so in the smoke 2 Purified Negative Pressure Multistage Nested Absorption-Analysis Citrate Process

A process and negative pressure technology, applied in the field of negative pressure multi-stage nested absorption-analysis, can solve the problems of multi-stage nested absorption-analysis without negative pressure, achieve volume reduction, reduce the number of theoretical plates, and reduce energy consumption Reduced effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

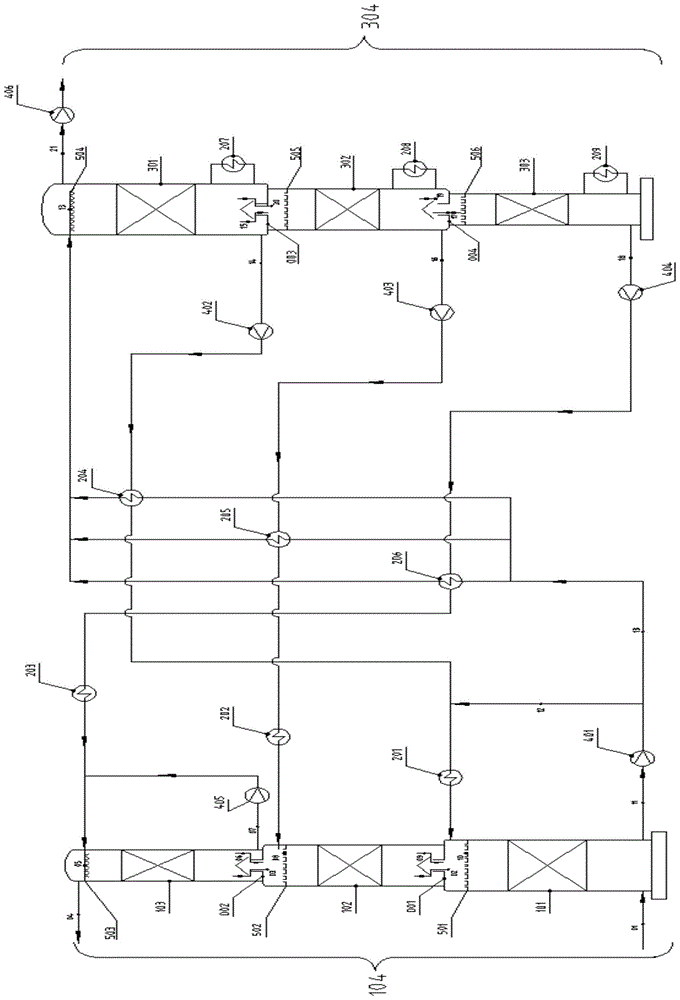

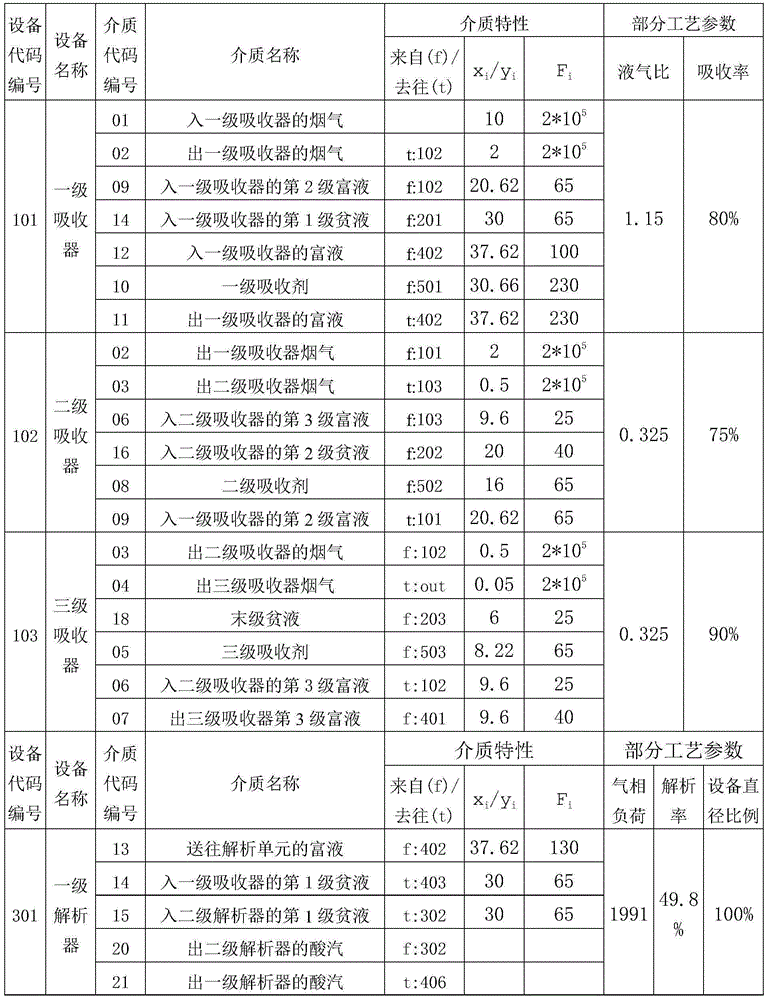

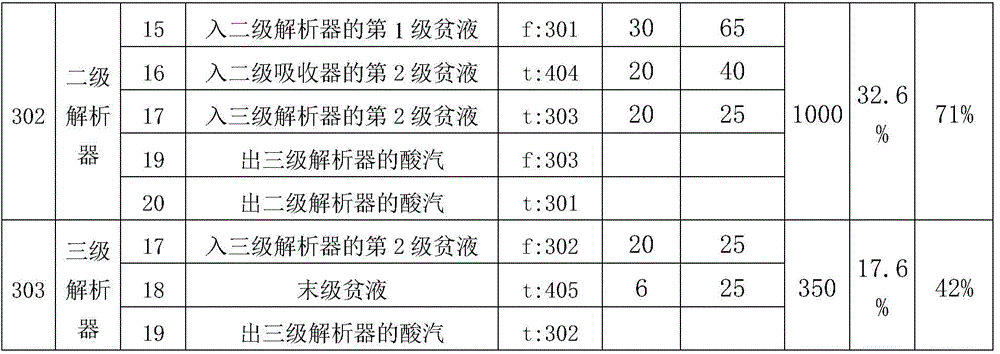

[0067] Example 1 ( figure 1 )

[0068] Flue gas flow:

[0069] After dedusting and cooling, the flue gas 01 entering the primary absorber, its y 01 10g / m 3 , F 01 200000m 3 / h (dry basis), enters from the bottom of the primary absorber 101, and in the primary absorber 101 is in countercurrent contact with the primary absorbent 10 sprayed down from the liquid distributor 501 to remove part of SO 2 After that, it is flue gas 02 from the first-stage absorber, its y 02 2g / m 3 The flue gas 02 enters the bottom of the secondary absorber 102 through the partition 001 between the primary absorber 101 and the secondary absorber 102, and sprays down from the liquid distributor 502 in the secondary absorber 102 The secondary absorbent 08 is in countercurrent contact, and part of the SO is removed 2 After that, it is flue gas 03 from the secondary absorber, its y 03 0.5g / m 3 ; The flue gas 03 enters the bottom of the third-stage absorber 103 through the partition 002 arranged be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com