Tower crane, lifting mechanism thereof and method for leveling lifting mechanism

A hoisting mechanism and driving mechanism technology, applied in cranes, load hanging components, transportation and packaging, etc., can solve the problems of unbalanced balance arm, hoisting weight, low rope capacity, low mechanism transmission efficiency, etc. The effect of increasing the amount of rope and increasing the lifting capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in many different ways defined and covered by the claims.

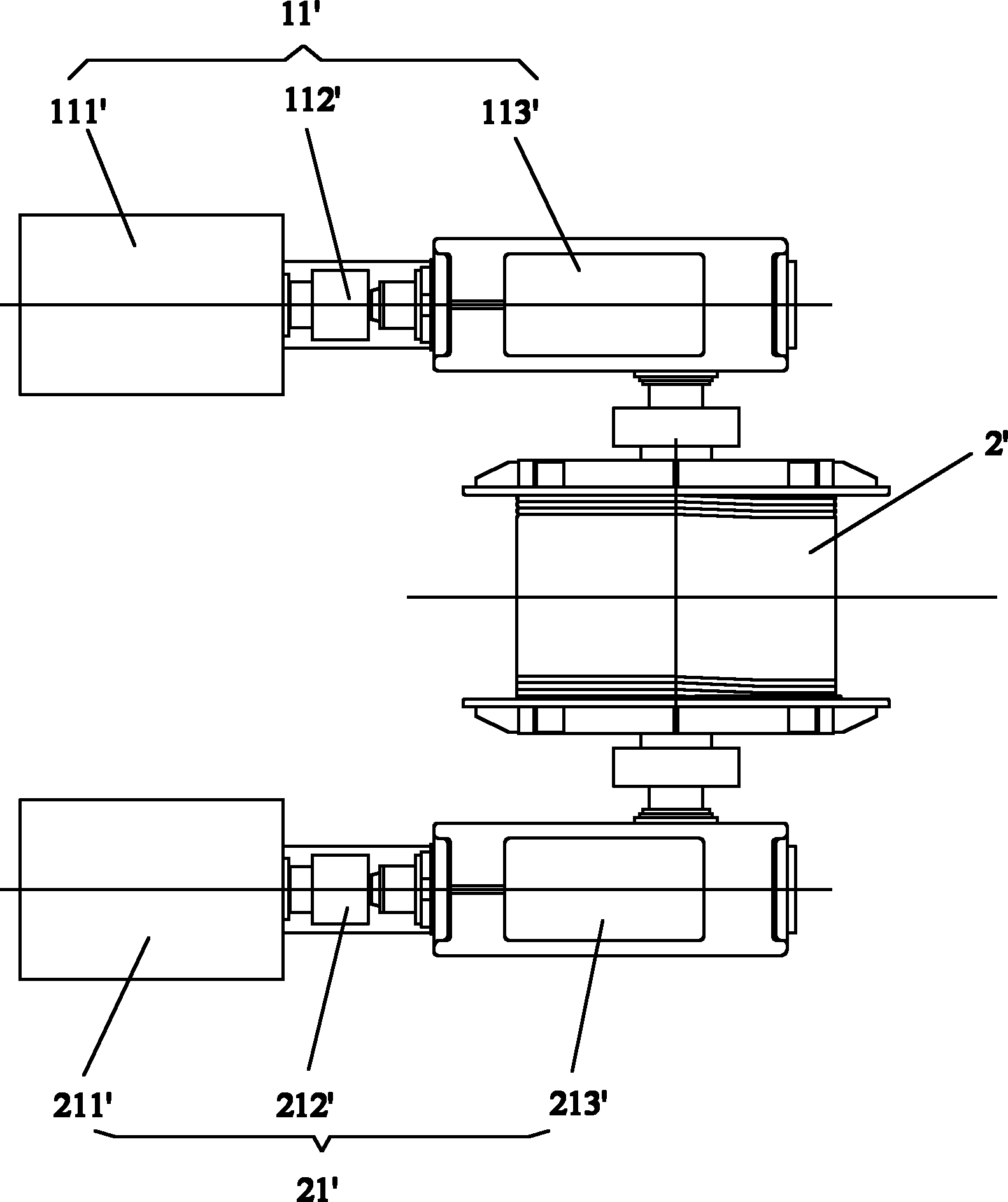

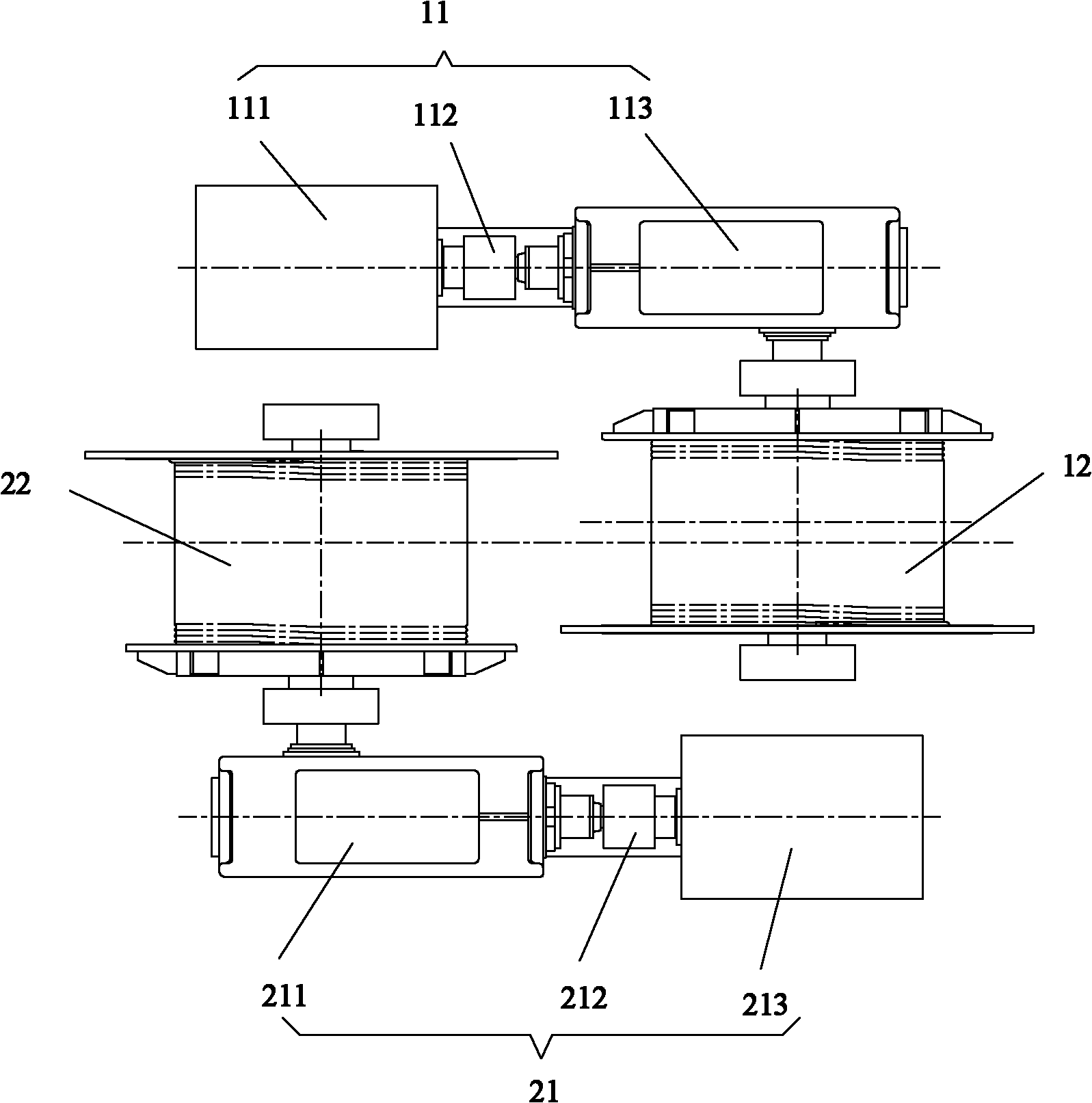

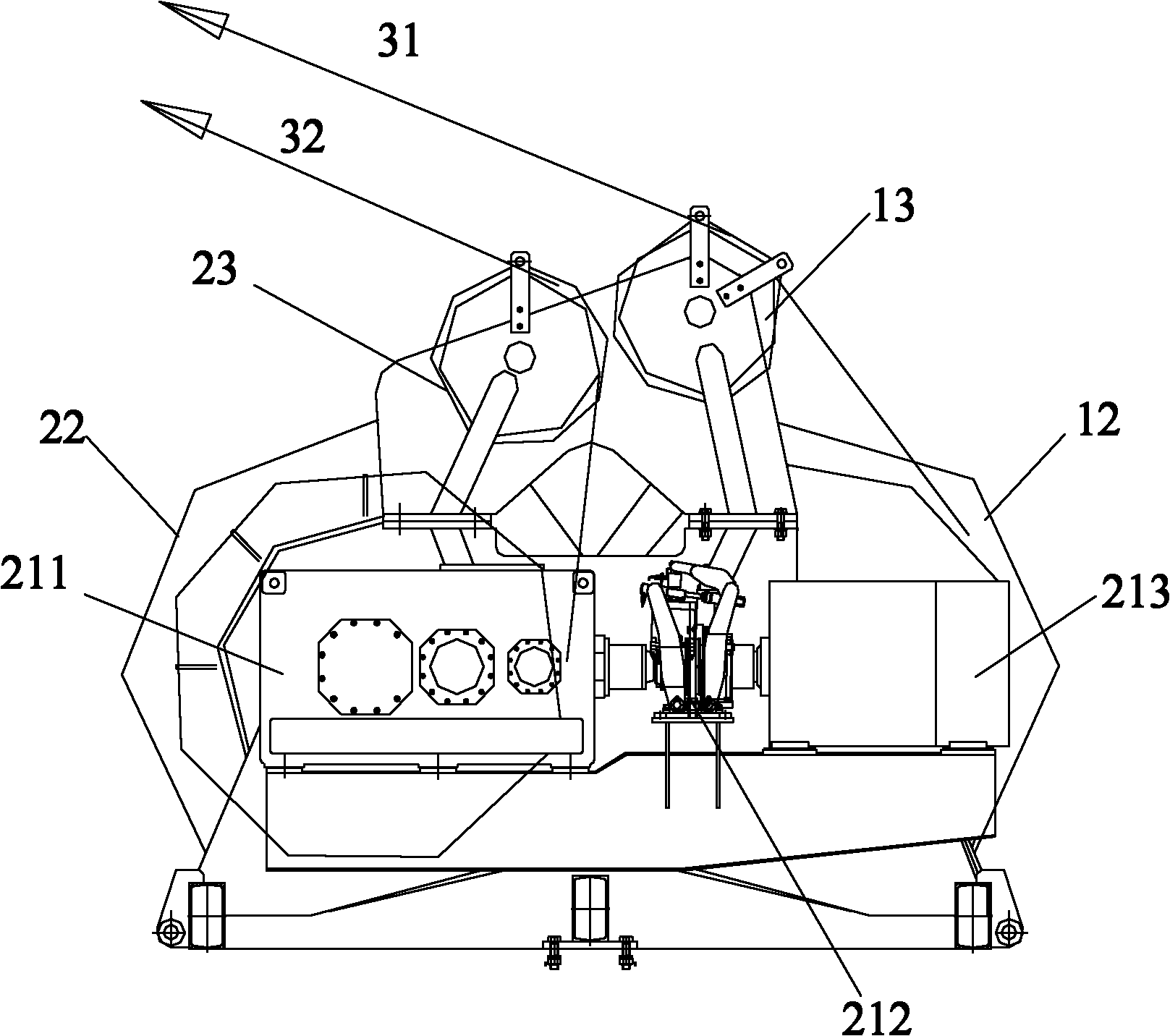

[0038] like figure 2 , image 3 and Figure 4 As shown, the hoisting mechanism in the present invention includes a first hoisting unit and a second hoisting unit, the first hoisting unit includes a first drive mechanism 11 and a first reel 12, and the first drive mechanism 11 drives the first reel 12; the second lifting unit includes a second drive mechanism 21 and a second reel 22, and the second drive mechanism 21 drives the second reel 22 to rotate. Additionally, if Figure 4 and Figure 5 As shown, the lifting assembly has a hook beam 4 and a hook arranged below the hook beam 4 . from image 3 and Figure 4 As can be seen in the figure, the first rope 31 on the first reel 12 stretches out from the first reel 12 and is connected to one en...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com