Polar plate feeding mechanism for lead acid battery plate packing machine

A technology of plate feeding and lead-acid battery, applied in the direction of mechanical conveyor, conveyor, charge control, etc., can solve the problems of error, low production efficiency, time-consuming and troublesome, etc., to achieve stable and reliable action, high work efficiency, continuous convenient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

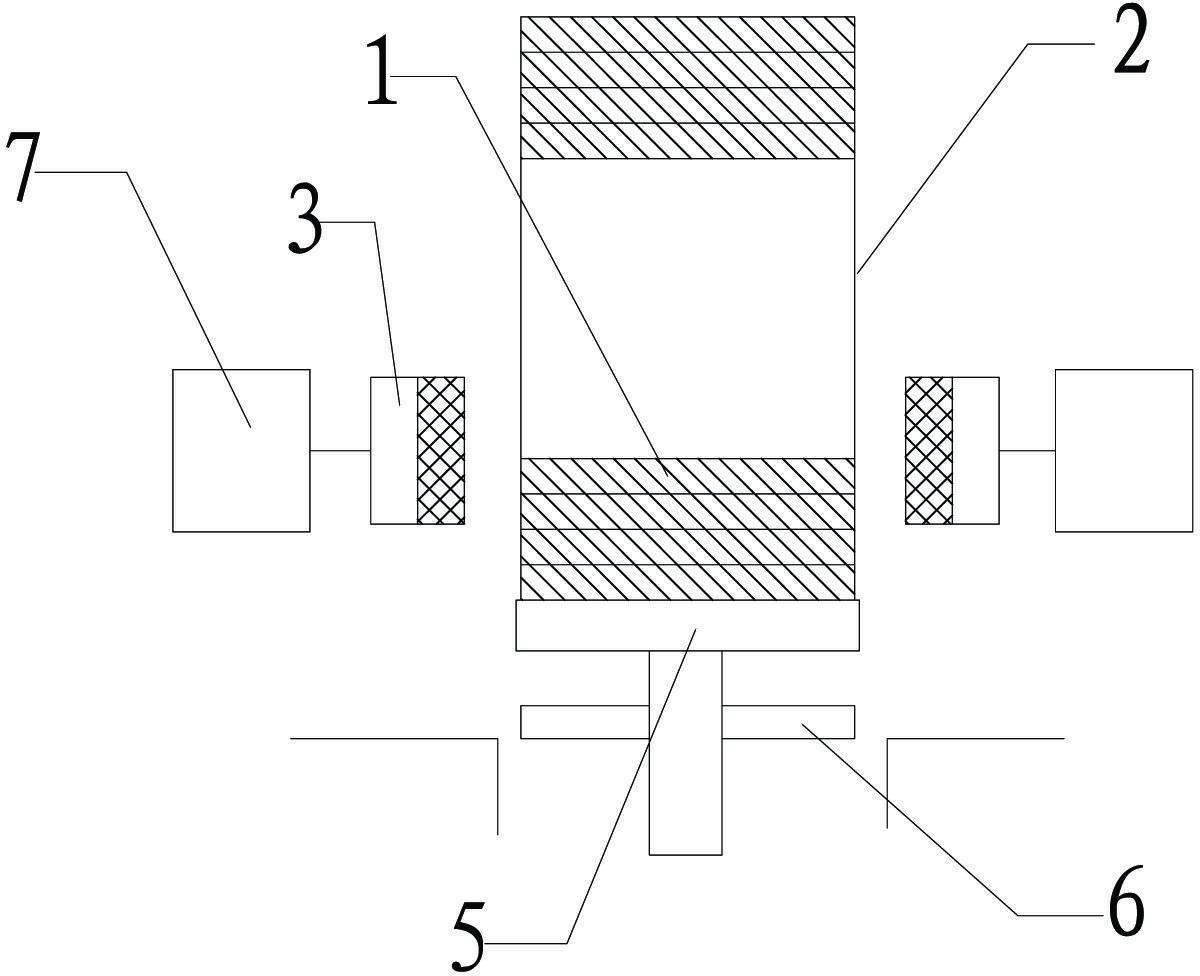

[0013] Embodiment 1: see attached figure 1 to attach image 3 As shown, the electrode plate feeding mechanism for the automatic lead-acid battery sheeting machine described in this embodiment includes a material bin 2 capable of vertically stacking a plurality of electrode plates 1, and holds the inner electrode of the material bin 2. The jaws 3 of the plate 1, the material receiving plate 5 that can be lifted up and down, and the horizontal pushing device 6 for pushing the polar plate 1 that falls on the material receiving plate 5, wherein the jaws 3 are arranged in the silo 2, at the same time, the power source 7 on each side provides pressure to jointly clamp the pole plate 1 in the bin 2; The pole plate 1 falling from the bottom of the bin 2; the horizontal pushing device 6 is correspondingly arranged on one side of the material receiving plate 5, and cooperates with the material receiving plate 5 to act. In addition, the aforementioned power source 7 in this embodiment ...

