Pressing rope wheel device for endless rope continuous tractor

A technology of pressing rope pulleys and tractors, which is applied in the field of tractors, and can solve problems such as potential safety hazards, chaotic rope rails, friction, etc., and achieve the effect of prolonging the service life and preventing wire ropes from being chaotic

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

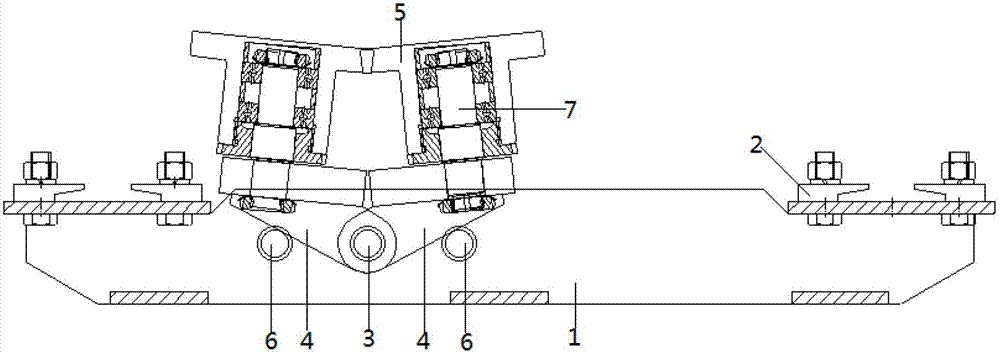

[0012] Referring to the accompanying drawings, the rope-pressing wheel device of the endless rope continuous tractor includes a rope-pressing wheel chassis 1, and both ends of the chassis 1 are fixed with rail pressure plates 2 by bolts, and a pin shaft 3 is passed on the rope-pressing wheel chassis 1. One group and two vertical wheel pendulums 4 are installed for rotation, and rope pulleys 5 are installed on the pendulum frames 4 through shafts 7. On the bottom frame 1 of the rope pulleys, the bottoms of the two vertical wheel pendulum frames 4 are all fixed. A pin shaft 6 is installed;

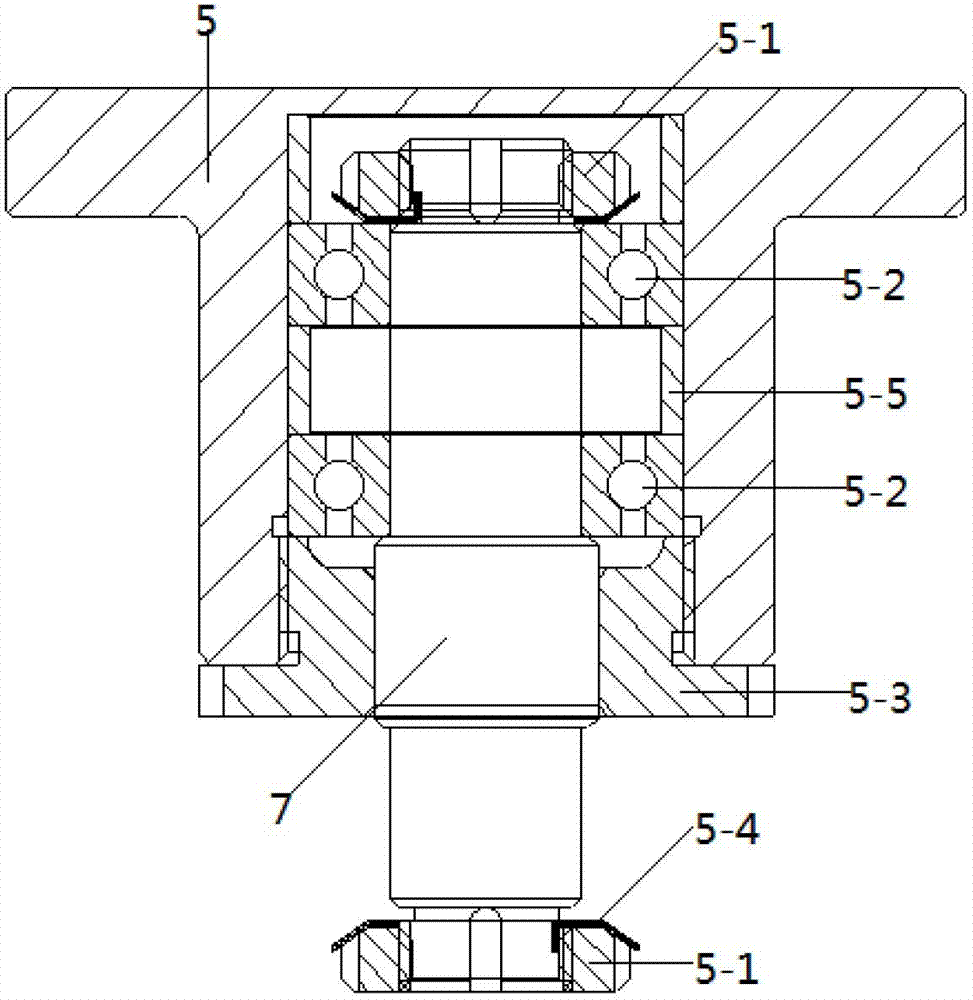

[0013] The two ends of the shaft 7 are screwed with round nuts 5-1 and fixed on the vertical wheel pendulum 4. The shaft 7 is fixedly installed with a set of bearings 5-2 through its own step surface and the round nuts at its upper end. The bearing 5 -2 is equipped with a pressure rope wheel 5, and the lower end opening of the pressure rope wheel 5 is screwed with a screw cover 5-3, so that ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com