Patents

Literature

54results about How to "Reduce bore" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

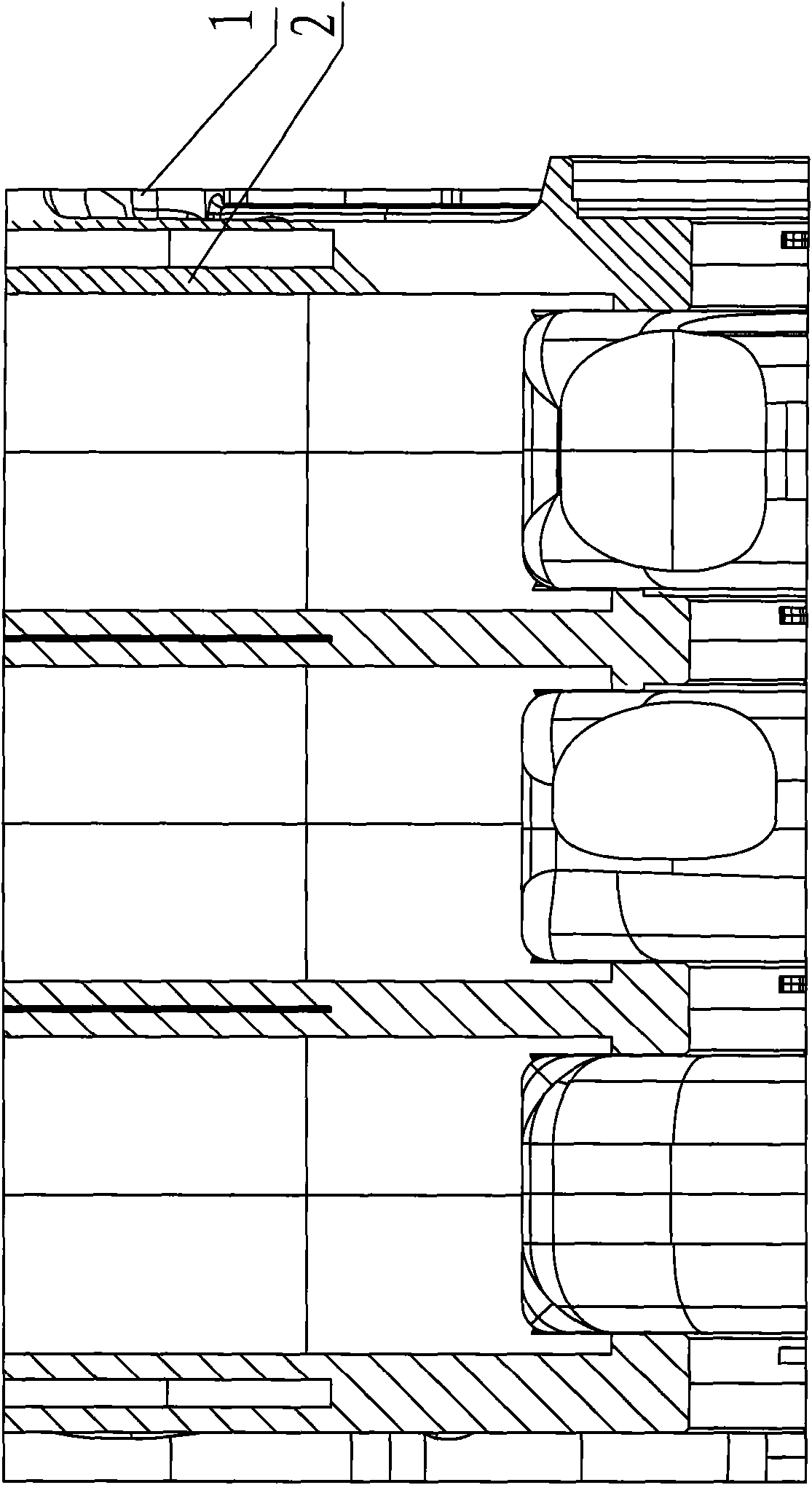

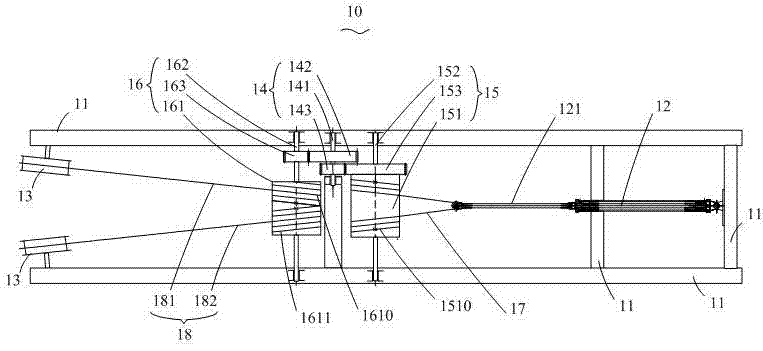

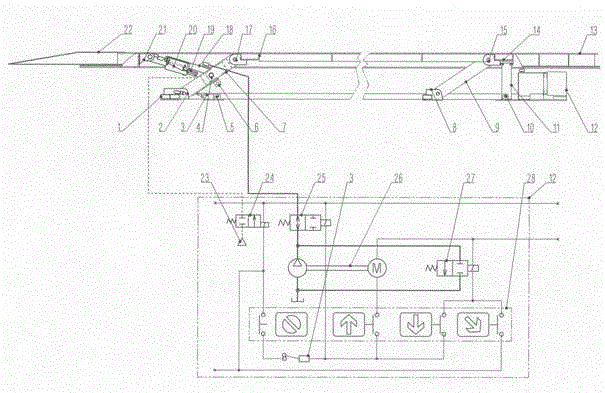

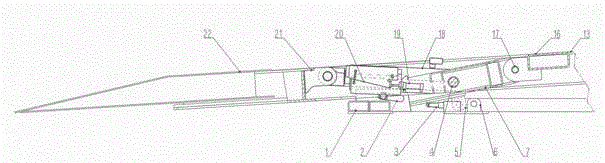

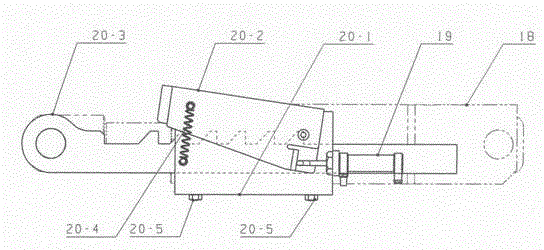

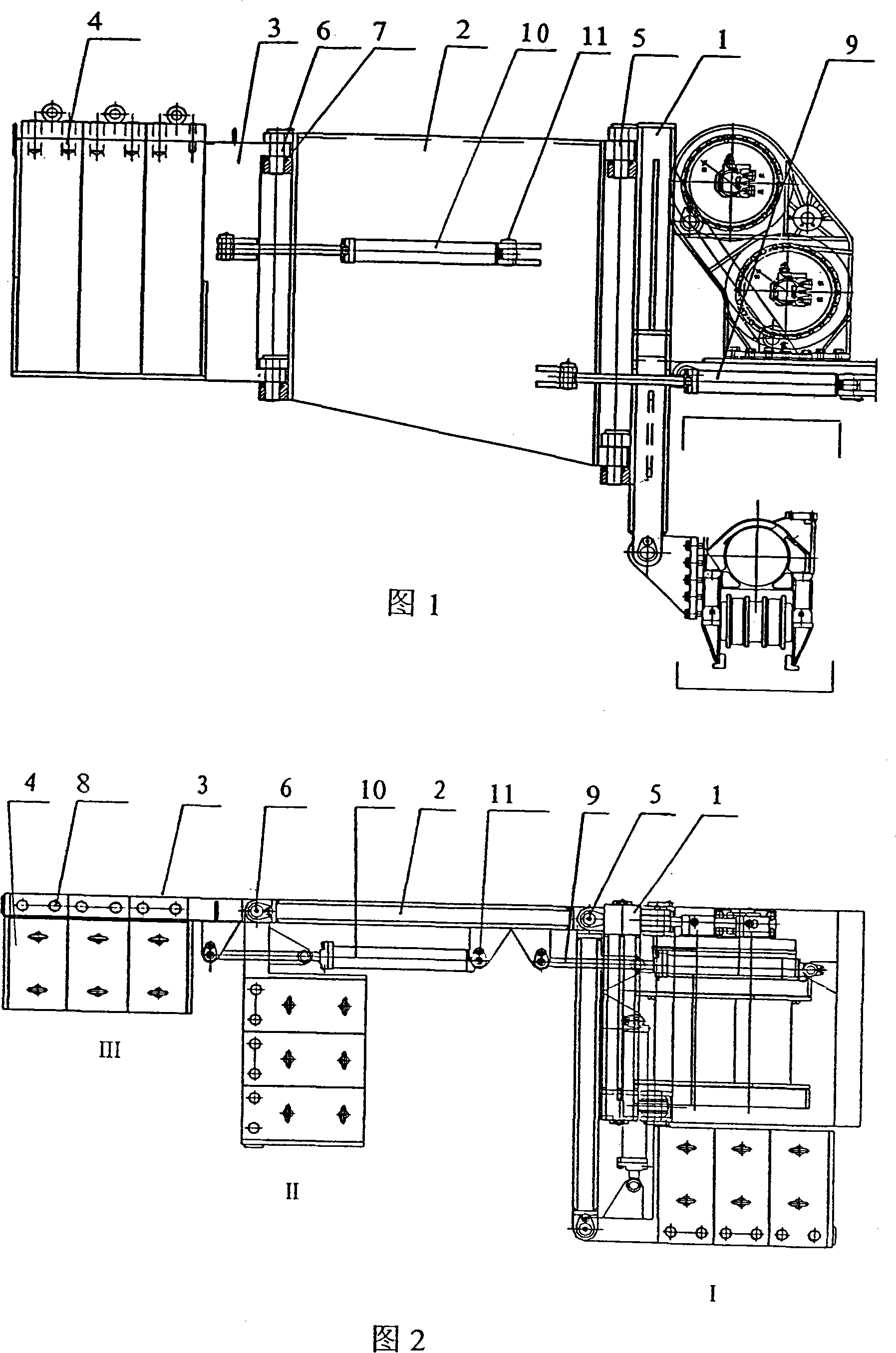

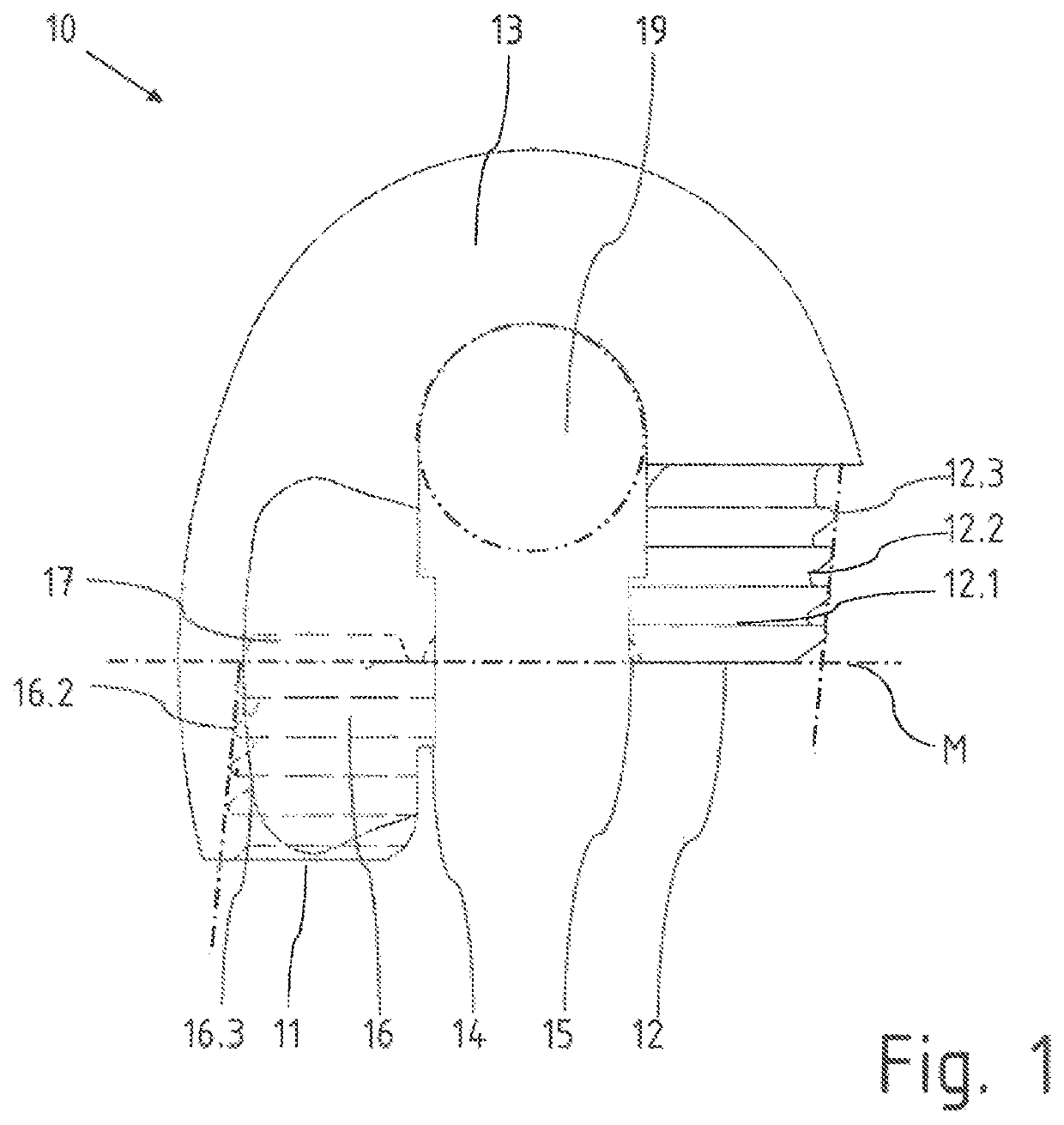

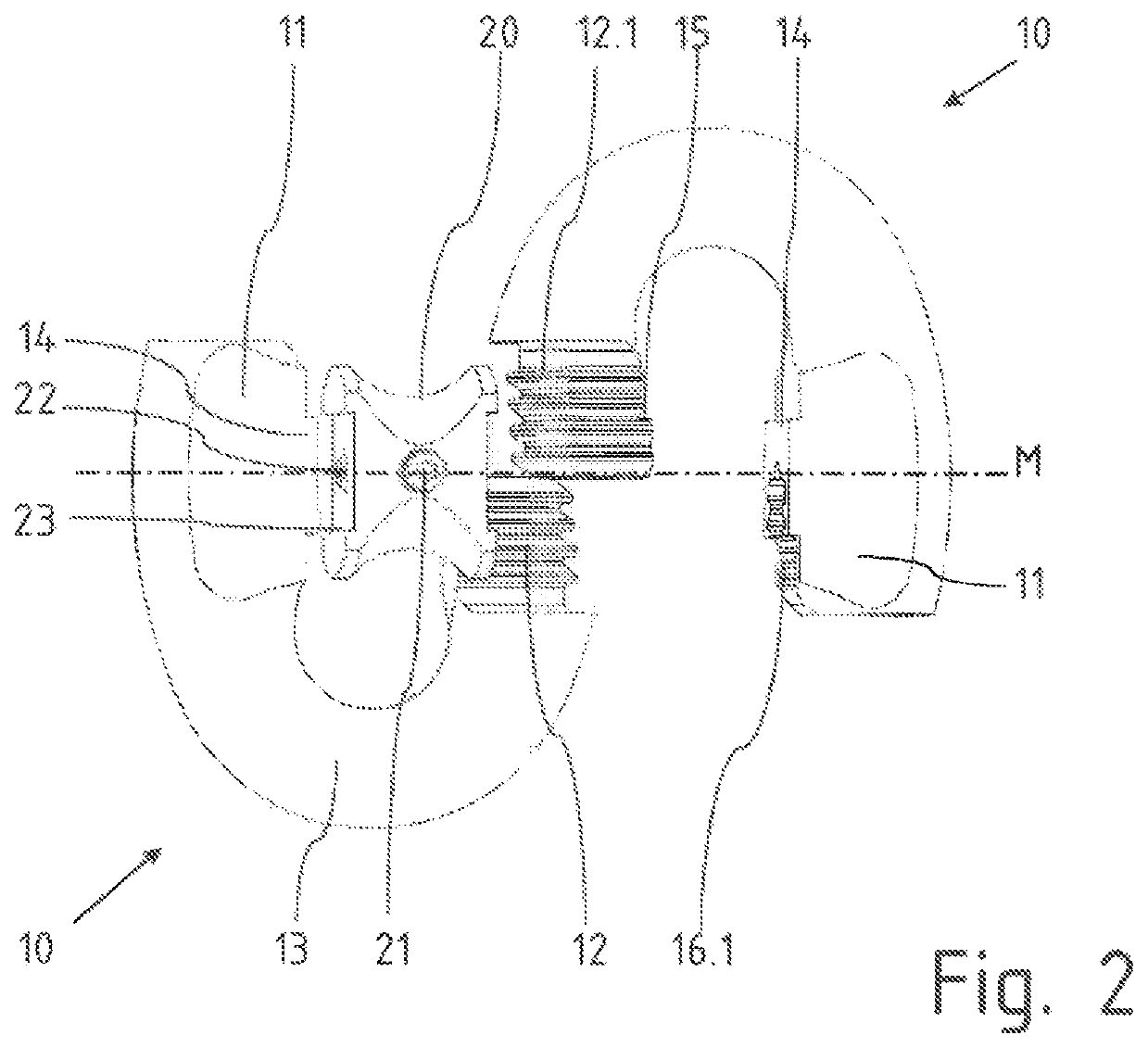

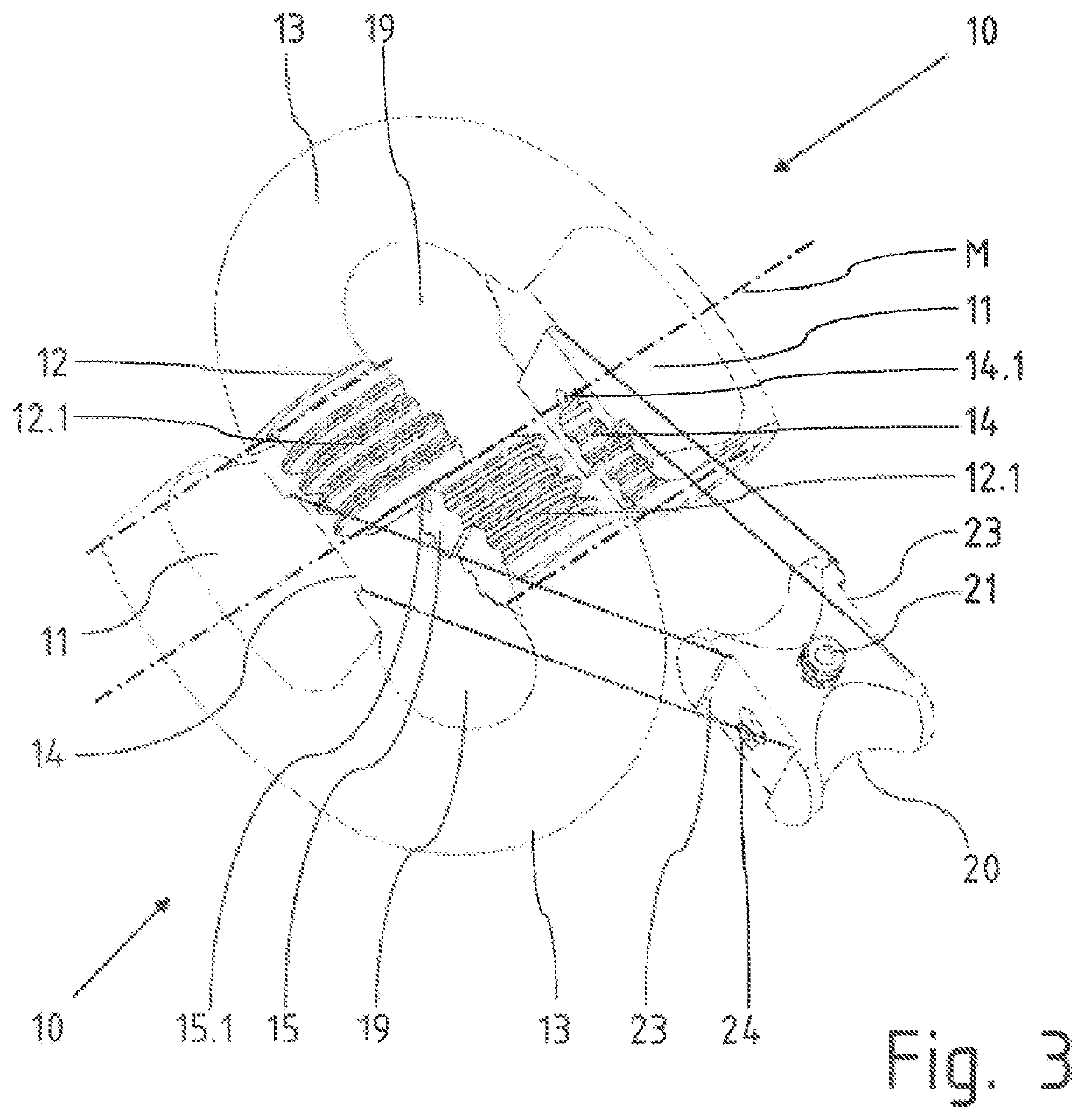

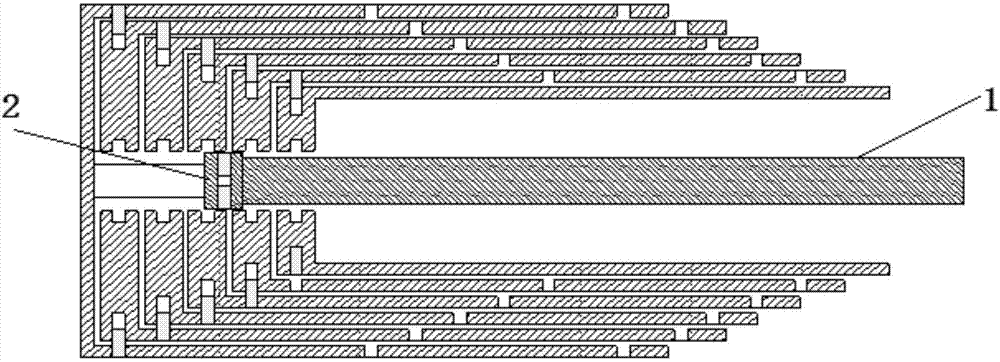

Single-cylinder plug pin type telescopic arm, crane and telescoping method of single-cylinder plug pin type telescopic arm

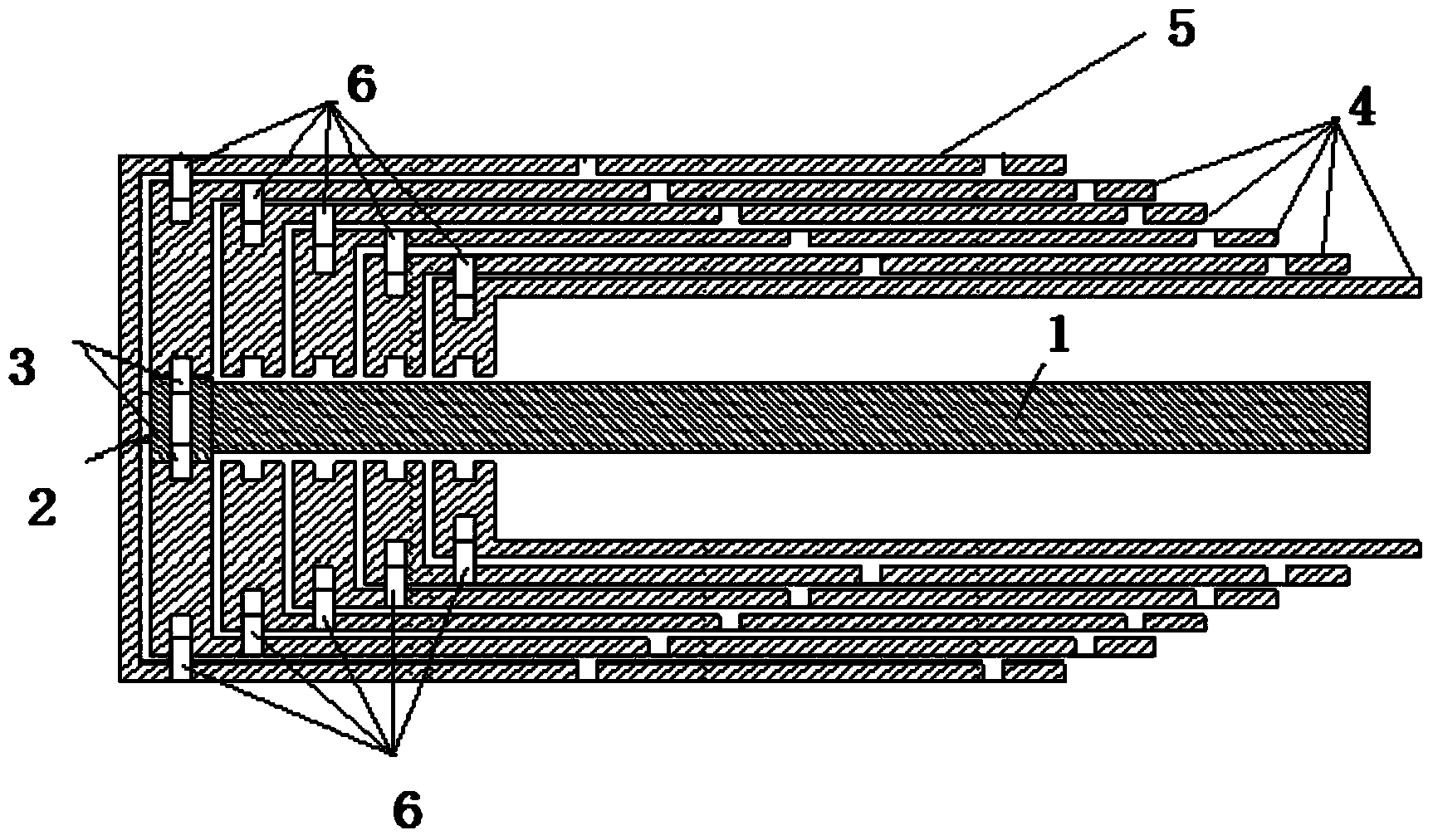

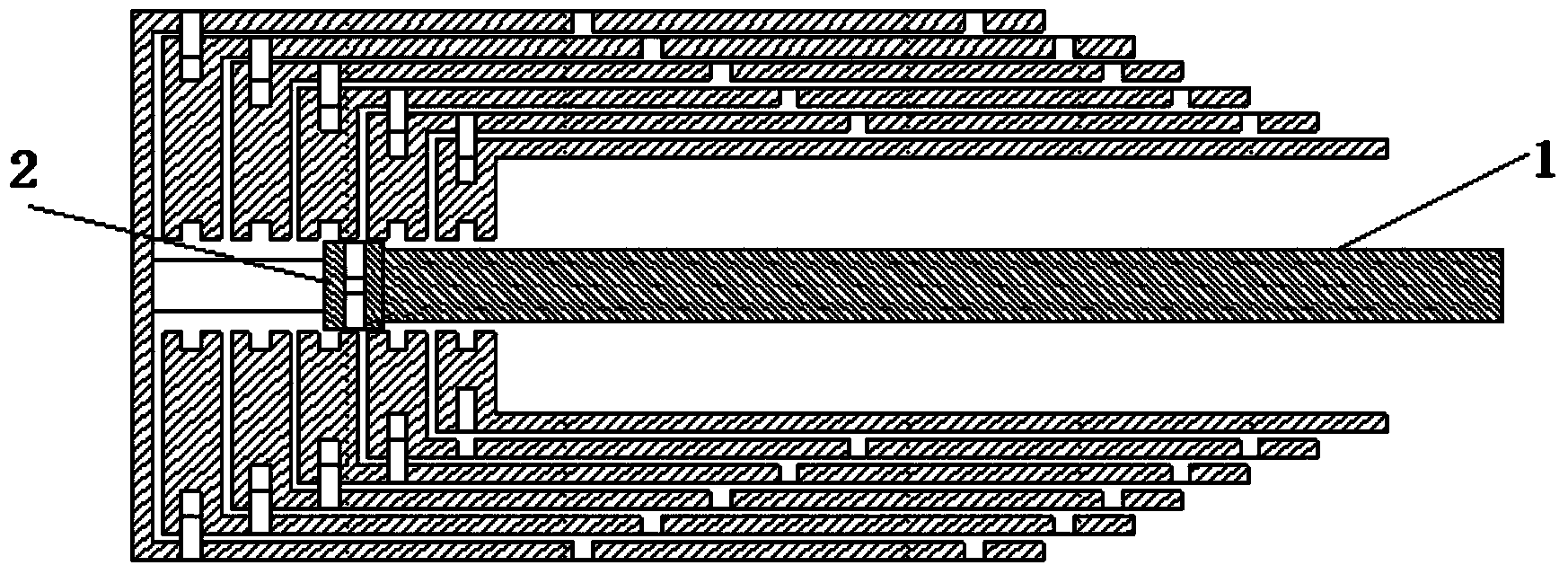

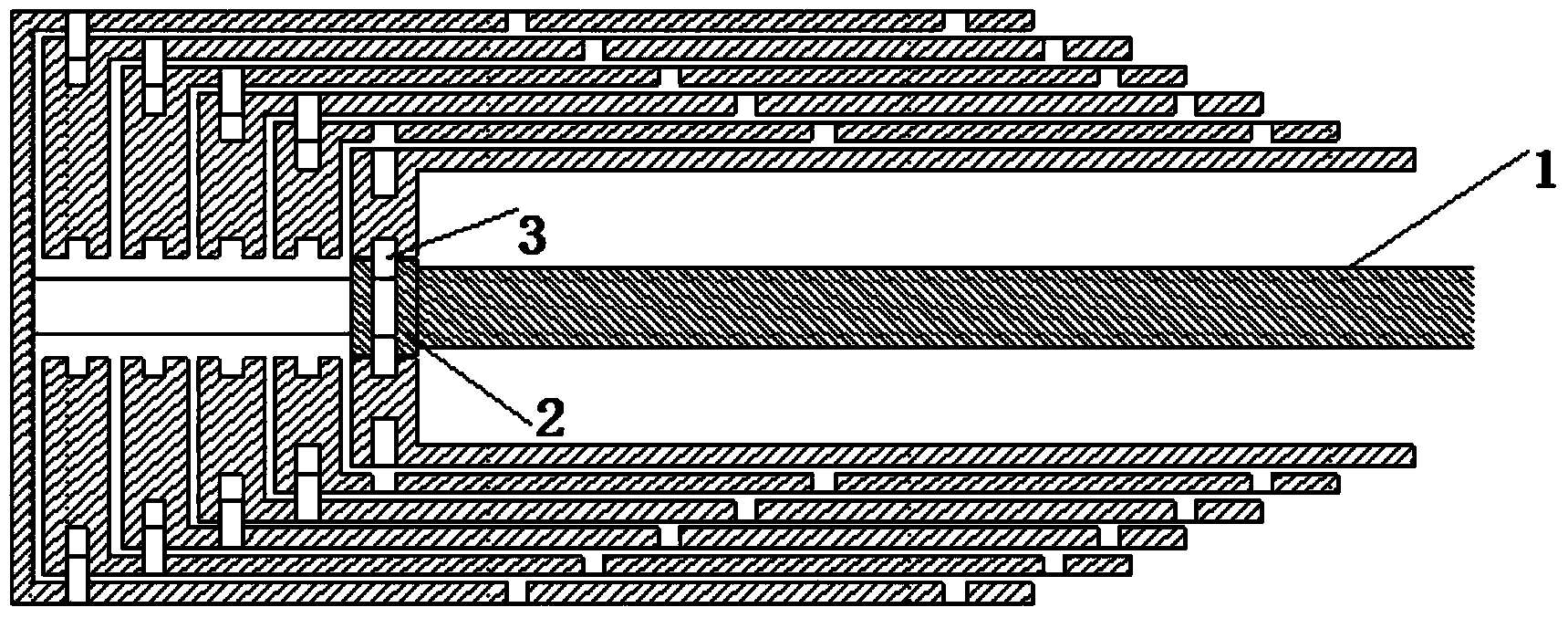

The invention relates to a single-cylinder plug pin type telescopic arm, a crane and a telescoping method of the single-cylinder plug pin type telescopic arm. The single-cylinder plug pin type telescopic arm comprises a basic arm and at least one section of telescopic arm which is sleeved in the basic arm, wherein coaxial central holes are formed in the tails of the telescopic arms; a telescopic oil cylinder is arranged in the central holes and comprises a cylinder rod and a cylinder barrel; at least two cylinder heads are fixedly sleeved outside the cylinder barrel in the longitudinal direction; at least three arm pin holes are respectively formed in the basic arm and the telescopic arm in the longitudinal direction. The single-cylinder plug pin type telescopic arm provided by the invention adopts the telescopic oil cylinder and the at least two cylinder heads; each cylinder head can be used for locking and unlocking the telescopic oil cylinder and any one telescopic arm; in a relay manner, the telescopic arms stretch or shrink; telescoping of the single-cylinder plug pin type telescopic arm is realized; the length of the oil cylinder is reduced; the cylinder diameter and the rod diameter of the oil cylinder are reduced; the cost of the oil cylinder is lowered; the loading weight is reduced; the hoisting capability is improved; the design capability of the crane is improved.

