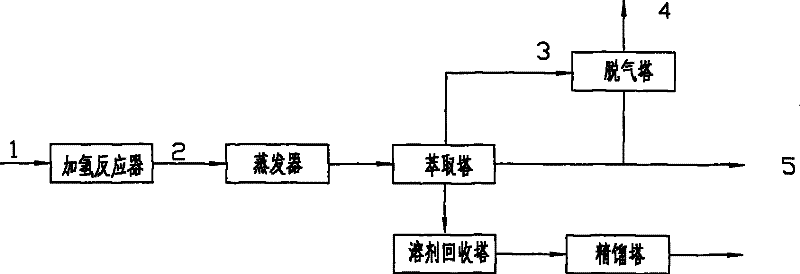

[0047] The C4 fraction after the removal of alkynes enters the evaporator, and enters the extraction tower after gasification. Under the action of the solvent, the gas containing butane, butene, propane, propylene, methane and hydrogen is extracted from the top of the extraction tower, and enters Degassing tower.

[0048] The degassing tower adopts a packed tower structure with a theoretical plate number of 20. Under the conditions of pressure 0.35MPa, tower top temperature -5°C, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com