Wind energy conversion mechanism and upper-air wind power generation device

A conversion mechanism, wind energy technology, applied in wind energy power generation, wind turbine components, wind turbines, etc., can solve problems such as weak ability to adapt to changes in wind direction, low power transmission efficiency, and low actual conversion rate, and achieve stable adaptation to wind direction changes. , High power transmission efficiency, the effect of improving energy conversion rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] In order to enable those skilled in the art to better understand the solution of the present invention, the present invention will be further described in detail below with reference to the accompanying drawings and specific embodiments.

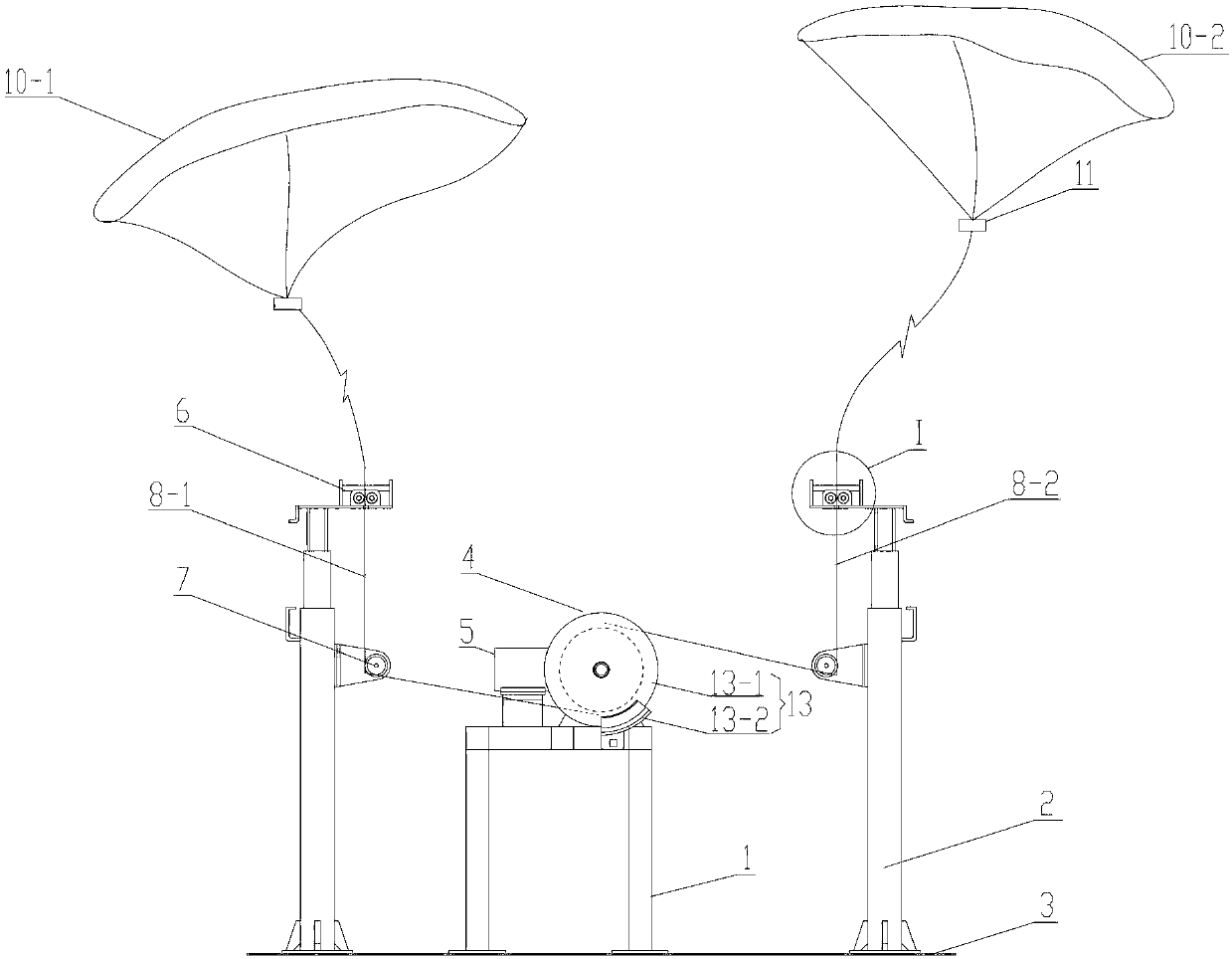

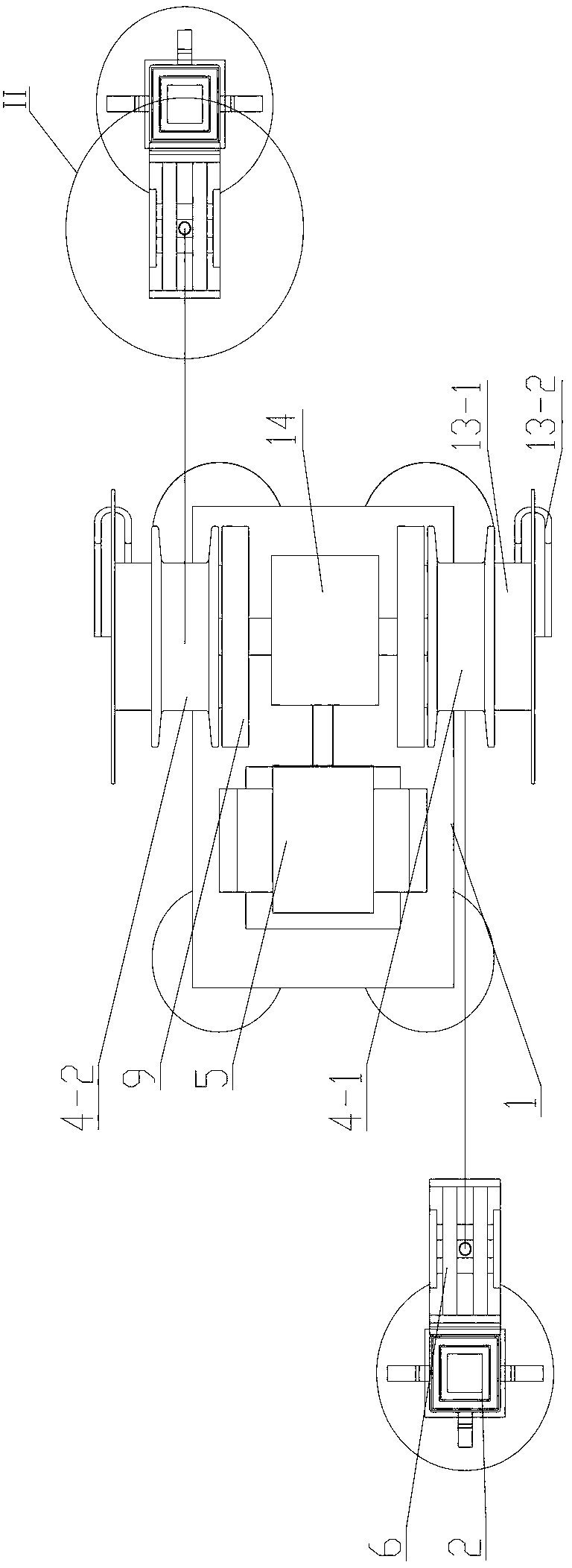

