Reducing piled force-expanding type oil cylinder opening-closing device and using method thereof

A technology for opening and closing device and power cylinder, which is applied in the field of devices for opening and closing metal molds of hydraulic cylinders, can solve problems such as inability to draw and open molds, and achieve the effects of reducing waste of shutdown, convenient use and reducing cylinder diameter.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

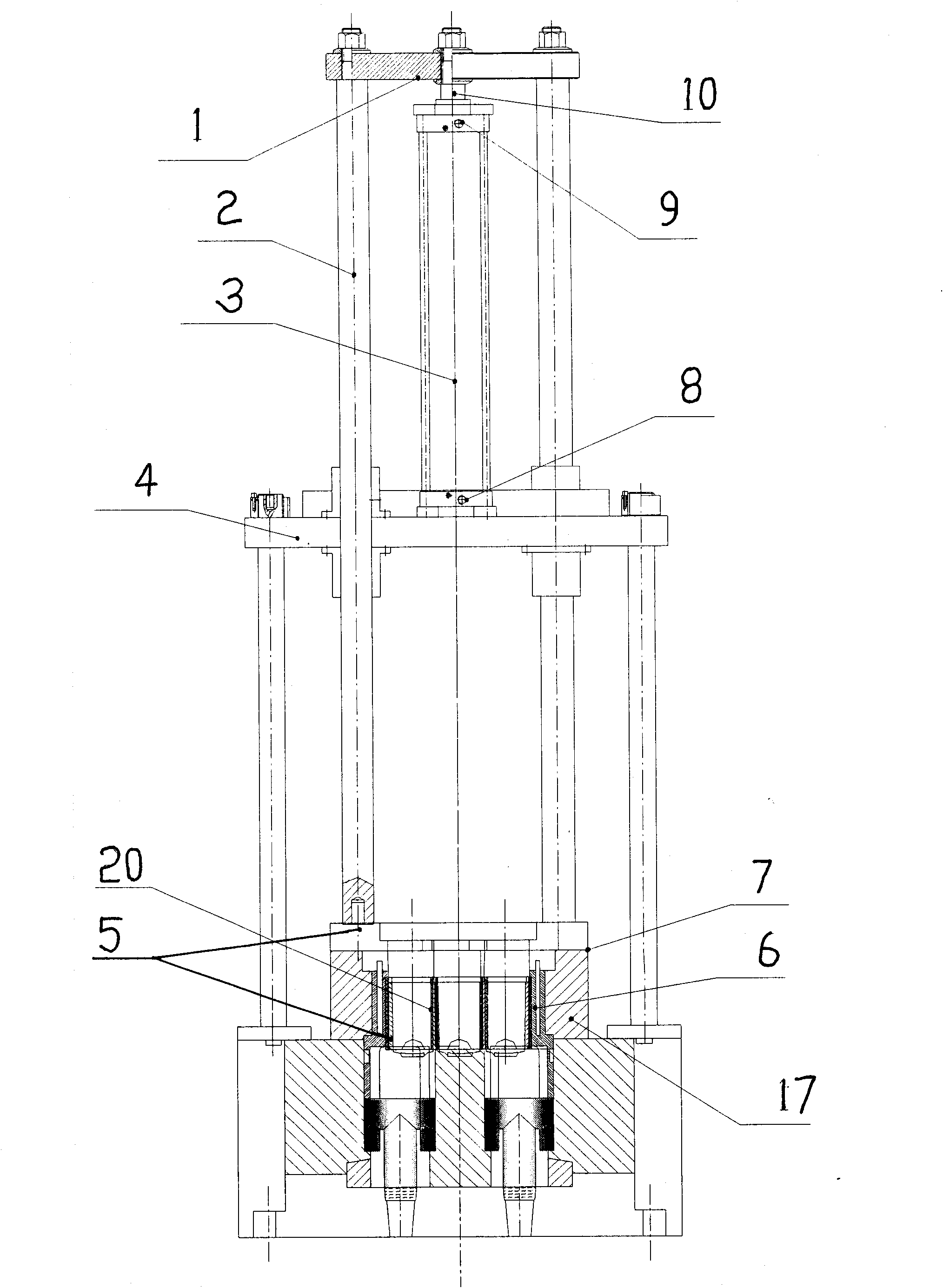

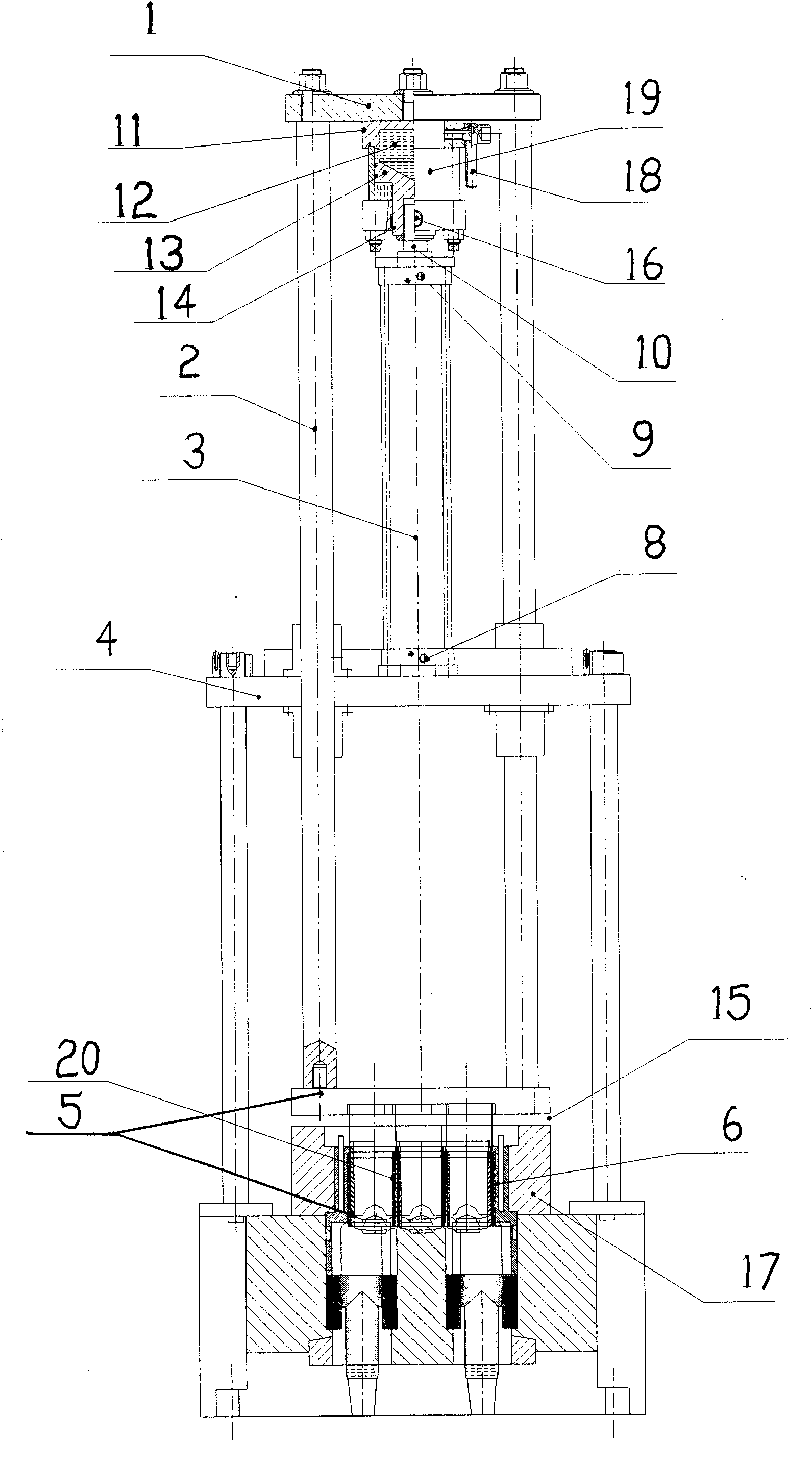

