Built-in compact-typed winch transmission device

A transmission device, a compact technology, applied in the direction of the hoisting device, the spring mechanism, etc., can solve the problems of high construction environment requirements and large space occupation of the winch, and can solve the problems of high construction environment requirements, small occupation space, and large tension. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

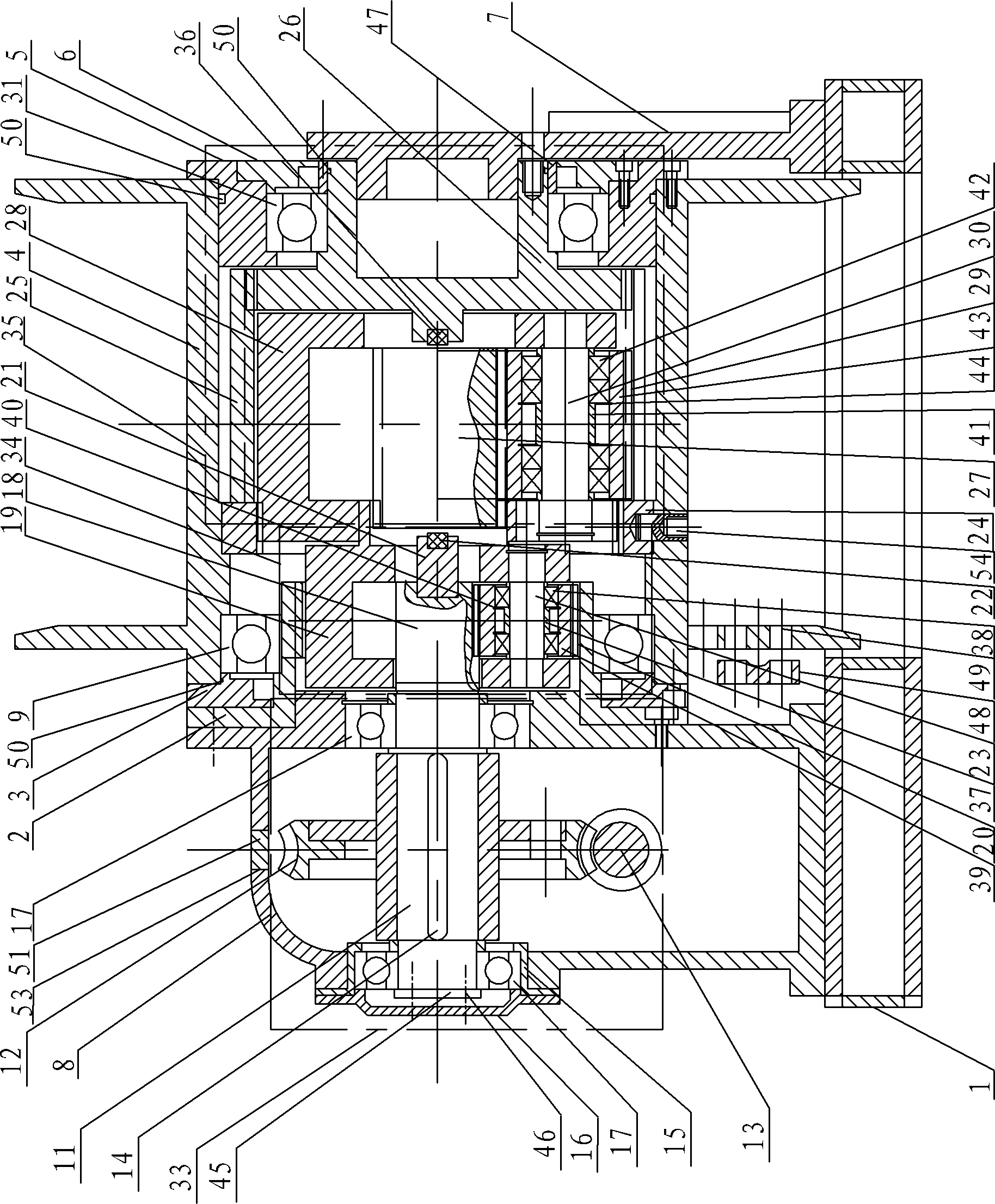

[0011] Specific implementation mode one: combine figure 1 Describe this embodiment, a built-in compact winch transmission device in this embodiment includes a chassis 1, a first ring gear 2, a first transparent cover 3, a drum 4, a first bearing cup 5, a second transparent cover 6. Bracket 7, transmission box 8 and first bearing 9, transmission box 8, first ring gear 2, first transparent cover 3, roller 4, first bearing cup 5, second transparent cover 6 and bracket 7 from the left To the right, it is fixedly arranged on the bottom frame 1 in turn, and the first bearing 9 is arranged between the drum 4 and the first ring gear 2, the transmission box 8 is fixedly connected with the first ring gear 2, and the first bearing cup 5 1. The second transparent cover 6 is fixedly connected with the drum 4, and a built-in compact winch transmission device also includes a primary transmission device 33, a secondary transmission device 34 and a tertiary transmission device 35, and a primar...

specific Embodiment approach 2

[0016] Specific implementation mode two: combination figure 1 To illustrate this embodiment, each secondary transmission planetary device 20 of this embodiment includes a secondary transmission sleeve 37, two secondary transmission bearings 38 and a secondary planetary wheel 39, and the secondary transmission sleeve 37 is set on the secondary transmission pin On the shaft 23, two secondary transmission bearings 38 are respectively arranged on both sides of the secondary transmission sleeve 37, and the secondary planetary gear 39 is set on the secondary transmission bearing 38, and the secondary planetary gear 39 is in phase with the first internal ring gear 2 engage. Such setting facilitates the realization of a large transmission ratio and effectively adjusts the rotational speed of the drum of the winch. Other compositions and connections are the same as in the first embodiment.

specific Embodiment approach 3

[0017] Specific implementation mode three: combination figure 1 To illustrate this embodiment, each secondary transmission planetary device 20 of this embodiment also includes two circlips 40 for secondary holes, and the two circlips 40 for secondary holes are respectively arranged on two secondary transmission bearings 38 On the secondary drive sleeve 37 of the inner side. With such setting, the axial fixing effect is the best. Other compositions and connections are the same as those in Embodiment 1 or Embodiment 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com