Double-layer winding steel wire rope reel

A steel wire rope reel and reel technology, which is applied in the field of double-layer winding steel wire rope reels, can solve the problems of inability to realize double-layer winding of steel wire ropes, excessive wear, and disordered ropes of the second layer of steel wire ropes, and achieve simple structure, reduced wear, and low cost effect

Inactive Publication Date: 2011-06-29

SHANDONG SHANTUI MASCH CO LTD

View PDF6 Cites 17 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

The object of the present invention is to provide a double-layer winding steel wire rope reel, which overcomes the disadvantage that the ordinary helical rope groove reel cannot realize the double-layer winding of the steel wire rope, the rope groove is easy to cast or machine, and can effectively improve the second layer of steel wire Rope tangling and excessive wear and tear

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

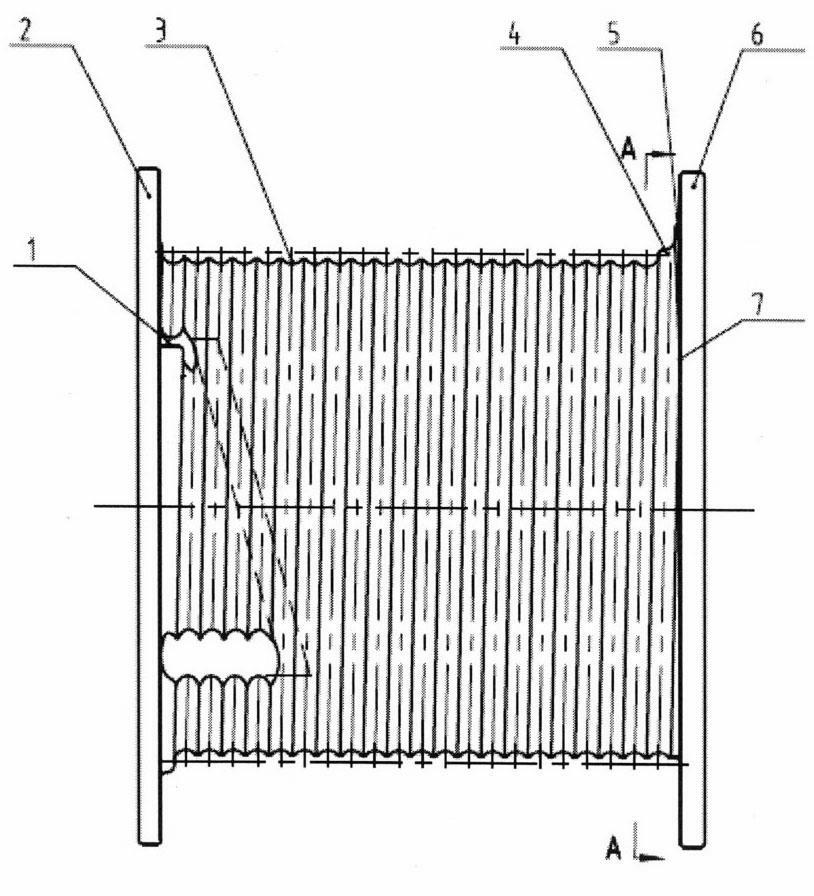

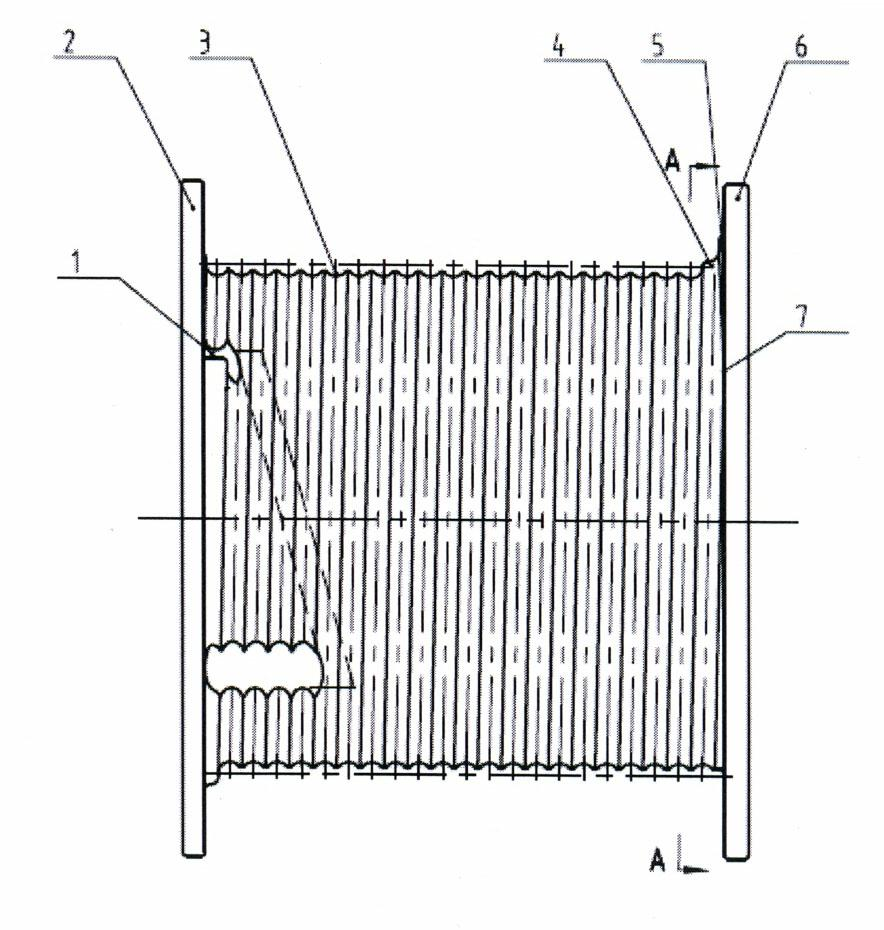

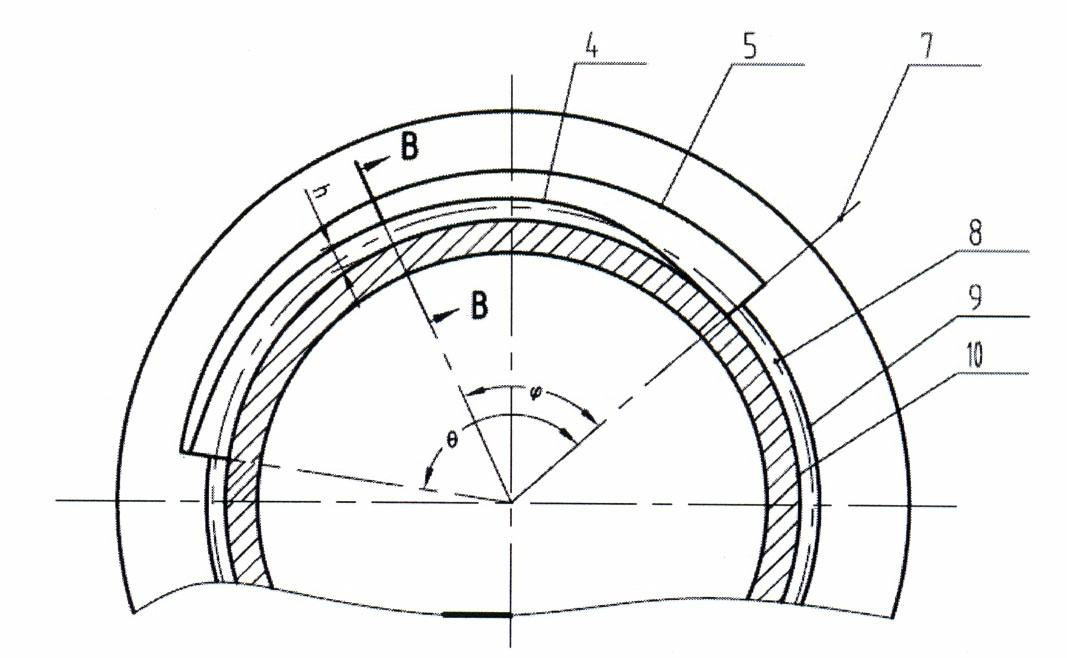

The invention relates to a double-layer winding steel wire rope groove reel. The double-layer winding steel wire rope groove reel is provided with a reel body with a left flange and a right flange, wherein a rope groove is formed on the circumferential surface of the reel body; a steel wire rope fixing groove is formed at the starting end of the rope groove on the circumferential surface of the reel body; the rope groove is a spiral line rope groove; a climbing boss is arranged on the reel circle, at the tail end of the rope groove, of the reel body; the height of the climbing boss is gradually increased on the circumferential surface of the reel body along the circumferential extension angle; a guide baffle ring is arranged on the inner side, corresponding to the climbing boss, of the right