Construction method of double-type maintenance warehouse for PC component assembly line

A construction method and technology of maintenance silo, which can be used in basic structure engineering, excavation, manufacturing tools, etc., and can solve the problems of safety accidents, time-consuming and laborious, and large construction errors of foundation base plates.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0061] For ease of understanding, combined here Figure 2-20 , the concrete construction process of the present invention and the mode of work of each part are further described as follows:

[0062] Concrete construction process of the present invention is as Figure 2-10 As shown, the steps are as follows:

[0063] Step a: According to the positions of the front warehouse 40a and the rear warehouse 40b, correspondingly dig out the foundation pit;

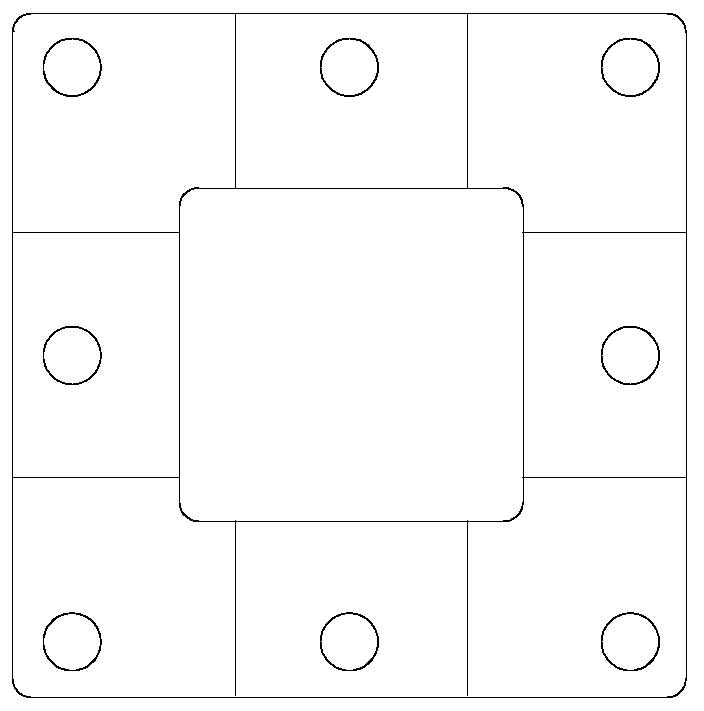

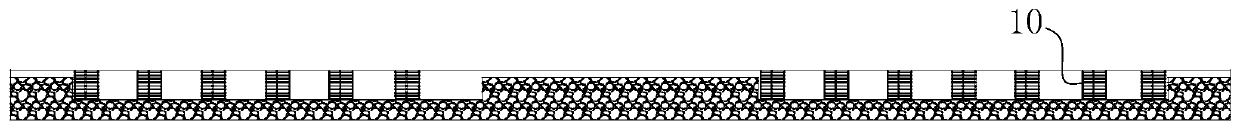

[0064] Step b: Pre-embed the reinforced grid frame 10 to form the foundation, and put the foundation reinforced frame 20 in the reserved pit at the foundation;

[0065] Step c: Fix each mounting seat of the positioning tool 30 in one-to-one correspondence on the foundation steel frame 20 through anchor bolts, and then adjust the level and elevation of the positioning tool 30 and then fix them;

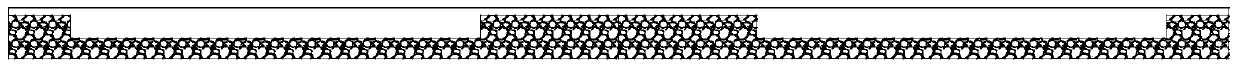

[0066] Step d: pouring concrete for the first time;

[0067] Step e: remove the anchor bolts, and remove the positioning tool 30;

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com