Method for producing isopropylbenzene by using benzene and propylene

A technology of cumene and polycumene, which is applied in the field of cumene production from benzene and propylene, can solve the problem of high n-propylbenzene content, and achieve the effects of reducing content and improving product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

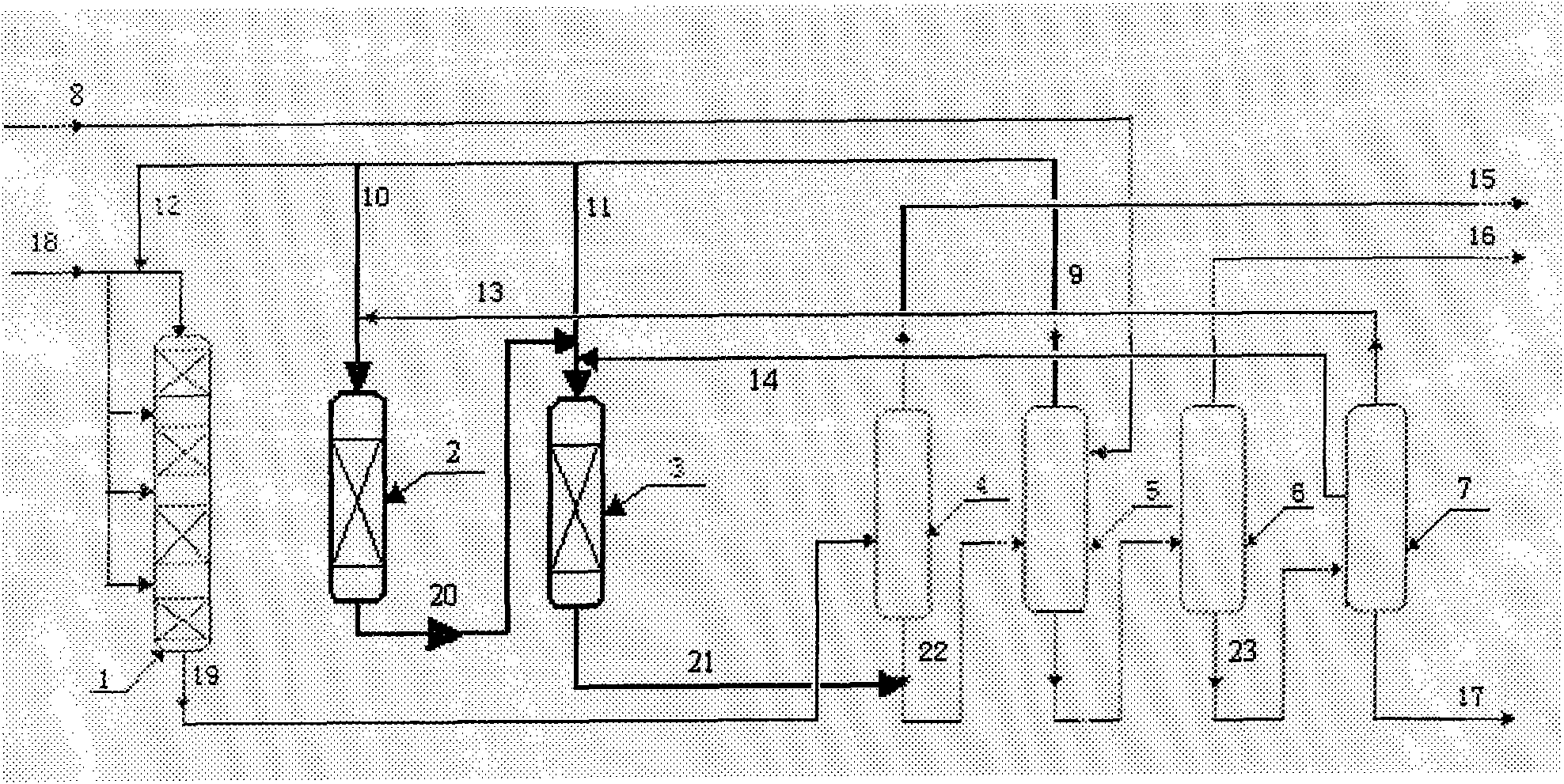

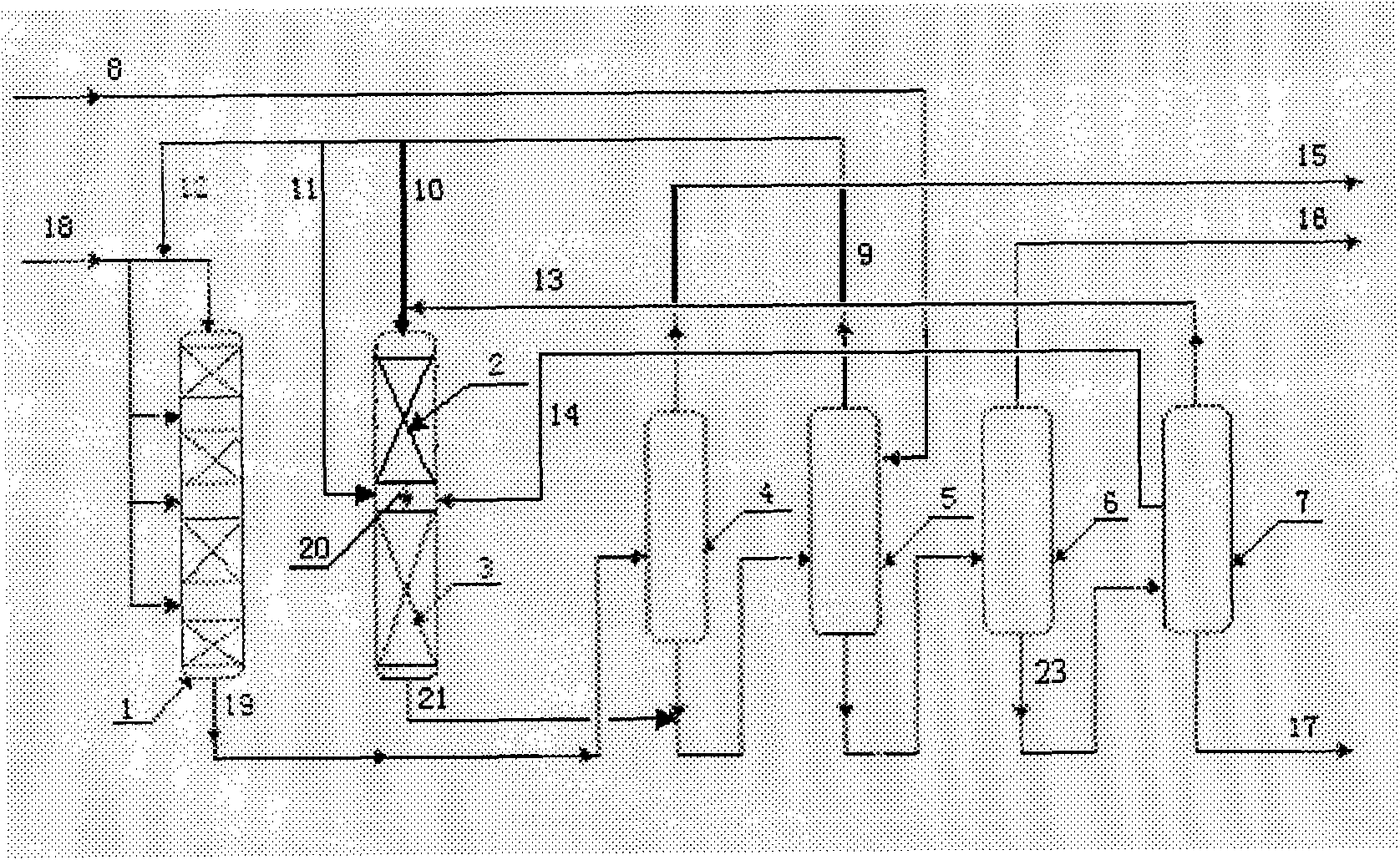

[0030] according to figure 1 The technological process, the catalyst bed of the alkylation reactor is divided into four sections, loaded with 170 grams of shaped catalyst containing MCM-22 zeolite, the four sections are equipped with 35, 40, 45, 50 grams in turn, and propylene is fed in four sections . The reaction conditions of the alkylation reactor are: 130°C of reaction temperature, 2.5MPa of reaction pressure, 550 g / hour of benzene feed (stream 12) entering the alkylation reactor, 110 g / hour of propylene feed, four sections The amount of propylene fed in sequence is 20, 25, 30, 35 g / h.

[0031] The transalkylation reactor uses two fixed-bed reactors connected in series. The first transalkylation reaction zone is loaded with 40 grams of shaped catalyst containing Beta zeolite, and the second transalkylation reaction zone is loaded with 50 grams of shaped catalyst containing PSH-3 zeolite. The reaction conditions of the first transalkylation reactor are: 150 DEG C of rea...

Embodiment 2

[0038] Same as [Example 1], except that the catalyst bed of the alkylation reactor is divided into four sections, loaded with 200 grams of molded catalyst containing MCM-22 zeolite, and the four sections are successively equipped with 45, 50, 50, 55 grams, propylene fraction Four stage feeding. The