Safety shutoff value device for on-line interception of high-temperature fused slag

A shut-off valve and slag technology is applied in the field of safety shut-off valve devices for intercepting high-temperature slag online, which can solve problems such as large heat consumption and achieve the effects of small maintenance, stable chain transmission and simple structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

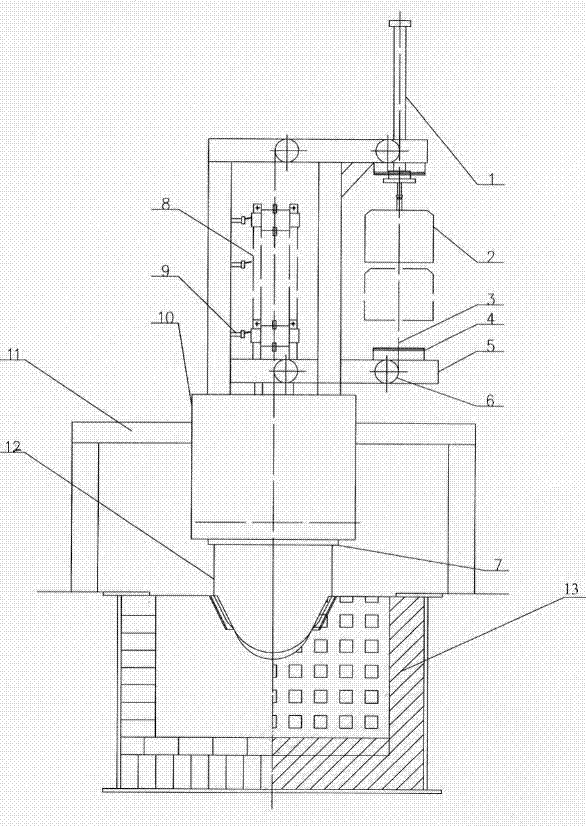

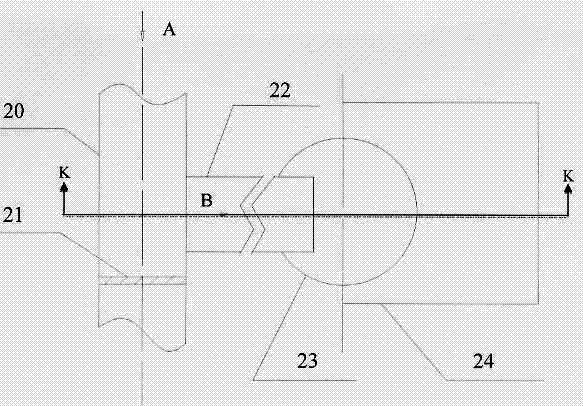

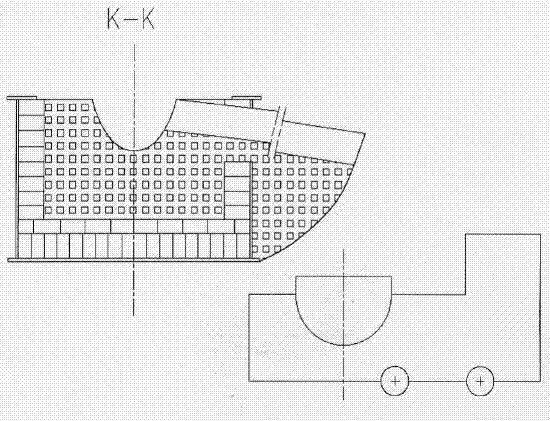

[0029] see figure 1 , the present invention provides a safety shut-off valve device for intercepting high-temperature slag online, which is mainly composed of a cylinder 1, a counterweight 2, a chain 3, a positioning block 4, a bracket 5, a sprocket assembly 6, a cooling water pipe 8, and a limit position 9. Valve box 10, bracket two 11, valve plate 12 and slag ditch 13 are composed.

[0030] The valve box 10 is fixed above the slag ditch 13 through the bracket two 11, and the bracket one 5 is fixed above the valve box 10. Cylinder 1, sprocket assembly 6, limit place 9, positioning block 4 are fixed on the support one 5. The counterweight 2 is connected with the cylinder 1 , one end of the chain 3 is connected with the counterweight 2 , and the other end of the chain 3 is connected with the valve plate 12 .

[0031] A part of the cooling water pipe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com