Electric hoist rope guide

An electric hoist and rope guide technology, applied in the field of rope guides, can solve problems such as disordered ropes and loose ropes, and achieve the effects of avoiding disordered ropes, prolonging the life of steel wire ropes, and being light in weight.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

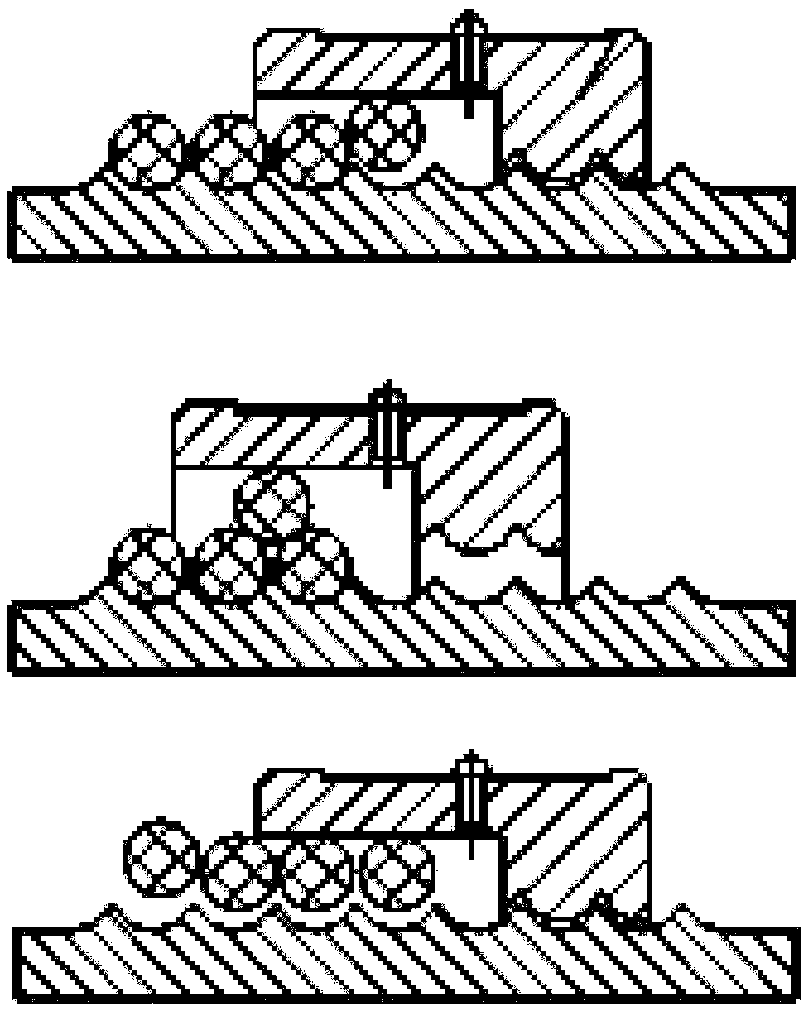

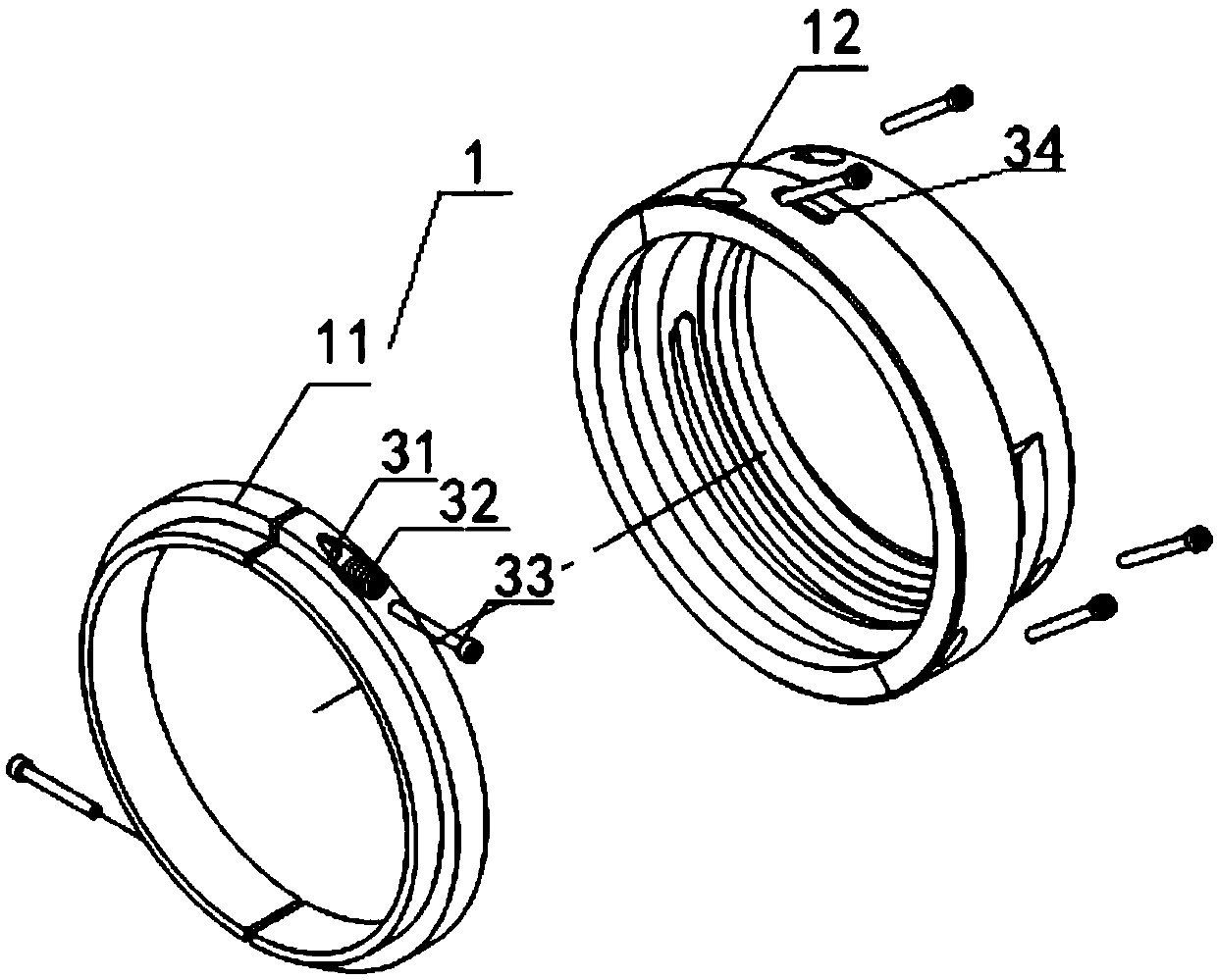

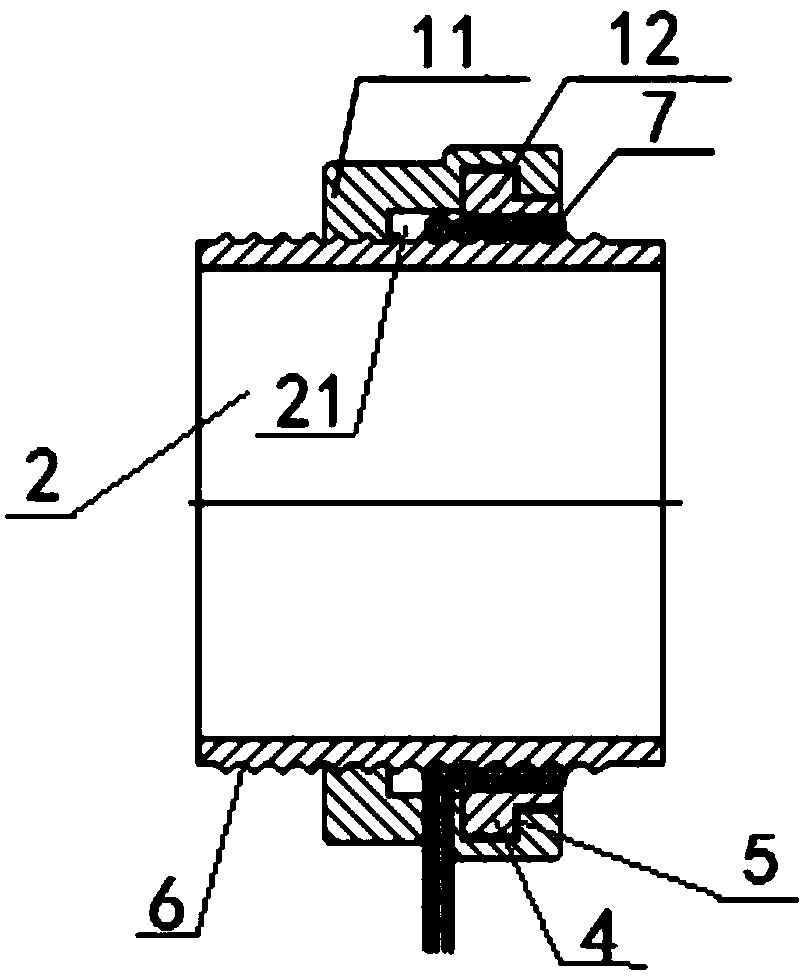

[0029] An electric hoist rope guide provided in this embodiment has a structure such as figure 2 and image 3 As shown, it includes a rope guide body 1 that is arranged in a ring shape as a whole. The rope guide body 1 includes a rope guide inner ring 11 and a rope guide outer ring 12 that are correspondingly arranged and can rotate relative to each other. The rope guide inner ring 11 Cooperate with the outer ring 12 of the rope guide, the inner ring 11 of the rope guide and the outer ring 12 of the rope guide are composed of two semi-rings arranged symmetrically, and the whole body of the rope guide 1 is made of molybdenum nylon (MoS2) material become.

[0030] Molybdenum nylon (MoS2) material has high resistance to breaking, permanent deformation, wear resistance, self-lubrication and good elastic recovery performance, light weight, no wear on the wire rope 7, and prolongs the life of the wire rope 7.

[0031] Such as figure 2 and image 3 As shown, the rope guide body...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com