Owner:XUZHOU HEAVY MASCH CO LTD

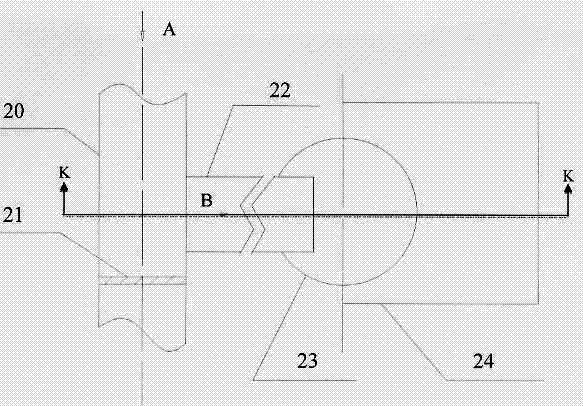

Differential type pneumatic angle pedestal valve

ActiveCN101614282AIncrease flexibilityImprove air tightnessOperating means/releasing devices for valvesLift valveEngineeringAir tightness

The invention relates to a differential type pneumatic angle pedestal valve, relating to a pneumatic angle pedestal valve. The valve comprises a valve body, a piston, a plastic cylinder, a return spring, an indicator, an actuating cylinder, a transparent observation window, a piston rod and a valve seat. The valve is mainly technically characterized in that a differential moveable cylinder and a differential fixed piston are arranged in the valve seat, wherein one end of the differential moveable cylinder is connected with the differential fixed piston, and the other end thereof is connected with the diversion head of the valve seat; and a balance hole B is arranged on the differential moveable cylinder and is communicated with a balance hole A of the diversion head. By adopting the differential type angle pedestal valve, the invention increases the flexibility and the pressuretightness of the valve; and the invention also greatly reduces the cylinder diameter of the actuating cylinder, the consumption of compressed air is reduced, for example, the cylinder diameter of a Phi 65 valve actuating head is only Phi50, and the pressure of controlled media is higher.

Owner:HANGZHOU FANGYUAN PLASTICS MASCH CO LTD

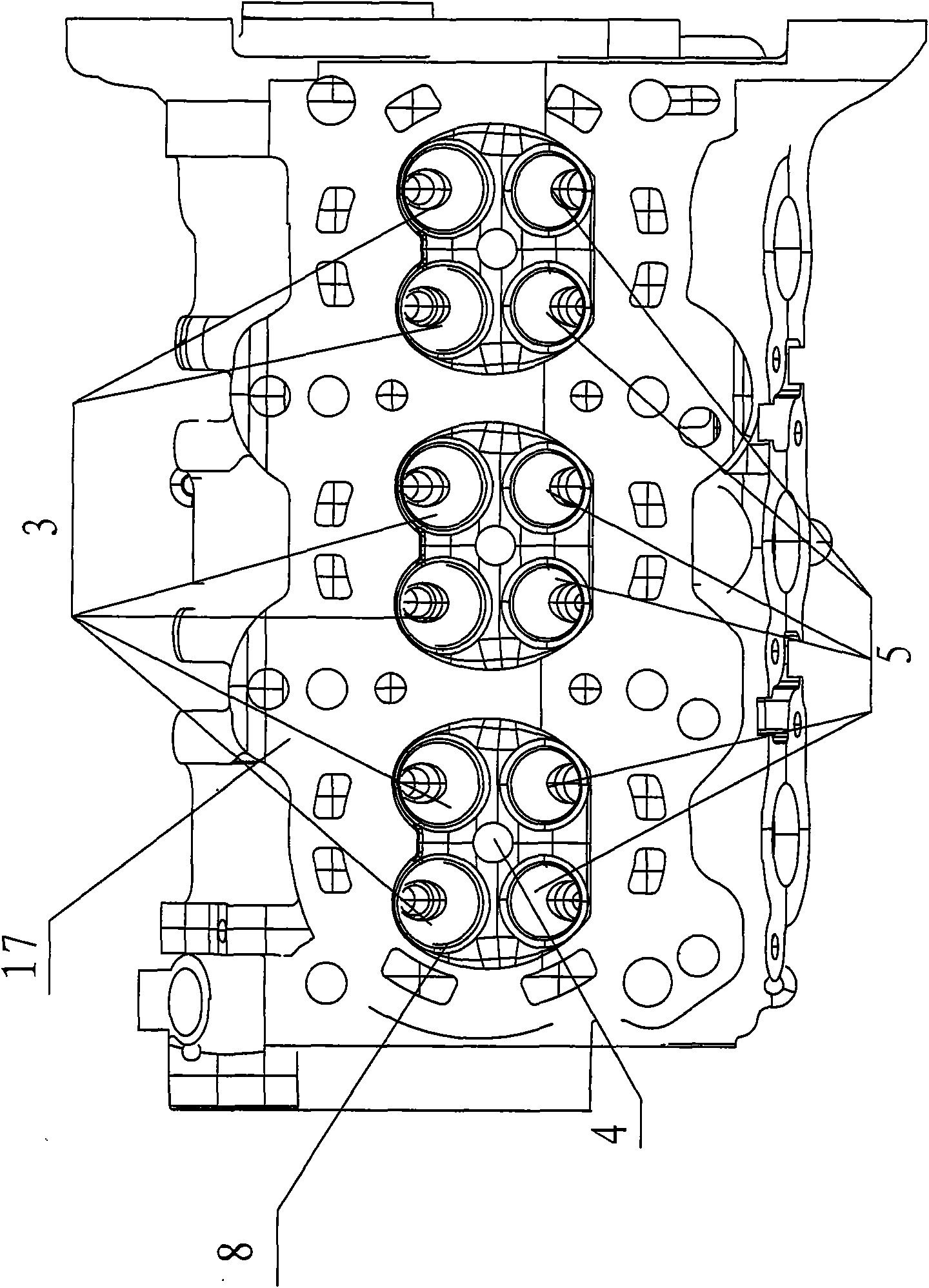

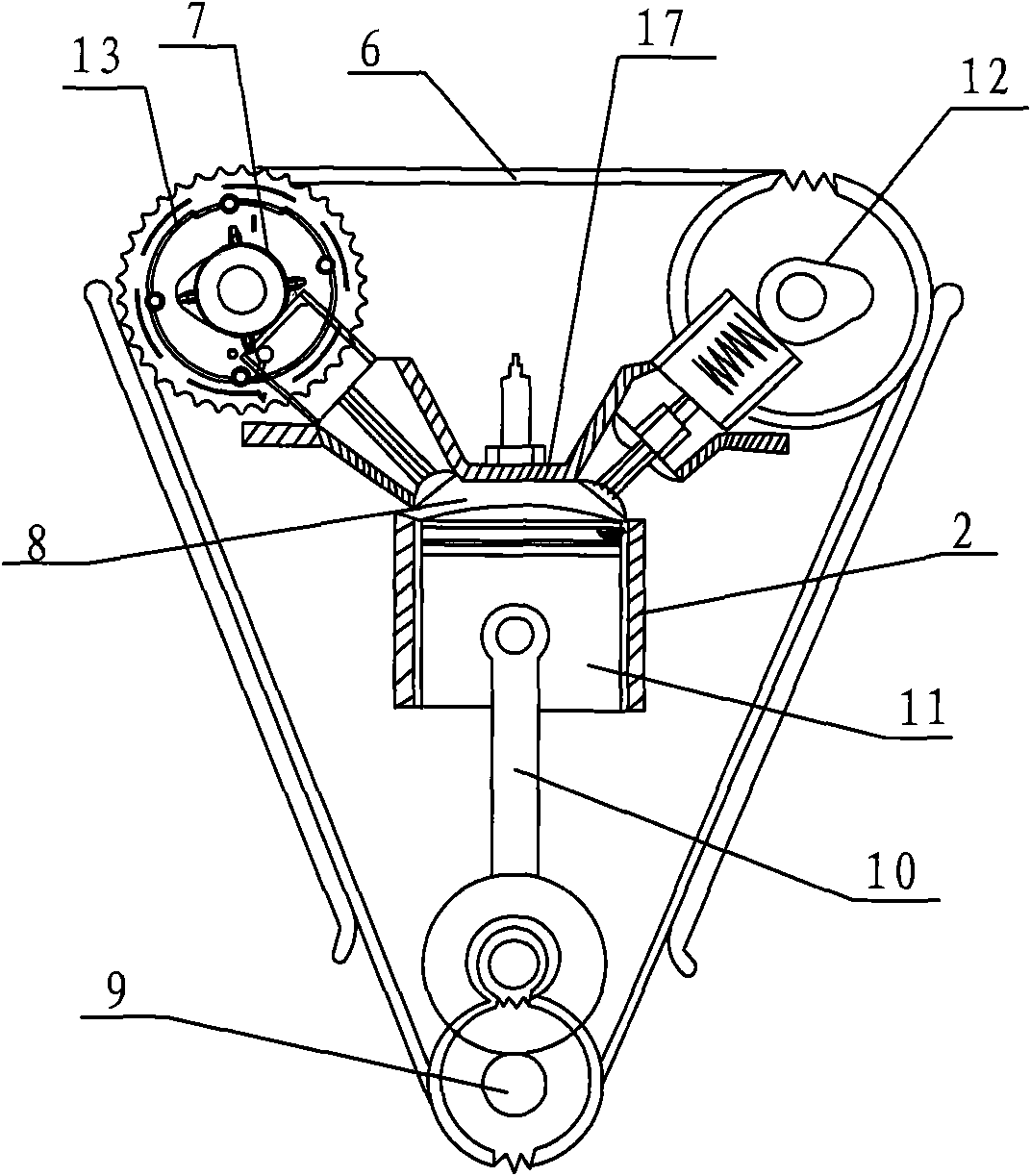

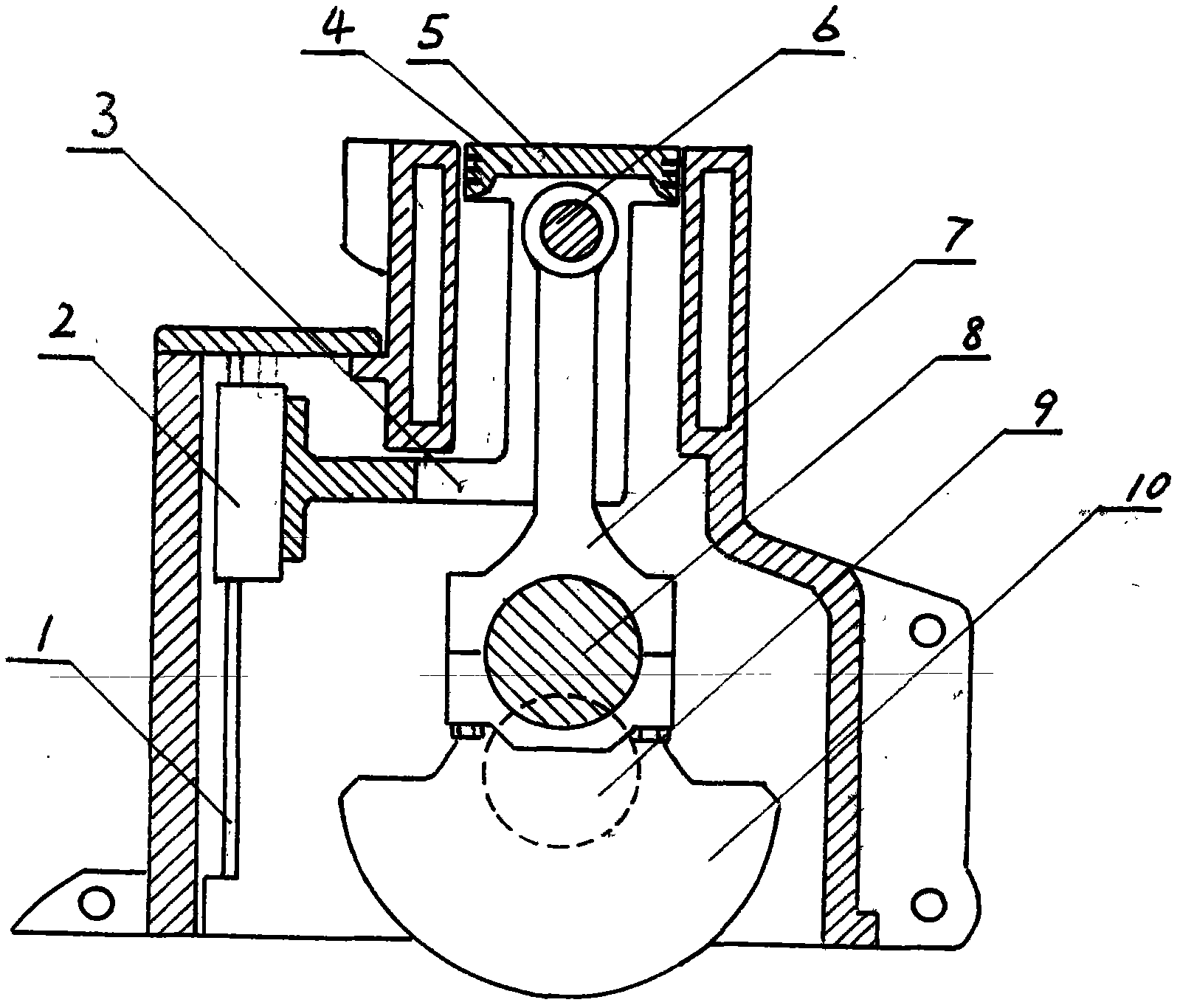

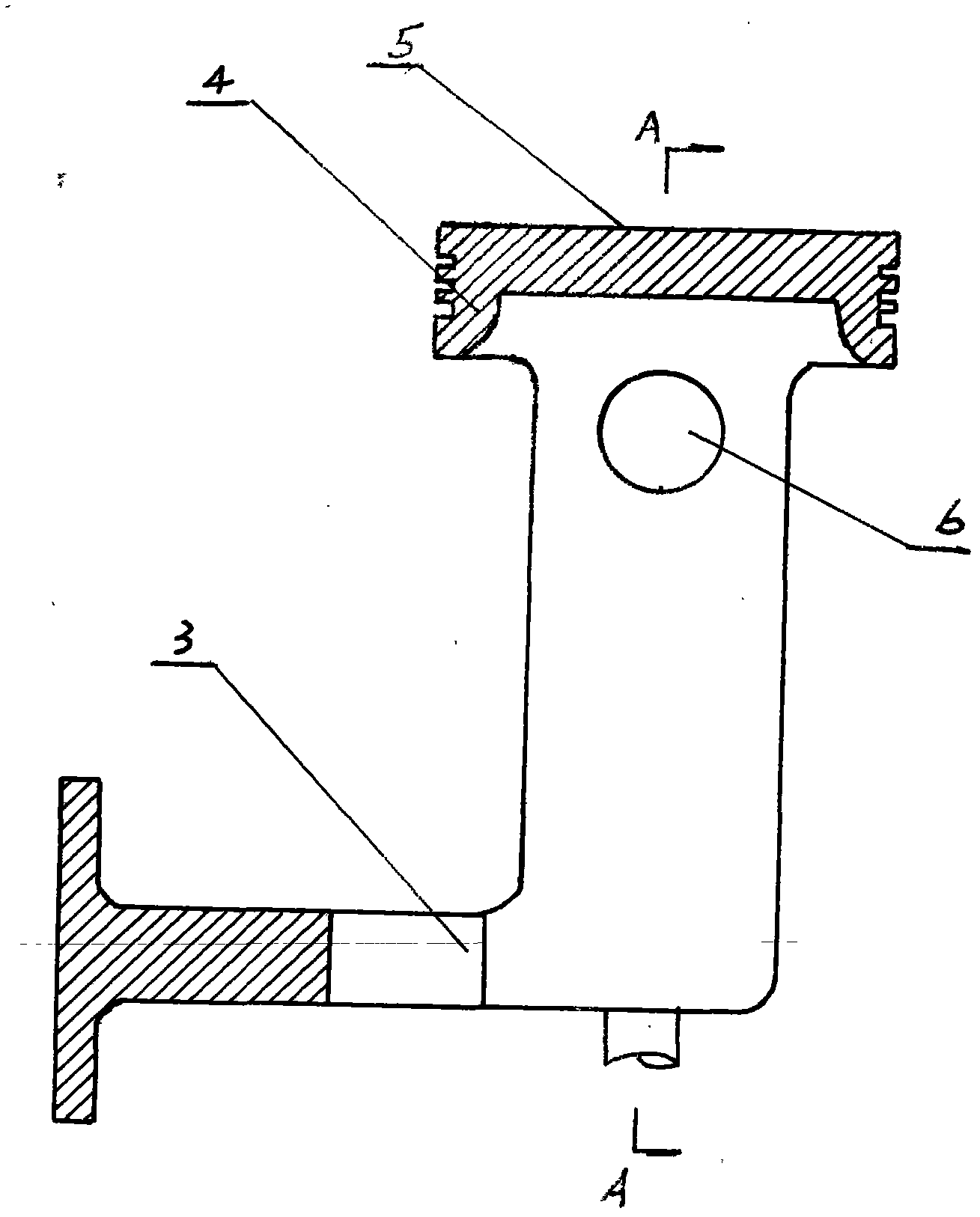

Petrol engine with turbo charging

InactiveCN101608572AIncrease intake pressureIncrease output powerValve arrangementsInternal combustion piston enginesExhaust valveCombustion chamber

The invention relates to a petrol engine with turbo charging, which comprises a cylinder body, a cylinder sleeve, an intake valve, a spark plug hole, an exhaust valve, a combustion chamber, a crankshaft, a connecting rod, a piston, an intake manifold, an exhaust manifold and a turbo charging device. The petrol engine also comprises a twin cam shaft valve timing adjusting structure arranged above a cylinder head; the twin cam shaft valve timing adjusting structure ensures that an admission cam shaft and an exhaust cam shaft is in transmission connection with the crankshaft through a timing chain; and the twin cam shaft valve timing adjusting structure is used for continuously and changeably adjusting the opening times of the intake valve and the exhaust valve of the combustion chamber, therefore, the fuel utilization and the rotation speed and the output power of the engine can be improved. The turbo charging device can increase the intake pressure of the engine, and quicken the combustion of the fuel of the engine, so as to enable the combustion to be more sufficient, therefore, the output power of the engine is improved, and the exhaust emissions are reduced. A three-way catalysis device is arranged on the exhaust manifold, therefore, the harmful gas emissions can be reduced.

