Double rope groove multi-layer hoisting mechanism

A lifting mechanism and rope groove technology, which is applied in the field of double rope groove multi-layer lifting mechanism, can solve the problems that have not been found in the same or similar literature reports of window cleaning machines, and achieve simple structure, no rope disorder, and flexible operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The embodiments of the present invention are described in detail below in conjunction with the accompanying drawings: this embodiment is implemented on the premise of the technical solution of the present invention, and detailed implementation methods and specific operating procedures are provided, but the protection scope of the present invention is not limited to the following the described embodiment.

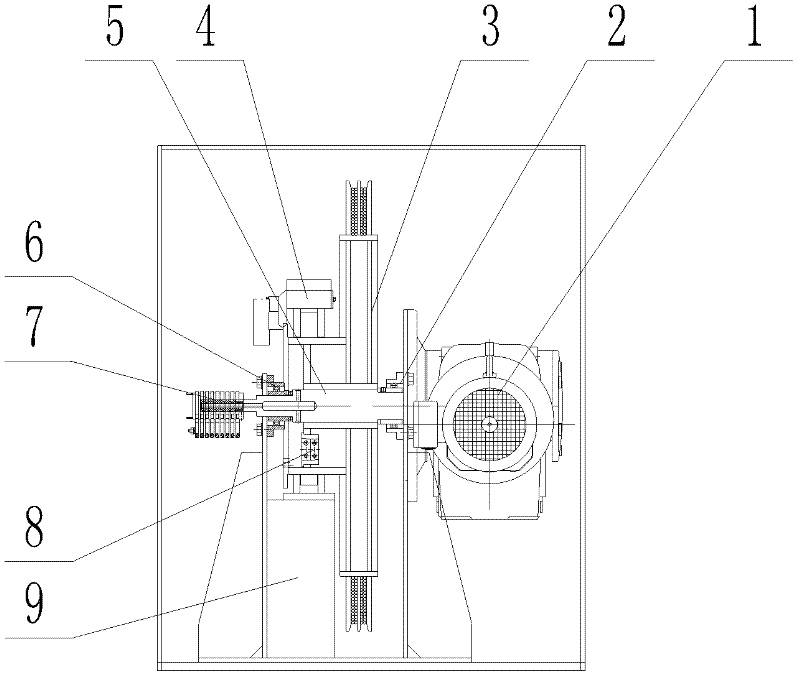

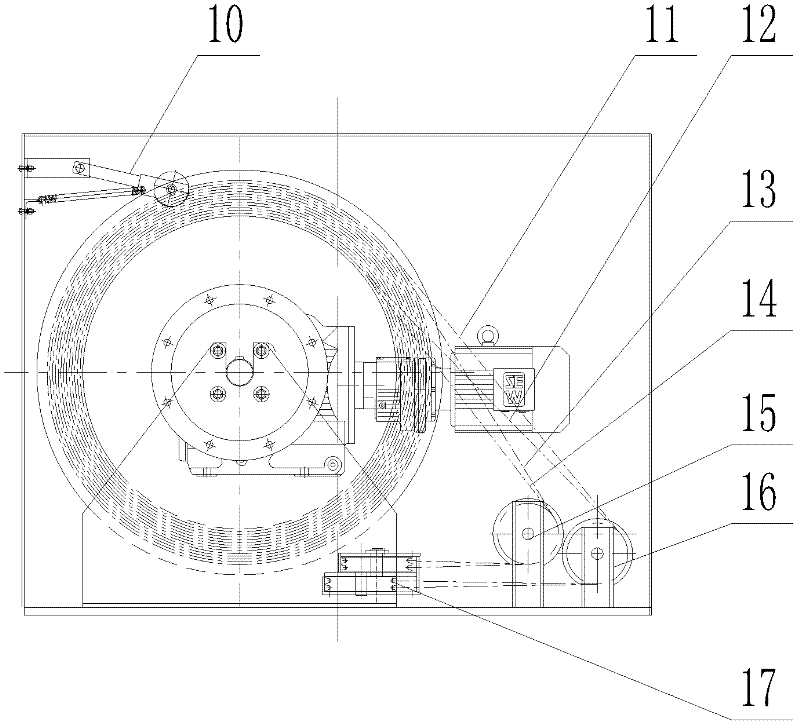

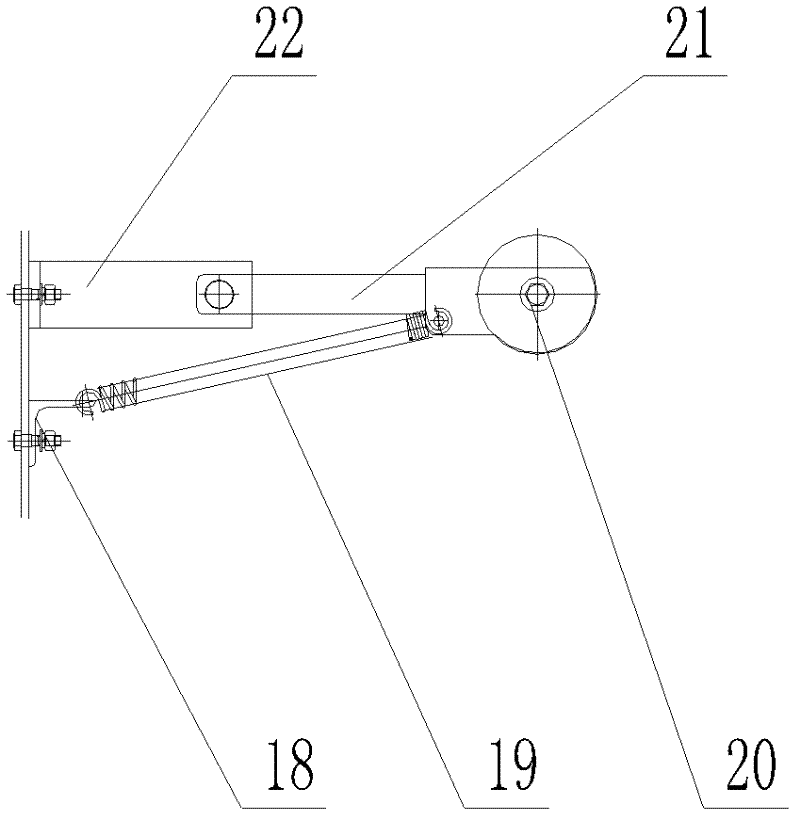

[0022] Such as figure 1 , figure 2 As shown, the overall structure of the present invention includes: geared motor 1, right bearing housing 2, reel main body 3, brake 4, main transmission shaft 5, left bearing housing 6, carbon brush assembly 7, wire rope clamp assembly 8, reel Support frame 9, pressure rope device 10, steel wire rope 11, steel wire rope 12, steel wire rope 13, steel wire rope 14, left vertical pulley 15, right vertical pulley 16, horizontal pulley block 17. The relevant positional relationship and connection relationship are as follows: the reduct...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com