Embodiment 2

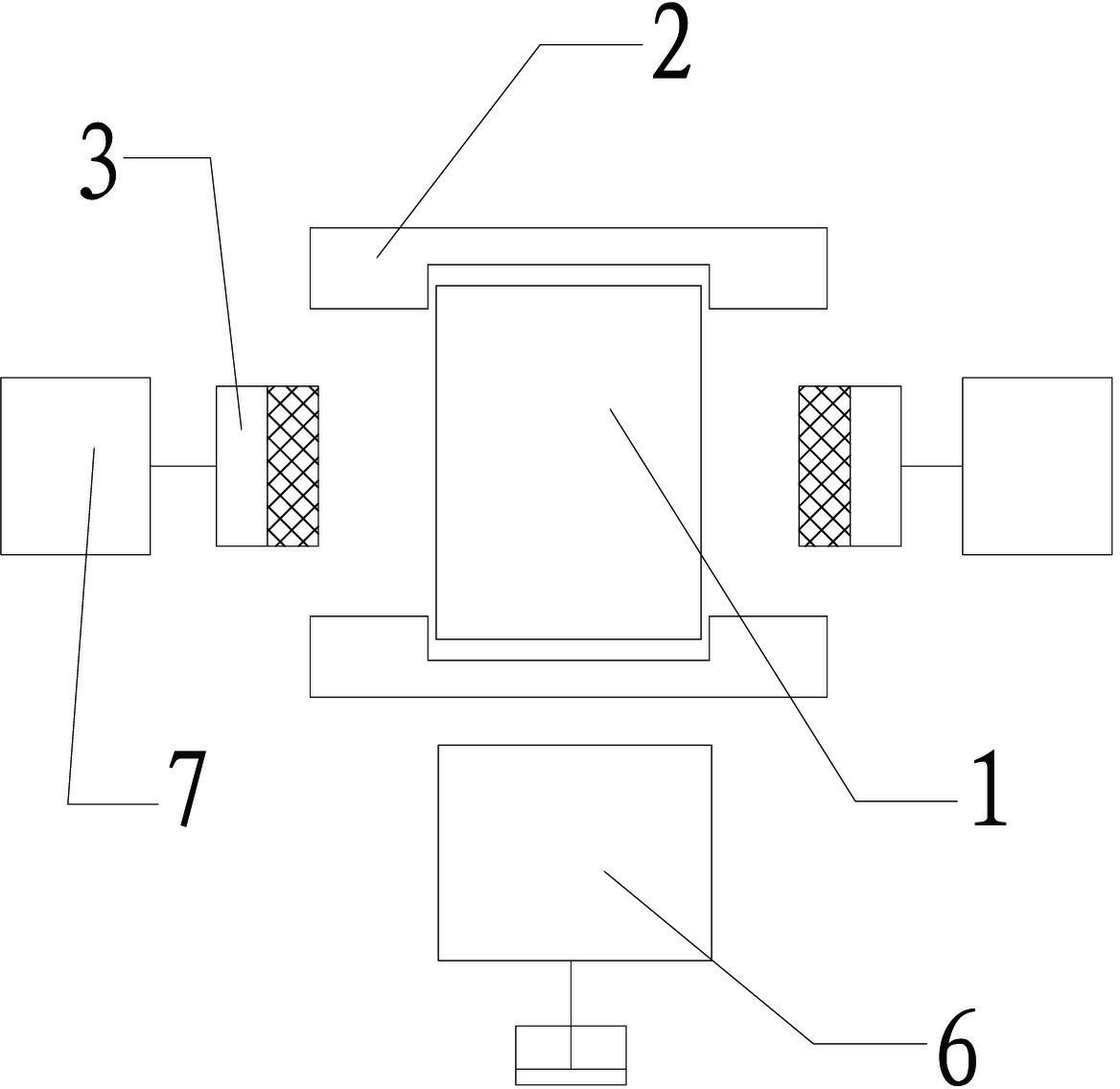

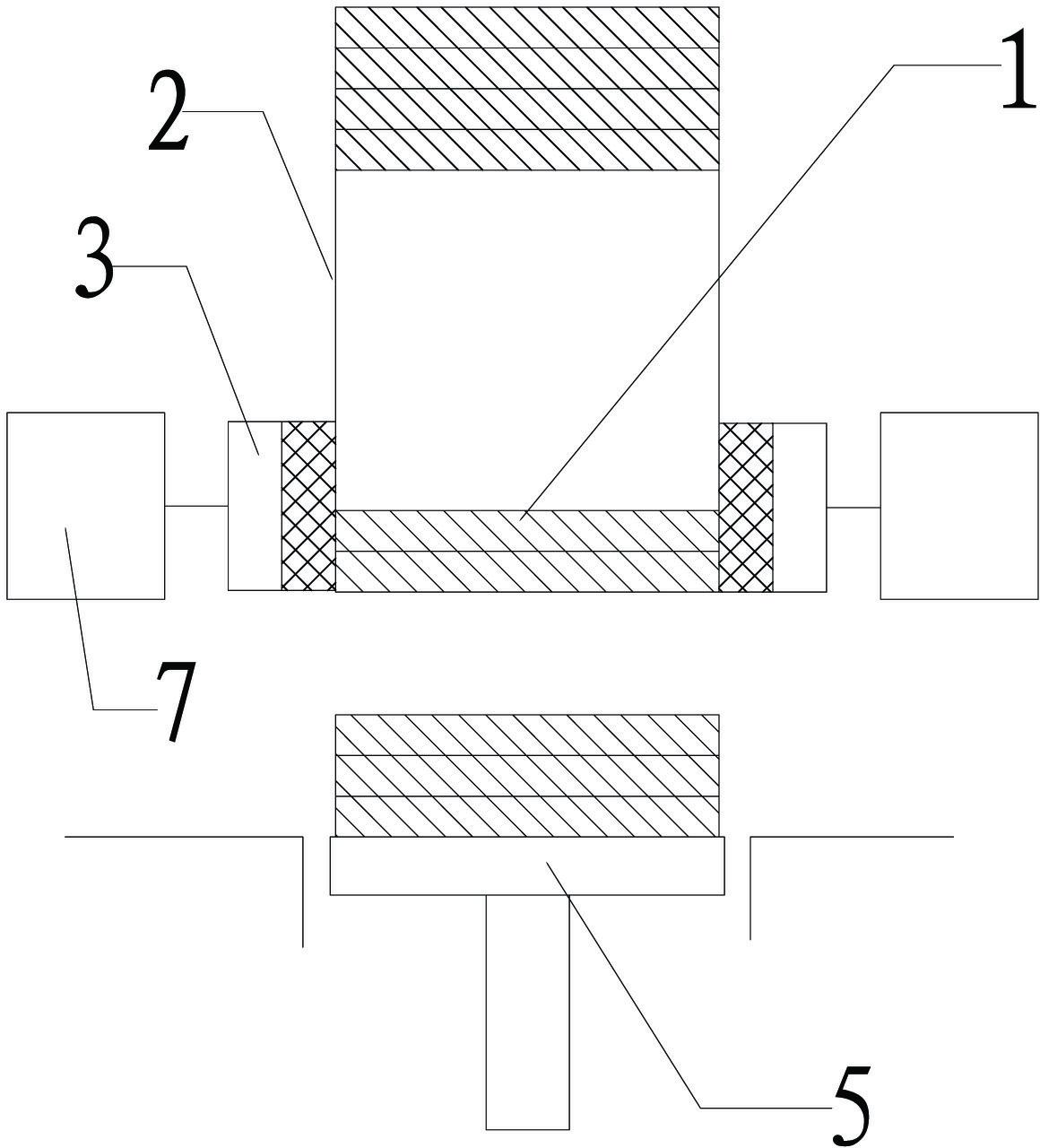

[0015] Embodiment 2: see attached Figure 4 And attached Figure 5 As shown, the difference from Embodiment 1 is that this embodiment does not use clamping jaws 3 to clamp the pole plate 1 in the bin 2, but supports the bin by providing supporting plates 4 on opposite sides of the bin 2. The polar plates 1 in 2 and the supporting plates 4 of this embodiment are respectively driven by the power source 7 on each side to act synchronously, and jointly support the stacked polar plates 1 in the material bin 2. When working, the material receiving plate 5 first extends to the bottom of the material bin 2, and then starts to discharge materials into the material bin 2, and stacks a plurality of pole plates 1 in sequence. When the material bin 2 is full of pole plates 1, the material The supporting plates 4 on both sides of the bin 2 move immediately, driven by the power source 7 on each side to jointly support the upper pole plate 1 in the bin 2, so that the upper pole plate 1 in th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com