Side driving lifting roller bed with low energy consumption and high stability

A high-stability, low-energy-consumption technology, applied to roller tables, conveyor objects, transportation and packaging, etc., can solve the problems of large space occupation, high energy consumption, and unstable operation, and achieve energy saving, cylinder diameter reduction, The effect of reducing air consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

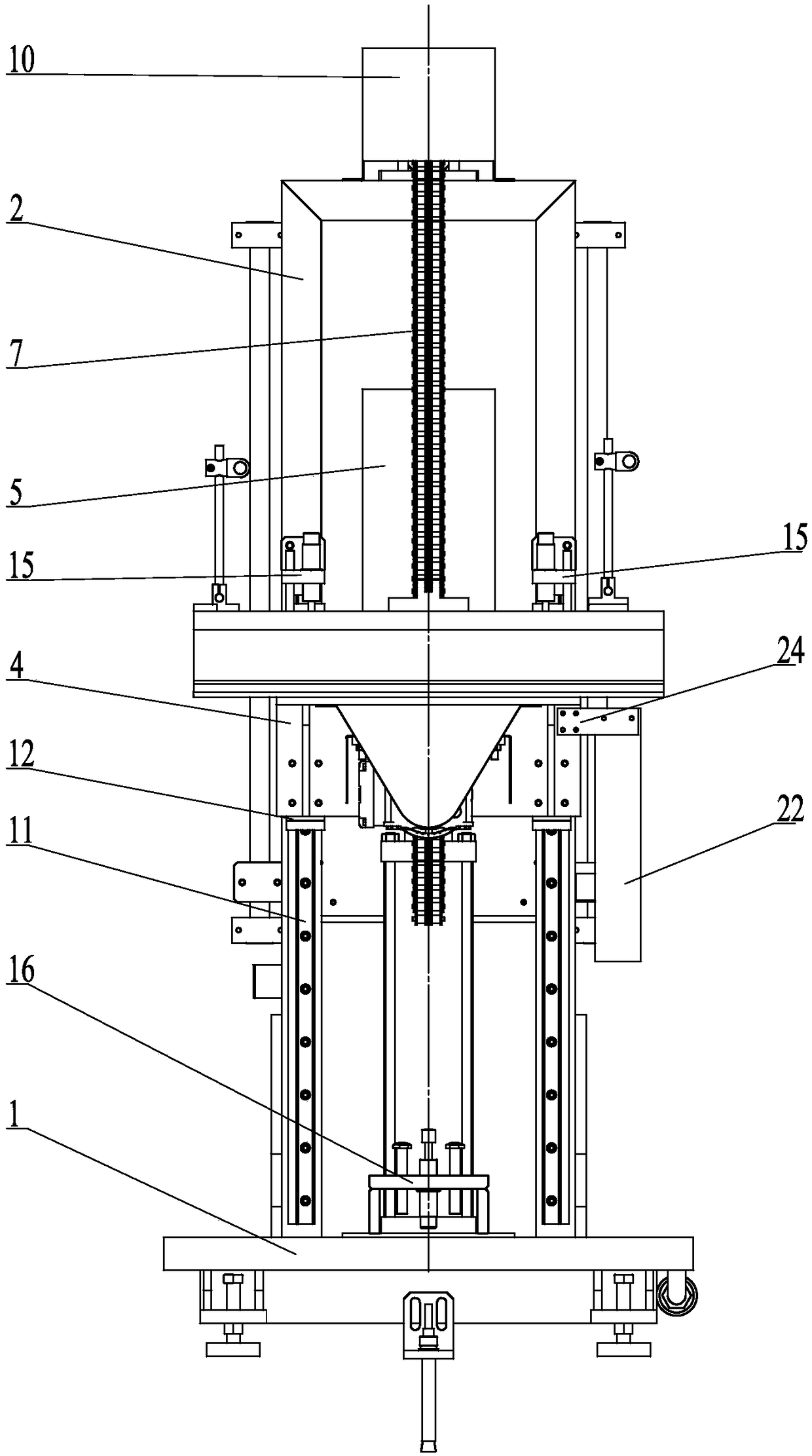

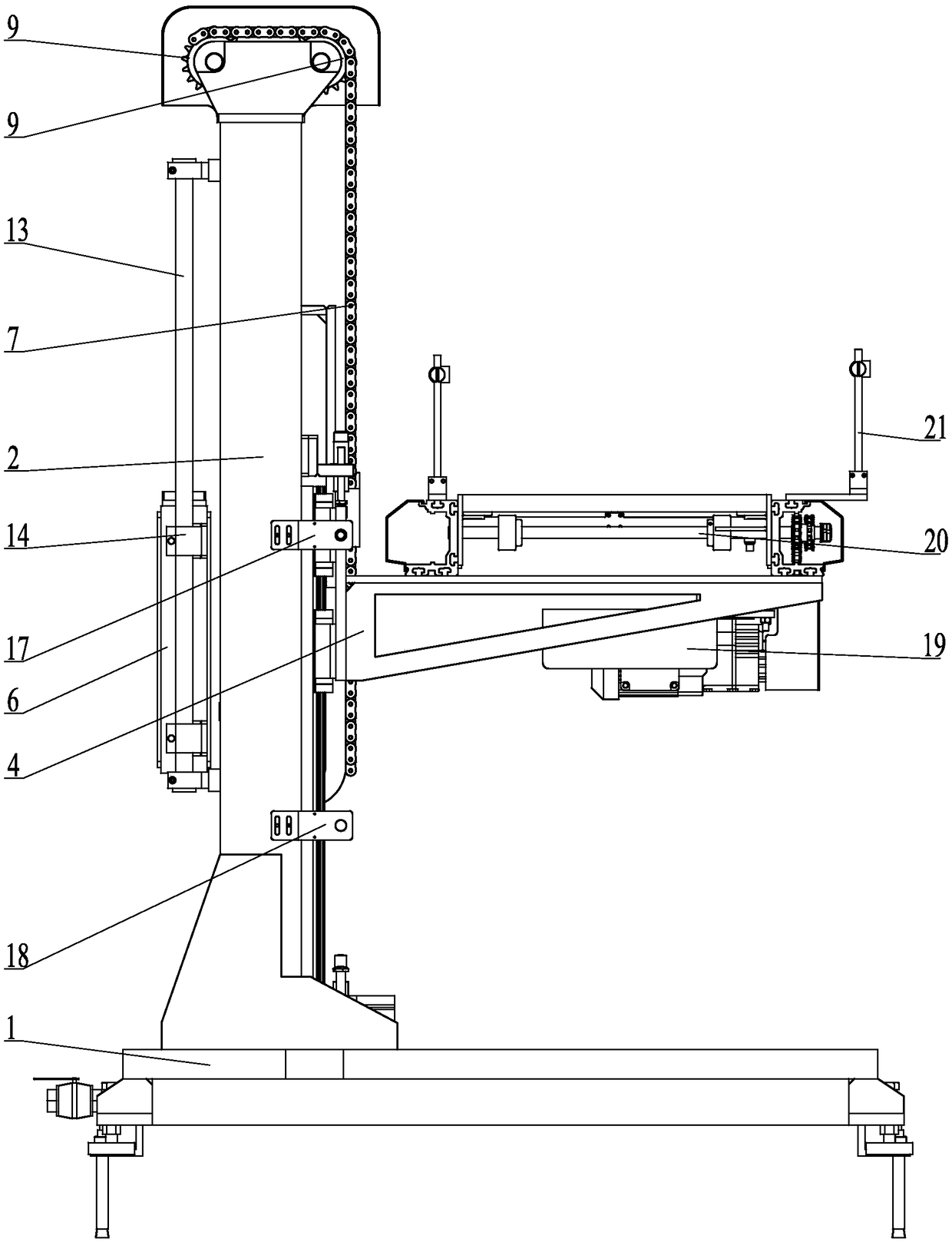

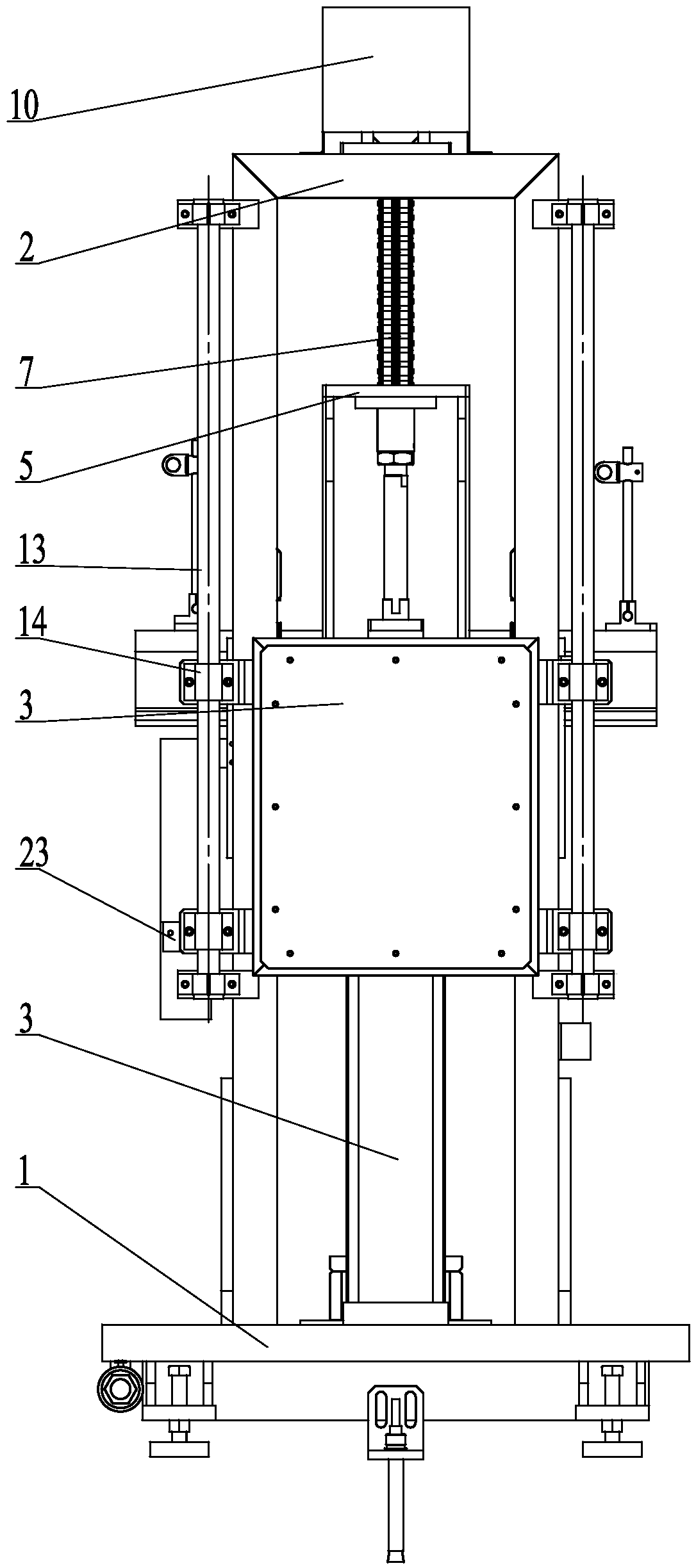

[0012] Specific implementation mode one: combine Figure 1 to Figure 4 Describe this embodiment. A side-mounted lifting roller table with low energy consumption and high stability described in this embodiment includes a base 1, a bracket 2, a cylinder 3, a roller table mounting frame 4, a cylinder connecting frame 5, a counterweight box 6, and a chain 7. The chain transmission mechanism, the roller guide mechanism, the