Pile frame jacking device of pile driving barge, and pile frame jacking and lying method

A technology of jacking device and piling ship, which is applied to sheet pile walls, transportation and packaging, special purpose ships, etc. Structural strength, convenient force application, and the effect of reducing the weight of the pile frame

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

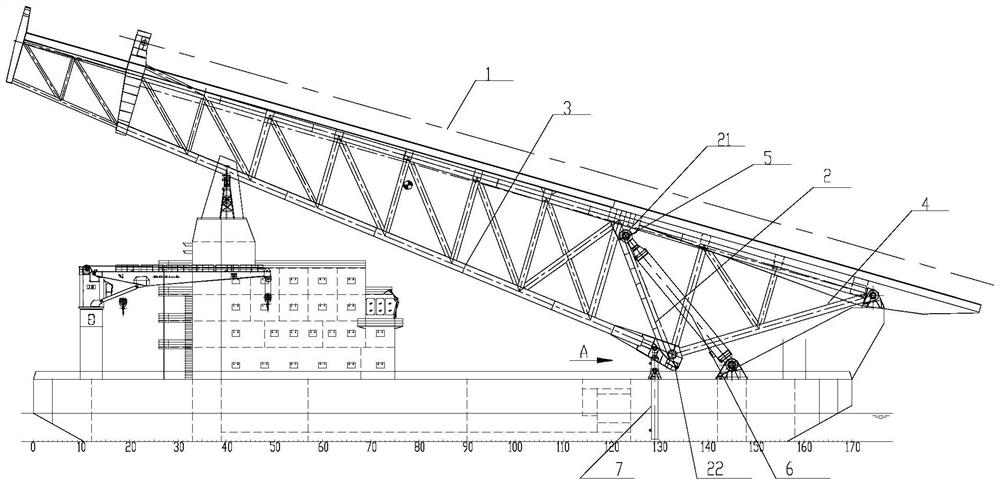

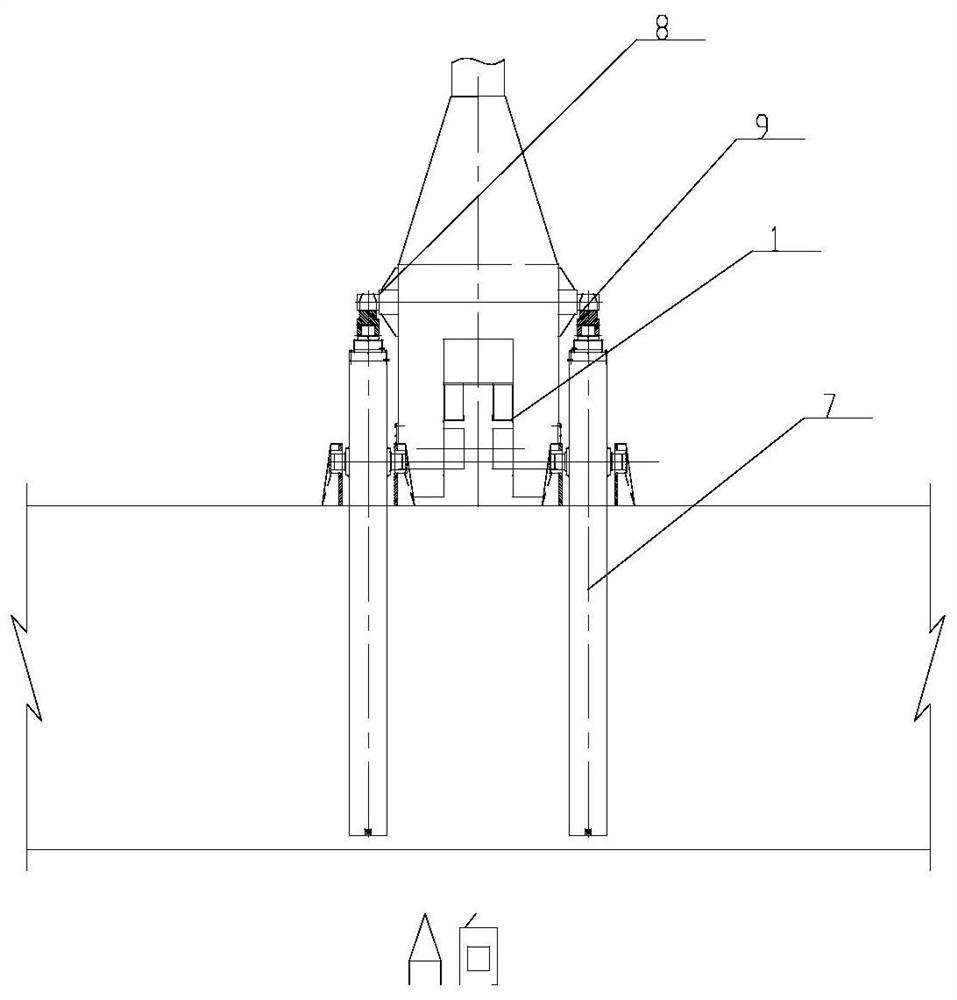

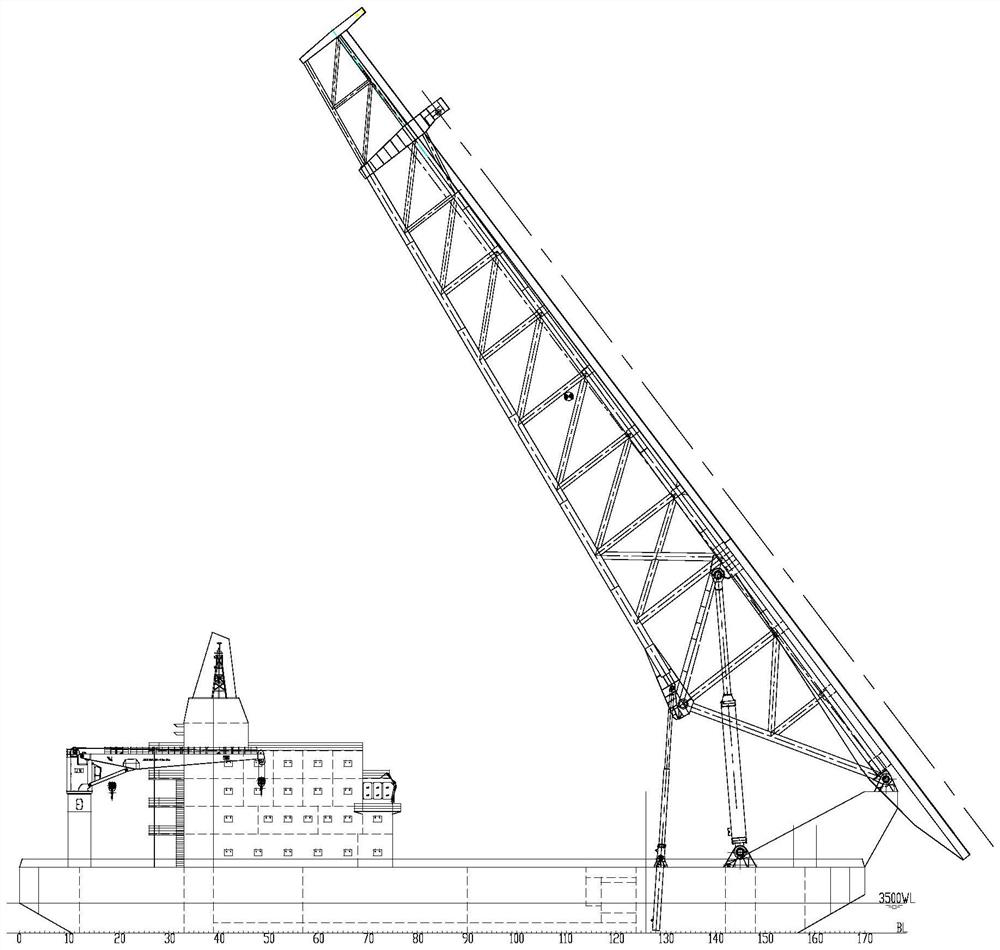

[0034] like Figure 1-6 As shown, a pile frame jacking device of a piling ship includes a slideway 2 arranged on the pile frame 1, one end of the slideway 2 is arranged at the junction of the rear side bar 3 and the lower side bar 4 of the pile frame 1, and the sliding The other end of the road 2 is arranged near the piling surface of the pile frame 1. When the pile frame 1 stands up, the end of the slideway 2 close to the piling surface of the pile frame 1 is higher than the other end; the slideway 2 is provided with a movable block 5; A main oil cylinder 6 is hinged, and the main oil cylinder 6 is a double-acting oil cylinder. The end of the piston rod of the main oil cylinder 6 is hinged with the movable block 5. One end of the slideway 2 at the piling surface is provided with an upper fixed point 21 for fixing the movable block 5, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com