Owner:苏州益方动力机械有限公司

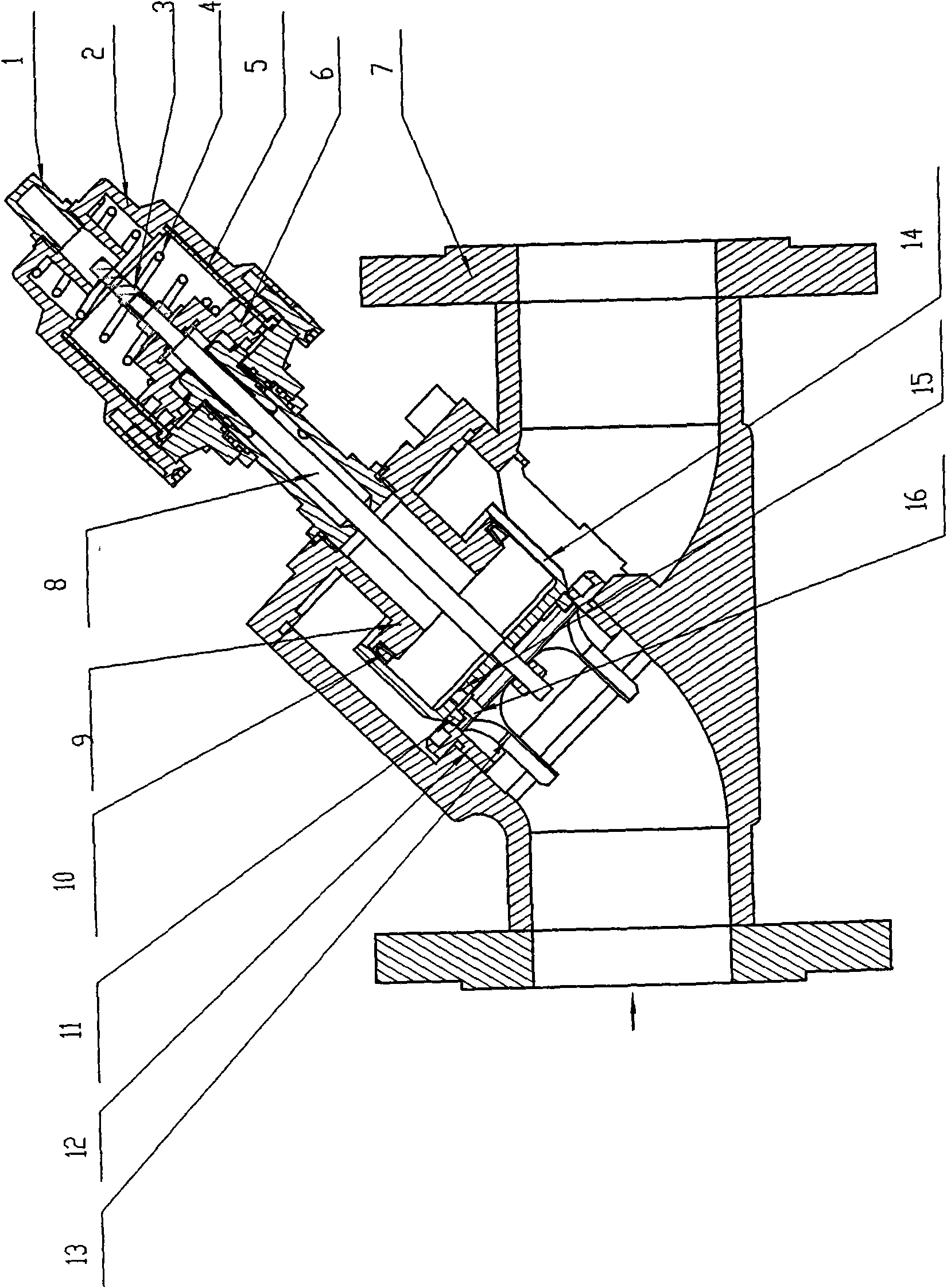

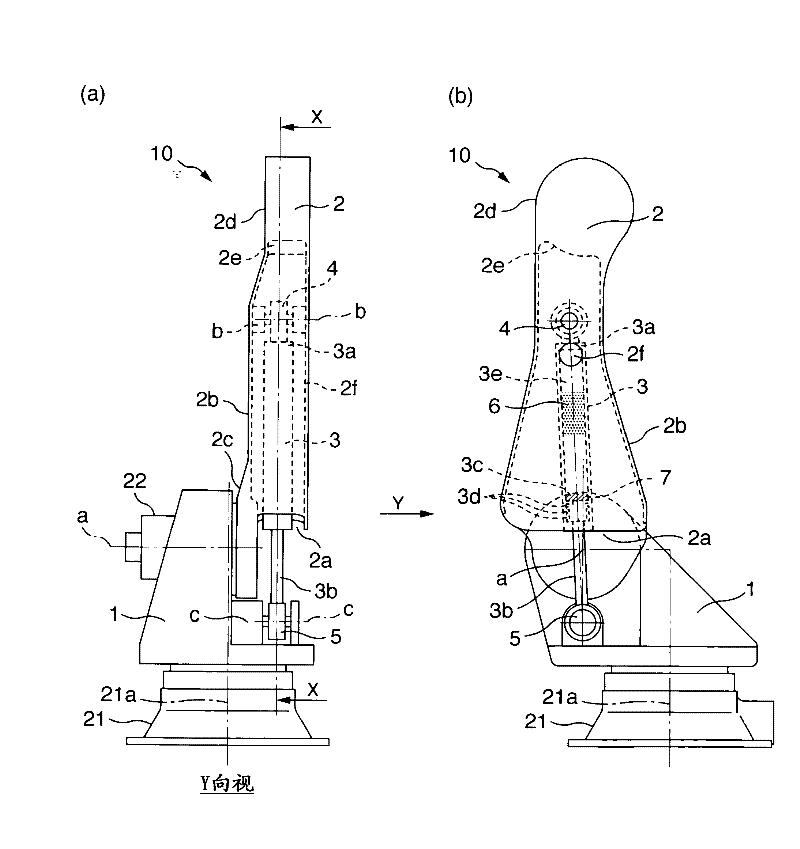

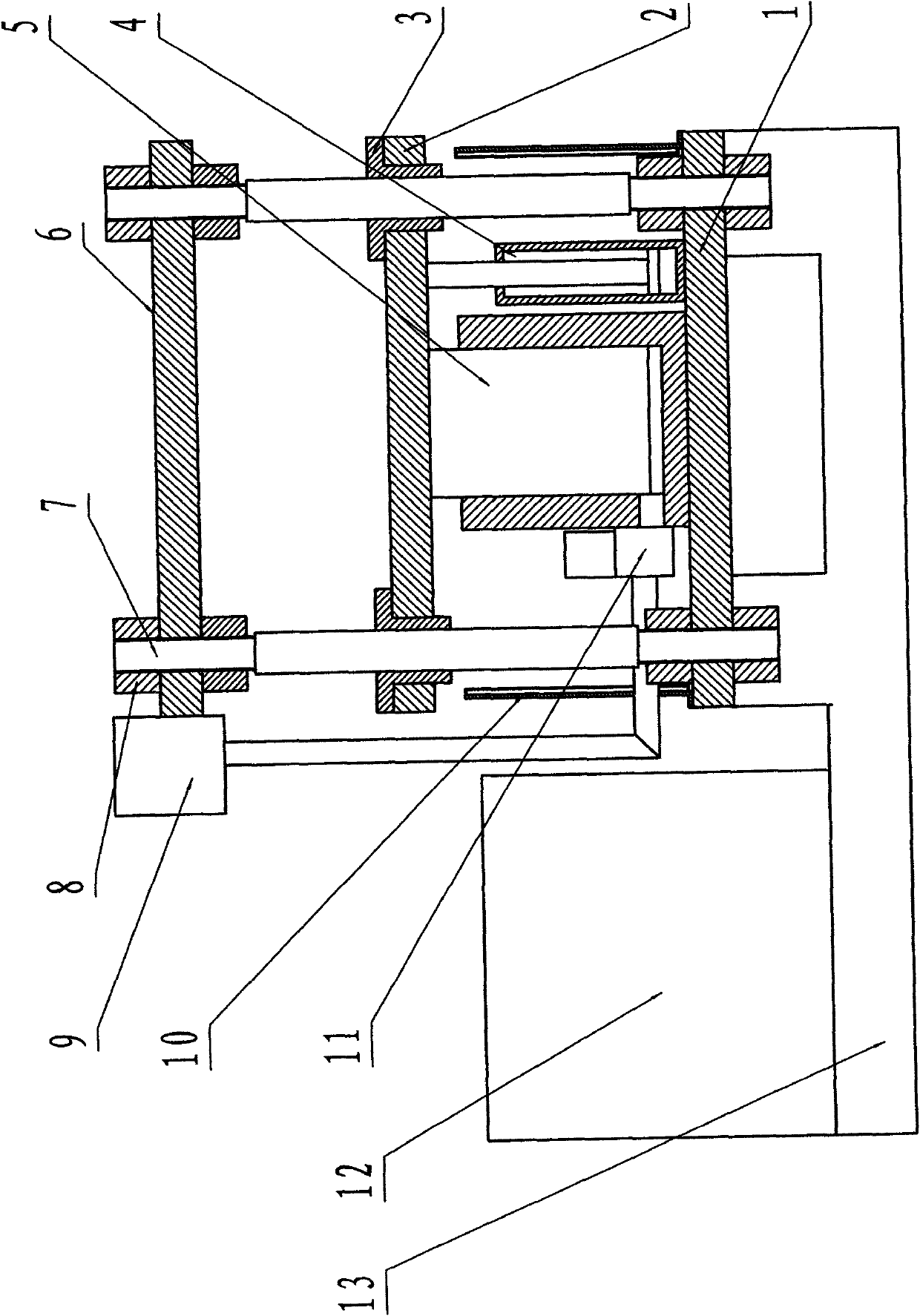

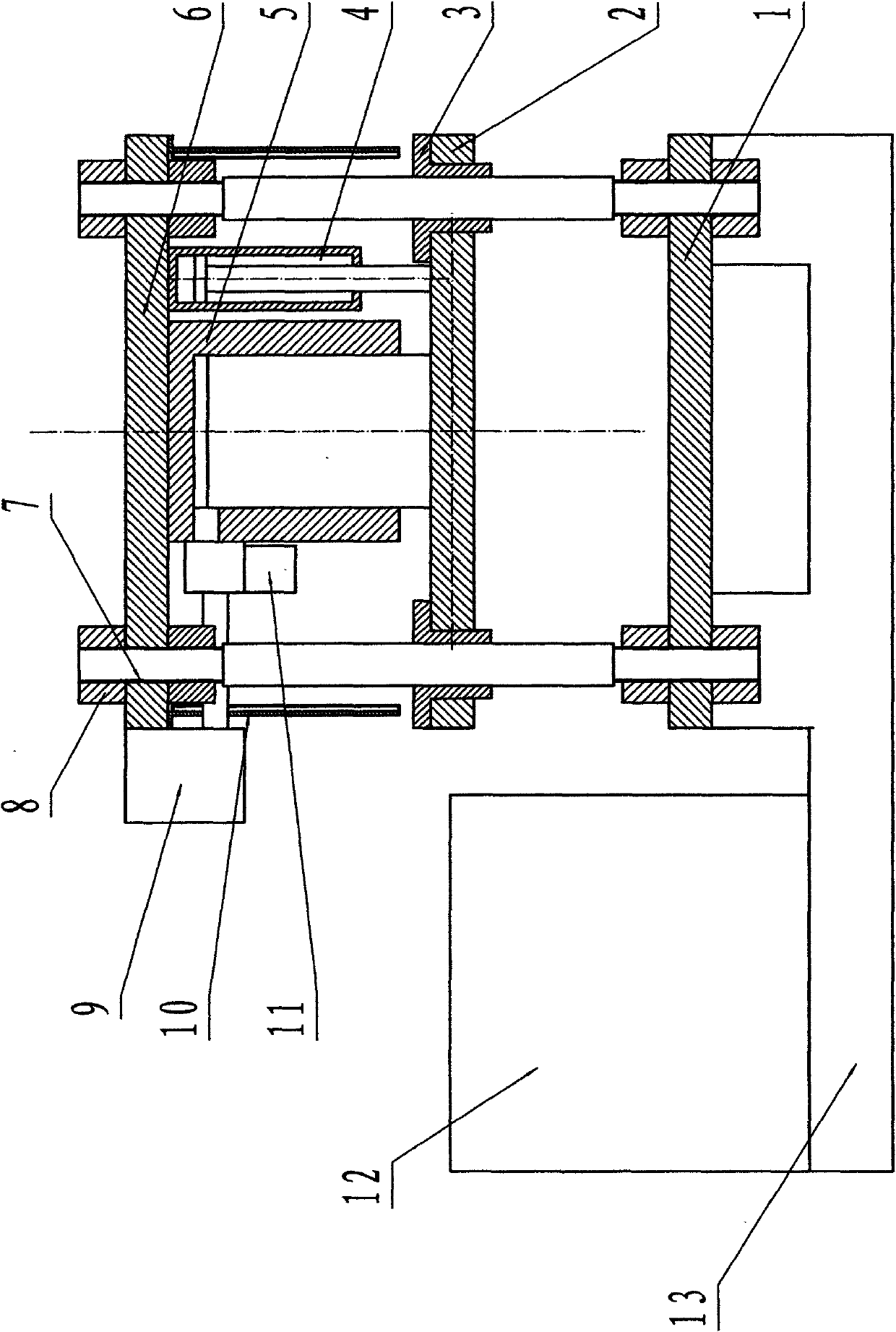

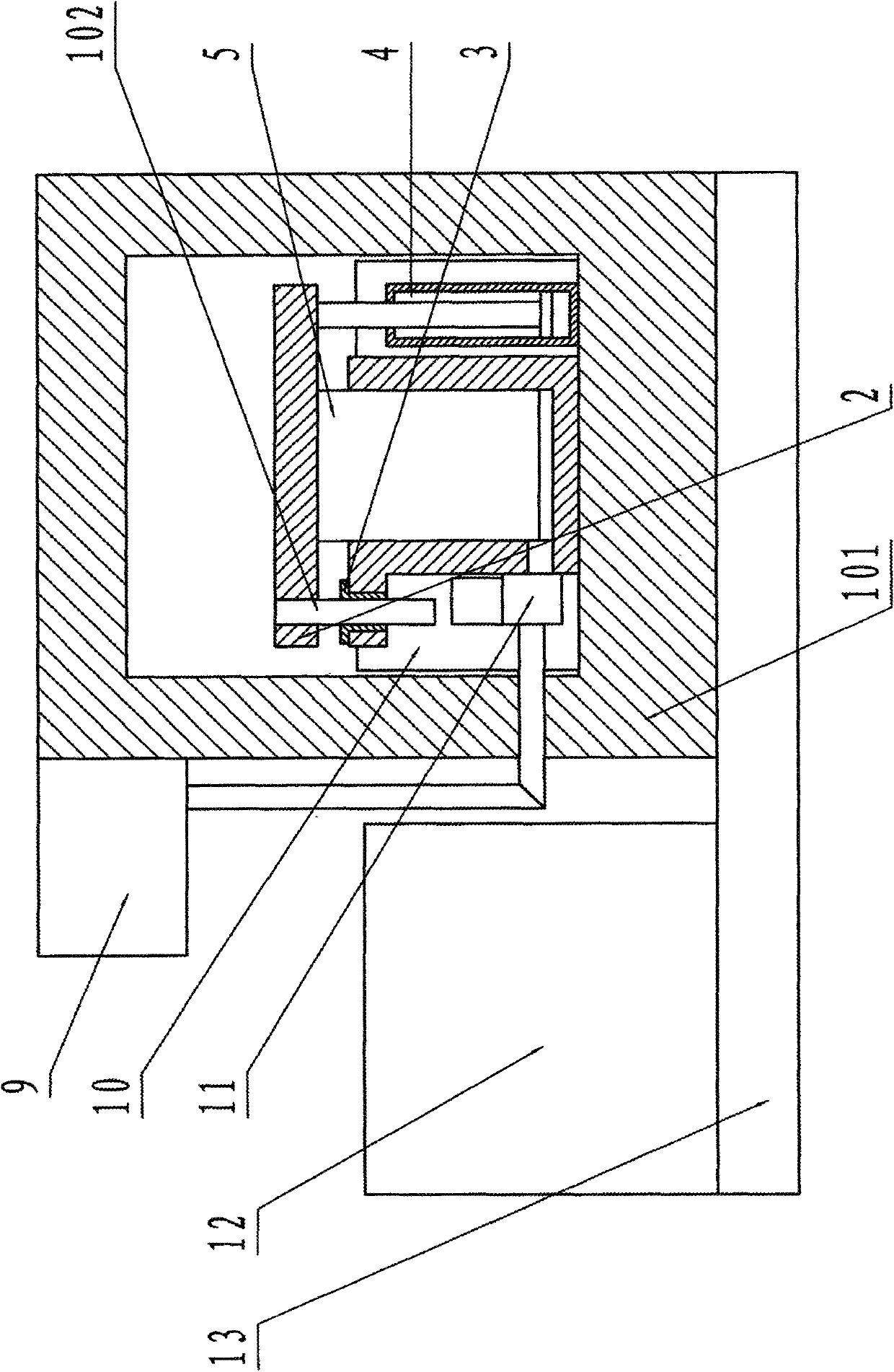

Industrial robot

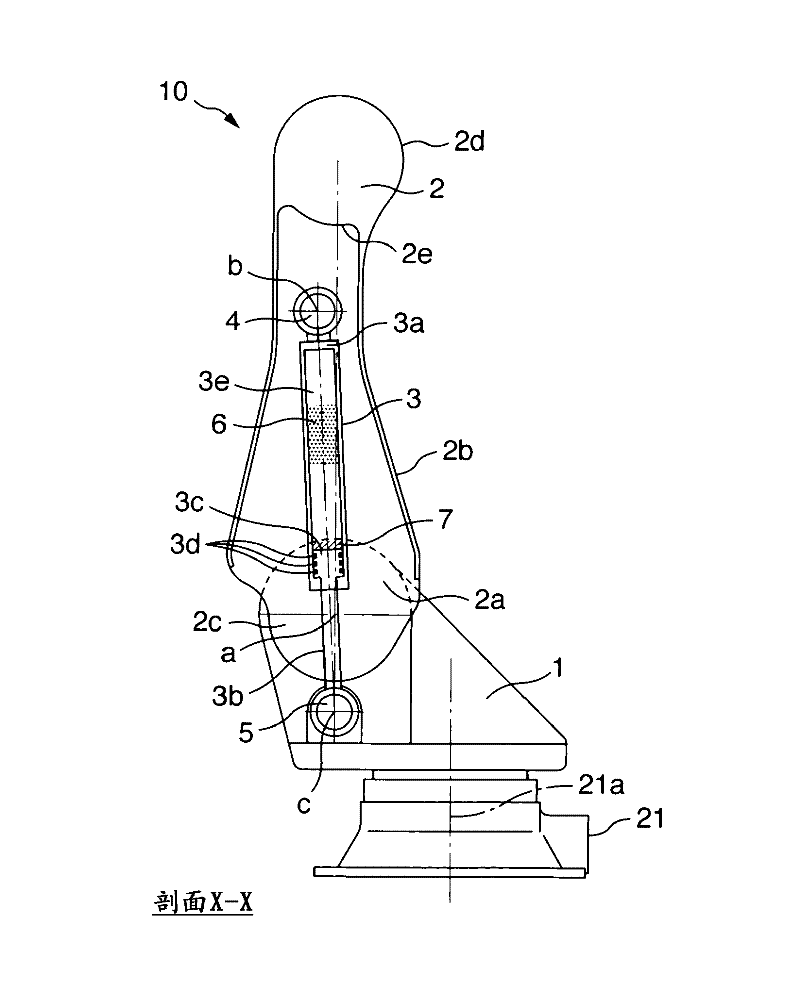

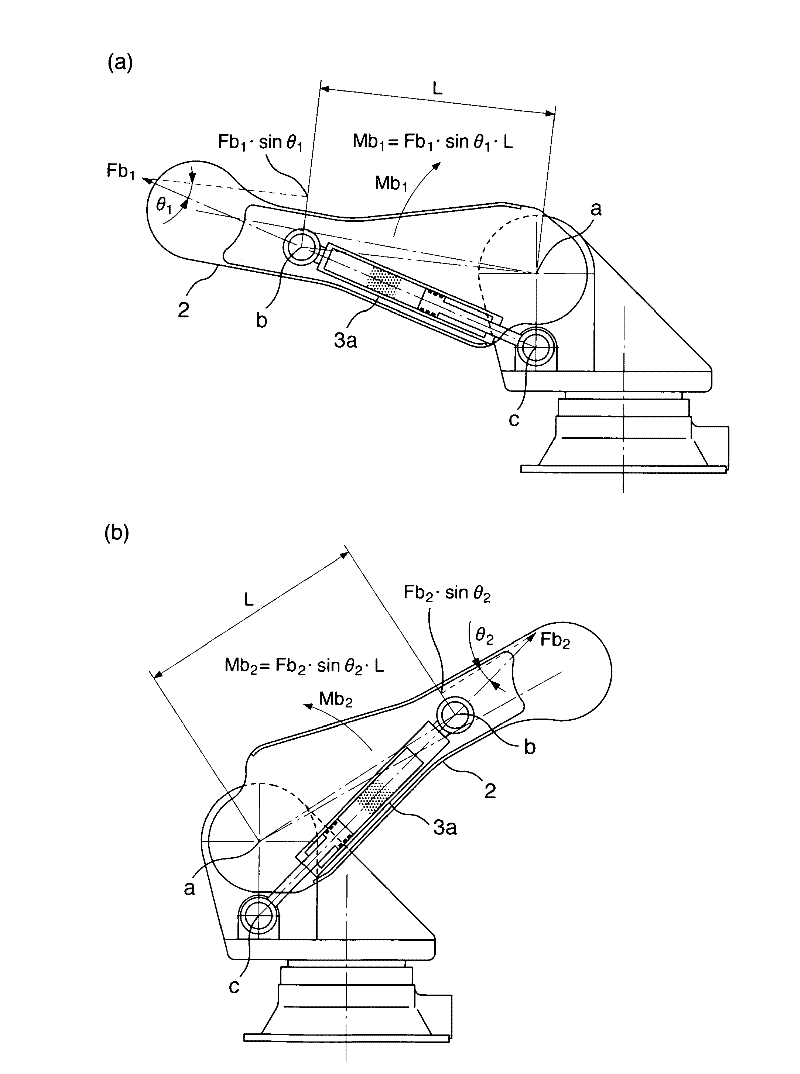

An industrial robot 10 comprises an arm 2 which includes a proximal portion rotatably supported on a horizontal rotation shaft of a frame 1 in a cantilever state, a cylindrical case portion formed from the proximal portion side to a distal end of the arm to have an opening portion on the proximal portion side, and an arm distal end portion. The industrial robot also comprises a balancer device which includes a rod 3b , and a cylinder 3a in which the rod 3b is reciprocated. An engagement portion at a distal end of the rod, and a rear end 5 of the cylinder are rotatably supported between a pair of first support portions c of the frame, and between a pair of second support portions b inside the cylindrical case portion, respectively, so that the cylindrical case portion and the balancer device do not interfere with each other in an extent of rotation of the arm.

Owner:NACHI-FUJIKOSHI

Linear motion guide rail engine

InactiveCN102400785AReduce friction lossEliminate frictional lossesMachines/enginesLinear motionEngineering

The invention relates to a linear motion guide rail engine; a piston is fixed by a linear motion guide rail device and makes reciprocating linear motion on the basis of reserving the whole structural form of the original engine, the structure of the piston is improved, the height of a cylinder is reduced, and the stroke of the piston is increased, so that the output power of the engine is improved, and the power performance, the economic performance and the emission performance of the engine can be improved; and therefore, the linear motion guide rail engine which is low in consumption and high in power can be provided for the technical field of the engine.

Owner:李长松

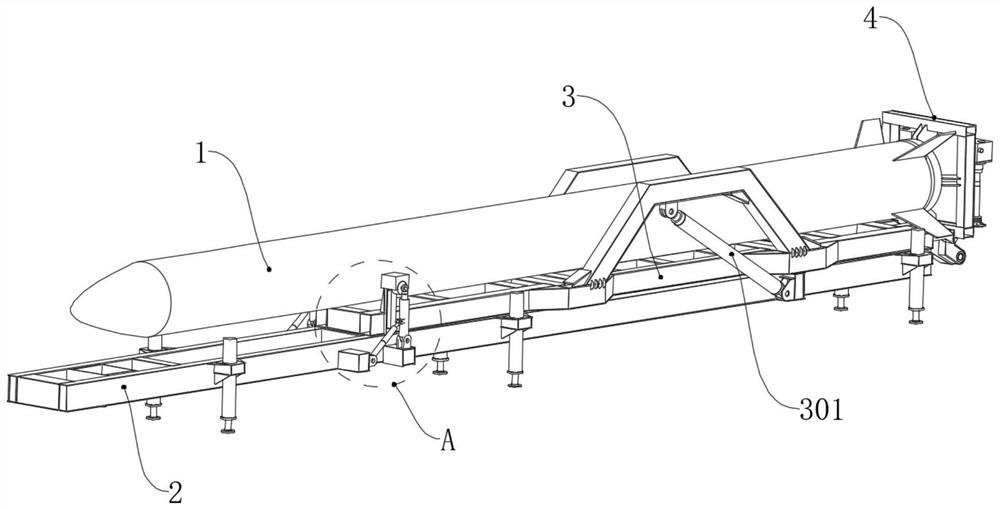

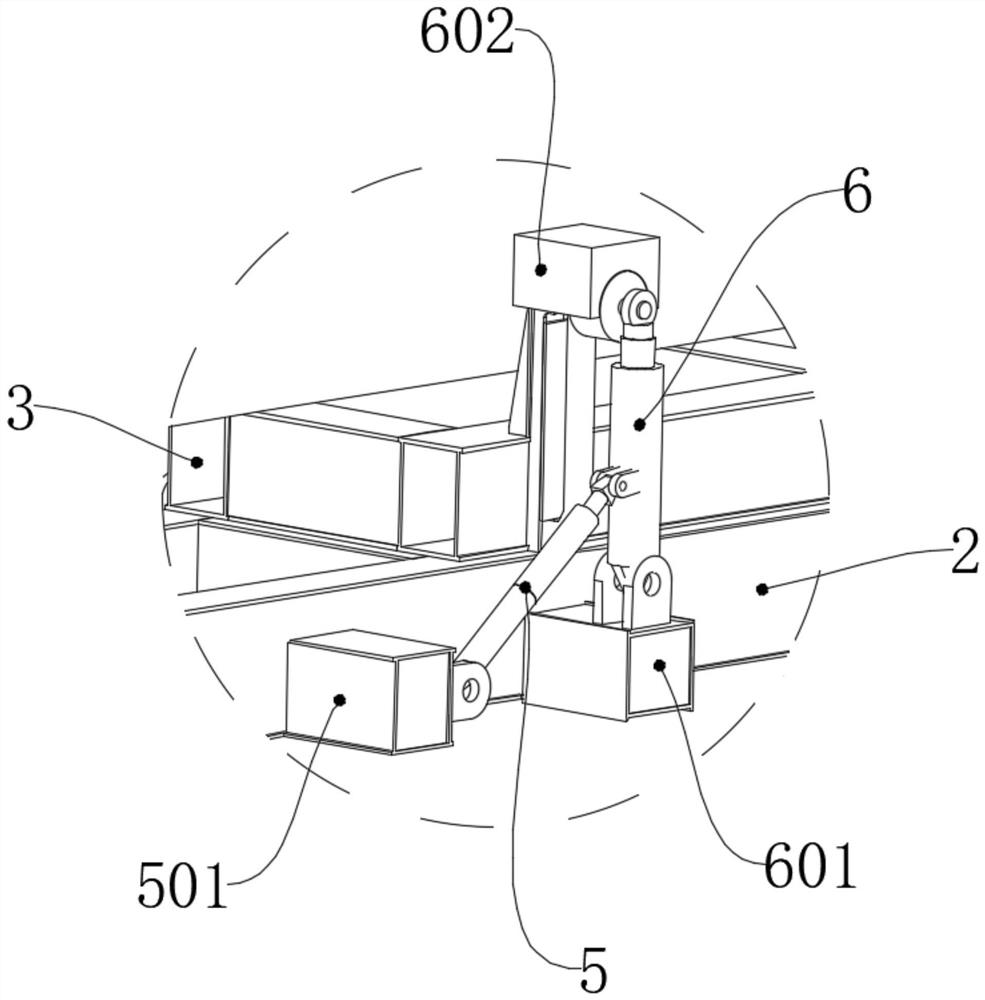

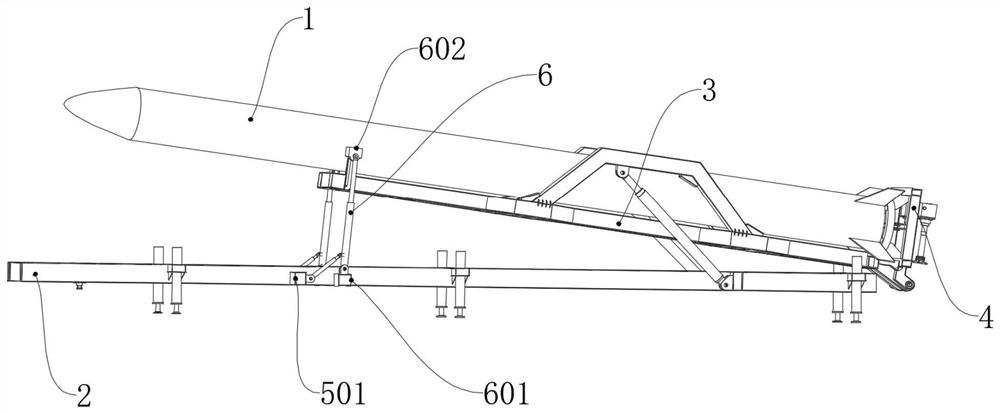

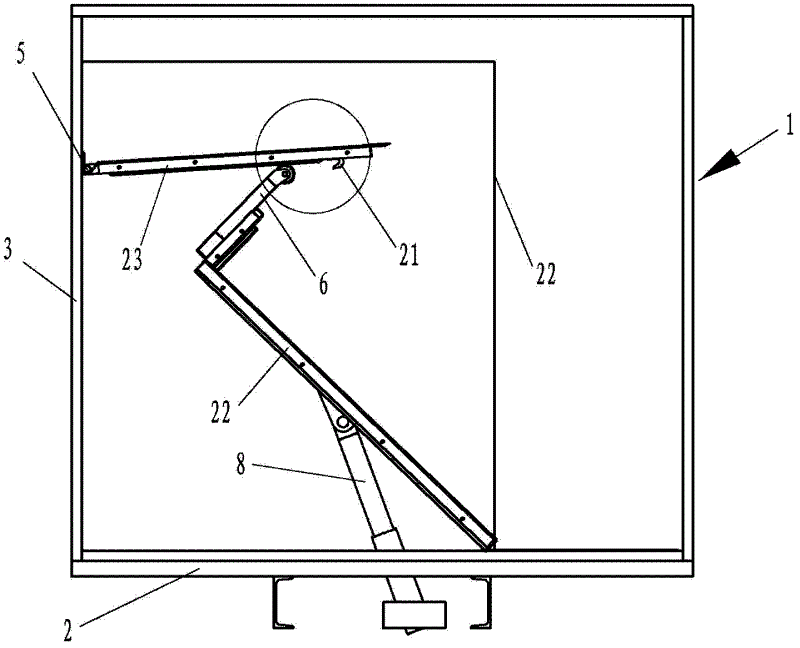

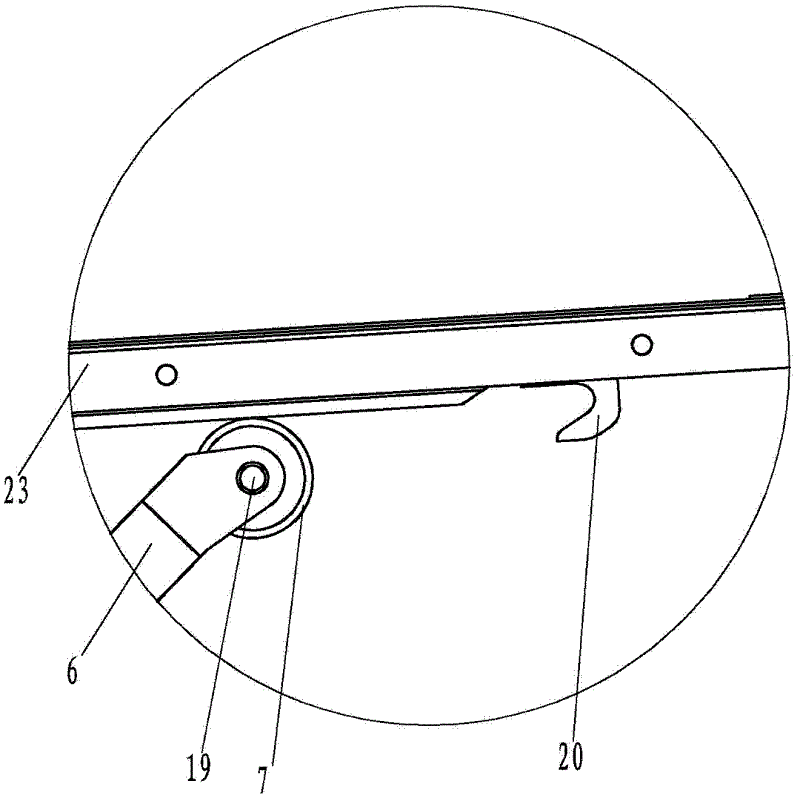

Launching vehicle with locking mechanism and auxiliary erecting device

PendingCN113959259AGuaranteed connection accuracyReduce adverse effectsRocket launchersVehicle frameRocket

The invention provides a launching vehicle with a locking mechanism and an auxiliary erecting device. The launching vehicle comprises the locking mechanism and the auxiliary erecting device, wherein one end of the auxiliary erecting device is hinged to a frame through a spring lower hinged support; the other end of the auxiliary erecting device is a movable end; the movable end is sleeved with a spring upper hinged support; the spring upper hinged support is hinged to an erecting arm; the locking mechanism is installed on the erecting arm; and the locking mechanism is used for fixedly connecting the erecting arm and a launching pad. The launching vehicle solves the problems that the mode of manually assembling and disassembling the erecting arm and the launching pad is inconvenient to operate, the connecting precision is reduced, the requirement for structural rigidity in the rocket erecting process is high, and the cost is high, the process of manually connecting the launching pad and the erecting arm is replaced with the locking mechanism, the operation is convenient, the connecting precision is guaranteed, and the cost of each component in the rocket erecting process is reduced by utilizing the auxiliary erecting device.

Owner:BEIJING ONESPACE TECH CO LTD +4

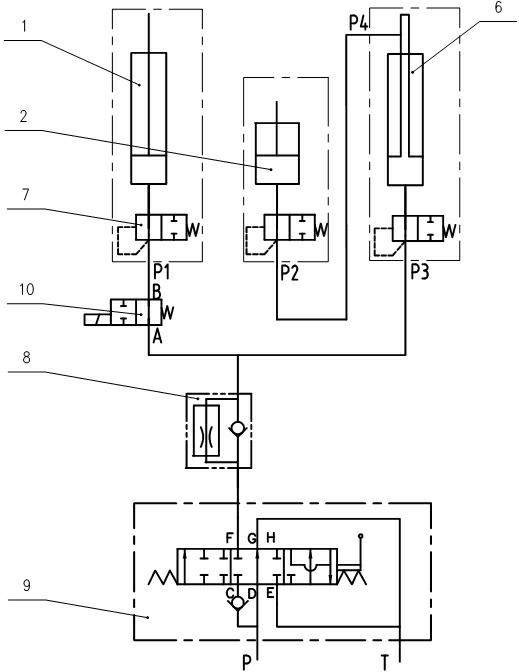

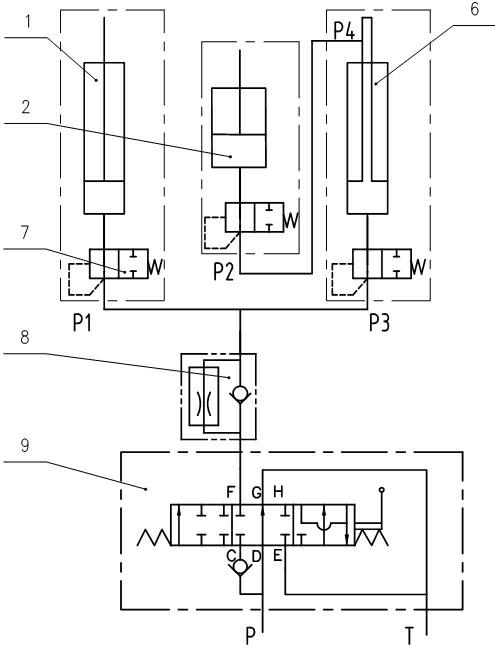

Hydraulic pipeline system for forklift two-section full-free gantry

ActiveCN102530780AExpand field of viewConsistent speedLifting devicesBlocked valvesElectromagnetic valve

The invention relates to a hydraulic pipeline system for a forklift two-section full-free gantry. The system comprises a left rear lifting oil cylinder, a right rear lifting oil cylinder, a front lifting oil cylinder, a speed limiting valve and a lifting valve. The lifting valve is a three-position six-way valve. The hydraulic pipeline system is improved in that a two-position two-way electromagnetic valve is connected in series at an inlet of a block valve on an oil inlet of the left rear lifting oil cylinder; the effective working area of the front lifting oil cylinder is equal to twice of the sum of the effective areas of the left rear lifting oil cylinder and the right rear lifting oil cylinder; and the effective area of the left rear lifting oil cylinder is equal to that of the rightrear lifting oil cylinder. As the two-position two-way electromagnetic valve is added and the cylinder diameter of the front lifting oil cylinder is obtained by reducing the cylinder diameter of the front lifting oil cylinder of a common two-section full-free gantry, the gantry can be ensured to have consistent speed in the complete lifting process, the pressure fluctuation of the hydraulic system is reduced, the comfort of a driver is improved and the visual field of the gantry is enlarged.

Owner:ANHUI HELI CO LTD

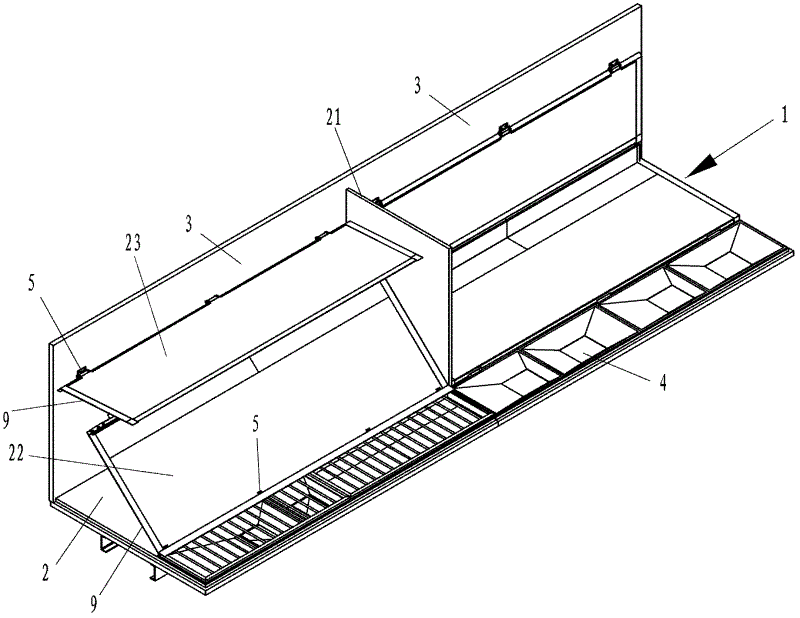

Bulk cargo transport vehicle carriage with unloading system

InactiveCN102616165AImprove securityImprove reliabilityVehicle with loading rampRear quarterBulk cargo

The invention discloses a bulk cargo transport vehicle carriage with an unloading system. The carriage comprises a bottom plate and side plates; the unloading system is arranged in the carriage and comprises movable side plates and a movable bottom plate; the movable side plates are arranged on the side plates of the carriage; straight rods are respectively arranged at the ends of the sides, which are close to the movable side plates, of the movable bottom plate, rollers are disposed at the top ends of the straight rods, each straight rod is disposed between the corresponding movable side plate and the corresponding side plate, so that the movable side plates can be jacked up when the movable bottom plate turns over, and further, the movable side plates turn over; and the lower end of the movable bottom plate is fixedly connected with a hydraulic lifting mechanism used for jacking up the movable bottom plate and leading the movable bottom plate to turn over. The bulk cargo transport vehicle carriage with the unloading system has the advantages that the purpose of completely unloading without lifting the carriage can be realized, safety and reliability are good, cost is low, and the like.