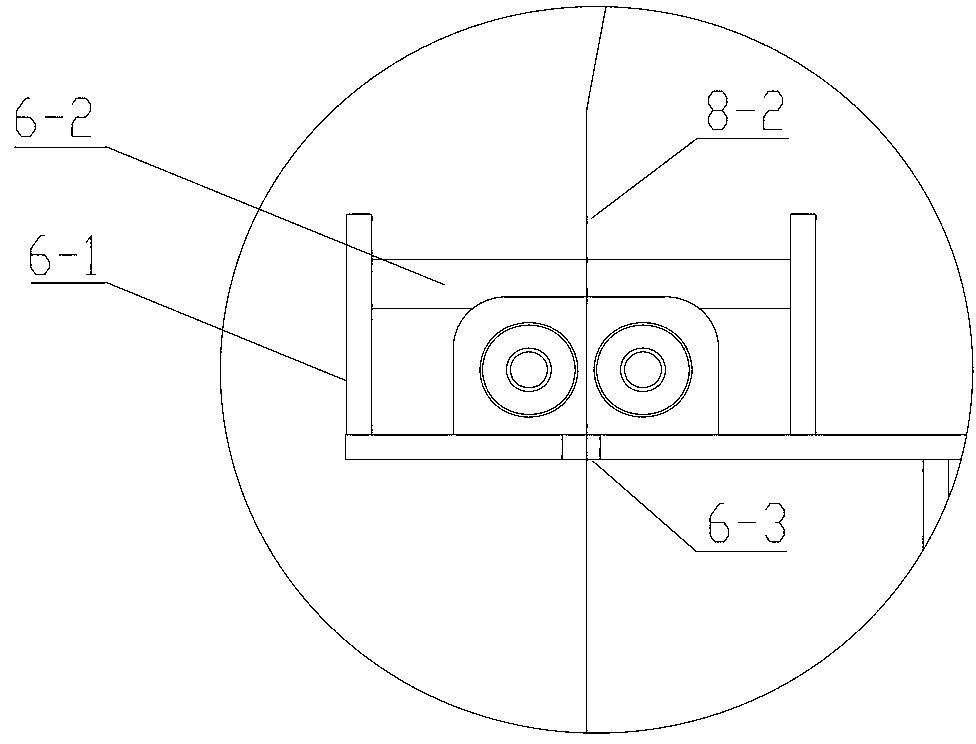

[0044] Please refer to figure 1 , figure 2 , figure 1 It is a schematic structural diagram of a specific implementation of the wind energy conversion mechanism provided by the present invention; figure 2 for figure 1 The top view of the wind energy conversion mechanism shown.

[0045] As shown in the figure, in the first specific embodiment, the main part of the wind energy conversion mechanism provided by the present invention is the drive frame 1 and the rope guide frames 2 on both sides thereof, and the drive frame 1 is welded from a profile into a rectangle with a certain height. The bottom of the frame is fixed on the foundation 3 by flanges, and the reciprocating wheel 4 and the electric generator 5 are installed on the top.

[0046]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com