Drilling winch capable of achieving automatic rope arrangement

An automatic arranging and drilling technology, applied in the direction of the spring mechanism, hoisting device, etc., can solve the problems of no rope arranging system, disordered wire rope ordering, mutual extrusion deformation, etc., so as not to waste rope arranging space and prevent rope disorder. Phenomenon, easy-to-control effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0007] In order to facilitate those skilled in the art to understand the present invention, the present invention will be described in detail below in conjunction with the accompanying drawings.

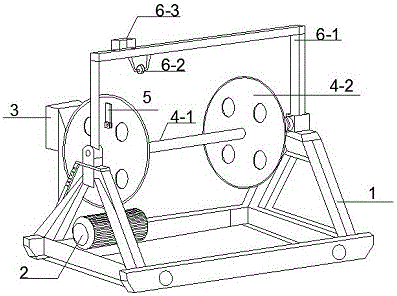

[0008] Such as figure 1 A drilling winch with automatic arranging of ropes is shown, and its structure includes the following parts: winch frame 1, motor 2, gearbox 3, drum system 4, braking system 5, and rope arranging device 6. Both the motor and the gearbox are arranged on the winch frame, and the gearbox is an external meshing cylindrical gearbox. The drum system includes a roller 4-1 and a turntable 4-2, and the brake system is located on the turntable of the drum system; the rope arrangement includes a bracket 6-1, a pulley 6-2, and a speed limiter 6-3 , the bracket is provided with a track, the pulley is buckled in the track and can slide freely on the track, the speed limiter is located on the bracket and connected with the pulley, when the winch starts drilling, the wire ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com