Owner:ANHUI BOWEI CHANGAN ELECTRONICS

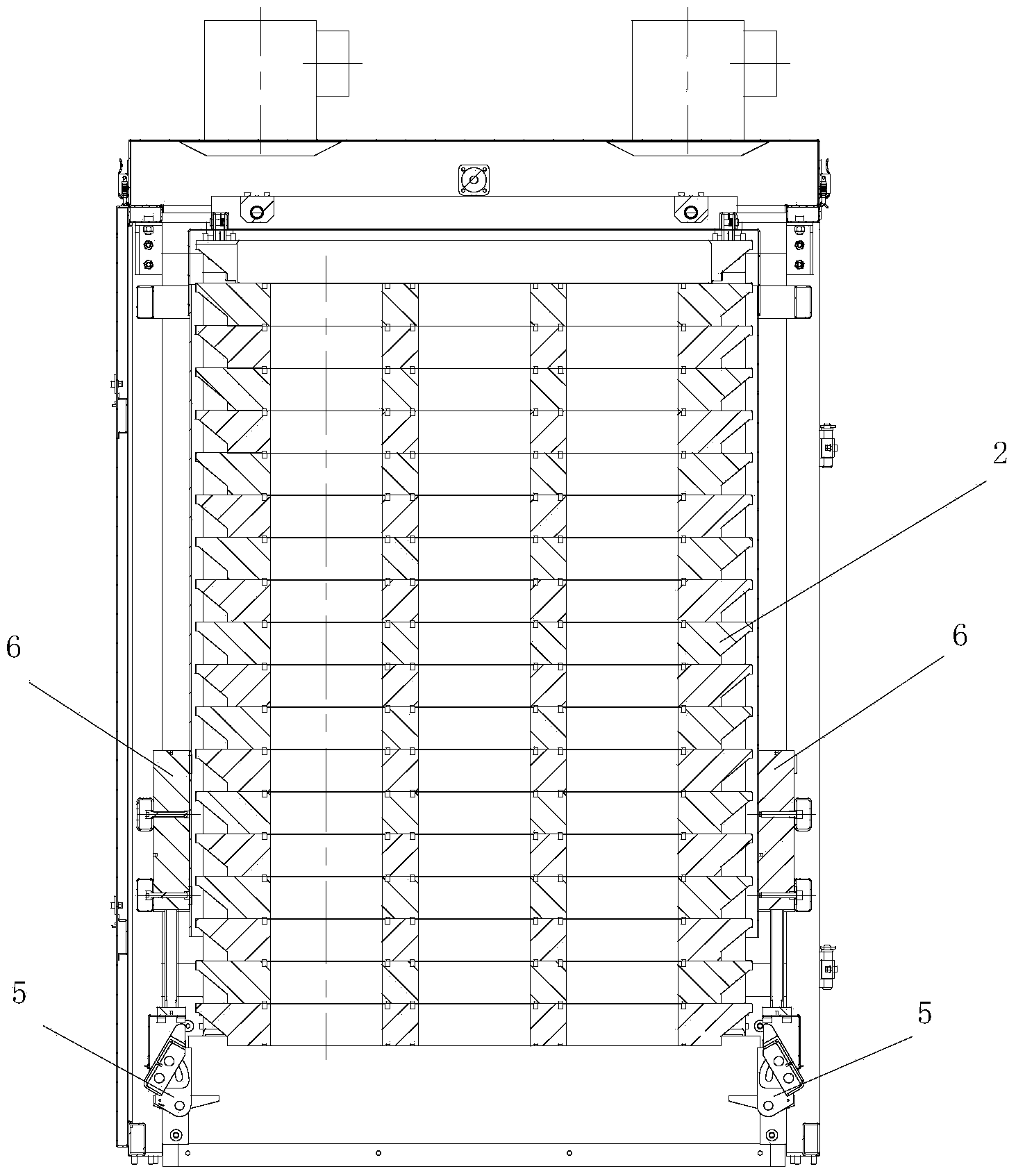

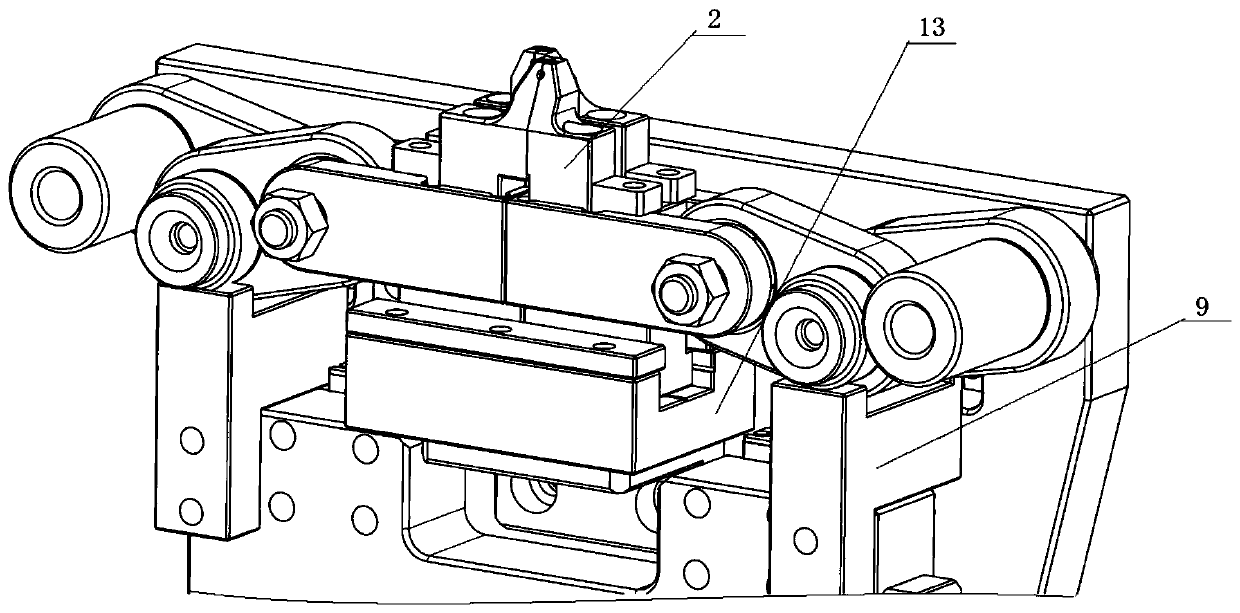

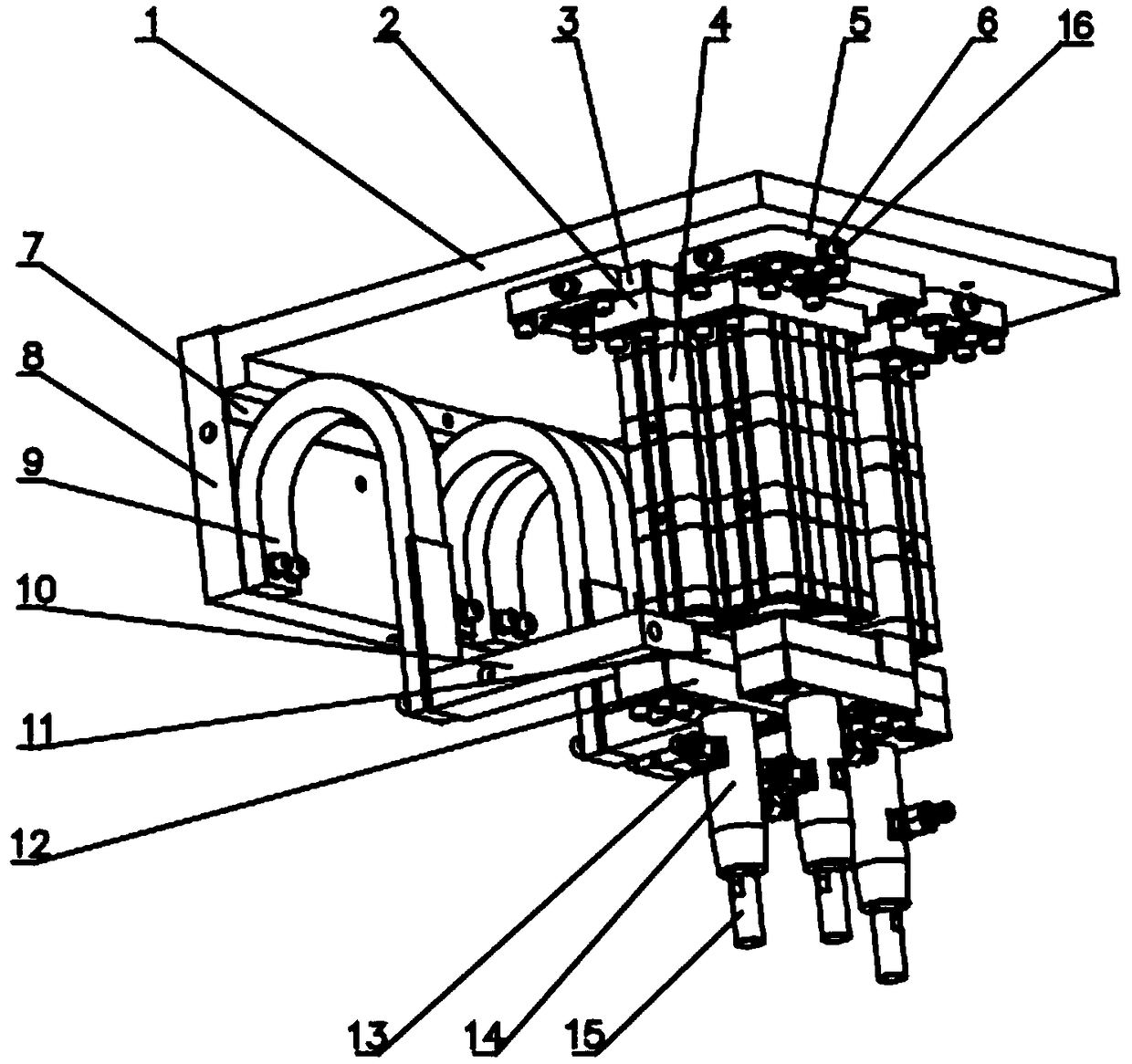

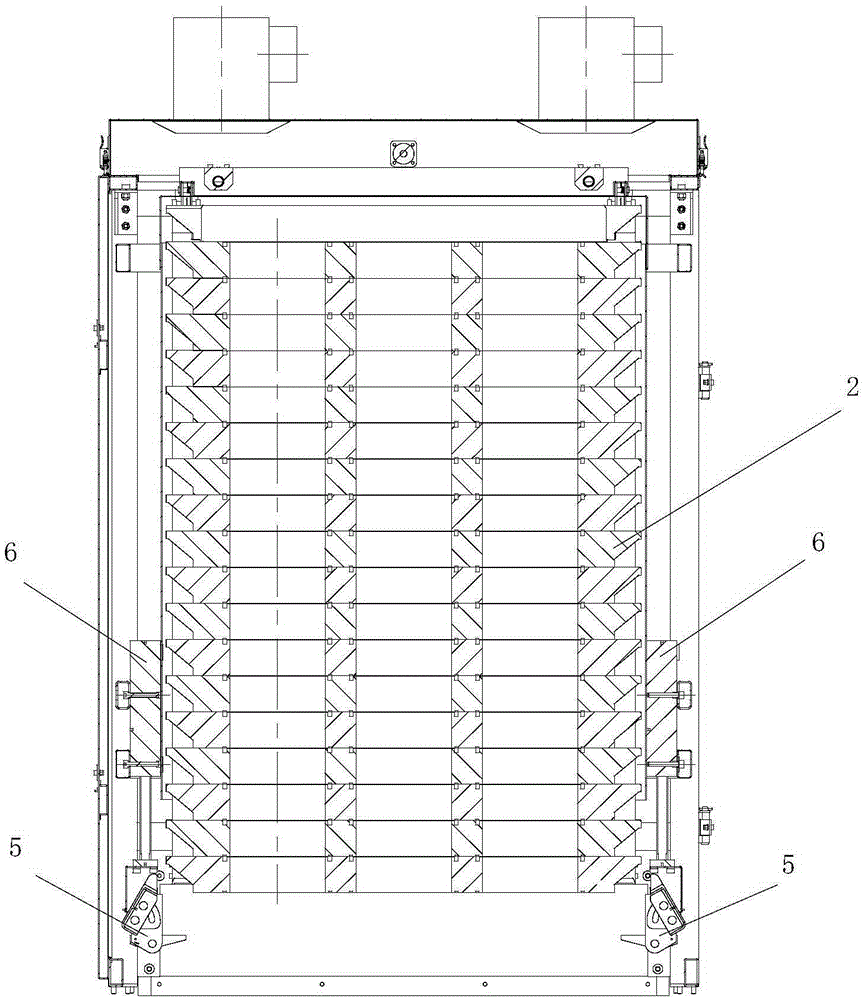

Stacking manipulator capable of expanding, opening and closing employing connecting rod mechanism

ActiveCN106829515AImprove space utilizationImprove securityStacking articlesDe-stacking articlesEngineeringManipulator

The invention discloses a stacking manipulator capable of expanding, opening and closing employing a connecting rod mechanism. The stacking manipulator comprises a palm for clamping turnover boxes through a cylinder-driven force amplifier, and fingers which are carried by guide rods of a double-guide rod thin cylinder and are stretched into a horizontal state by a thick connecting rod to liftthe turnover boxes. The manipulator has the function of horizontally or vertically clamping a corrugated case and the plastic turnover boxes, and is capable of horizontally or vertically lifting the plastic turnover boxes in a non-clamping manner by virtue of long handles at two sides; and especially the stacking manipulator does not need an action space at the outer side of one box body during verticalliftingin a stretching manner and four side surfaces of the box body can be kept seamlessly clung to other box bodies. The stacking manipulator has the advantages of being high in space utilization rate, high in security and low in energy consumption, and belongs to the field of transport package, logistics transportation requirement and robots.

Owner:JIANGNAN UNIV

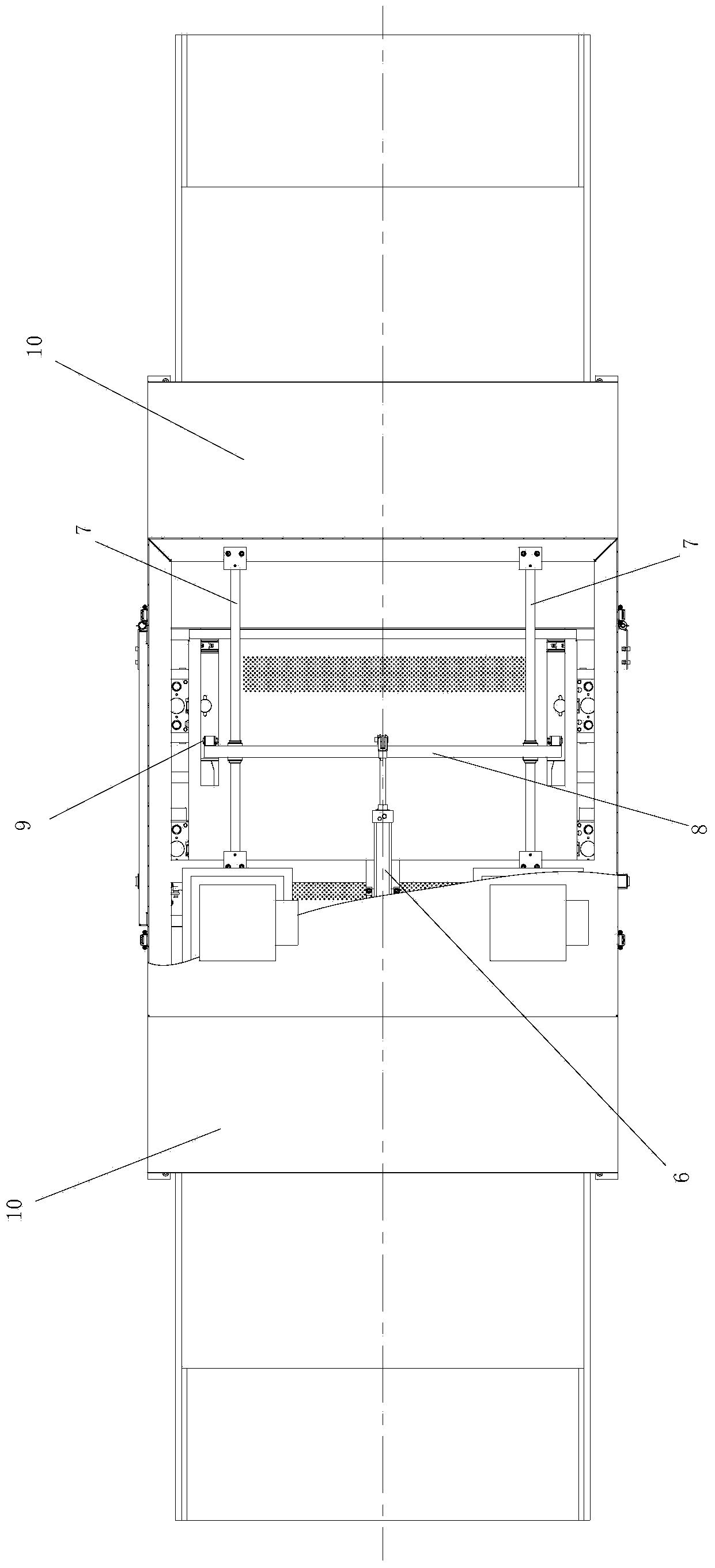

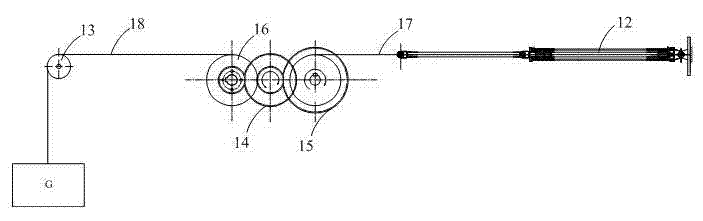

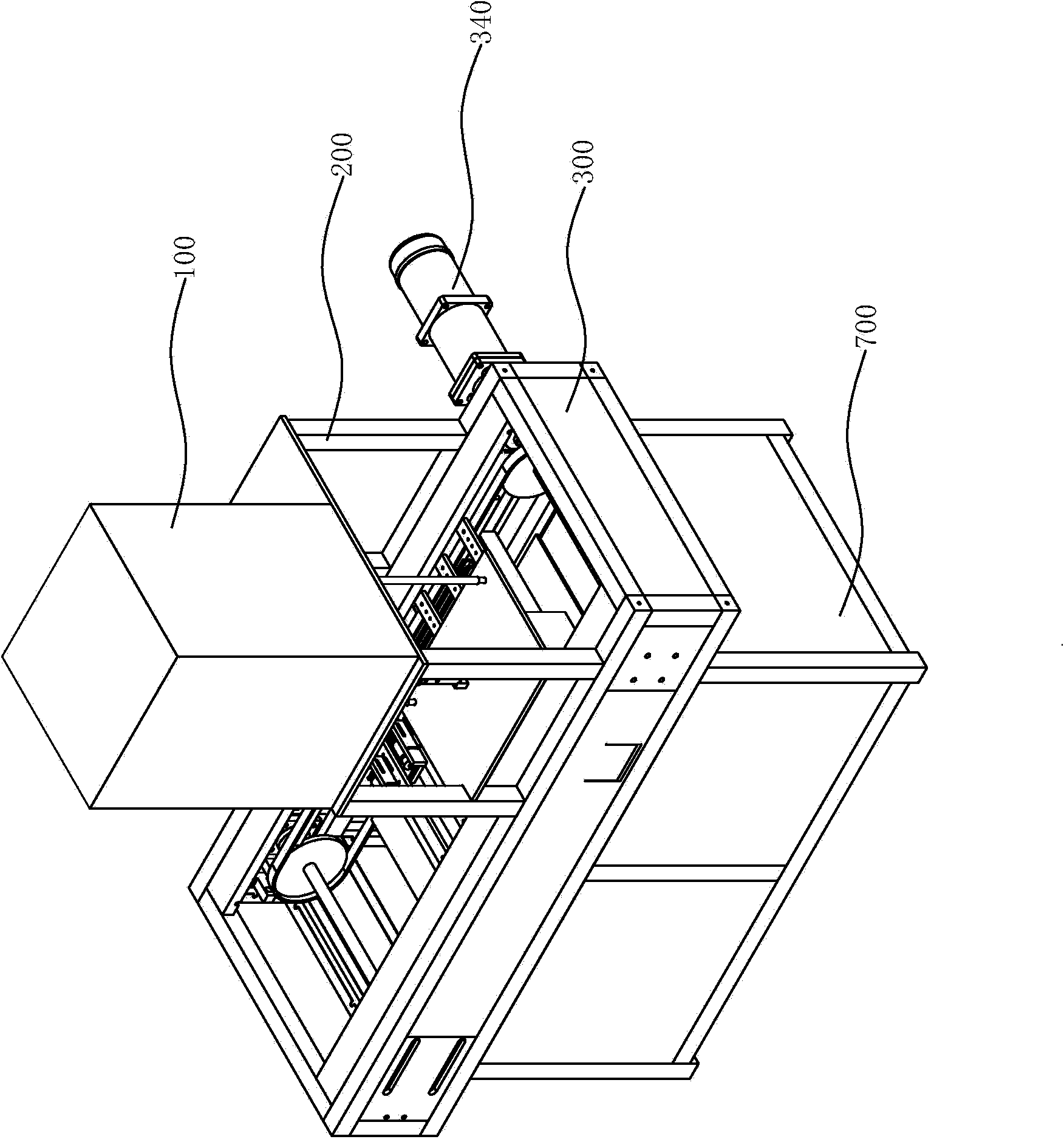

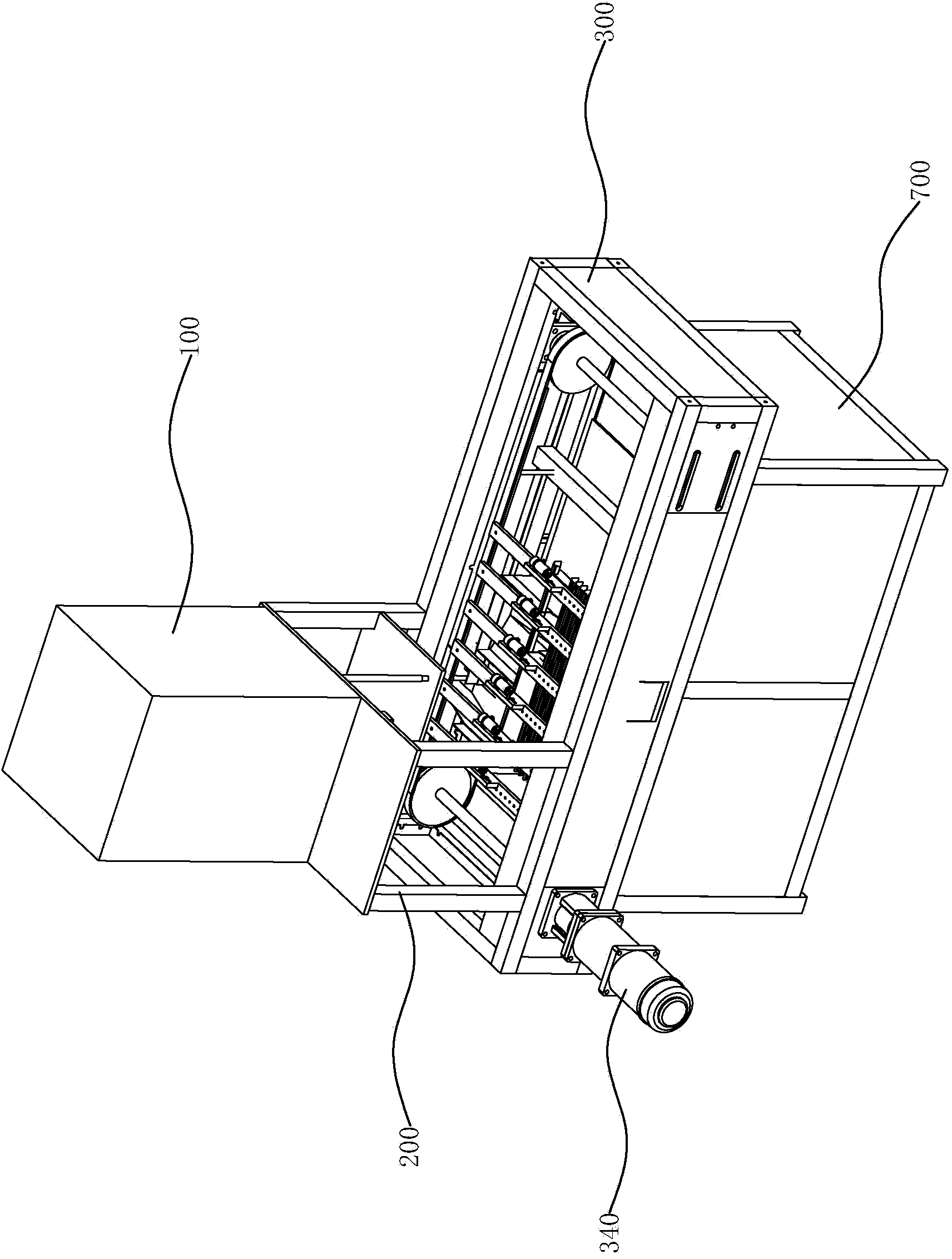

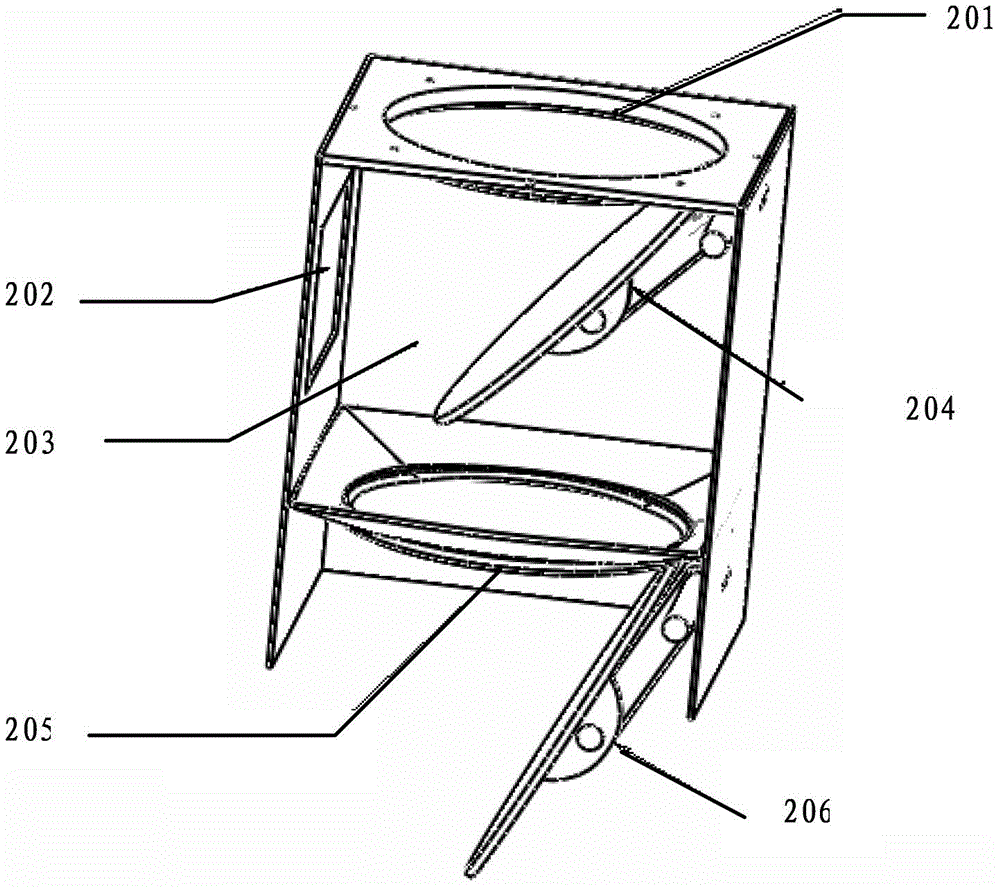

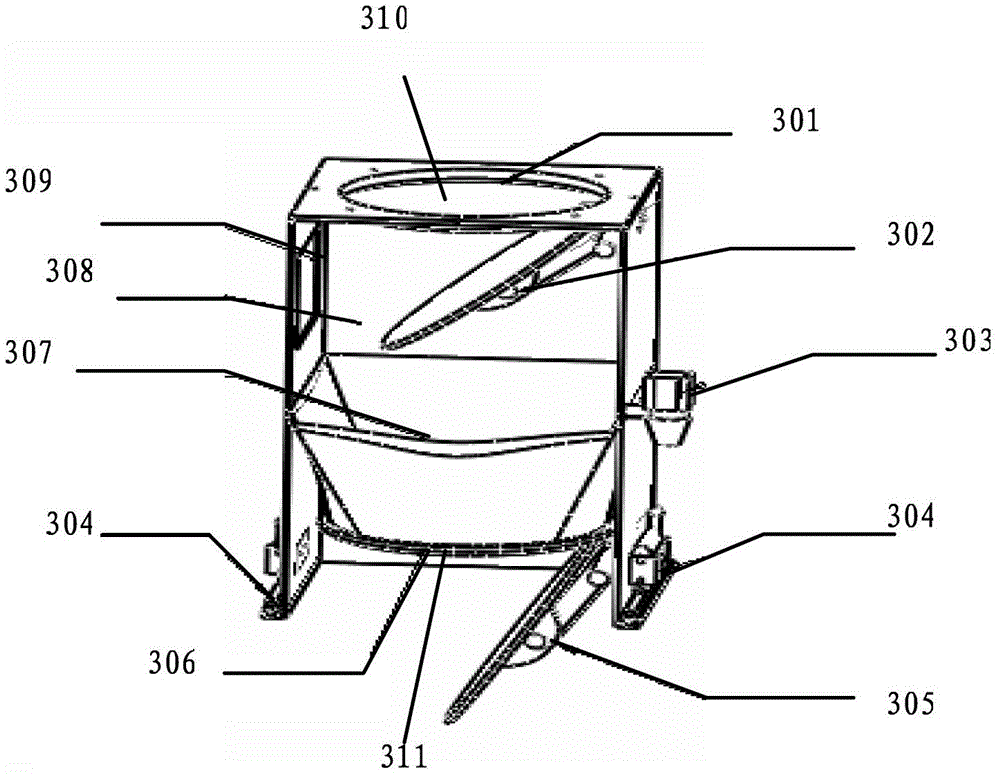

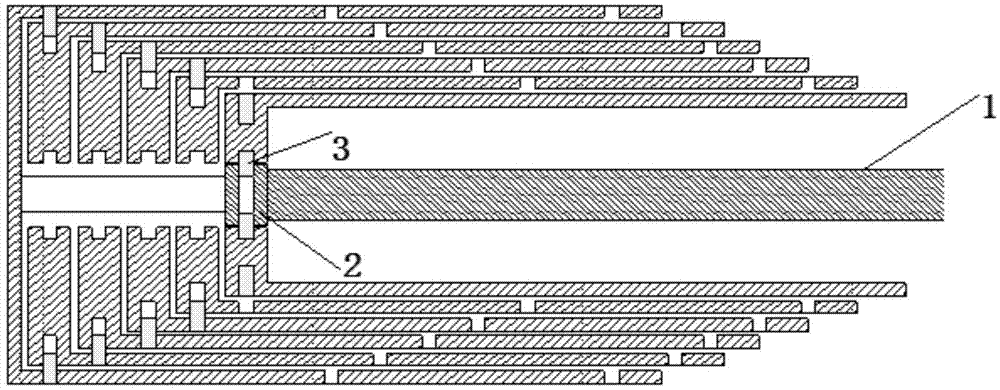

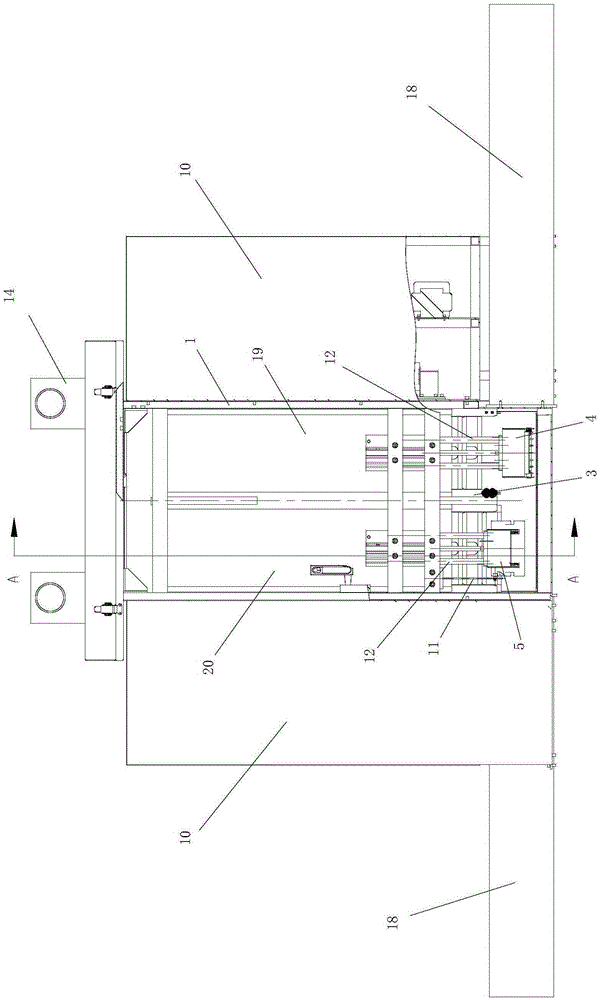

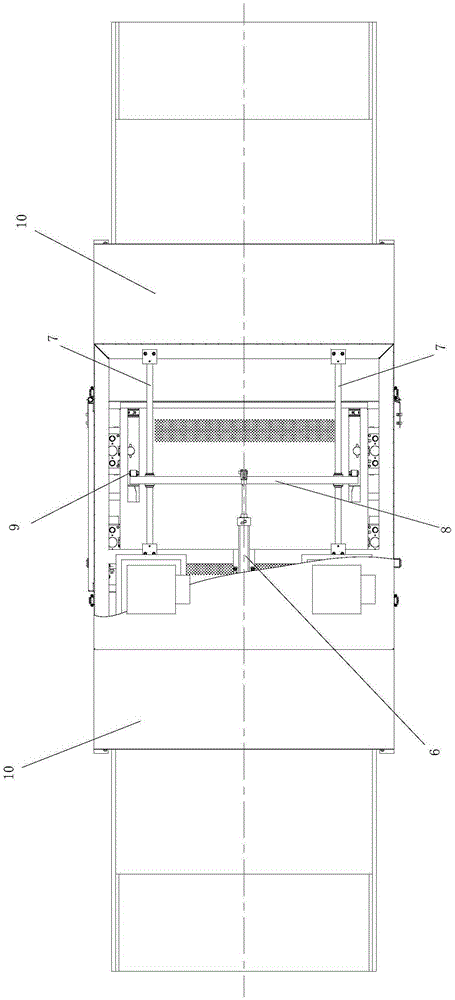

Multifunctional rolling type steam box production line

ActiveCN103654379AIncrease productivityEnsure safetyCooking vesselsProduction lineIndustrial engineering

The invention relates to a multifunctional rolling type steam box production line. The production line comprises a square box frame without a bottom, a heat source and a plurality of molds which are used for containing foods and can be mutually stacked, wherein each mold is a square framework, an air exchange opening is formed in the top of the square box frame, and the bottom of the square box frame is fixed to a rail of the production line. The production line is characterized in that the square box frame is divided into a lifting side and a releasing side which are symmetrical, a pile of molds are arrayed in the lifting side, a pile of molds are arrayed in the releasing side, a lifting mechanism is arranged on the lifting side, a releasing mechanism is arranged on the releasing side, a flat pushing mechanism is arranged at the top of the square box frame, each mold on the rail of the production line is conveyed to the top of the lifting side by the lifting mechanism in a stepping mode, then conveyed to the top of the releasing side from the top of the lifting side by the flat pushing mechanism and finally conveyed to the rail of the production line in a stepping mode by the releasing mechanism, and the stepping interval is the height of one mold. Uncooked foods enter from the lifting side of the multifunctional rolling type steam box production line, cooked foods go out from the releasing side, and full-automatic production is achieved.

