Hydraulic system capable of achieving constant pressure control and load sensitive control and control method

A load-sensitive control and hydraulic system technology, applied in the field of hydraulic systems, can solve the problems of additional auxiliary pumps, etc., and achieve the effects of reduced energy consumption, reliable operation, and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

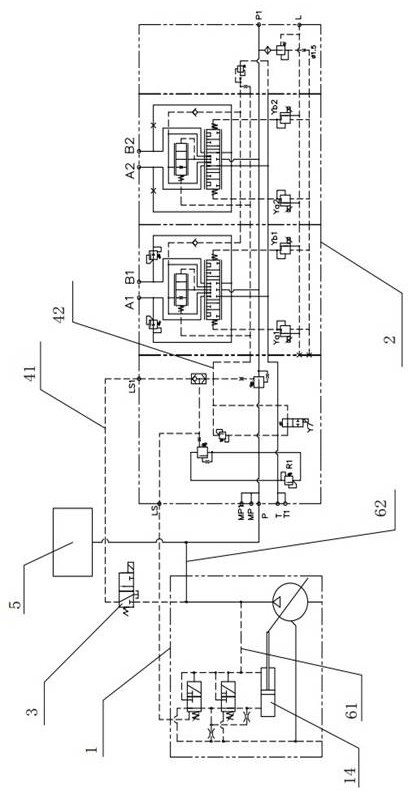

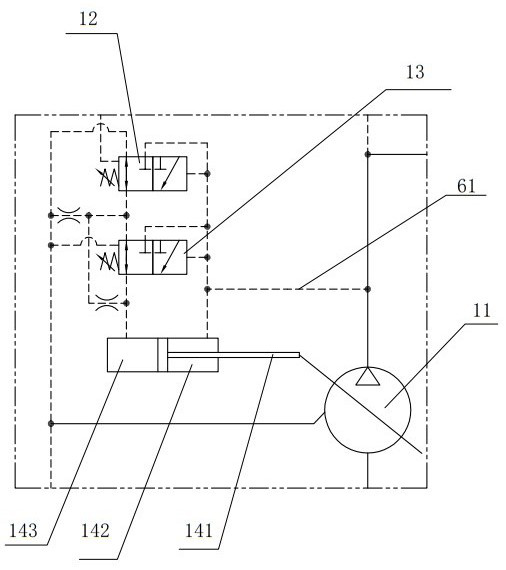

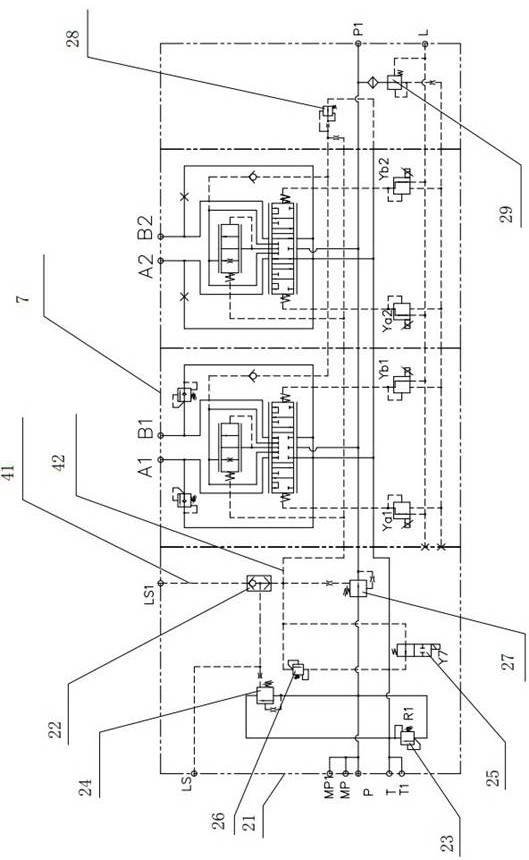

[0023] Embodiments of the present invention will be further described below in conjunction with accompanying drawings:

[0024] Depend on figure 1 combine Figure 2-3 As shown, a hydraulic system capable of realizing constant pressure control and load-sensing control includes a load-sensing variable pump 1, a multi-way valve 2, a reversing valve 3, a first feedback oil circuit 41 and a suspension module 5. The multiple The road valve includes a control module 21, a second feedback oil circuit 42, a shuttle valve 22 and at least one working module 7, and the load sensitive variable pump includes a variable pump 11, a control valve 12, a cut-off valve 13 and a control cylinder 14. The control cylinder includes a piston rod 141, a rod chamber 142 and a rodless chamber 143. The variable pump is connected to the first oil circuit 61 and the second oil circuit 62 respectively, and the first oil circuit is respectively connected to the control valve. cavity, the cut-off valve contr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com