Industrial robot

An industrial robot and horizontal rotation technology, which is applied in the direction of manipulators, manufacturing tools, mechanical equipment, etc., can solve the problems of time-consuming assembly, weight of the balance device, and more parts, so as to ensure the strength of the arm and the effect of longer stroke

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

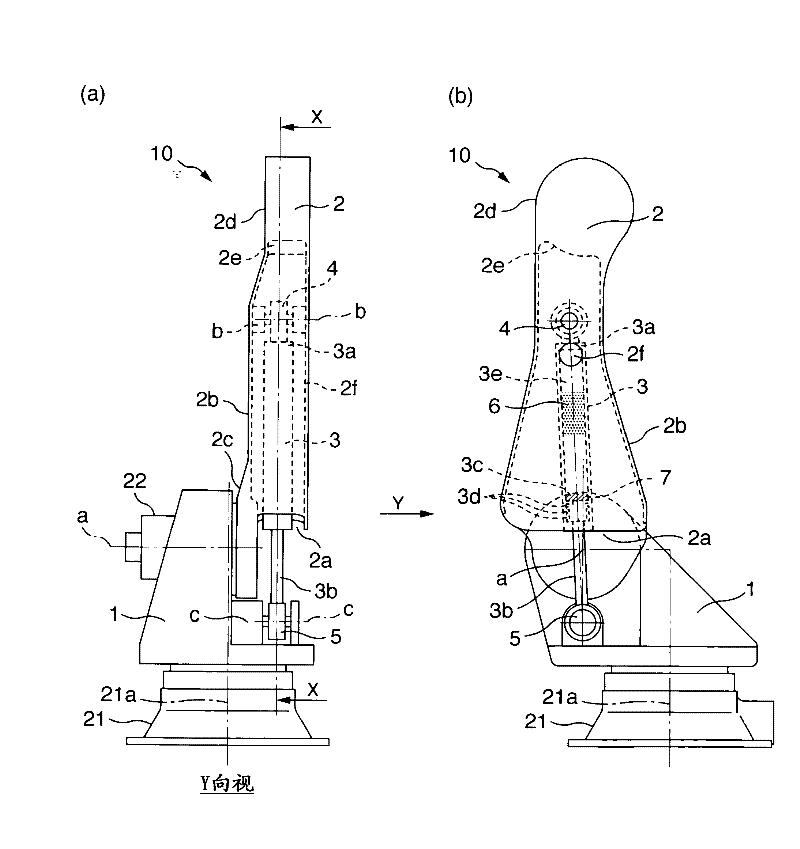

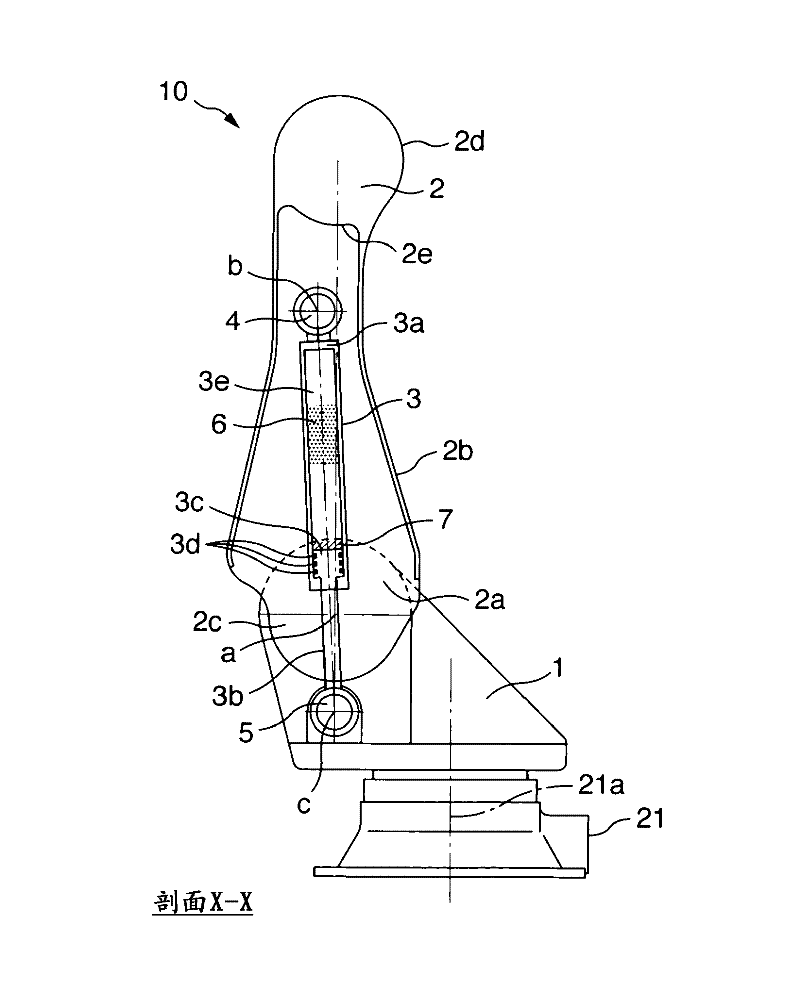

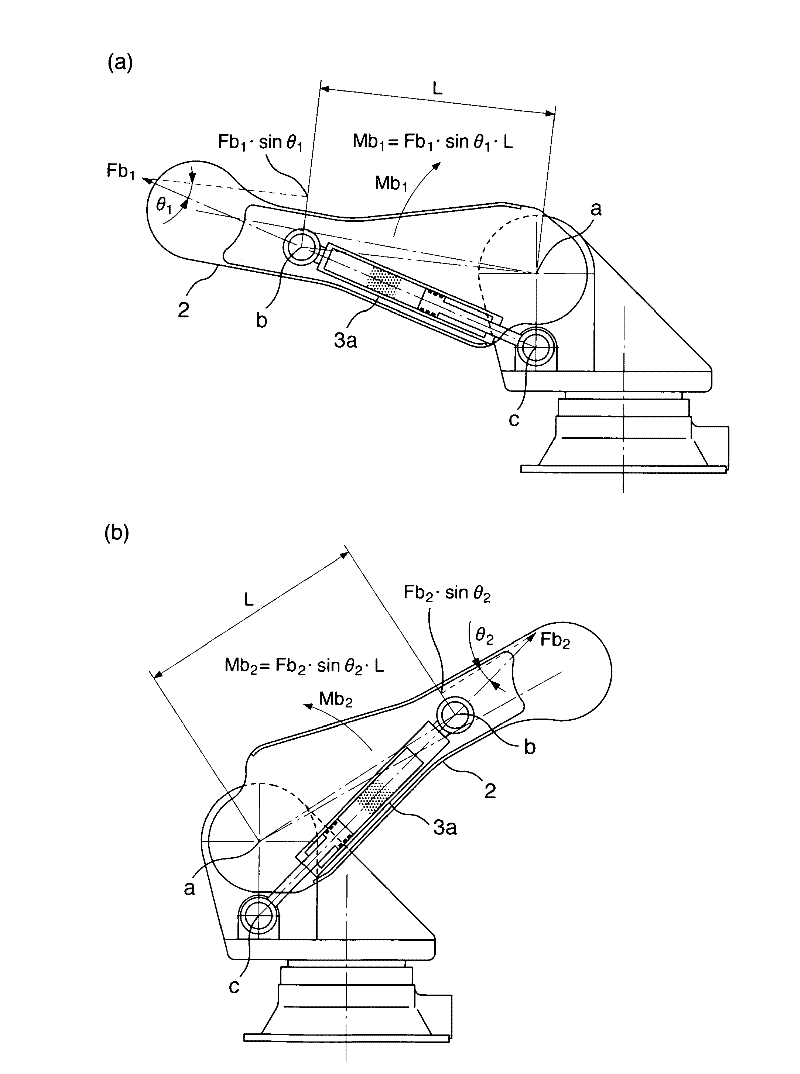

[0032] Embodiments of the present invention will be described with reference to the drawings. figure 1 (b) is a partial external view showing an industrial robot according to an embodiment of the present invention, figure 1(a) is figure 1 (b) Y-direction view, figure 2 yes means figure 1 (a) Partial sectional view of the X-X line section. Such as figure 1 , figure 2 As shown, the industrial robot 10 of the present invention has a frame 1 rotatable around a rotation axis 21a of a base 21, an arm 2 freely supported around a horizontal rotation axis a horizontally arranged on the frame (tilted rotation) and Balancing device 3 for lightening the load on the arm. The arm 2 is further provided with a second arm and a wrist (not shown) to constitute a multi-joint industrial robot, which is the same as conventional ones, and thus description thereof will be omitted.

[0033] The arm 2 is provided with a base portion 2c freely rotatable in a cantilever state and supported...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com