Owner:蒋群 +1

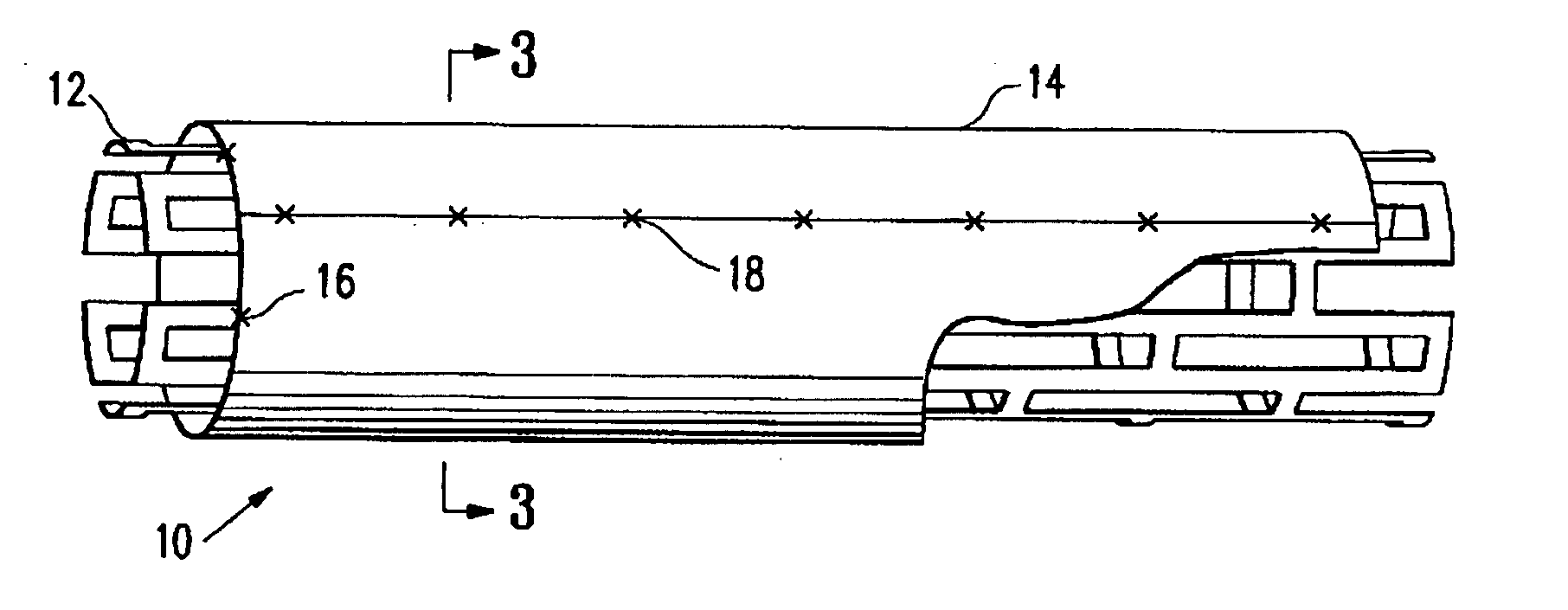

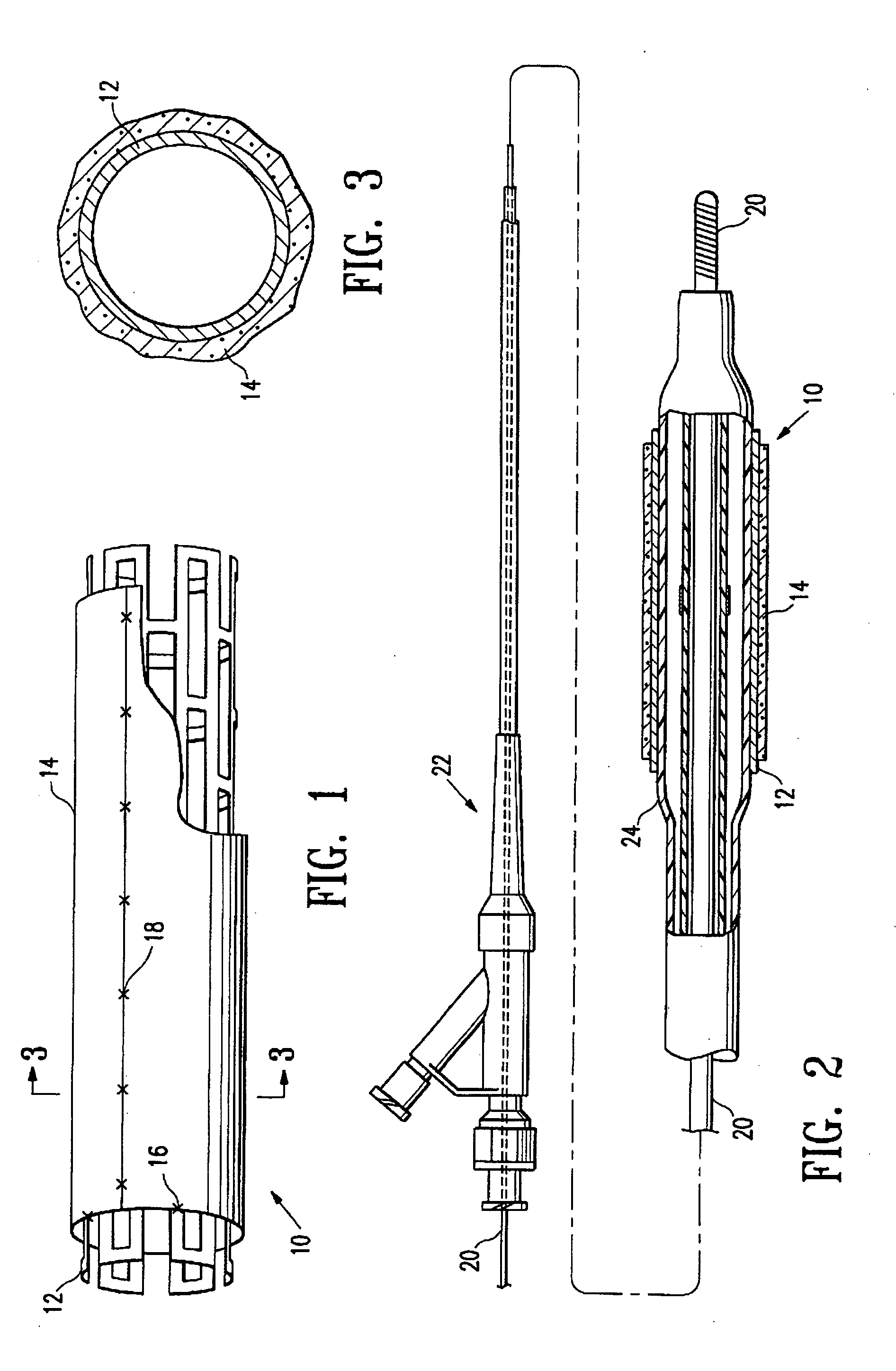

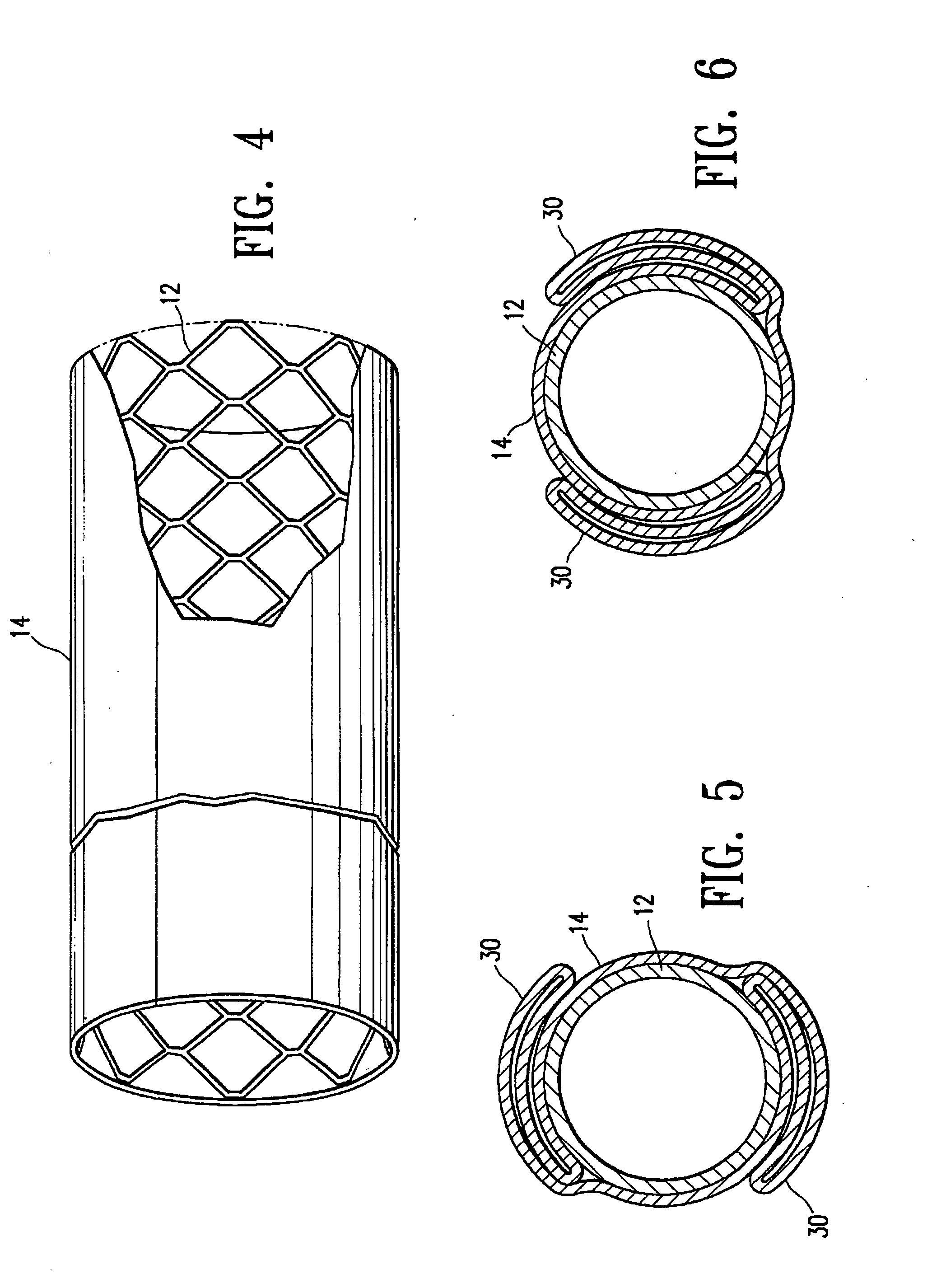

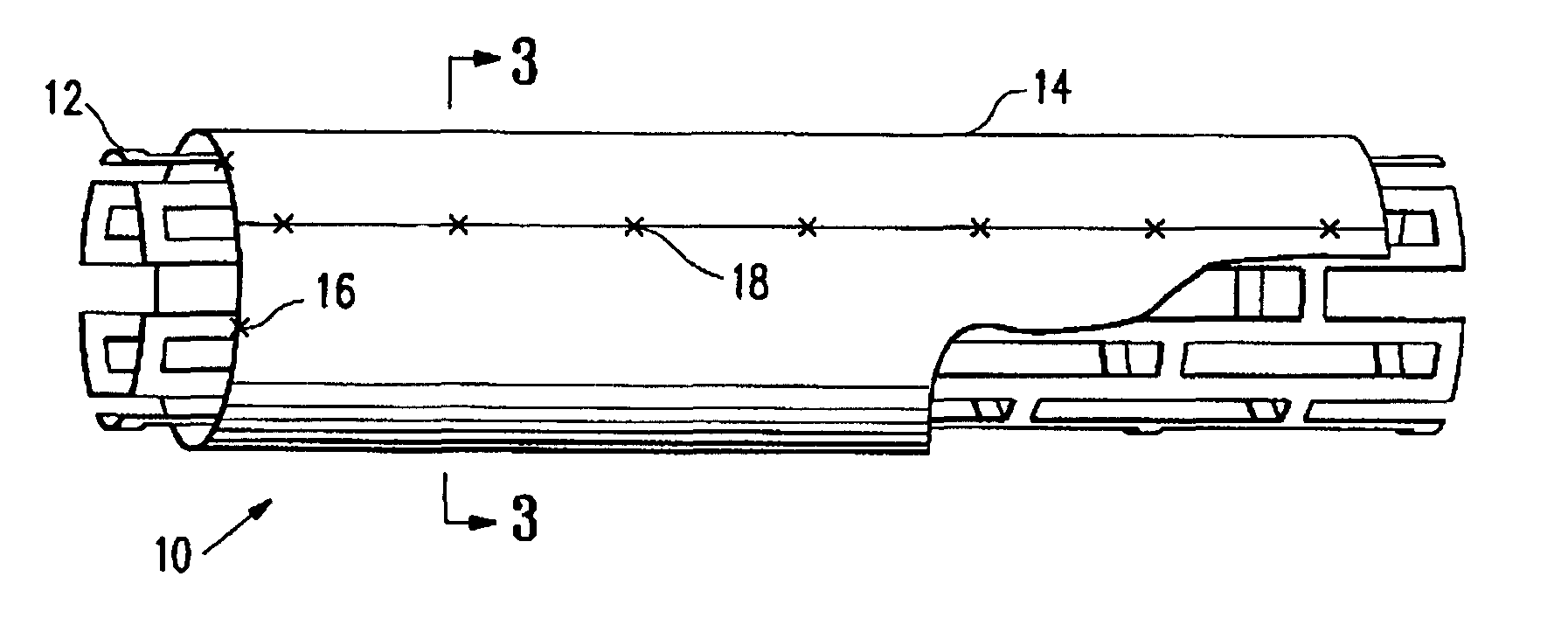

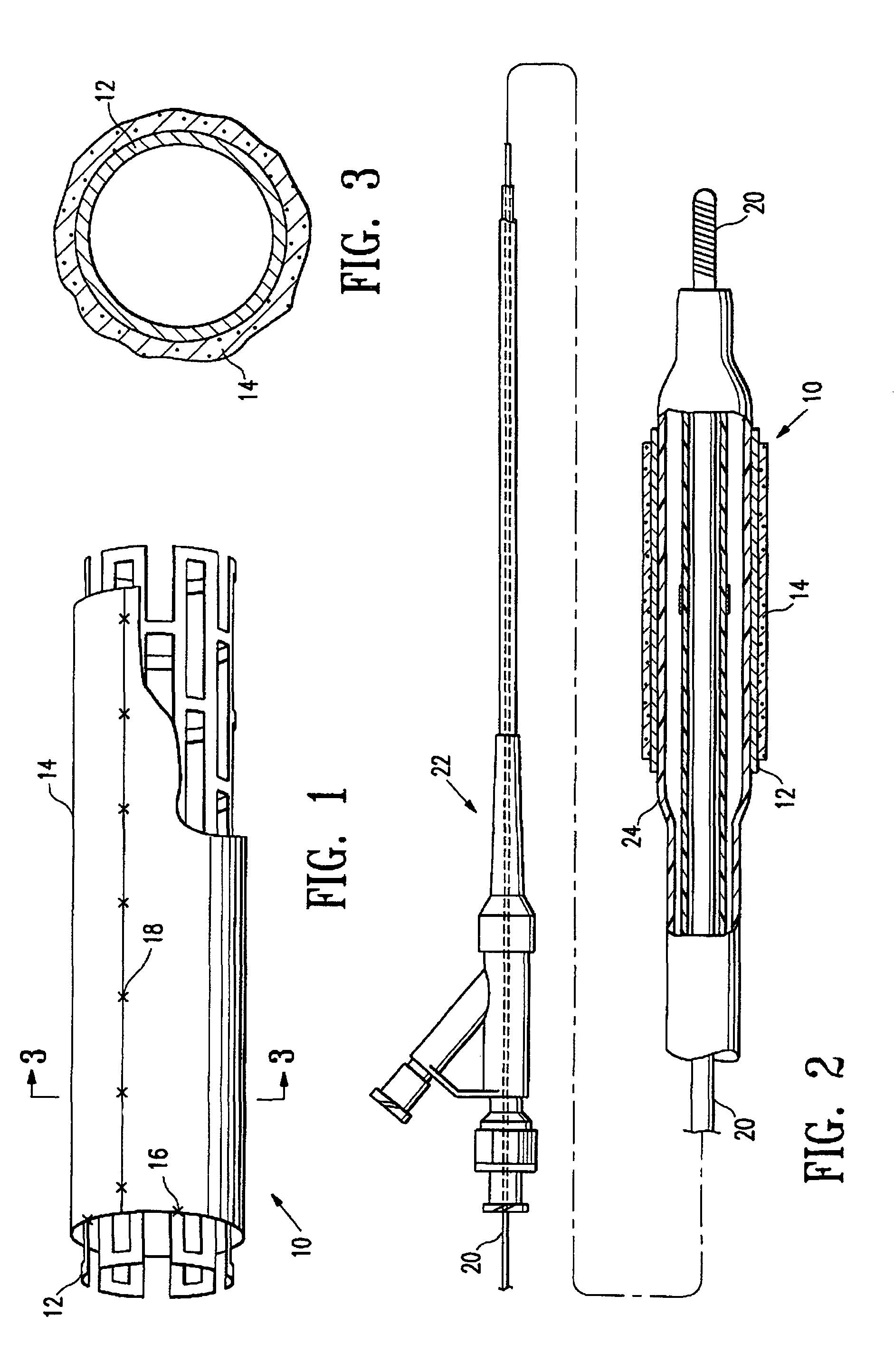

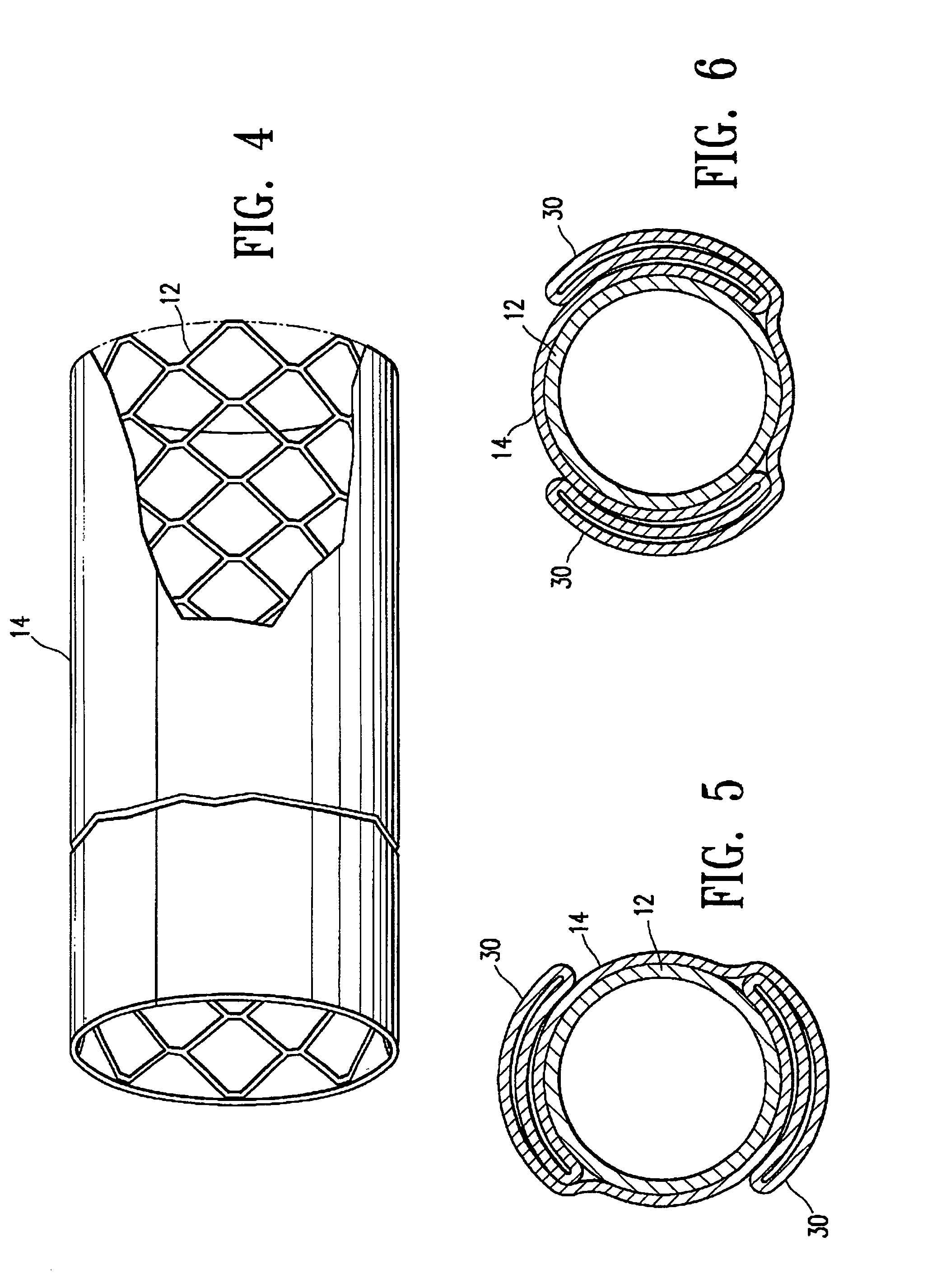

Non-thrombogenic stent jacket

Disclosed is the use of serous tissue, such as pericardium, as a component of intracorporeal implants. Particularly, disclosed is a jacketed stent assembly comprising an expandable stent provided with a jacket of processed serous tissue which, in some embodiments, is impregnated with a therapeutic or diagnostic agent. In a preferred embodiment, the jacket of the expandable stent is formed of pericardial tissue, preferably bovine or porcine pericardial tissue.

