Miniature crane

A crane and miniature technology, applied in cranes and other directions, can solve problems such as deficiencies, and achieve the effects of reducing constraints, supporting stability, and improving lifting capacity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

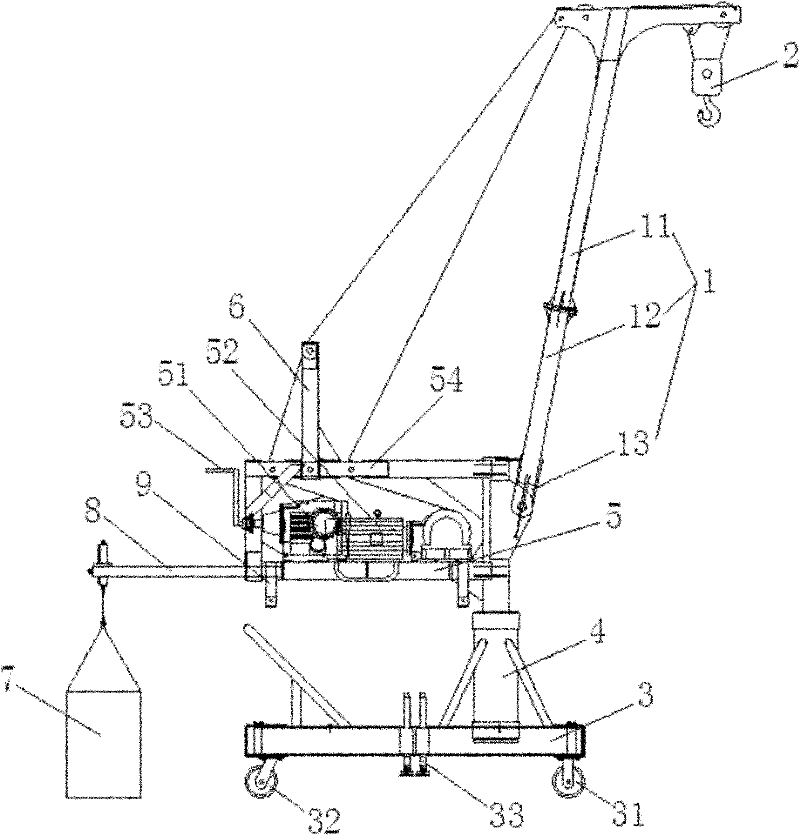

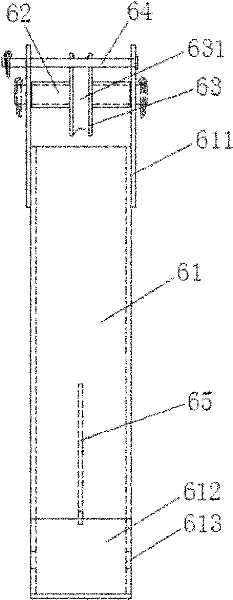

[0031] See figure 1 , This embodiment includes a boom 1, a hook 2, a base 3, a slewing mechanism 4, a turntable 5, a luffing rope support frame 6, a counterweight box 7, a counterweight arm 8 and a bracket 9.

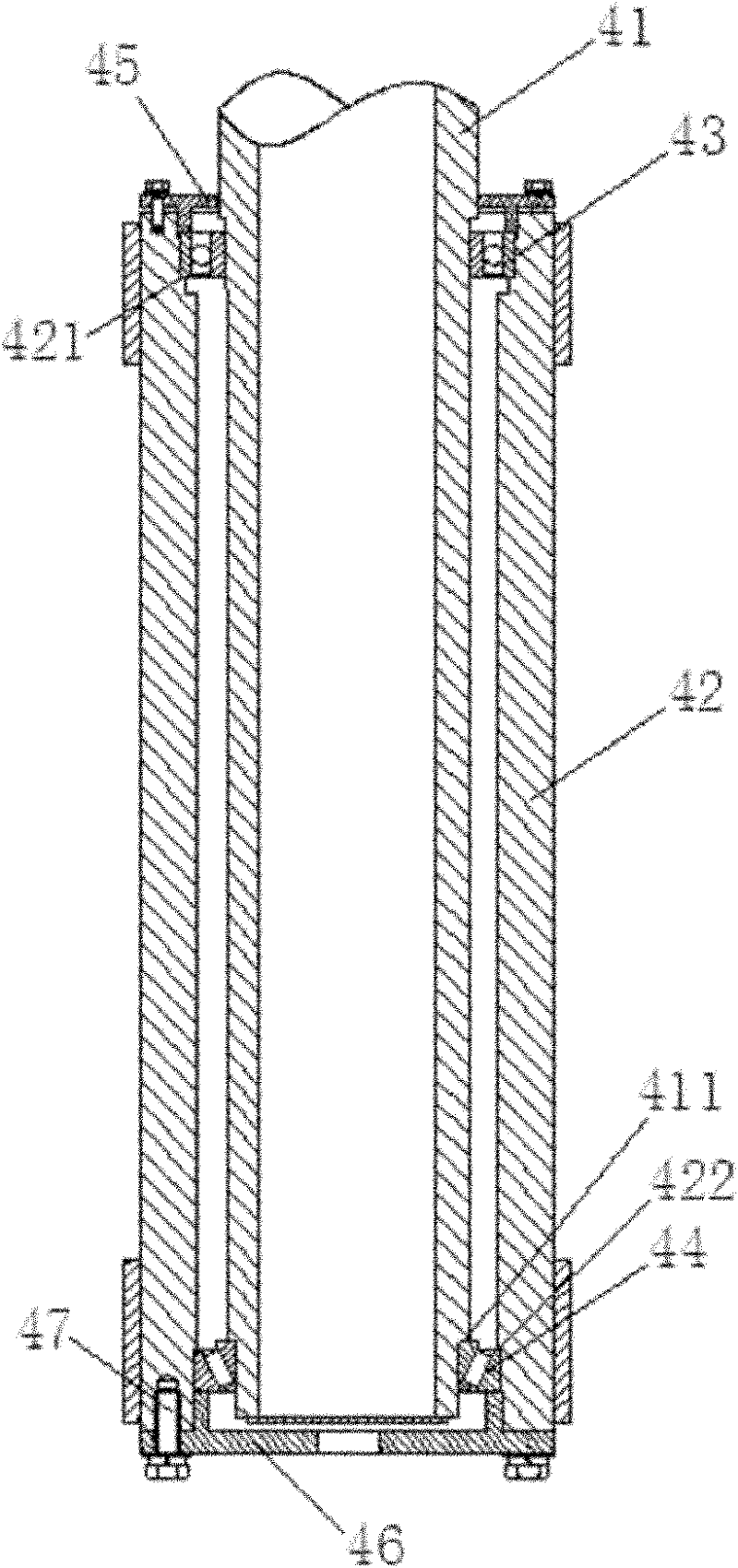

[0032] The hook 2 is hung on the top of the jib 1 by a hoisting rope. The rotary mechanism 4 can rotate at any angle of 360°, so that the range of motion of the heavy object can be extended from plane to three-dimensional. The rotary mechanism 4 includes a rotary shaft 41 and a shaft sleeve 42 that are rotatably connected. The jib 1 is hinged on the front side of the rotary shaft 41, so that the jib 1 can flexibly lift or lie down. This structure is conducive to welding and reduces deformation of the base metal. The turntable 5 is fixed on the rear side of the rotating shaft 41 , and the shaft sleeve 42 is fixed on the base 3 . Both the base 3 and the turntable 5 adopt a box structure.

[0033] A worm gear luffing mechanism 51 and a worm gear hoisting mechanism 52 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com