flange; and the thickness of the guide baffle ring is gradually increased in the circumferential direction along with the extension angle. In the process of the steel wire rope climbing among layers, the guide baffle ring can guide the steel wire rope to change the winding direction, so that rope skipping and rope disordering are avoided and the rope can be tidily and tightly arranged on the second layer of the reel; the climbing boss has the effects of supporting and positioning, so that the contact stress between the steel wire ropes in the climbing process is effectively reduced and abrasion is reduced; the reel has a simple structure; the rope groove is easy to process; and precision is high and cost is low.

Description

Double-layer winding steel wire rope drum Technical field The invention relates to a double-layer winding steel wire rope reel, which is a reel that uses a steel wire rope to lift or pull heavy objects. Background technique There are three key issues when designing a double-layer (or multi-layer) winding drum: First, when the steel wire rope enters the second layer, because the winding direction is opposite to that of the bottom steel wire rope, the steel wire rope cannot be wound in the first layer. In the spiral groove formed by the wire rope, irregular wire rope arrangement and disorder are prone to occur; second, when the wire rope enters the second layer of winding, because the wire rope is arranged irregularly at the end of the reel, the wire rope is in the reel Repeated entanglement and accumulation on the upper surface caused severe wear and tear of the wire rope; third, when the wire rope entered the second layer, there was no supporting object at the bottom, and it o...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): B66D1/30

Inventor 陈士桐徐健刘新华董尚奎董振华

Owner SHANDONG SHANTUI MASCH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com