Owner:AMNIS THERAPEUTICS

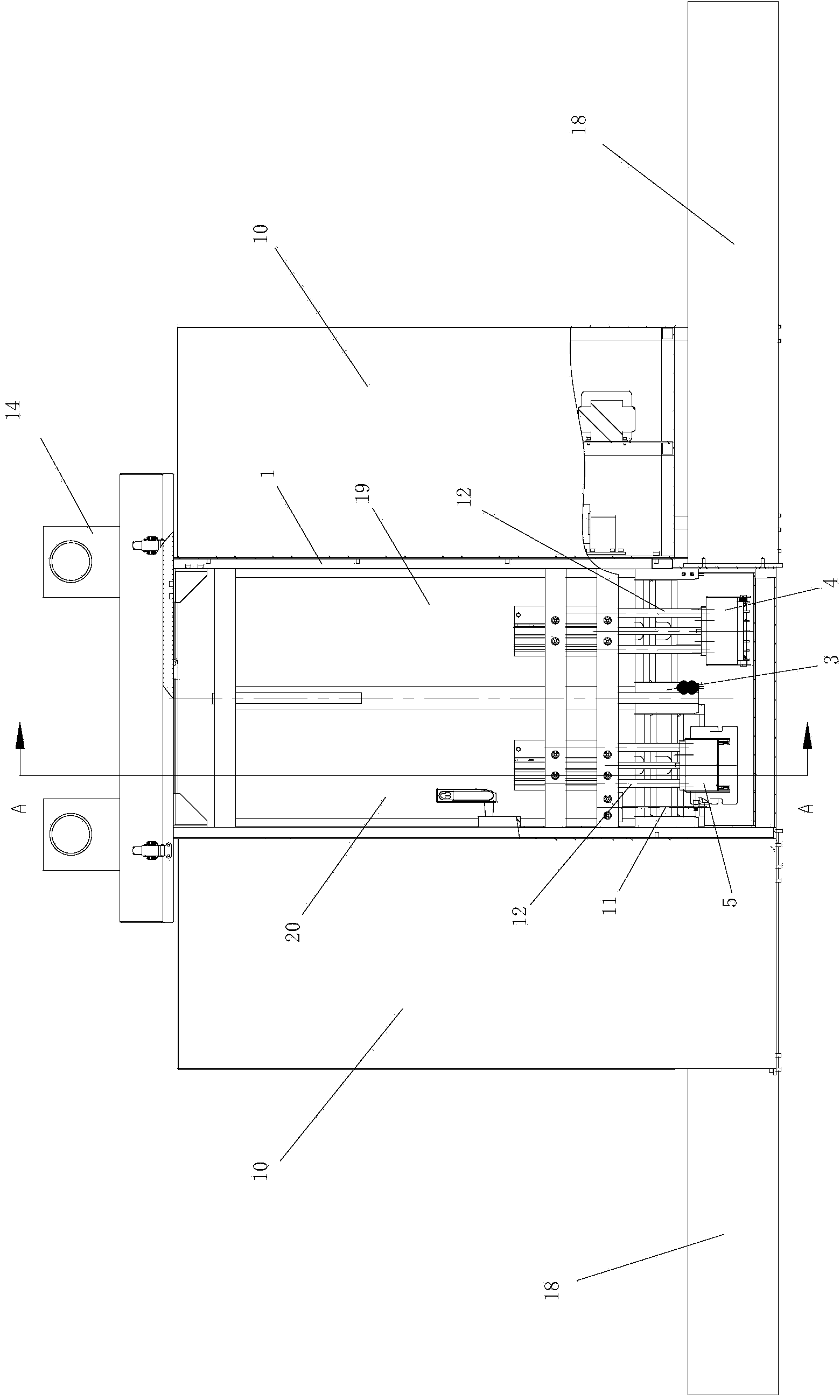

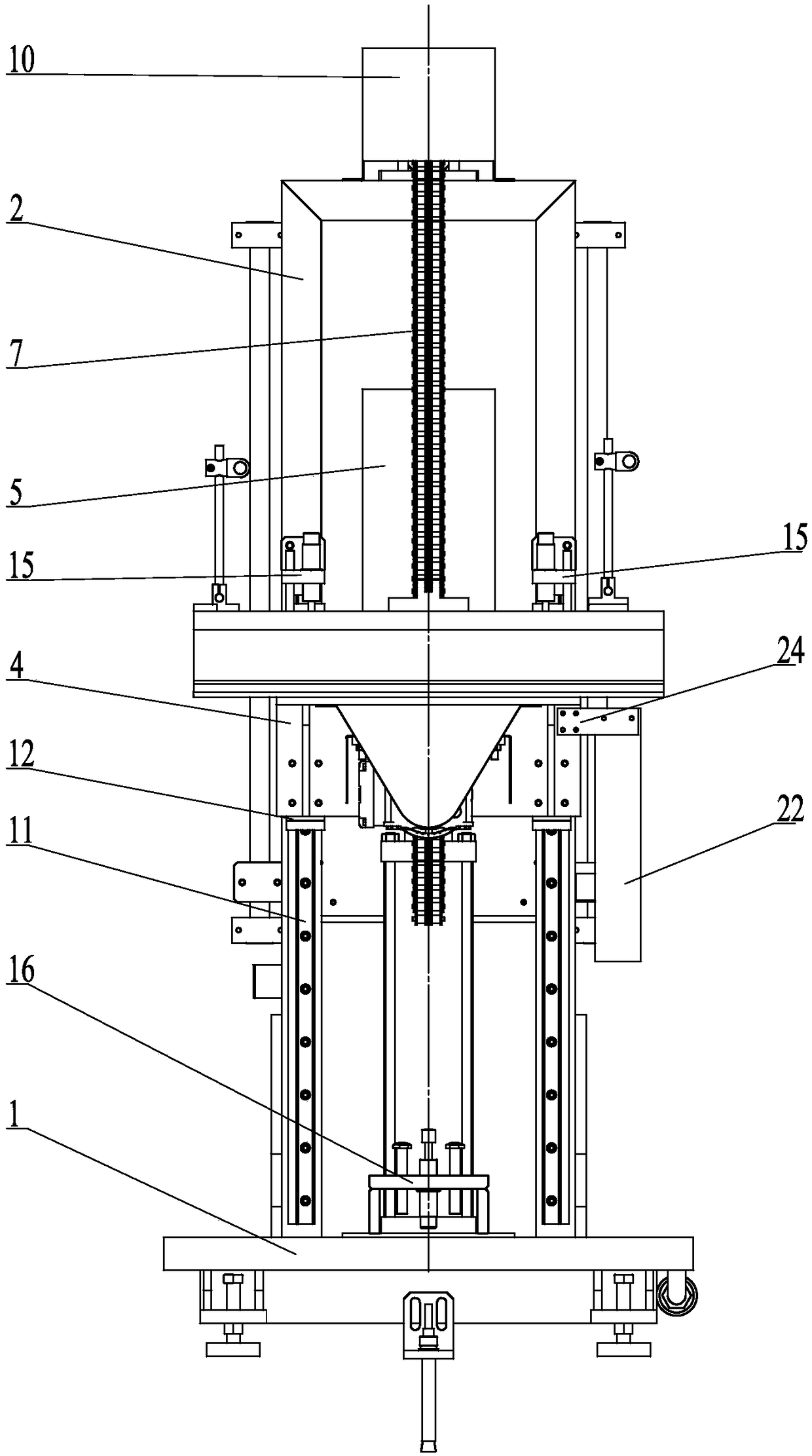

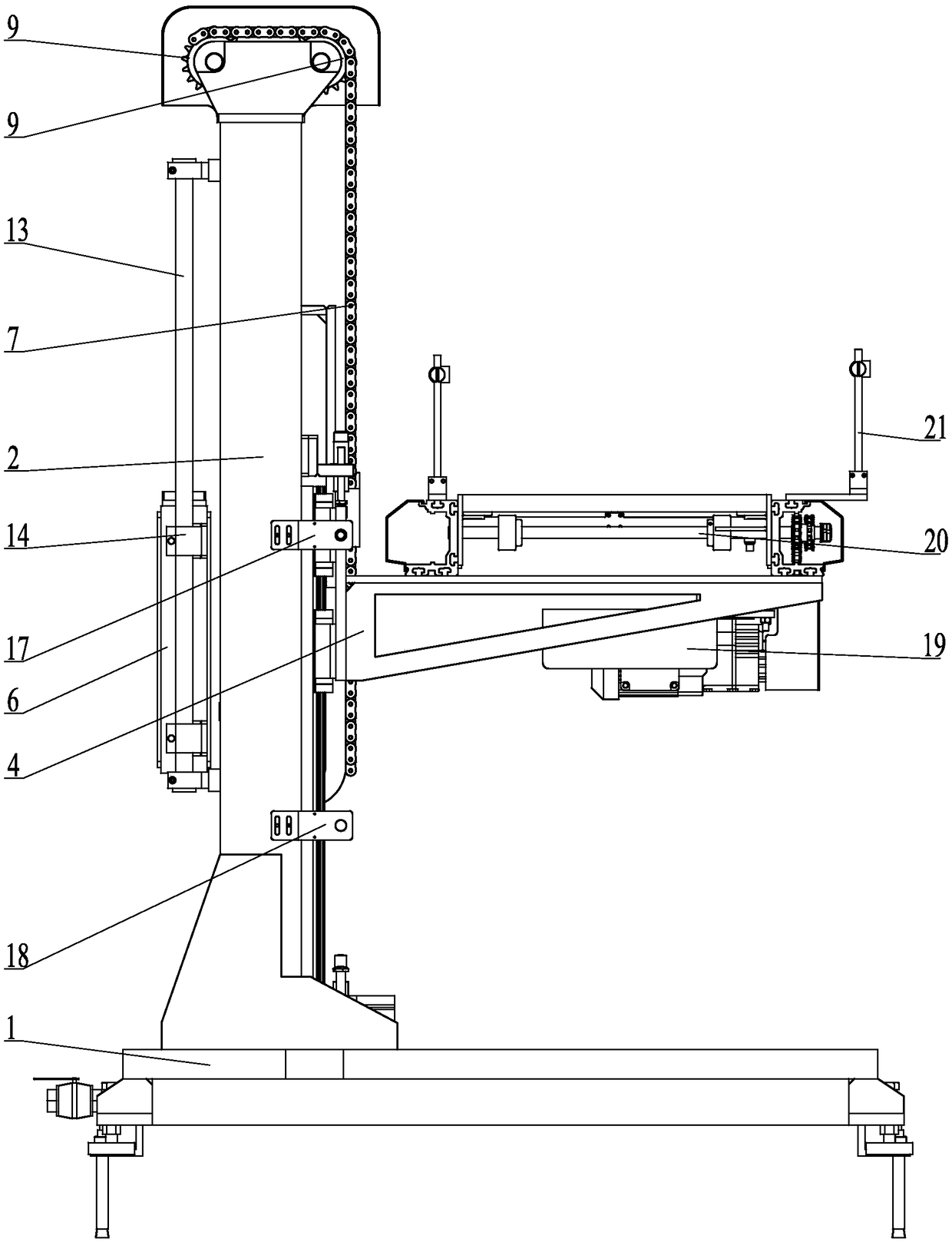

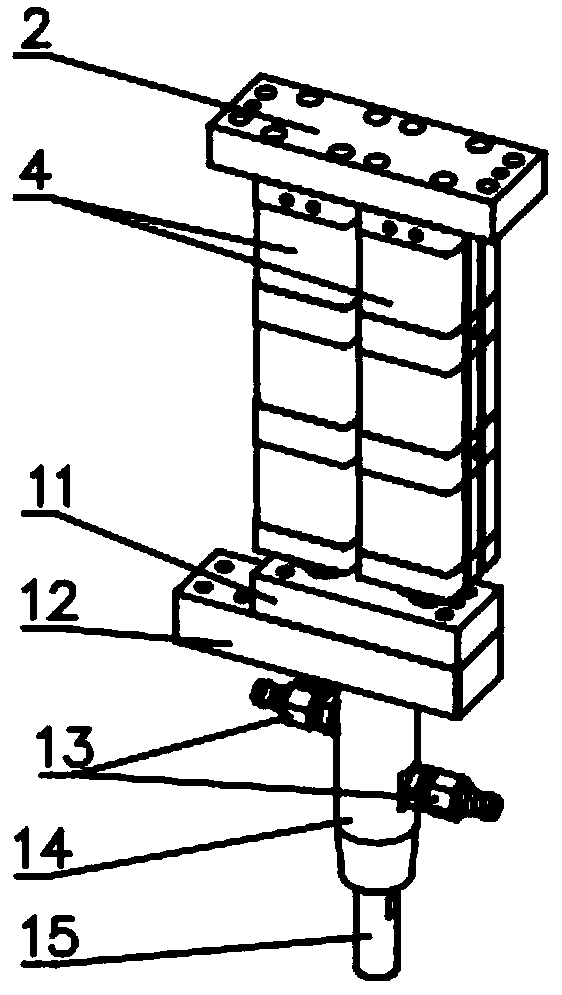

Side driving lifting roller bed with low energy consumption and high stability

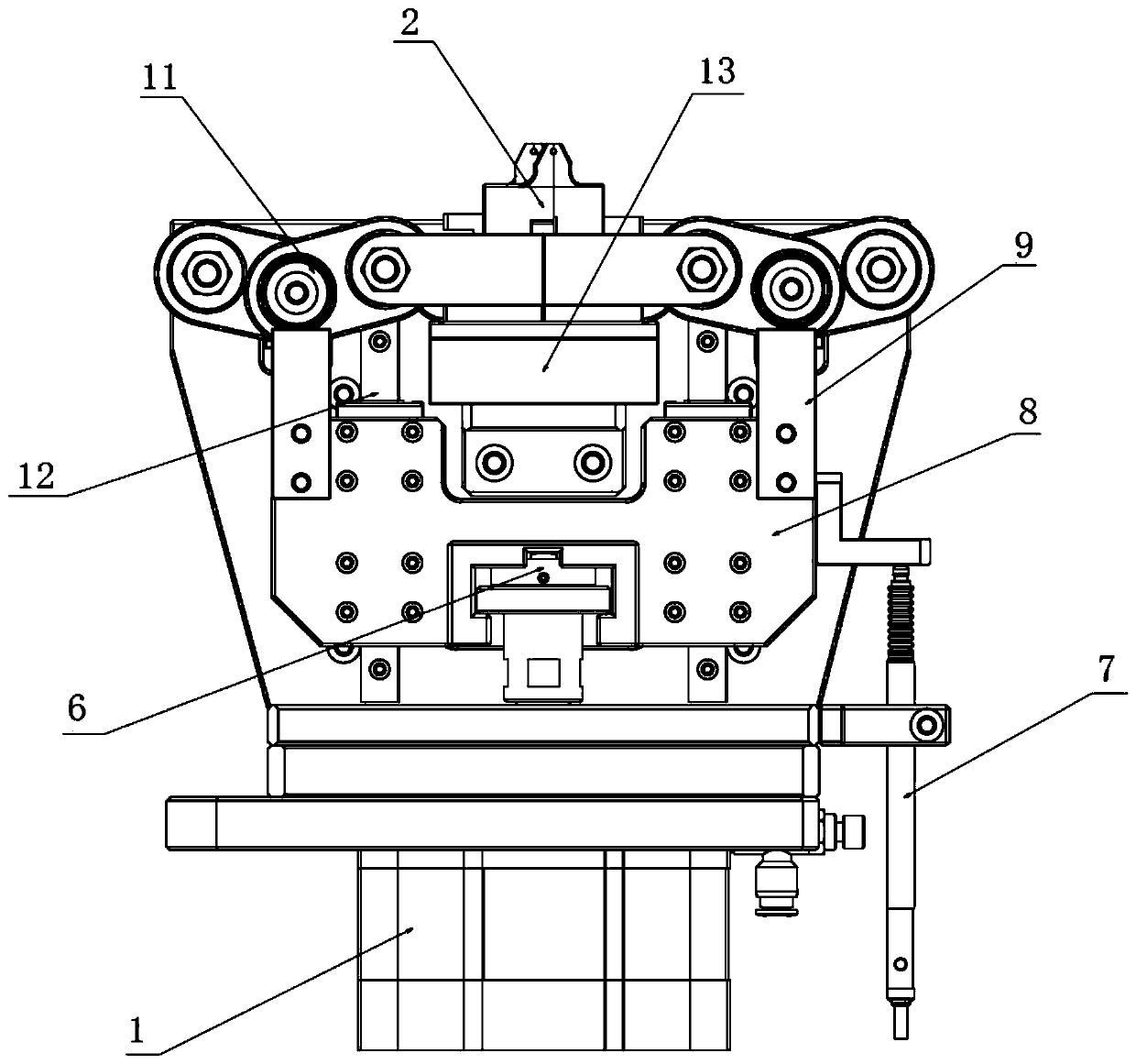

PendingCN109335617ASmooth and reliable actionAvoid vibrationConveyor partsRoller-waysReciprocating motionEngineering

The invention relates to the technical field of roller bed conveying and provides a side driving lifting roller bed with the low energy consumption and high stability in order to solve the problems that an existing lifting roller bed structure is large in occupied space, high in energy consumption and not stable enough in operation. The side driving lifting roller bed comprises a base, a support,a cylinder, a roller bed mounting rack, a cylinder connecting rack, a weight box, a chain, a chain transmission mechanism, a roller bed guide mechanism, a balance weight guide mechanism and a roller bed operating mechanism. The support is vertically and fixedly connected to one side of the upper end face of the base. The cylinder is arranged in the middle portion of the inner side of the support.The roller bed mounting rack is horizontally arranged at the front end of the support. The roller bed operating mechanism is arranged on the roller bed mounting rack. The rear end of the roller bed mounting rack is fixedly connected with a piston rod of the cylinder through the cylinder connecting rack. The weight box is arranged at the rear end of the support. The middle portion of the chain is rotatably connected with the support through the chain transmission mechanism. The two ends of the chain does reciprocating motion in the vertical direction of the support. The weight box and the roller bed mounting rack are fixedly connected with the chain correspondingly. The side driving lifting roller bed is applied to a roller bed conveying line.

Owner:HARBIN SHIMADA BIG BIRD IND

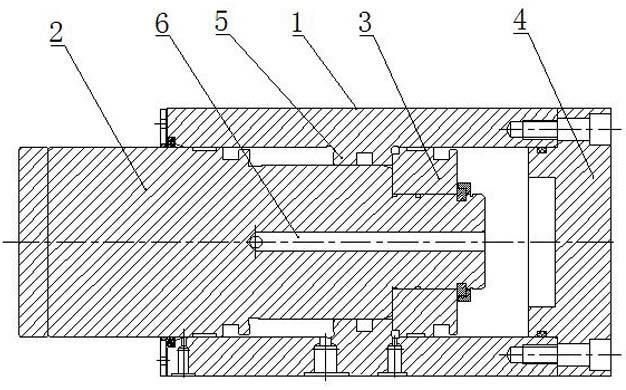

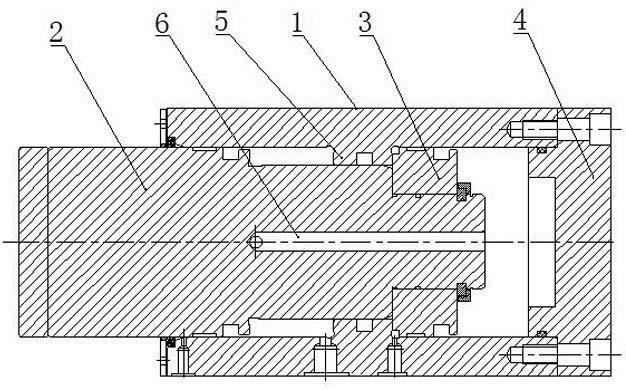

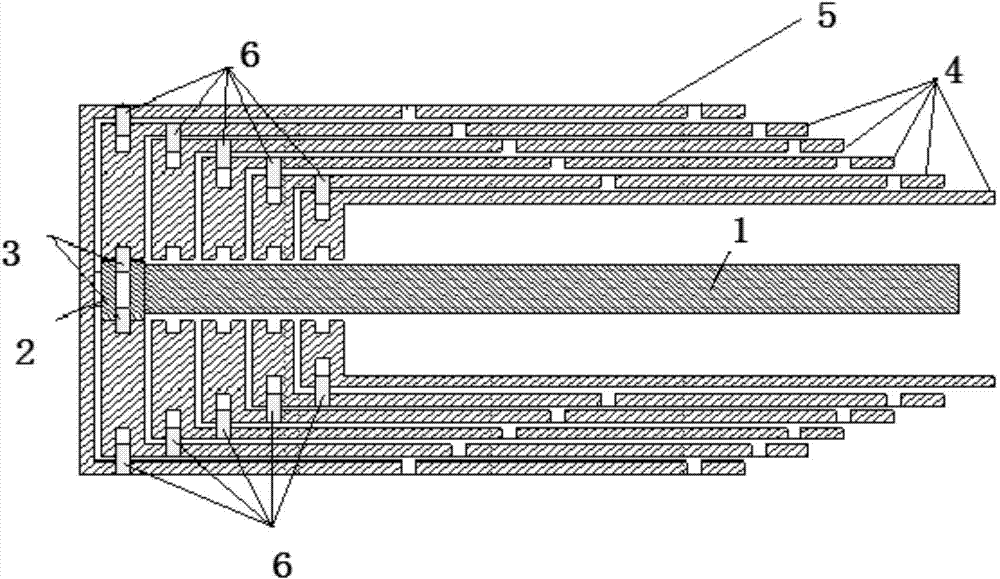

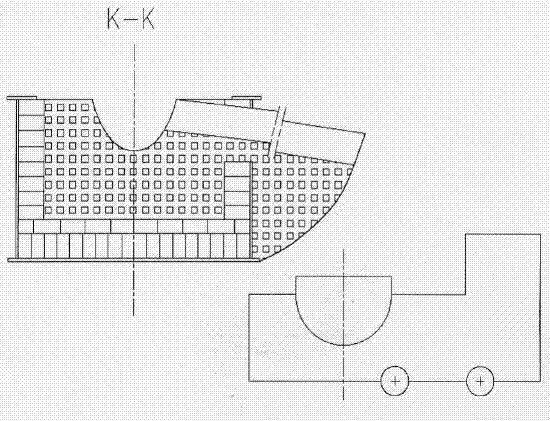

Compact buffering cylinder

ActiveCN102562707AReduce boreIncrease the buffer force areaFluid-pressure actuatorsPulp and paper industryMultiple point

The invention relates to a compact buffering cylinder which comprises a cylinder body and a piston rod. The compact buffering cylinder is characterized in that the middle part of the inner wall of the cylinder wall is provided with a raised isolating ring, the isolating ring, the piston rod and the upper part of the cylinder body match one another to form an upper oil cylinder structure, the isolating ring, the piston rod and the lower part of the cylinder body match one another to form a lower oil cylinder structure, a diversion channel is drilled on the piston rod, and the upper port and the lower port of the diversion channel are communicated with the upper cavity of the upper oil cylinder structure and the lower cavity of the lower oil cylinder structure respectively. During buffering, the upper cavity and the lower cavity are both filled with hydraulic oil and matched with all valve groups of a hydraulic system to bear impact and finish buffering, thus the buffering force carrying area of the buffering cylinder is increased, the diameter is decreased, and the volume and the manufacturing cost are reduced. In addition, because the buffering cylinder is small in volume, the buffering cylinder can be arranged on multiple points to achieve multi-point buffering with good effect.

Owner:江苏朗能机械科技有限公司

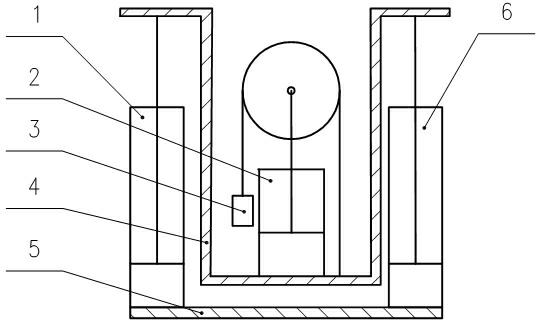

Hydraulic high-speed lifting device for stereo garage and stereo garage

The invention discloses a hydraulic high-speed lifting device for a stereo garage. The lifting device comprises a linear speed increasing mechanism, a driving metal flexible piece retraction jack, a driven metal flexible piece retraction jack, a driving metal flexible piece and a driven metal flexible piece. The driven metal flexible piece retraction jack, the linear speed increasing mechanism and the driving metal flexible piece retraction jack are fixed to a supporting frame in sequence and are connected in a gear engagement mode. One end of the driving metal flexible piece and one end of the driven metal flexible piece are correspondingly and fixedly connected with the driving metal flexible piece retraction jack and the driven metal flexible piece retraction jack respectively, and correspondingly wind the driving metal flexible piece retraction jack and the driven metal flexible piece retraction jack respectively, the other end of the driving metal flexible piece is fixedly connected with the telescopic end of a hydraulic cylinder, and the other end of the driven metal flexible piece is guided by a guide wheel and then is connected with an object which needs to be lifted. The invention further discloses the stereo garage.

Owner:宁夏博金特立体泊车设备有限公司

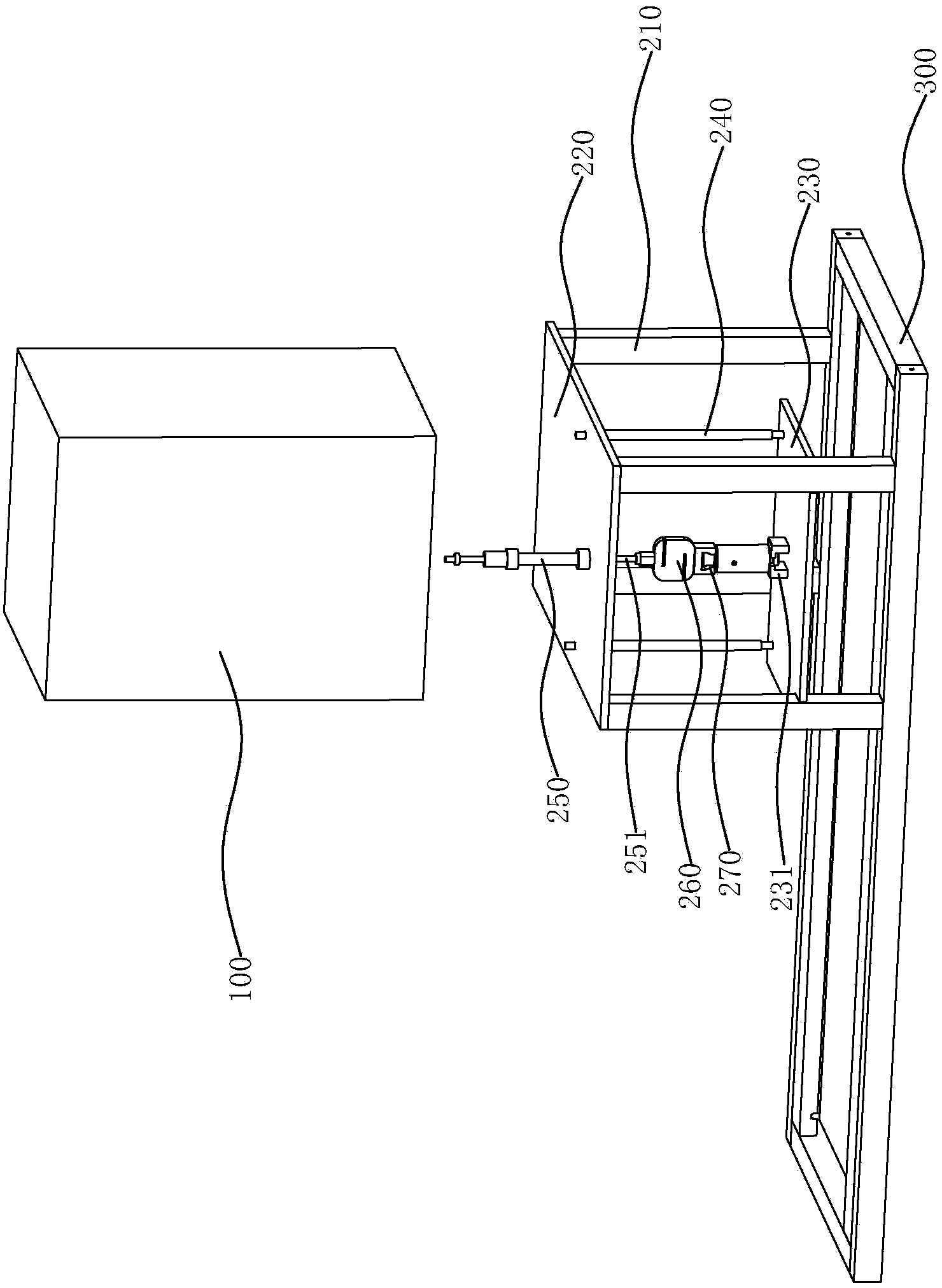

Reset time and withdrawal force testing device of cigarette lighter

ActiveCN103727560AGood mechanical propertiesWill not affect normal workApparatus for force/torque/work measurementCombustion ignitionElectricityEngineering

The invention relates to a reset time and withdrawal force testing device of a cigarette lighter. The reset time and withdrawal force testing device comprises a detection box, wherein a withdrawal force test unit and a reset time test unit are arranged on the detection box; the withdrawal force test unit comprises a detection frame arranged at the upper end of a detection table; a drive cylinder, a force sensor and a first clamping jaw which are orderly connected are arranged on the detection rack; a second clamping jaw is correspondingly arranged at the upper surface of the detection box; two ends of the cigarette lighter are respectively clamped by the first clamping jaw and the second clamping jaw; the force sensor is electrically connected with a control unit; a drive cylinder drives the first clamping jaw and pulls the cigarette lighter and is induced by the force sensor; the pressure of an air source of the drive cylinder is 0-0.6MPa; the diameter is 100-160mm; a cylinder barrel of the drive cylinder and an end cover are made of aluminum alloy. The reset time and withdrawal force testing device of the cigarette lighter, disclosed by the invention, is wide in detection range, high in detection efficiency, and portable in equipment, and an energy source is saved.

Owner:NINGBO UNIVERSITY OF TECHNOLOGY

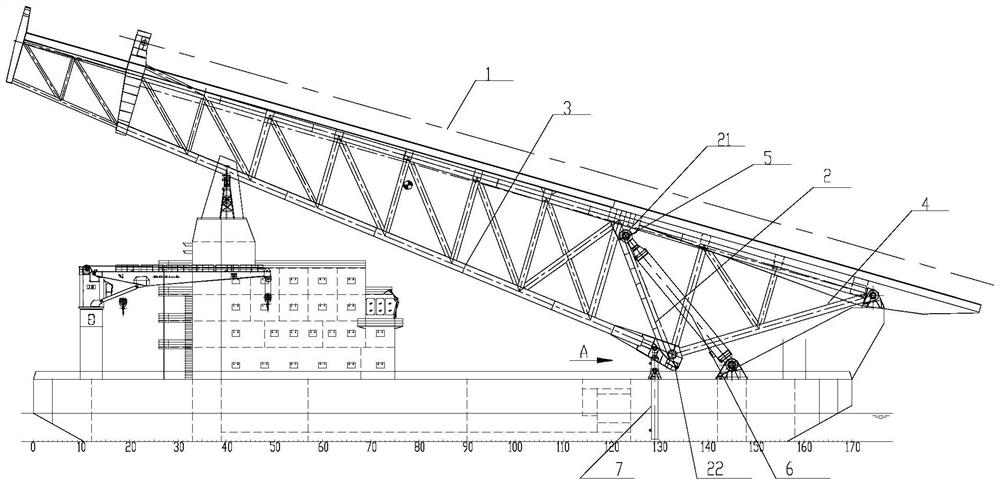

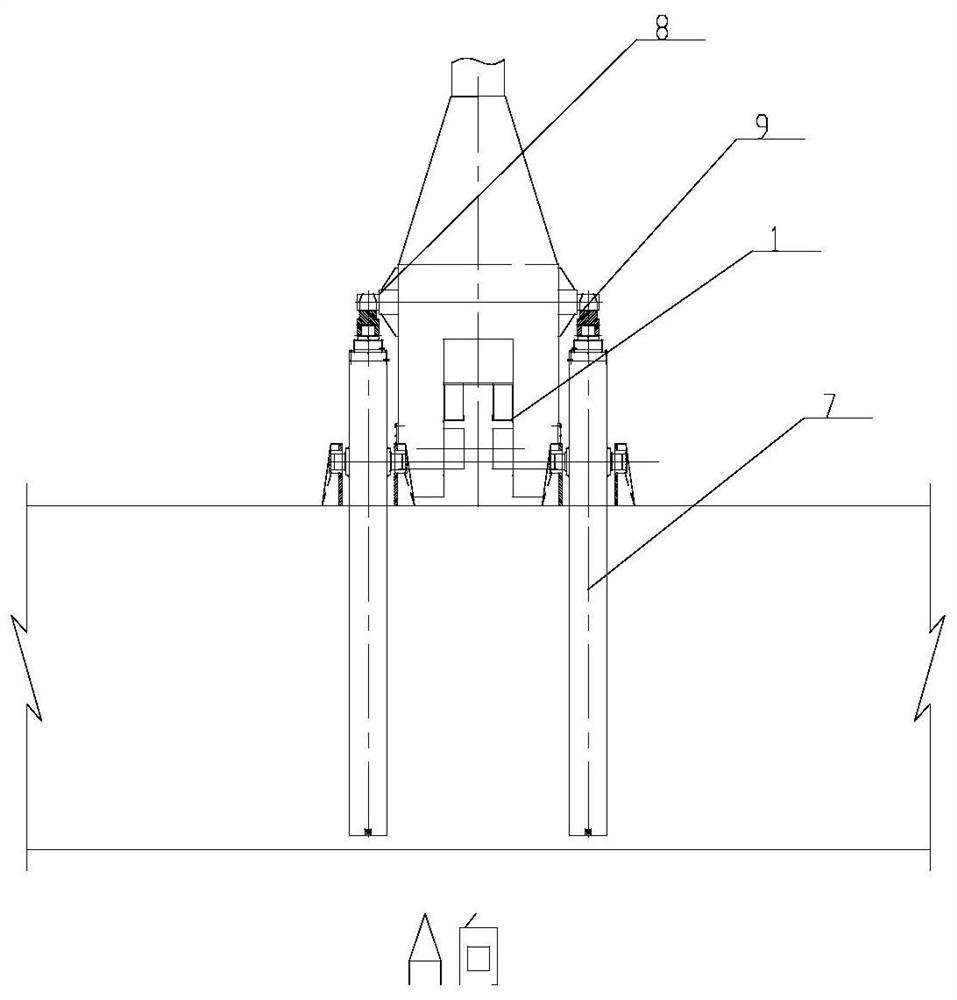

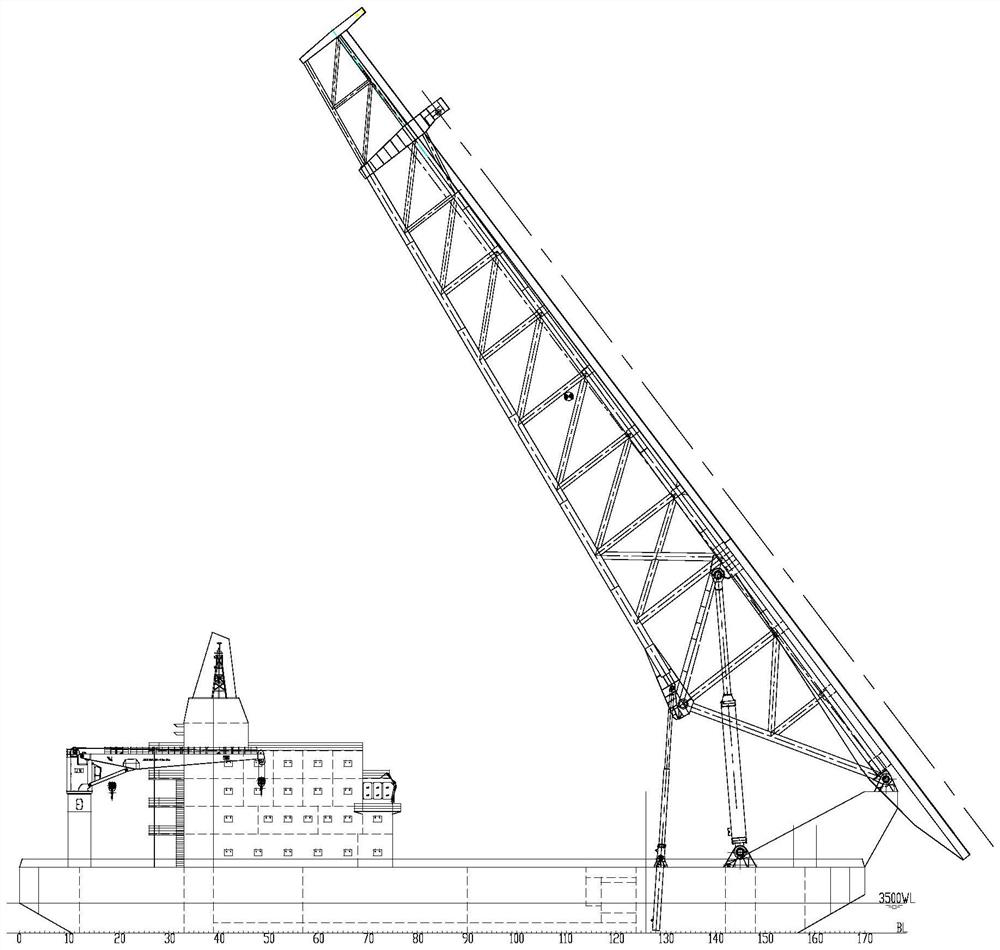

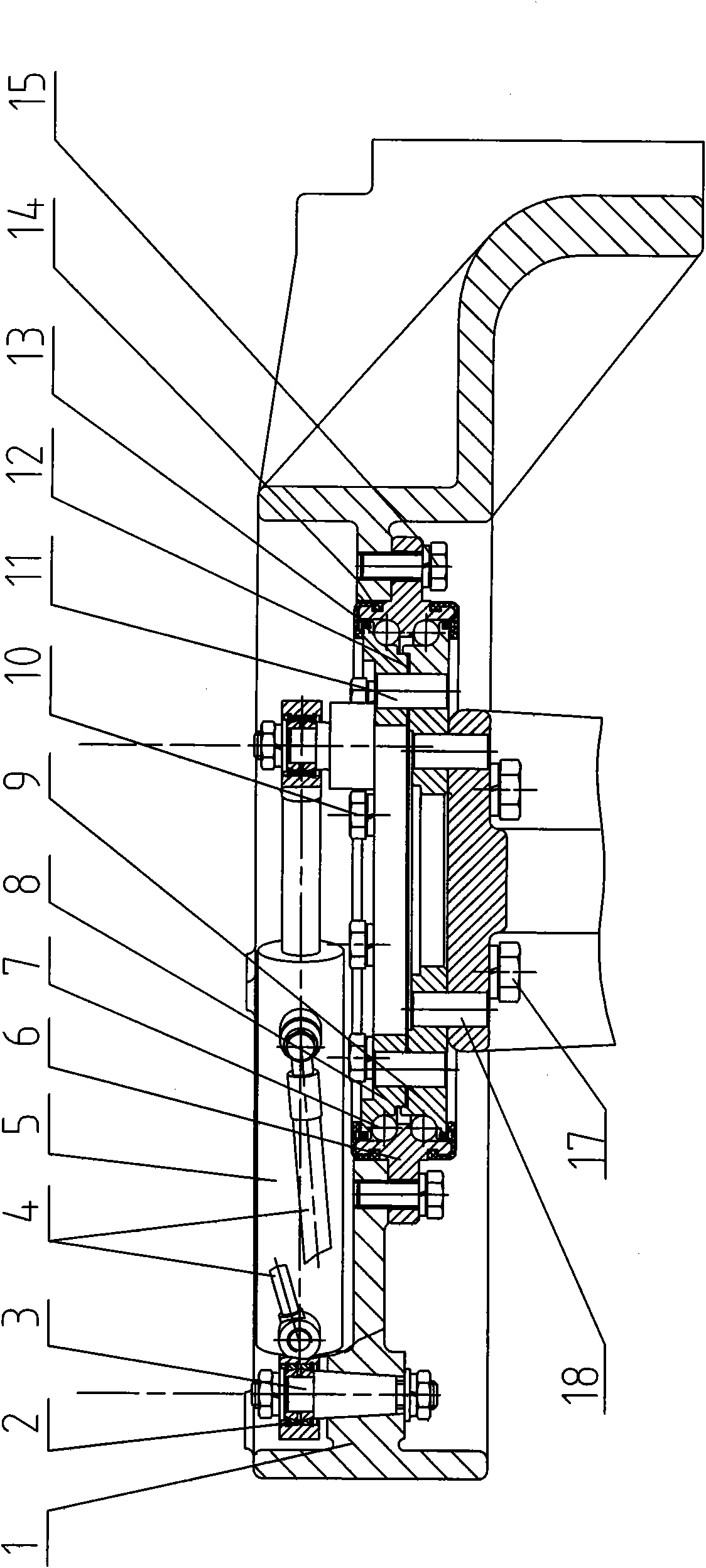

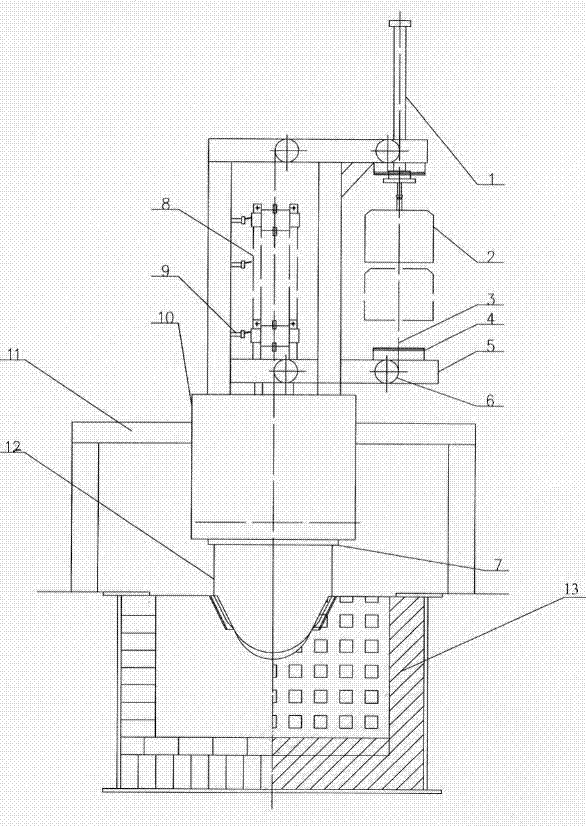

Pile frame jacking device of pile driving barge, and pile frame jacking and lying method

PendingCN111636426AReduce boreReduce local stressWaterborne vesselsSpecial purpose vesselsEngineeringArchitectural engineering

The invention discloses a pile frame jacking device of a pile driving barge, and a related pile frame jacking and lying method. The pile frame jacking device comprises a slideway arranged on a pile frame; one end of the slideway is arranged at the joint of a rear side rod and a lower side rod of the pile frame, and the other end of the slideway is arranged at the position close to a pile driving surface of the pile frame; one end, close to the pile driving surface of the pile frame, of the slideway is higher than the other end of the slideway when the pile frame is erected; a movable block isarranged in the slideway; a main oil cylinder is hinged to a barge body; the end part of a piston rod of the main oil cylinder is hinged to the movable block; an upper fixing point for fixing the movable block is arranged at one end, positioned at the pile driving surface, of the slideway; a lower fixing point for fixing the movable block is arranged at the other end of the slideway; when the movable block on the pile frame is fixed to the lower fixing point, the piston rod of the main oil cylinder stretches out to enable the pile frame to be in an upright state; two auxiliary pushing oil cylinders for assisting in pushing the pile frame at the front half section of the pile frame erecting process and then are separated from the pile frame are hinged to the barge body in parallel; and theincluded angle between the pile frame and a vertical plane is less than 45 degrees when piston rods of the auxiliary pushing oil cylinders extend out completely.