counterweight guide mechanism and the roller table running mechanism, the bracket 2 is vertically fixed on one side of the upper end surface of the base 1, and the middle part of the inside of the bracket 2 is provided with a cylinder 3, and the cylinder 3 is vertical Fixed on the base 1, the roller table mounting frame 4 is horizontally arranged on the front end of the bracket 2, the roller table running mechanism is arranged on the roller table mounting frame 4, and the rear end of the roller table mounting frame 4 is connected to the cylinder 3 through the cyl...

specific Embodiment approach 2

[0014] Specific implementation mode two: combination Figure 1 to Figure 4 Describe this embodiment, the shape of cylinder connecting frame 5 described in this embodiment is L shape, and the inner end face of the short arm of cylinder connecting frame 5 is vertically affixed to the piston rod of cylinder 3, and the outer end face of the long arm of cylinder connecting frame 5 It is affixed to the rear end face of the roller table mounting frame 4. The undisclosed technical features in this embodiment are the same as those in the first embodiment.

[0015] Such design realizes that the roller table mounting frame 4 moves upwards in the vertical direction when the piston rod of the cylinder 3 is stretched out by the design of the cylinder connecting frame 5 .

specific Embodiment approach 3

[0016] Specific implementation mode three: combination Figure 1 to Figure 4 Describe this embodiment, the chain transmission mechanism described in this embodiment includes two upper sprockets 9, each of the front and rear sides of the upper end of the bracket 2 is respectively provided with an upper sprocket 9, the two upper sprockets 9 are horizontally arranged, and the chain 7 is wound around On the outside of two upper sprockets 9. The undisclosed technical features in this embodiment are the same as those in the first or second specific embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com