Hydraulic pipeline system for forklift two-section full-free gantry

A hydraulic pipeline and free door technology, applied in the direction of the lifting device, can solve the problems of inconsistent lifting speed of the mast, affect the field of view of the mast, and high processing cost, and achieve the effect of consistent speed, increased field of view, and lifting priority

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be further described through the embodiments below in conjunction with the accompanying drawings.

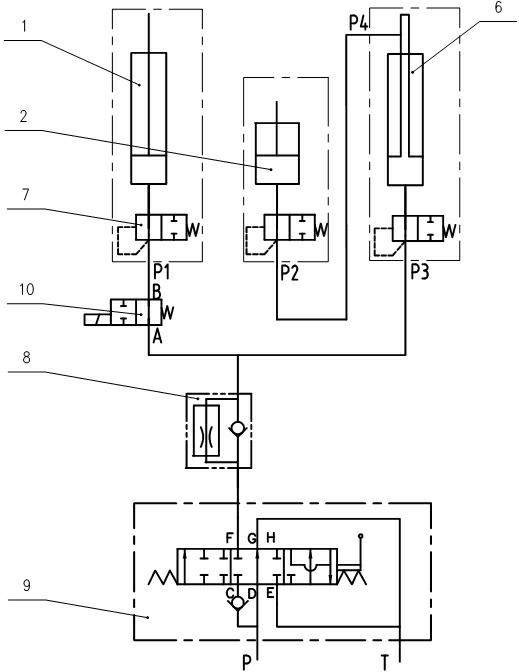

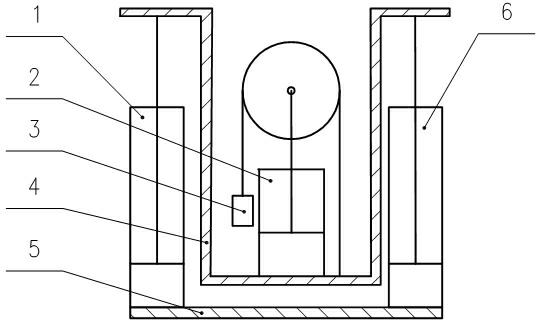

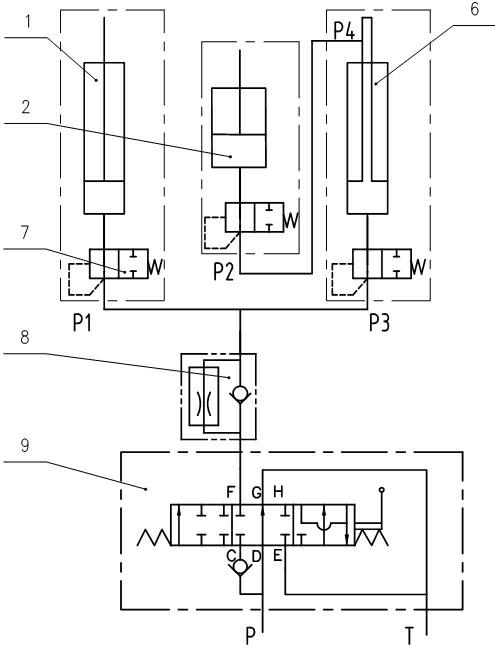

[0013] see figure 1 , The hydraulic piping system for the two-section full-free mast of the forklift includes the left rear lifting cylinder 1, the right rear lifting cylinder 6, the front lifting cylinder 2, the speed limiting valve 8 and the lifting valve 9. The effective area of the front lifting oil cylinder 2 is equal to 2 times of the sum of the effective area of the left rear lifting oil cylinder 1 and the effective area of the right rear lifting oil cylinder 6. The lifting valve 9 is a three-position six-way valve, the first oil inlet C and the second oil inlet D are connected to the system through a three-way pipe to supply oil; the first oil outlet E and the second oil outlet G are connected through a three-way The pipe is connected to the oil tank; the first working oil port F is connected to the oil outlet of the speed limiti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com