Projection welding upper electrode structure capable of sequentially welding multiple nuts in time sharing manner

An electrode structure and nut technology, applied in pressure electrodes, electrode features, welding equipment, etc., can solve the problems of inability to guarantee nut pressure and welding current, increase the manufacturing and use costs of projection welders, and increase the size of projection welders. Achieve the effect of reducing the diameter of the welding cylinder and the capacity of the transformer, reducing the procurement cost, and reducing the volume and weight of the whole machine

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

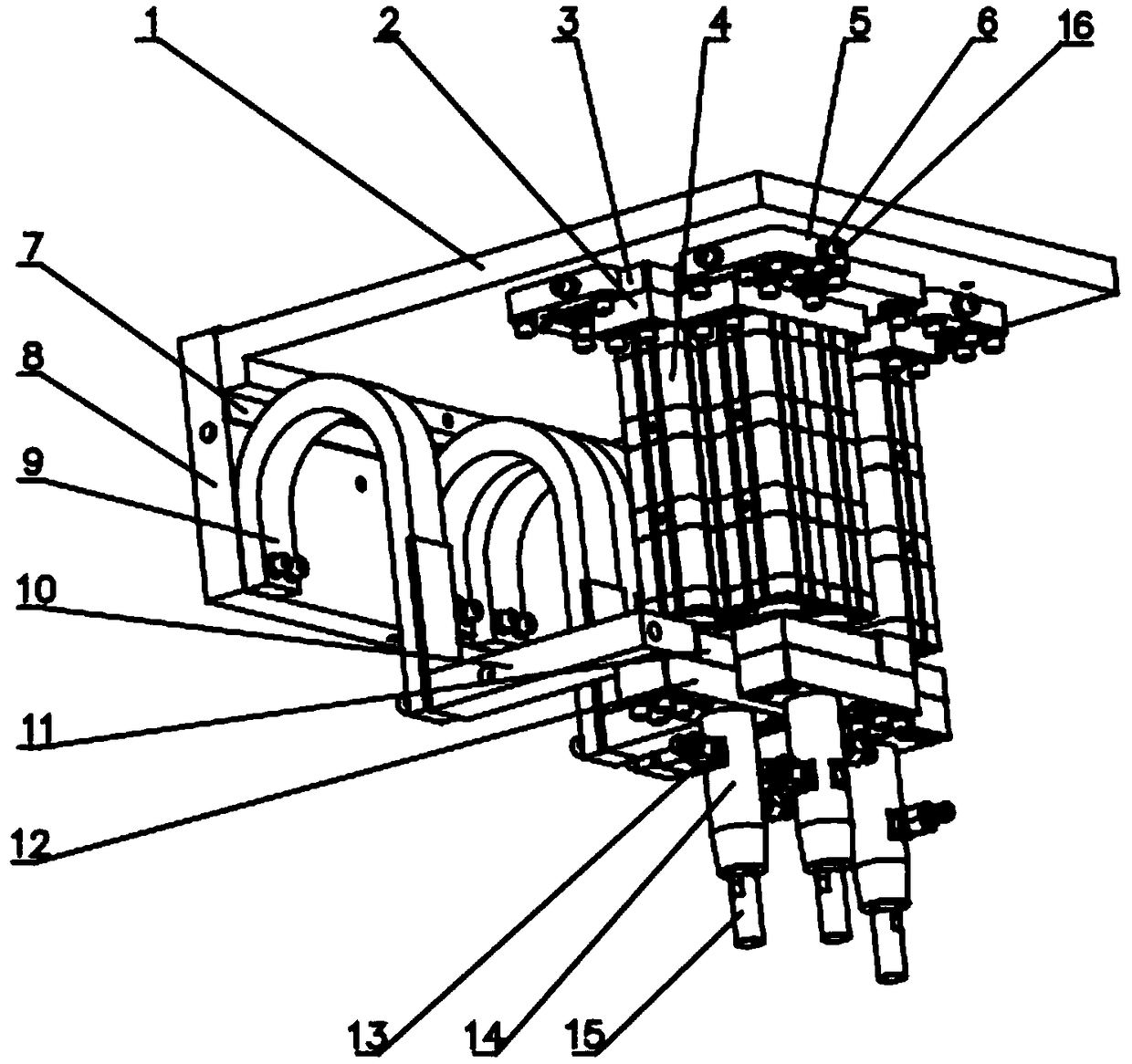

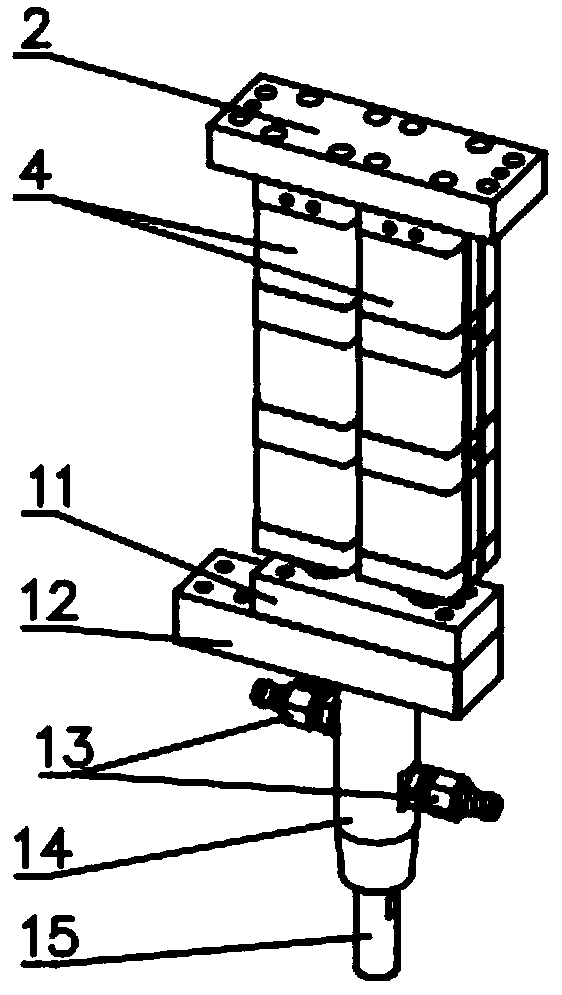

[0023] like figure 1 , 2 The projection welding upper electrode structure that can weld a plurality of nuts sequentially in a time-sharing manner as shown includes a base plate 1 and at least three sets of electrode assemblies arranged on the base plate 1, and an adjustable mounting plate 3 is connected to the base plate 1 by screws. , the mutually vertical sides of the adjustable mounting plate 3 are connected to the positioning block 5 through screws 16, and each set of the electrode assembly includes an adjustable mounting plate 3, a cylinder mounting plate 2, a welding cylinder 4, a cylinder electrode transition plate 11, Electrode connection seat 12, electrode body 14, faucet 13 and electrode head 15, the tail of the welding cylinder 4 is connected with the cylinder mounting plate 2 by screws, and the head of the welding cylinder 4 is connected to the cylinder electrode transition plate by screws 16 11, the electrode cylinder transition plate 11 is connected to the elect...

Embodiment 2

[0031] The inside of the electrode body 14 is provided with threaded holes, and the outside of the electrode head 15 is provided with external threads, and the electrode head 15 and the electrode body 14 are fixed by threaded connection, that is, the electrode head 15 is screwed into the electrode body 14 by the external thread Inside, the outer end of the electrode body 14 is also covered with an insulating sleeve, which can be used as an insulating material for the electrode body 14 .

[0032] It should be noted that the actions of the above-mentioned components are all controlled by the welding controller in order. The controller can be a PLC system.

[0033] Way of working:

[0034]When performing nut welding, first adjust the position of the adjustable mounting plate 3 relative to the bottom plate 1 by increasing or decreasing the number of adjusting gaskets 6 inserted between the positioning block 5 and the adjustable mounting plate 3, so as to complete the positioning ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com