Borehole cleaning tool for horizontal-section gas drilling

A gas drilling and horizontal section technology, applied in construction and other directions, can solve the problems of changing the flow field, rare, and cannot well meet the cleaning of gas drilling horizontal wells, etc., to improve the ability to break cuttings and improve the ability to disturb the flow Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Below in conjunction with accompanying drawing and gas drilling horizontal well process, the present invention will be further described.

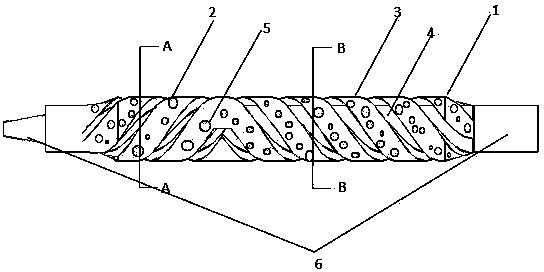

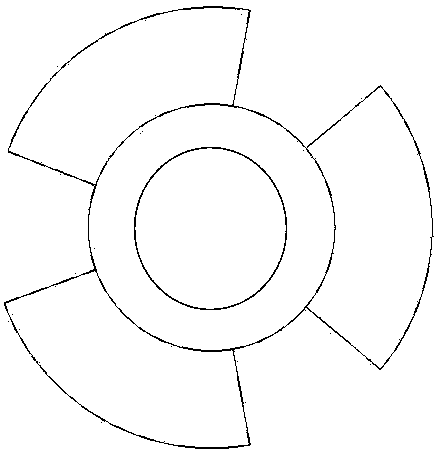

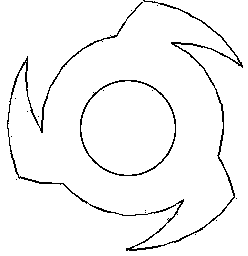

[0021] see figure 1 , figure 2 , image 3 .

[0022] A wellbore cleaning tool for gas drilling in the horizontal section, which consists of a main body 1, a spiral flow channel, alloy teeth 5 and a joint 6, the main body 1 is cylindrical, the two ends of the main body are joints 6, and the spiral flow channel is located in the main body Above, the width of the spiral flow channel is 7-14cm, and the depth is 5-10cm; the spiral flow channel includes a front spiral flow channel 2 and a rear spiral flow channel 3, and the front spiral flow channel accounts for 2% of the length of the spiral flow channel. 1 / 3, the rear spiral flow channel accounts for 2 / 3 of the length of the spiral flow channel, the axes of the front spiral flow channel and the rear spiral flow channel are at an angle of 30°~60° The helical angle of the channel is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com