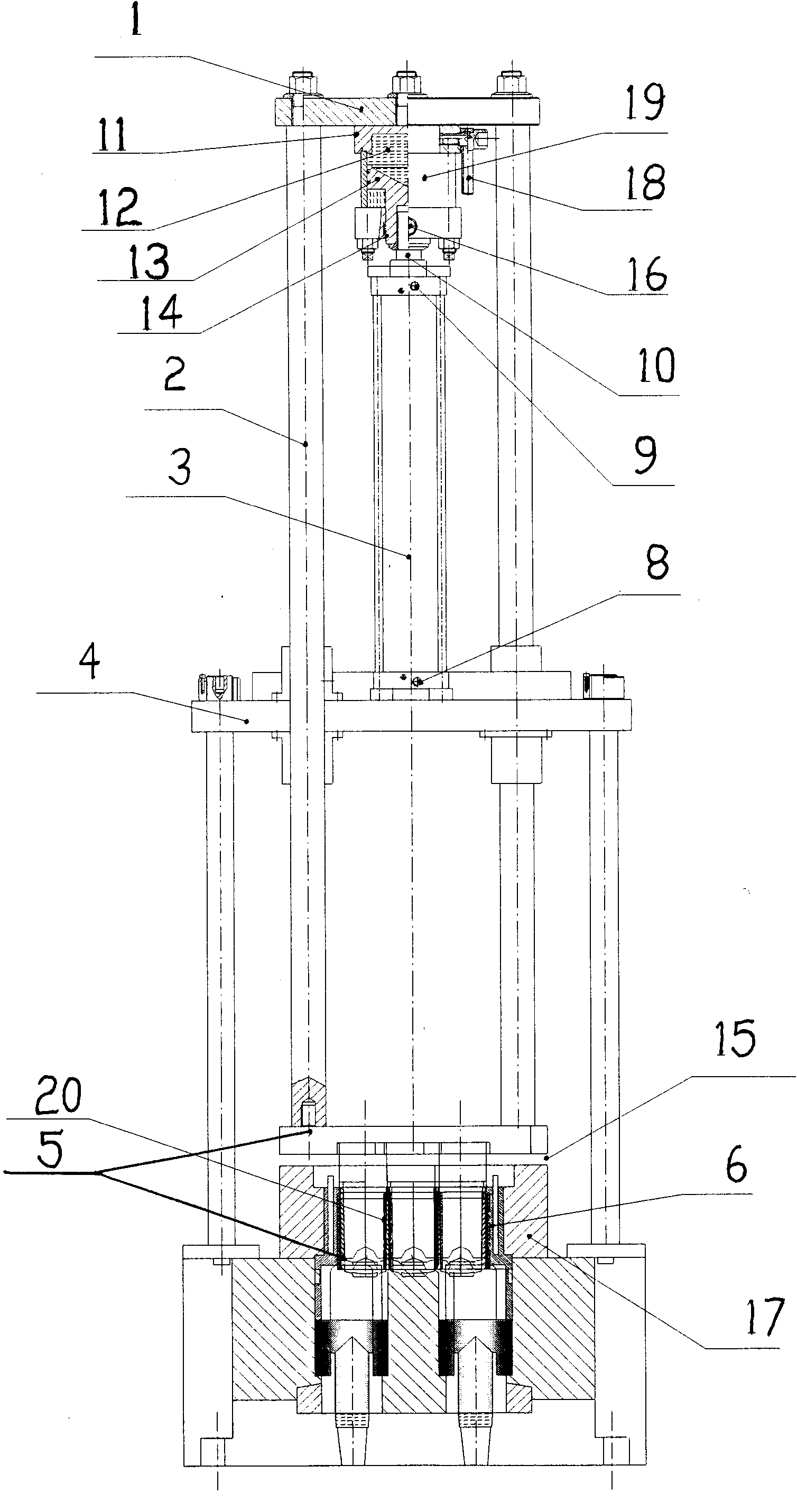

[0010] Such as figure 1 As shown, the known metal mold hydraulic cylinder opening and closing device that drives the metal mold with a hydraulic cylinder includes a power cylinder 3, the power cylinder 3 is fixed on the cylinder seat 4, and the power cylinder 3 has a piston cavity inlet and outlet oil hole 8 and a piston rod cavity The oil inlet and outlet holes 9, the outer end of the piston rod 10 of the power cylinder 3 are connected to the cross-dan 1, the cross-dan 1 is connected to the pull rod 2, the pull rod 2 is connected to the metal mold core 5, and the metal mold core 5 is equipped with a metal cylinder liner 20, and the metal mold core 5 will The metal cylinder liner 20 is inserted into the metal cavity 6 of the metal mold, and the metal mold core and the metal cylinder liner are molded into the outer mold 17 of the metal mold to form the mold clamping surface 7, but the mold clamping surface is generally After the 7 places are solidified and shrunk by the molten ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com