Axial rotary type dynamic torque measurement calibrator

A dynamic torque and rotary technology, which is applied in the calibration/testing of force/torque/work measuring instruments, measuring devices, measuring torque/torsion force during tightening, etc. It can solve the problem of wire entanglement, inability to measure the true value of torque, and operation Inconvenient and other problems, to achieve the effect of convenient operation, simple structure, high measurement and calibration accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

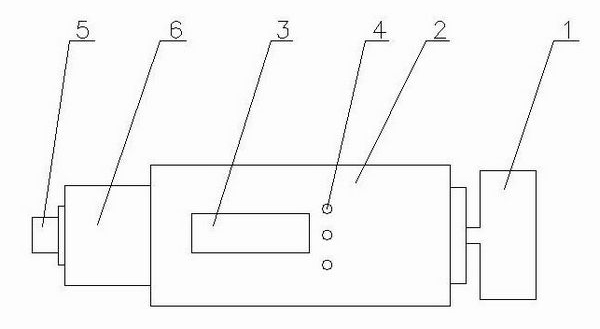

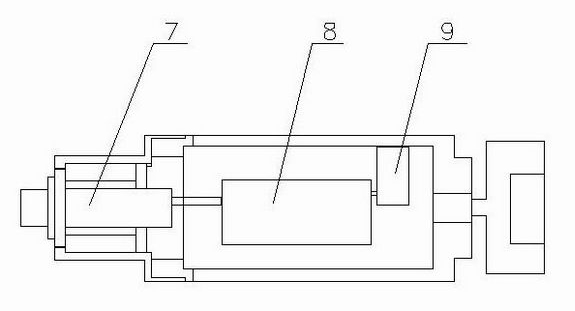

[0012] figure 1 , figure 2 The reference signs shown are as follows: conversion sleeve 1 , main housing 2 , LCD display screen 3 , indicator light 4 , measuring shaft 5 , sleeve 6 , sensor 7 , circuit board 8 , and battery 9 .

[0013] figure 1 , figure 2 In the schematic diagram of the axial rotary dynamic torque measurement calibrator shown, it includes: conversion sleeve 1, main housing 2, LCD display 3, indicator light 4, measuring shaft 5, sleeve 6, sensor 7, circuit board 8 and battery 9; the conversion sleeve 1 is connected with the main casing 2, and the LCD display 3 and the indicator light 4 are installed on the main casing 2, and the main casing 2 is connected with the measuring shaft 5, and the sleeve 6 is arranged on the measuring shaft The outer side of 5 is connected with the main casing 2 , the sensor 7 is connected with the measuring shaft 5 , the circuit board 8 is arranged inside the main casing 2 , and the battery 9 is connected with the circuit board ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com