Owner:SHANGHAI SSOEC MARINE ENG CO LTD

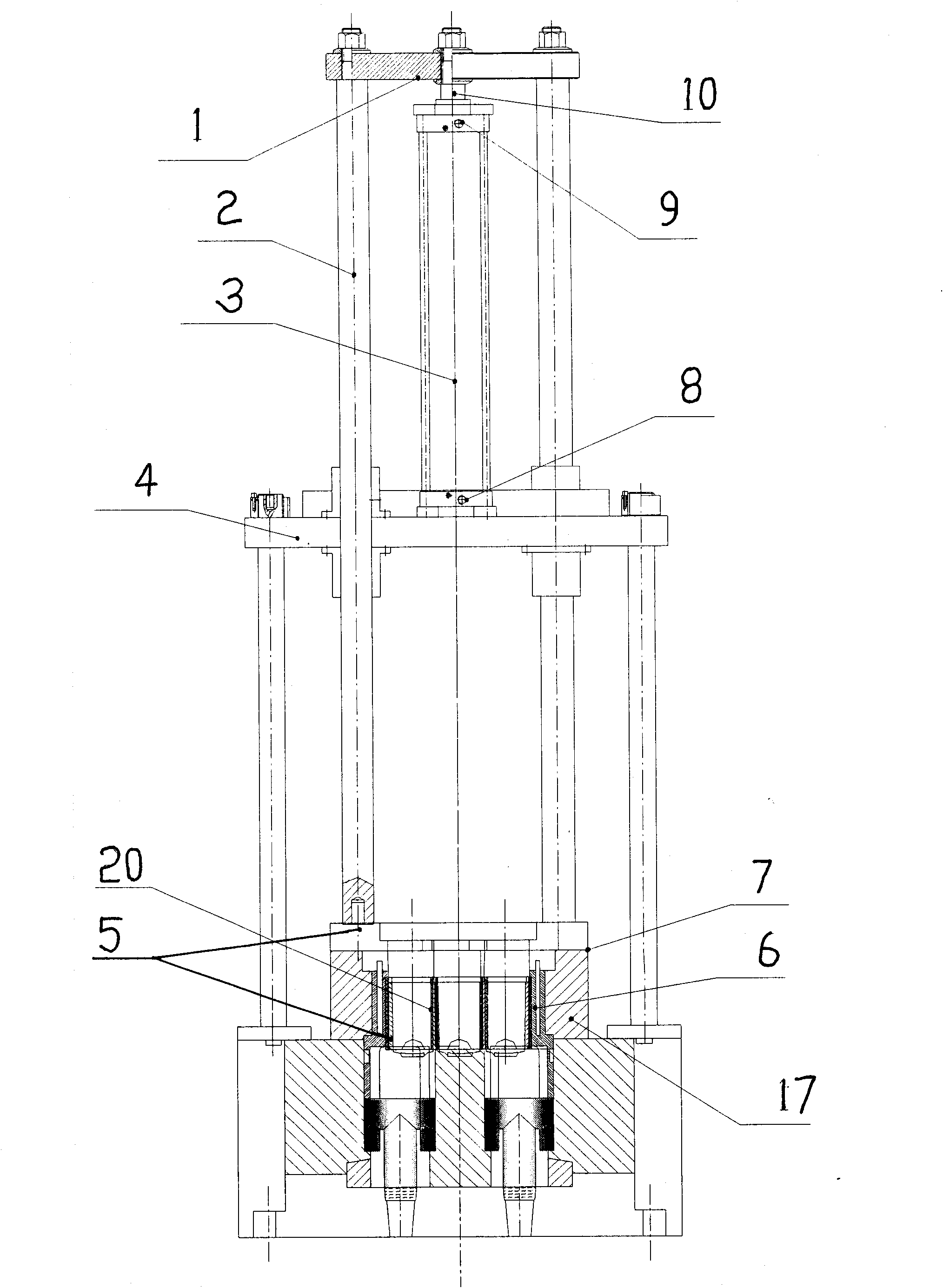

Reducing piled force-expanding type oil cylinder opening-closing device and using method thereof

The invention relates to a reducing piled force-expanding type oil cylinder opening-closing device. In the invention, a short-stroke large-cylinder-diameter flat oil cylinder is connected between a piston rod and a cross arm of a power oil cylinder, wherein the piston rod of the flat oil cylinder is connected with the piston rod of the power oil cylinder, and a close hole end cover of the flat oil cylinder is connected with the cross arm. The using method comprises the following steps of: filling hydraulic oil into an inlet-outlet oil hole of a piston cavity of the flat oil cylinder to ensure that oil enters the piston cavity and the piston rod is in a fixed state; acting on the close hole end cover of the flat oil cylinder by the piston cavity after the oil enters the piston cavity to ensure that the close hole end cover pushes the cross arm and a pull rod pulls a metal die core, wherein because the sectional area of the piston cavity of the flat oil cylinder is an odd number times that of the piston cavity of the power oil cylinder, under the action of several times of pulling force, the metal die core and an outer die of a metal die form a die opening and core pulling distance space; and then filling oil into the piston cavity of the power oil cylinder to finish the overall die opening and core pulling action of the metal mold. The invention is applied to a metal die core pulling and demoulding casting process, reduces the shut-down waste caused by the braking of the metal die core, saves the resources and improves the working efficiency.

Owner:WENZHOU RUIMING IND

Powerful chuck mechanism

The invention discloses a powerful chuck mechanism which comprises a machine frame, a cylinder, two forming clamping jaws and a transmission part. The two forming clamping jaws are symmetrically and movably arranged on the top of the machine frame. According to the powerful chuck mechanism, the forming clamping jaws on the two sides are driven by the cylinder to synchronously act, the two formingclamping jaws get close to each other or away from each other through the transmission part, the cylinder diameter of the cylinder is reduced, the size is small, the installing space is saved, the centralized clamping is ensured, the output force of the cylinder is increased by 2-2.5 times, the abrasion to the clamping claws is reduced, the service life is long, and maintenance is easy. Meanwhile,by adding a displacement sensor and a pressure sensor, it is ensured that each force and displacement value can be monitored, and the stable product quality is ensured.

Owner:长春工大检测技术有限责任公司

Non-thrombogenic stent jacket

Disclosed is the use of serous tissue, such as pericardium, as a component of intracorporeal implants. Particularly, disclosed is a jacketed stent assembly comprising an expandable stent provided with a jacket of processed serous tissue which, in some embodiments, is impregnated with a therapeutic or diagnostic agent. In a preferred embodiment, the jacket of the expandable stent is formed of pericardial tissue, preferably bovine or porcine pericardial tissue.

Owner:AMNIS THERAPEUTICS

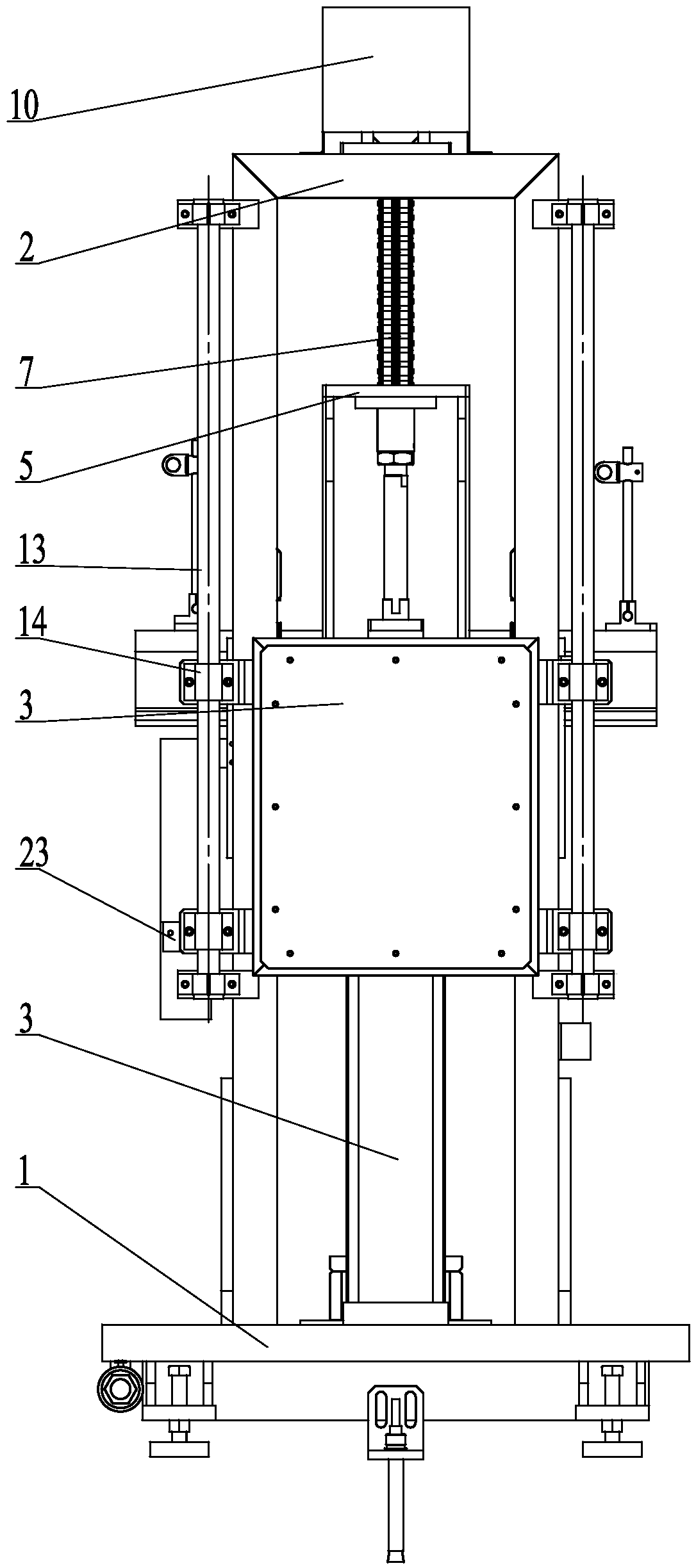

Ultrahigh pressure hydraulic press

InactiveCN102514221AHigh working pressureReduce borePress ramManufacturing cost reductionControl engineering

The invention relates to an ultrahigh pressure hydraulic press, belonging to the manufacturing field of large and medium hydraulic processing equipment. An ultrahigh-pressure pressurizer is added on the basis of the original hydraulic press structure, and the whole structure has the following four modes: an operating platform sliding plate press-down-type ultrahigh pressure hydraulic press, an operating platform sliding plate push-up-type ultrahigh pressure hydraulic press, an in-frame operating platform sliding plate press-down-type ultrahigh hydraulic press and an in-frame operating platform sliding plate push-up-type ultrahigh pressure hydraulic press. The ultrahigh pressure pressurizer is arranged on the side wall of the cylinder body part of an operating cylinder, the ultrahigh pressure pressurizer is provided with an oil circuit pipeline communicated with an oil charging tank, the operating cylinder and the cylinder body and the piston of a small cylinder are arranged on a lower base plate, an operating platform sliding plate and a push-up plate and an in-frame bottom and an in-frame top in four different manners. Working pressure of the hydraulic press is increased by N times compared with the working pressure of the original hydraulic press; compared with a conventional hydraulic press, under the same working state, the hydraulic press has the advantages that cylinder diameter, overall dimension and a motor are greatly reduced, manufacturing cost and energy consumption are reduced, and space occupied by equipment is reduced.

Owner:倪小银

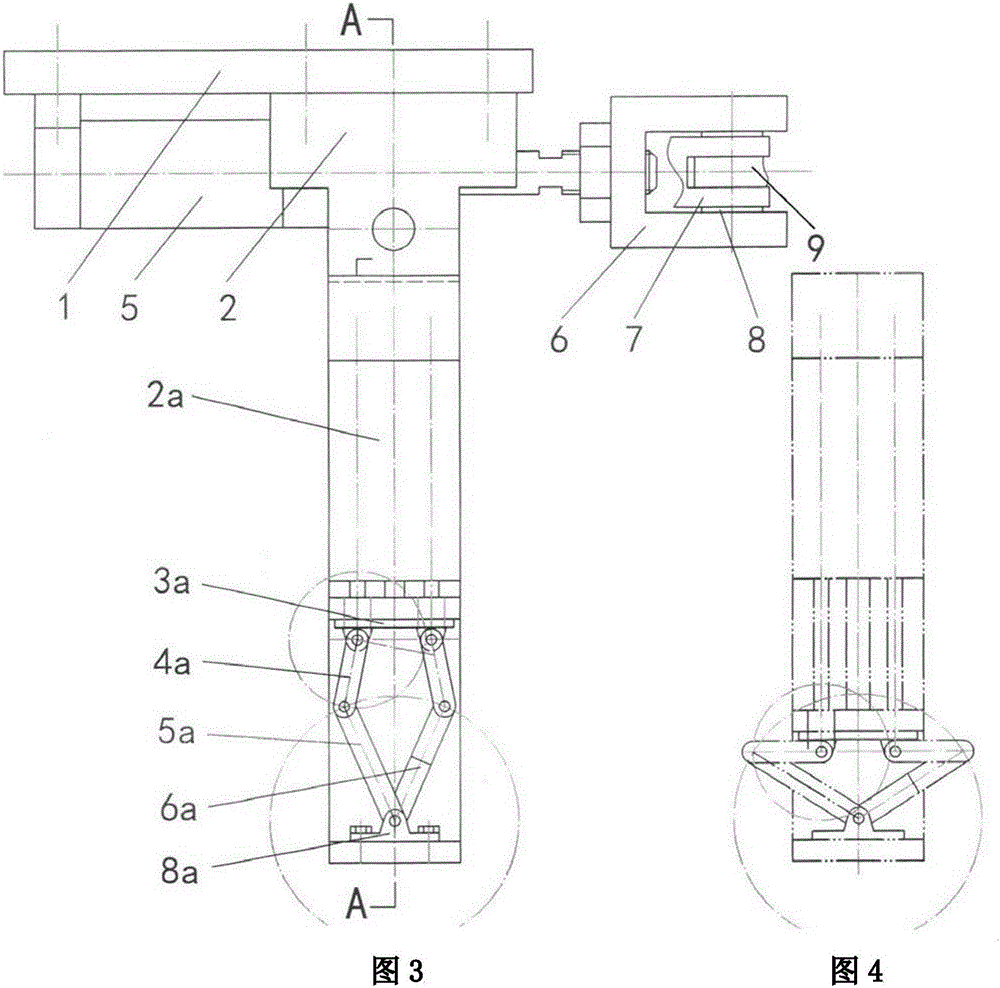

Bottom-groove single-cylinder flexible lifting mechanism of automobile body alignment machine

The invention discloses a bottom-groove single-cylinder flexible lifting mechanism of an automobile body alignment machine. A center of a front cambered surface of a long circular groove hole of a first hinged support (2) is higher than that of a rear cambered surface of the long circular groove hole of the first hinged support (2); the center of the rear cambered surface of the long circular groove hole of the first hinged support (2) and a center of a circular hole of a second hinged support (8) are equal in height; and a distance between the center of the rear cambered surface of the long circular groove hole of the first hinged support (2) and the center of the circular hole of the second hinged support (8) is equal to that between centers of a front upper rotating shaft and a rear upper rotating shaft. The underfloor long circular groove hole is adopted, so that a leveling problem is solved; an overhead oil cylinder is arranged between a platform and a front supporting arm, so that a lifting moment is raised, and a cylinder diameter parameter is optimized; a ratchet protection device is improved; and a structure corresponding to the ratchet protection device is simplified.

