Multifunctional rolling steamer production line

A production line and rolling technology, applied in cooking utensils, household utensils, applications, etc., can solve problems such as visual errors, manual operator burns, and production efficiency that cannot meet the needs of modern production, so as to improve production efficiency and ensure the system safe effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be further described in detail below in conjunction with the accompanying drawings.

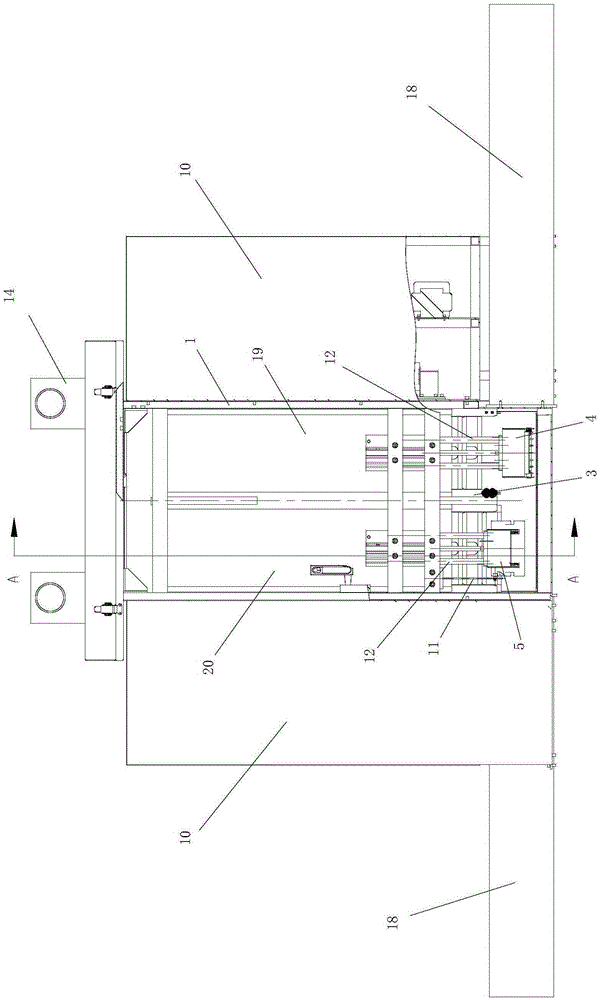

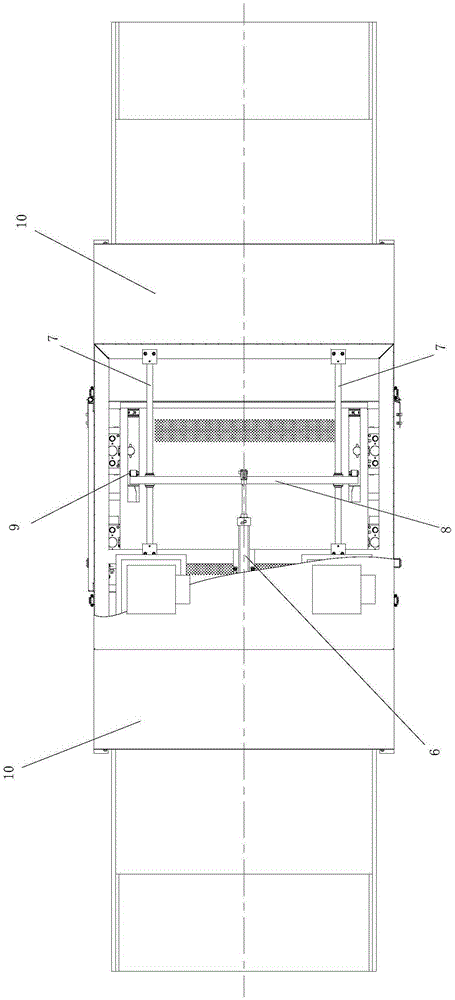

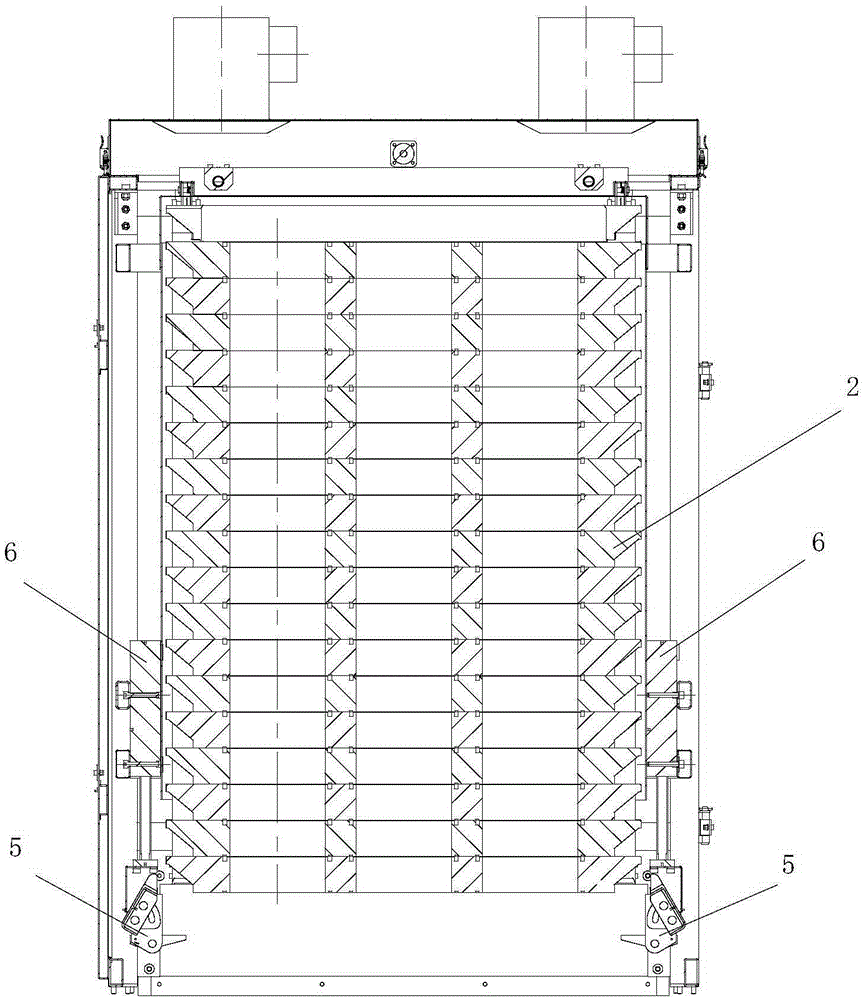

[0036] Such as figure 1 , 2 , 3, the multi-functional rolling steam box production line includes a bottomless square box frame 1, a heat source 10 (microwave oven or steam) and several molds 2 that can be stacked on each other for containing food. The top of the frame 1 is provided with an air exchange port 14, and the bottom of the square box frame 1 is fixed on the production line track 18. The square box frame 1 is divided into two parts, the symmetrical lifting side 19 and the lowering side 20, and the lifting side 19 and the lowering side 20 are respectively There is a stack of tires 2 in the array, the lifting side 19 is provided with a lifting mechanism, the lowering side 20 is provided with a lowering mechanism, the top of the square box frame 1 is provided with a flat pushing mechanism, and each tire 2 on the production line track 18 is lifted by th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com