reaction conditions of the alkylation reactor are: 150°C of reaction temperature, 2.5MPa of reaction pressure, 550 grams / hour of benzene feed (stream 12) entering the alkylation reactor, 160 grams / hour of propylene feed, four The amount of propylene fed into the stage successively is 35, 40, 40, 45 g / h.

[0039] The transalkylation reactor uses two fixed-bed reactors connected in series. Wherein the first transalkylation reactor is loaded with 80 grams of shaped catalyst containing Beta zeolite, and the second transalkylation reactor is loaded with 30 grams of shaped catalyst containing PSH-3 zeolite. The reaction conditions of the first transalkylation reactor are: 150 DEG C of r...

Embodiment 3

[0046] Same as [Example 1], except that the catalyst bed of the alkylation reactor is divided into four sections, and 170 grams of shaped catalysts containing SHY-1 zeolite are loaded, and 45, 50, 50, and 55 grams of propylene are loaded in the four sections successively. Four stage feeding. The reaction conditions of the alkylation reactor are: reaction temperature 130°C, reaction pressure 2.5MPa, 550 g / hour of benzene feed (stream 12) entering the alkylation reactor, 160 g / hour of propylene feed, four sections The amount of propylene fed in sequence is 35, 40, 40, 45 g / h.

[0047] The transalkylation reactor uses two fixed-bed reactors connected in series. Wherein the first transalkylation reactor is loaded with 80 grams of shaped catalyst containing Beta zeolite, and the second transalkylation reactor is loaded with 30 grams of shaped catalyst containing SHY-2 zeolite. The reaction conditions of the first transalkylation reactor are: 150 DEG C of reaction temperature, 40 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com