Owner:烟台三重技术股份有限公司

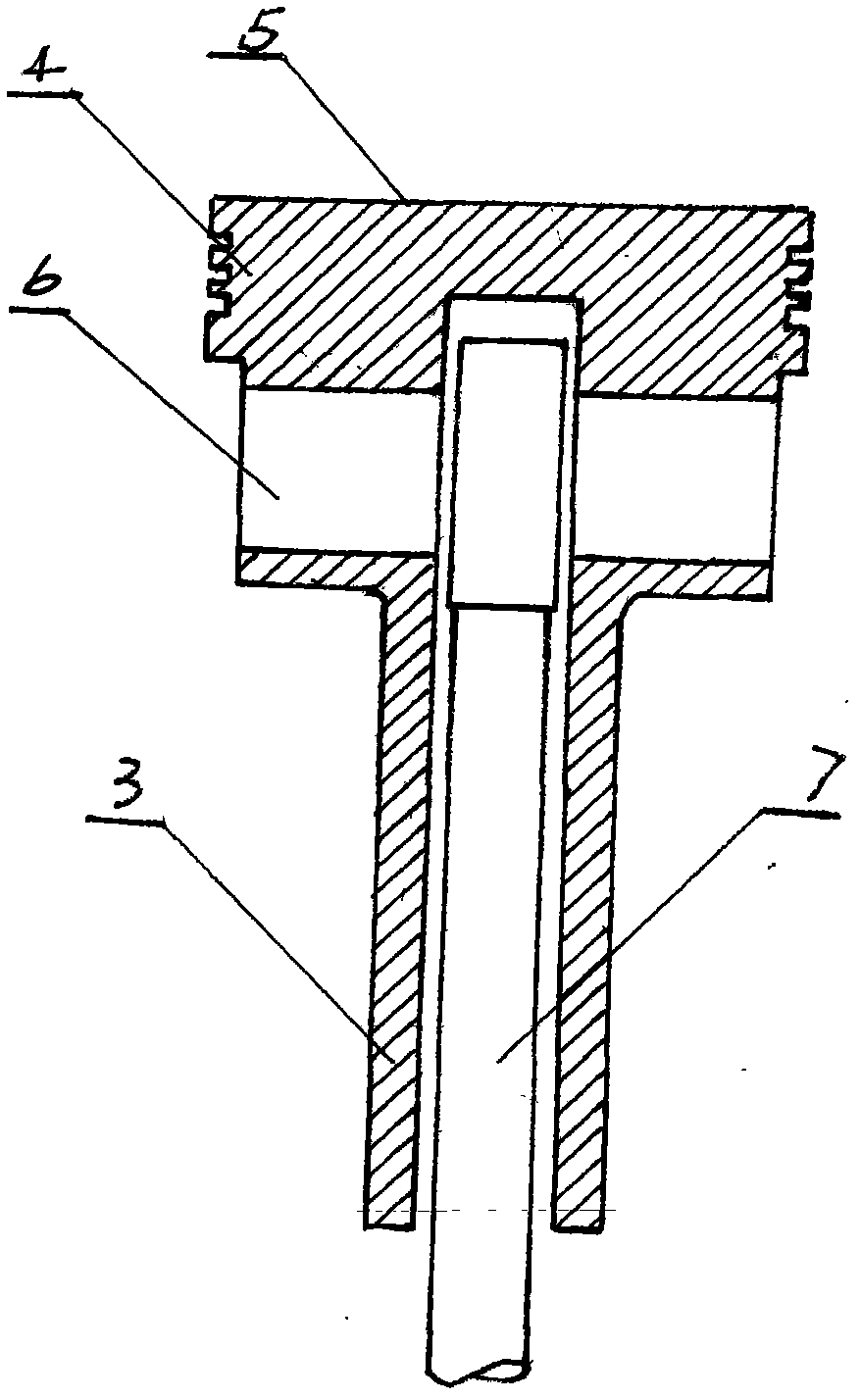

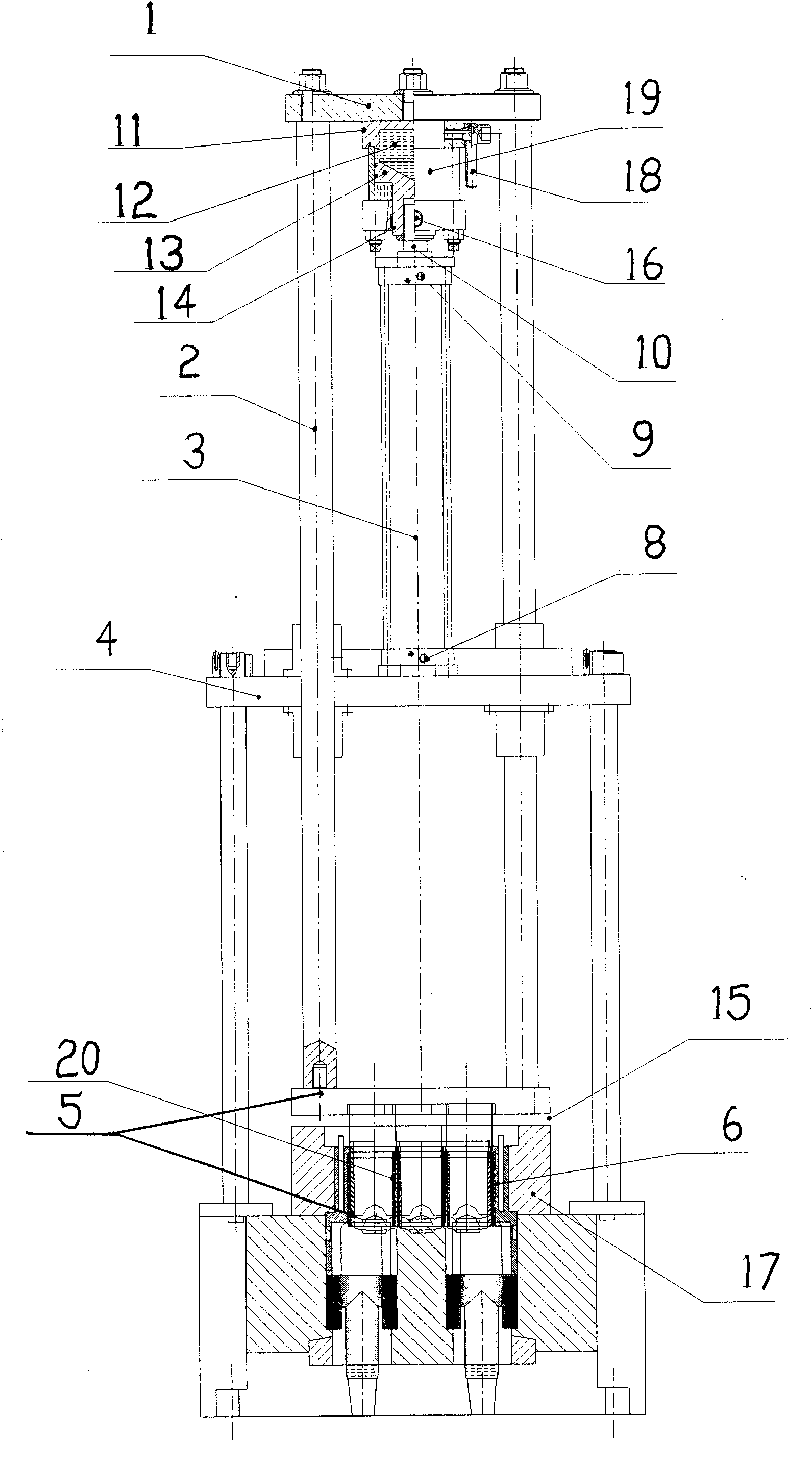

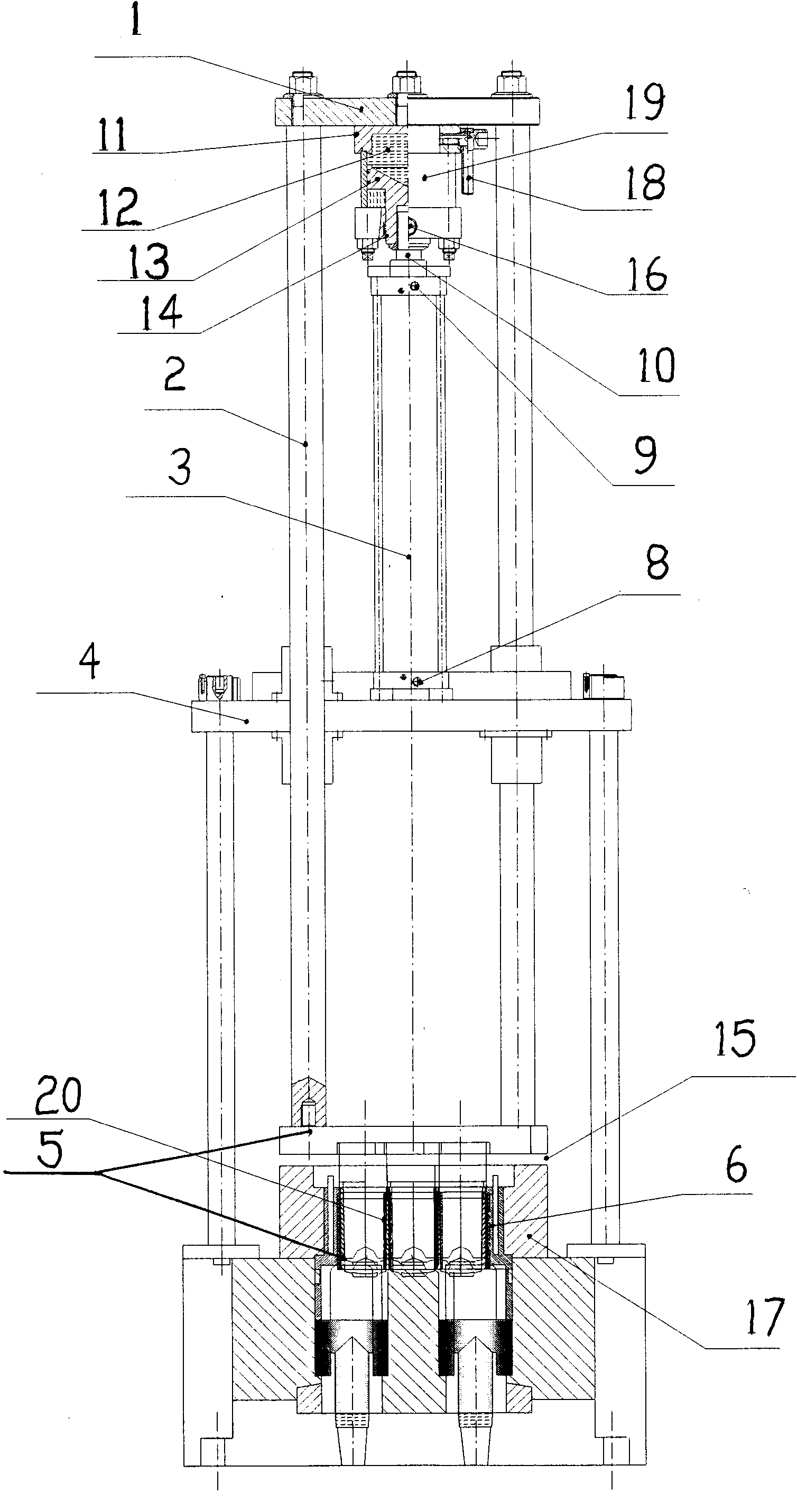

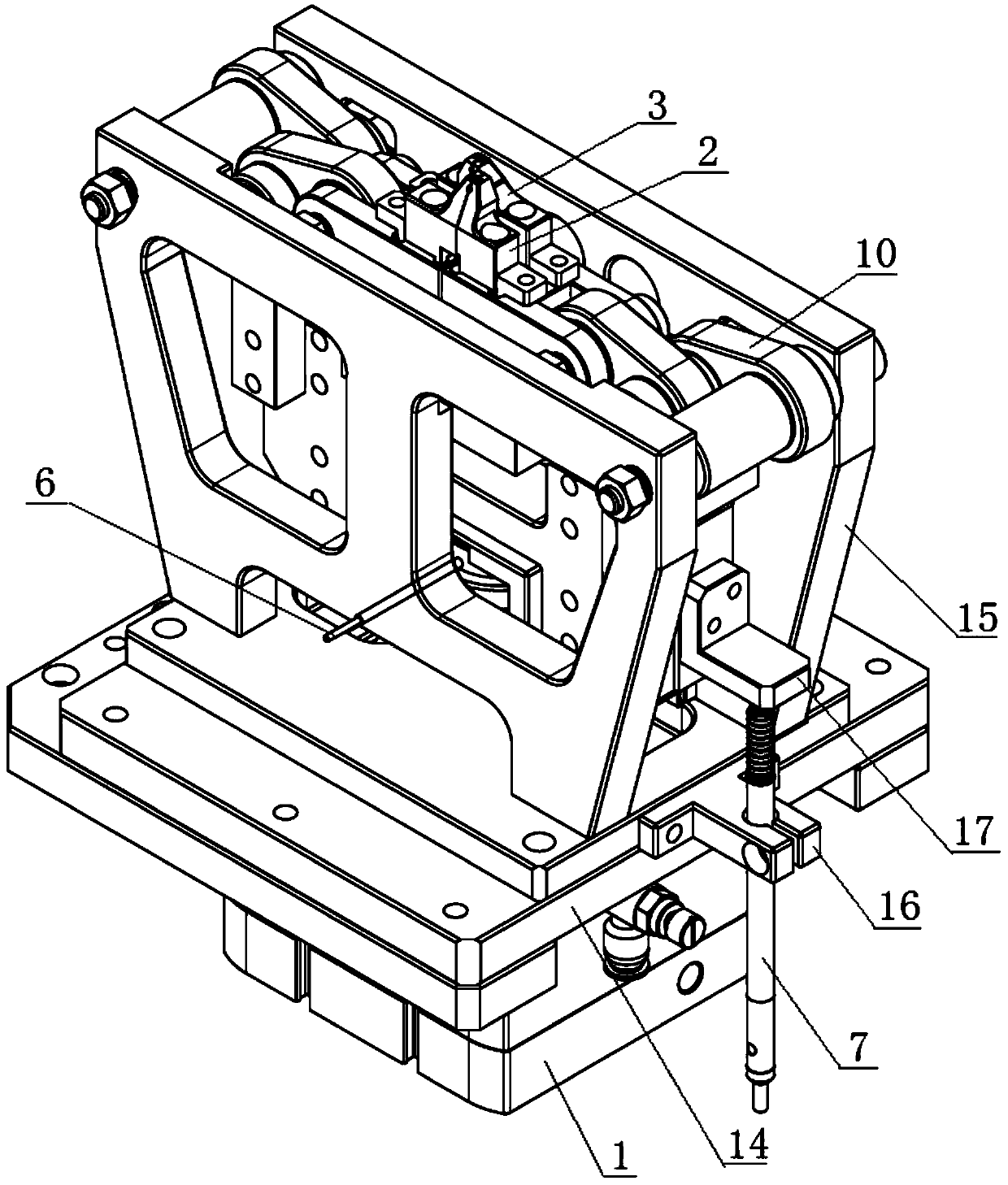

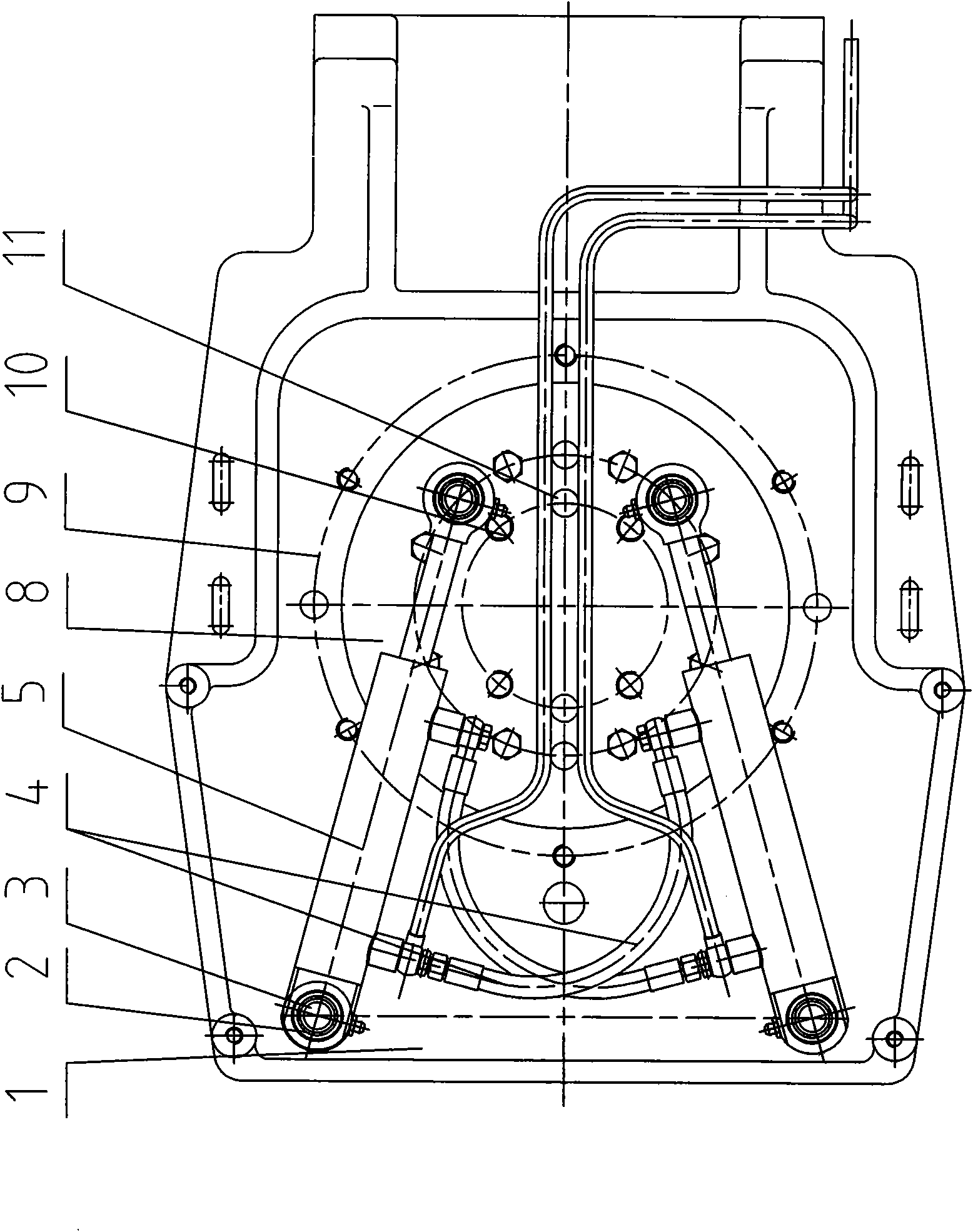

Projection welding upper electrode structure capable of sequentially welding multiple nuts in time sharing manner

PendingCN108994440AReduce boreReduce capacity requirementsPressure electrodesTransformerAgricultural engineering

The invention discloses a projection welding upper electrode structure capable of sequentially welding multiple nuts in a time sharing manner. The projection welding upper electrode structure comprises a bottom plate and at least three electrode assemblies arranged on the bottom plate. The bottom plate is connected with adjustable installing plates. The two perpendicular side faces of the adjustable installing plates are connected with positioning blocks. Each electrode assembly comprises the corresponding adjustable installing plate, an air cylinder installing plate, a welding air cylinder, an air cylinder electrode transition plate, an electrode connecting base, an electrode body, a water nozzle and an electrode head. A conductive belt adapter plate is connected to the rear side face ofthe bottom plate and connected with conductive belts, and conductive belt connection copper plates are connected with the electrode connecting bases of the electrode assemblies. Providing the projection welding upper electrode structure capable of sequentially welding the multiple nuts in the time sharing manner is the purpose, a plurality of electrodes can be used for sequentially welding a workpiece according to the set sequence after one-time workpiece installation, the requirements for the welding air cylinder diameter and the transformer volume are lowered, and the equipment manufacturingand using cost is reduced.

Owner:天津七所高科技有限公司

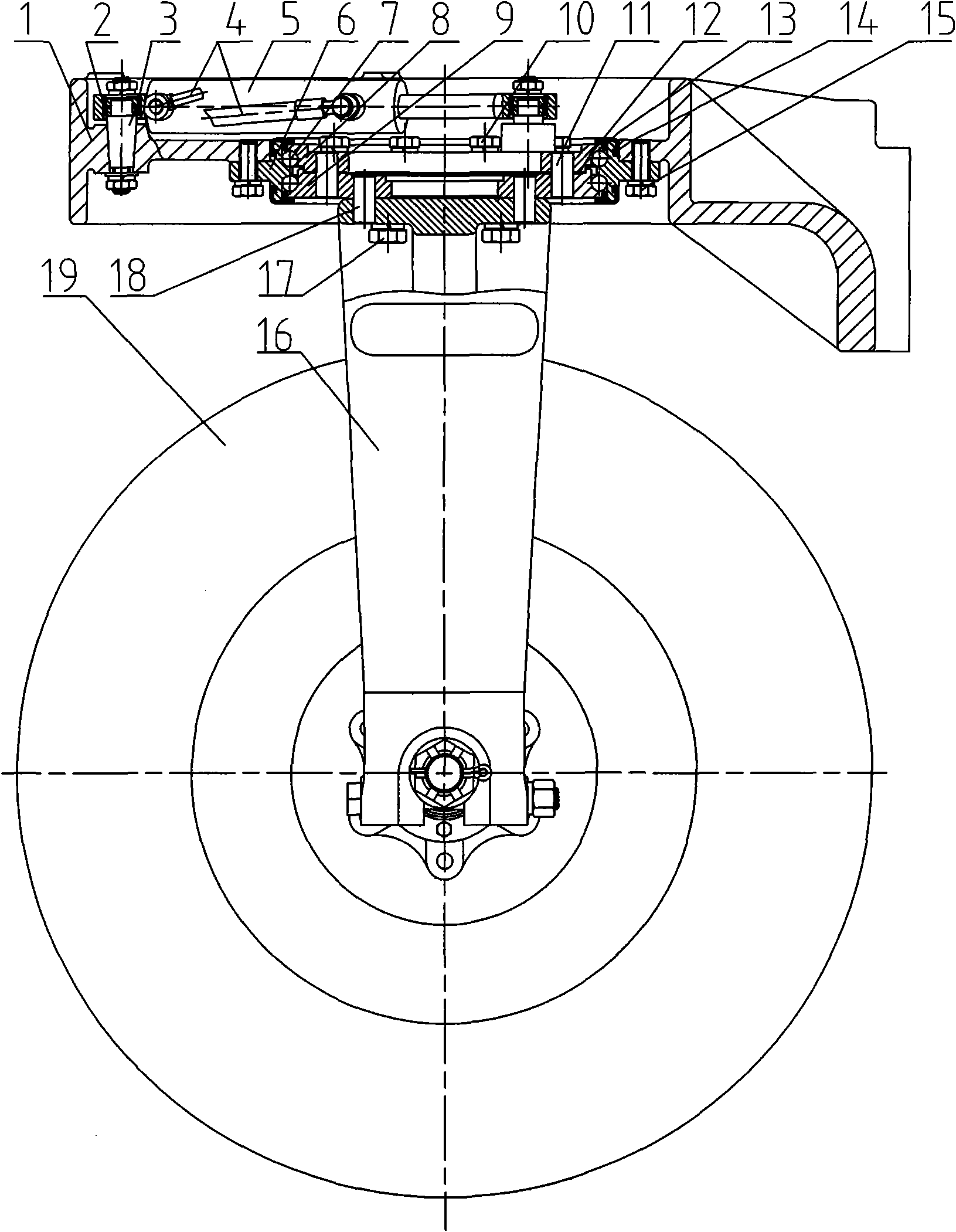

Steering mechanism of three-wheel tractor

The invention relates to a steering mechanism of a three-wheel tractor. The steering mechanism comprises a steering wheel, a frame, a plane bearing, steering oil cylinders and a U-shaped fork, whereinthe plane bearing comprises a bearing seat, a drive disk arranged on the upper part of the bearing seat as well as a driven disk and roll balls arranged on the lower part of the bearing seat; the lower part of the U-shaped fork is connected with the steering wheel, and the upper part is connected with the driven disk with a roller path; the frame is connected with the bearing seat which is arranged between an upper roller path and a lower roller path and provided with a radial shaft shoulder; the roll balls are respectively arranged among the a roller path of the driving disk, the upper roller path and the lower roller path of the bearing seat and the roller path of the driven disk; the driving disk and the driven disk are connected through a fastening piece, and an adjustment spacer is arranged between the driving disk and the driven disk; the two steering oil cylinders are symmetrically distributed at both sides along the longitudinal center of the tractor; one end of each steeringoil cylinder is hinged on the frame, while the other end is hinged on the driving disk; and front oil cavities and rear oil cavities of the two steering oil cylinders are connected in series through ahydraulic oil pipe. The invention has the characteristics of safety, reliability, flexible and light operation and high connecting strength and rigidity.

Owner:CHANGZHOU DONGFENG AGRI MACHINERY GROUP

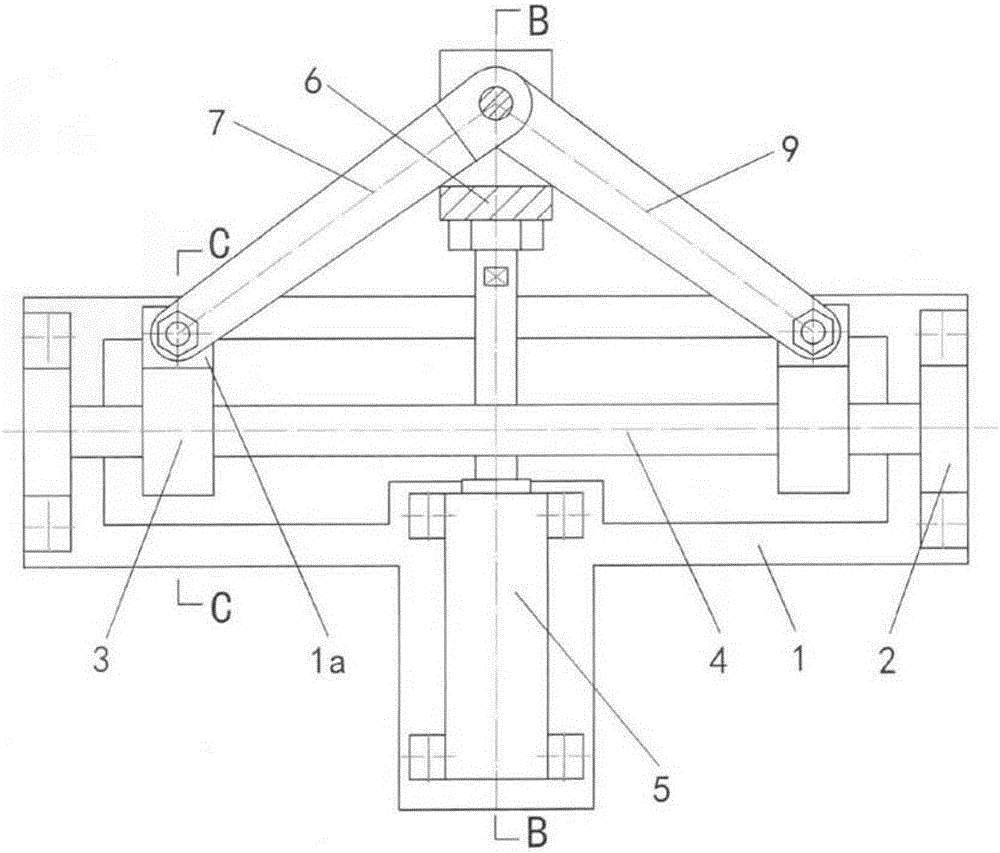

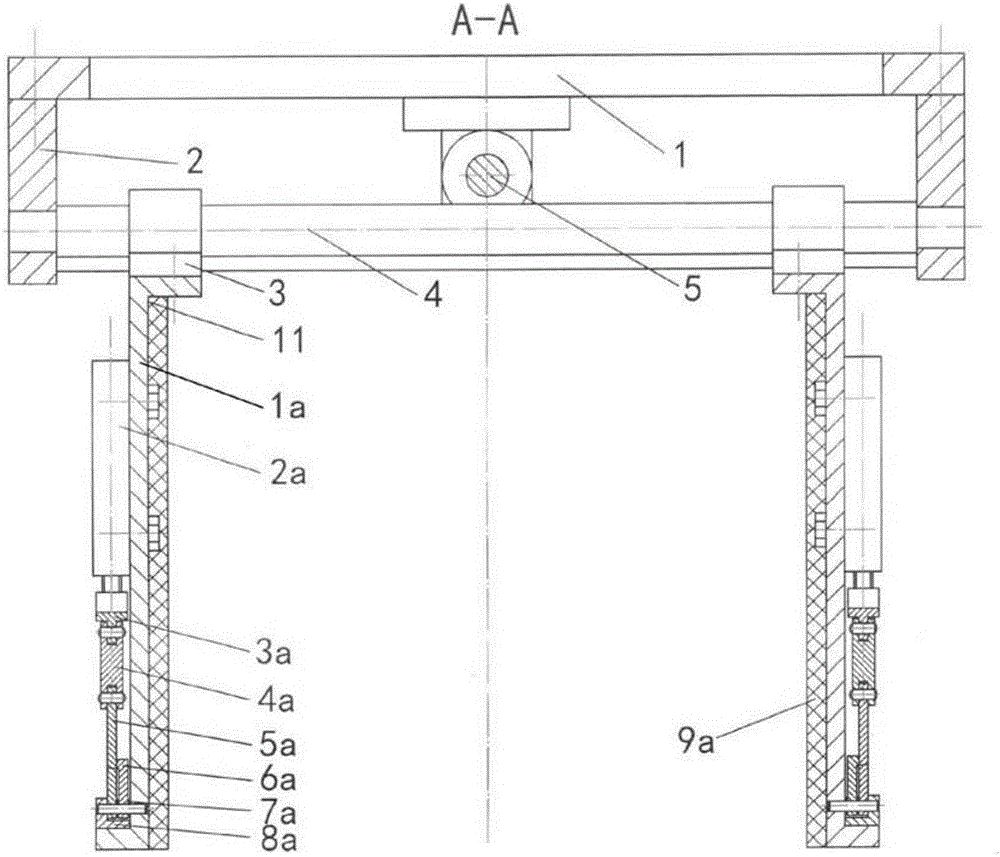

Two-stage folding type balance mechanism of pipe sling

InactiveCN101269784AReduce frictional resistanceIncreased lifting capacityCranesLifting capacityEngineering

The invention relates to a second stage foldaway balance mechanism of a pipelayer, and a counterweight bracket is fixed with a stander together. The second stage foldaway balance mechanism of the pipelayer is provided with a first stage cantilever, a second stage cantilever, a first stage hydrocylinder and a second stage hydrocylinder, wherein, the first stage cantilever is hinged with the counterweight bracket by a first stage cantilever pin roll; the second stage cantilever is hinged with the first stage cantilever by a second stage cantilever pin roll, and each counterweight block is connected with the second stage cantilever by two counterweight pin rolls; one end of the first stage hydrocylinder is connected with the stander by a hydrocylinder pin roll, and the other end is connected with the first stage cantilever by the hydrocylinder pin roll; one end of the second stage hydrocylinder is connected with the first stage cantilever by the hydrocylinder pin roll, and the other end is connected with the second stage cantilever by the hydrocylinder pin roll; axes of all pin rolls are in vertical directions. The second stage foldaway balance mechanism of the pipelayer has compact structure, long extension distance of the counterweight, great balance moment of unit weight, and small weight of needed counterweight, thereby the weight of the complete mechanism is small, and the lift capacity of unit mechanism weight is small; a level expansion mode makes the counterweight to not need to overcome the weight of the counterweight in the process of expansion and furl, the load of the hydrocylinder is small and the cylinder diameter of the hydrocylinder is small, and the power for consuming a host is small. The performance level of the complete mechanism can be increased visibly when the second stage foldaway balance mechanism of the pipelaver is used as a balance mechanism, and the manufacturing and the transporting costs are saved.

Owner:SHANTUI CONSTR MASCH CO LTD

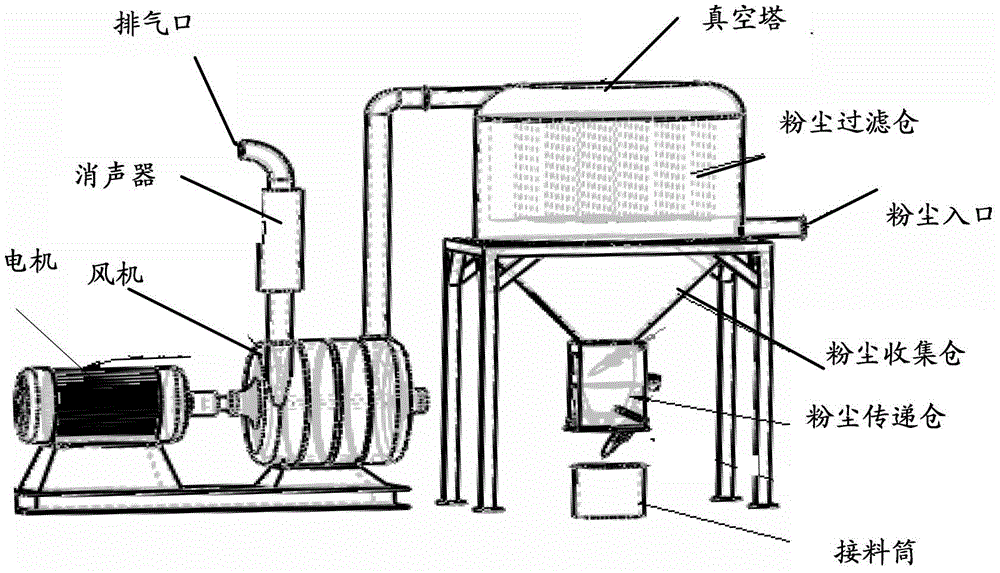

A discharge device and a discharge method

InactiveCN104174897BAvoid problems that cannot be opened normallyNo fatigueMetal working apparatusBoring/drilling componentsEngineeringPressure difference

The invention discloses a discharging device and a discharging method. The discharging device comprises a collecting bin, a transferring bin, a lower air door, a temporary storage bin and a material receiving device, wherein the transferring bin is located below a discharging opening of the collecting bin, and the temporary storage bin is connected with a discharging opening below the transferring bin, is located above the lower air door and is used for storing a material; a pressure regulating and converting device is arranged at the outer side of the temporary storage bin and comprises a first adjusting pipeline which is used for adjusting the pressure difference between the pressure of the temporary storage bin and outside atmospheric pressure. By adopting the technical scheme proposed by the invention, energy can be better saved, the production efficiency is increased, and the stability is better.

Owner:NEW FOUNDER HLDG DEV LLC +1

Kenter shackle

The Invention relates to a Kenter shackle for anchor chains, at least comprising two half elements which can be coupled to one another and a coupling piece element that can be introduced between the half-elements wherein the half elements each have an L-shaped or J-shaped configuration, wherein the external toothing having a plurality of parallel toothing planes is formed at the end of a short connection leg and wherein a receiving chamber is formed at the end of a long connection leg, having an internal toothing with a plurality of parallel toothing planes, into which the external toothing of the short connection leg engages, and wherein the connection legs are connected to one another via a curved clasp. In addition, the receiving chamber in the long leg is extended by means of a cavity above the end side of the external toothing of the short leg and / or above the uppermost toothing plane of the internal toothing pointing towards the clasp.

Owner:SCHMIEDESTUECK VERTRIEB FEUERSTEIN

Single-cylinder plug pin type telescopic arm, crane and telescoping method of single-cylinder plug pin type telescopic arm

The invention relates to a single-cylinder plug pin type telescopic arm, a crane and a telescoping method of the single-cylinder plug pin type telescopic arm. The single-cylinder plug pin type telescopic arm comprises a basic arm and at least one section of telescopic arm which is sleeved in the basic arm, wherein coaxial central holes are formed in the tails of the telescopic arms; a telescopic oil cylinder is arranged in the central holes and comprises a cylinder rod and a cylinder barrel; at least two cylinder heads are fixedly sleeved outside the cylinder barrel in the longitudinal direction; at least three arm pin holes are respectively formed in the basic arm and the telescopic arm in the longitudinal direction. The single-cylinder plug pin type telescopic arm provided by the invention adopts the telescopic oil cylinder and the at least two cylinder heads; each cylinder head can be used for locking and unlocking the telescopic oil cylinder and any one telescopic arm; in a relay manner, the telescopic arms stretch or shrink; telescoping of the single-cylinder plug pin type telescopic arm is realized; the length of the oil cylinder is reduced; the cylinder diameter and the rod diameter of the oil cylinder are reduced; the cost of the oil cylinder is lowered; the loading weight is reduced; the hoisting capability is improved; the design capability of the crane is improved.

Owner:XUZHOU HEAVY MASCH CO LTD

Multifunctional rolling steamer production line

ActiveCN103654379BSave single-step movement timeReduce boreCooking vesselsProduction lineIndustrial engineering

The invention relates to a multifunctional rolling type steam box production line. The production line comprises a square box frame without a bottom, a heat source and a plurality of molds which are used for containing foods and can be mutually stacked, wherein each mold is a square framework, an air exchange opening is formed in the top of the square box frame, and the bottom of the square box frame is fixed to a rail of the production line. The production line is characterized in that the square box frame is divided into a lifting side and a releasing side which are symmetrical, a pile of molds are arrayed in the lifting side, a pile of molds are arrayed in the releasing side, a lifting mechanism is arranged on the lifting side, a releasing mechanism is arranged on the releasing side, a flat pushing mechanism is arranged at the top of the square box frame, each mold on the rail of the production line is conveyed to the top of the lifting side by the lifting mechanism in a stepping mode, then conveyed to the top of the releasing side from the top of the lifting side by the flat pushing mechanism and finally conveyed to the rail of the production line in a stepping mode by the releasing mechanism, and the stepping interval is the height of one mold. Uncooked foods enter from the lifting side of the multifunctional rolling type steam box production line, cooked foods go out from the releasing side, and full-automatic production is achieved.

Owner:蒋群 +1

Safety shutoff value device for on-line interception of high-temperature fused slag

The invention relates to a safety shutoff value device for on-line interception of high-temperature fused slag. In the device, a value tank is fixed on a slag runner through a support I, and a support II is fixed above the value tank; a cylinder, a chain wheel assembly, a limit part and a fixed block are fixed on the support I; counter weight is connected with the cylinder; one end of a chain is connected to the counter weight, and the other end of the chain is connected to a valve plate; a part of a cooling water pipe is casted in the valve plate; and two paths of cooling water are formed on the valve plate, wherein one path of cooling water cools the upper part of the valve plate, and the other path of cooling water cools the lower part of the valve plate. If a driving system is in accident in the slag-taking process, the counter weight can directly elevate the valve plate after the valve position of a solenoid valve is regulated by hand. The safety shutoff value device for on-line interception of high-temperature fused slag provided by the invention is used for shunting off and taking slag in a mineral wool production process, and is capable of controlling the slag-taking amount in the slag-taking process so as to ensure the separation of iron and slag; and the service life of the valve plate is long, and the valve plate can also be timely elevated when equipment fails, thereby ensuring the smoothness of slag flow in the slag runner of a blast furnace.

Owner:BAOSTEEL ENG & TECH GRP

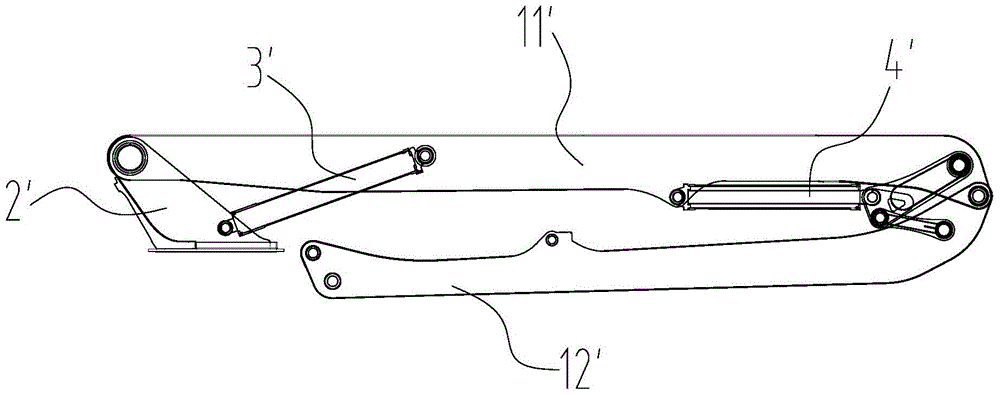

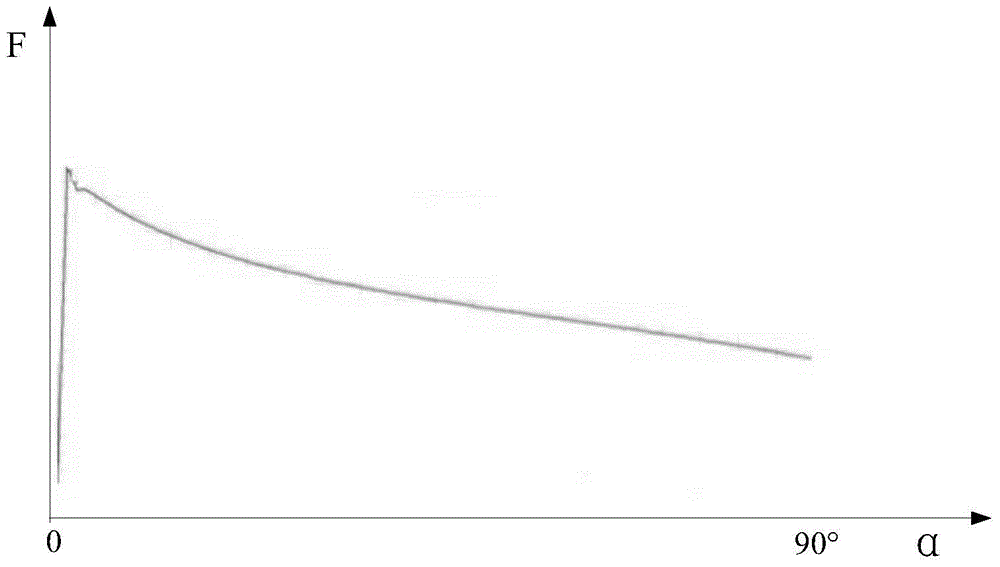

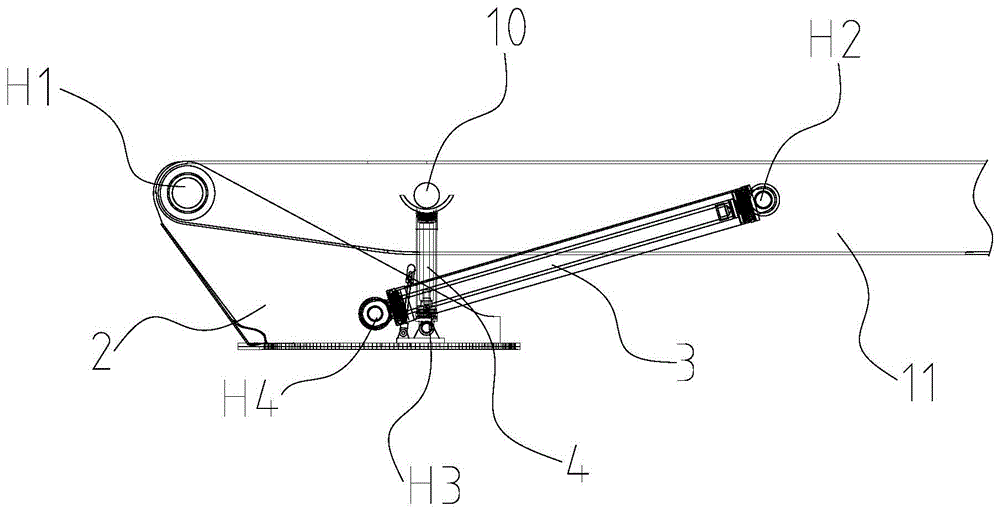

Luffing mechanism for construction machinery and construction machinery

ActiveCN103470048BGuaranteed to workReduce design requirementsBuilding material handlingArchitectural engineeringForce balance

Owner:SANY AUTOMOBILE MFG CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com