A tower gas-liquid exchange system

A technology of gas-liquid exchange and tower, which is applied in the field of gas-liquid mass transfer and heat transfer equipment, can solve the problems of unresolved physical limits, etc., and achieve the effects of facilitating capacity expansion and upgrading, low investment, and improving benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

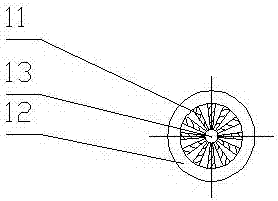

[0035] combined with figure 2 , the spray cover 8 on the tray 12 of a column gas-liquid exchange system designed by the present invention is cylindrical, and the tray lift hole 10 is circular, and the center corresponds to the center of the spray cover. The swirl blades 11 are inclined at 25° to the horizontal tray, and are in the shape of a fan. 12 sets of swirl blades are installed in the air hole.

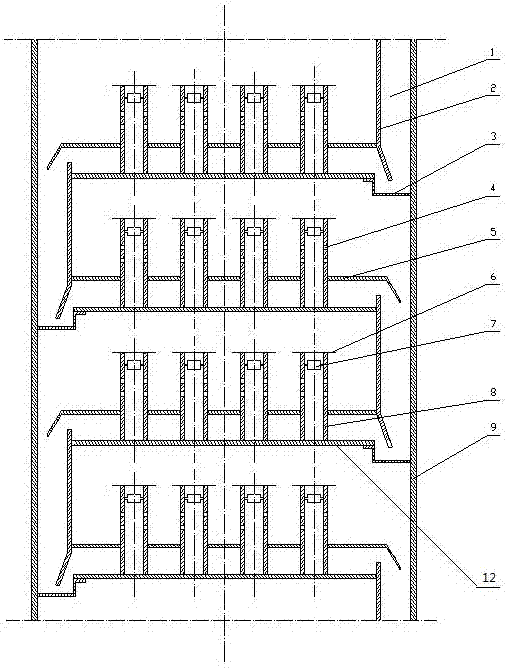

[0036] combined with image 3 , The collection plate 5 of the tower gas-liquid exchange system is in the shape of a dustpan as a whole, one end is fixed on the downcomer plate 2, the two sides are fixed on the tower wall 9, and the open end 14 is slightly bent downward and extends into the downcomer. The spray cover 8 passes through the collecting plate and is sealedly connected with the collecting plate.

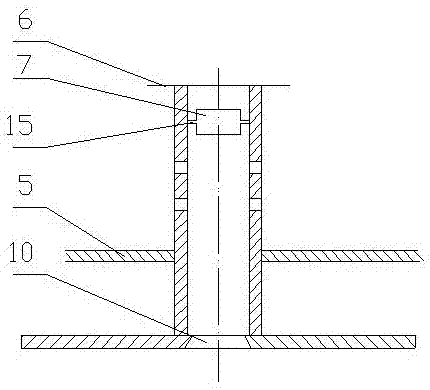

[0037] combined with Figure 4 , The separator 7 of the tower gas-liquid exchange system is a cylindrical hollow cylinder, and the horizontal axis 15 passes through the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com