Ultrahigh pressure hydraulic press

A technology of ultra-high pressure and hydraulic presses, which is applied in the field of hydraulic presses to achieve the effects of reducing energy consumption, reducing manufacturing costs, and reducing the space occupied by equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

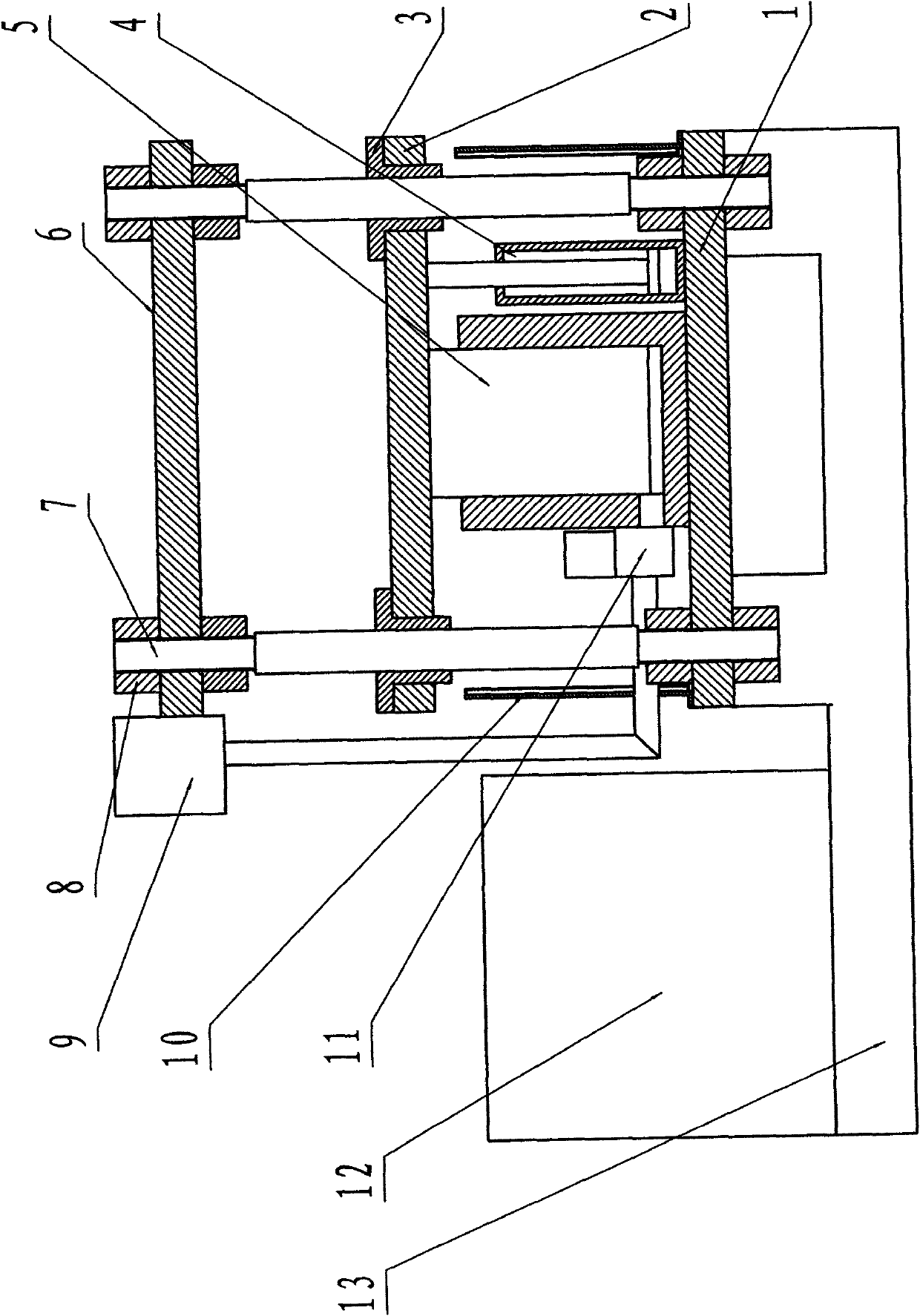

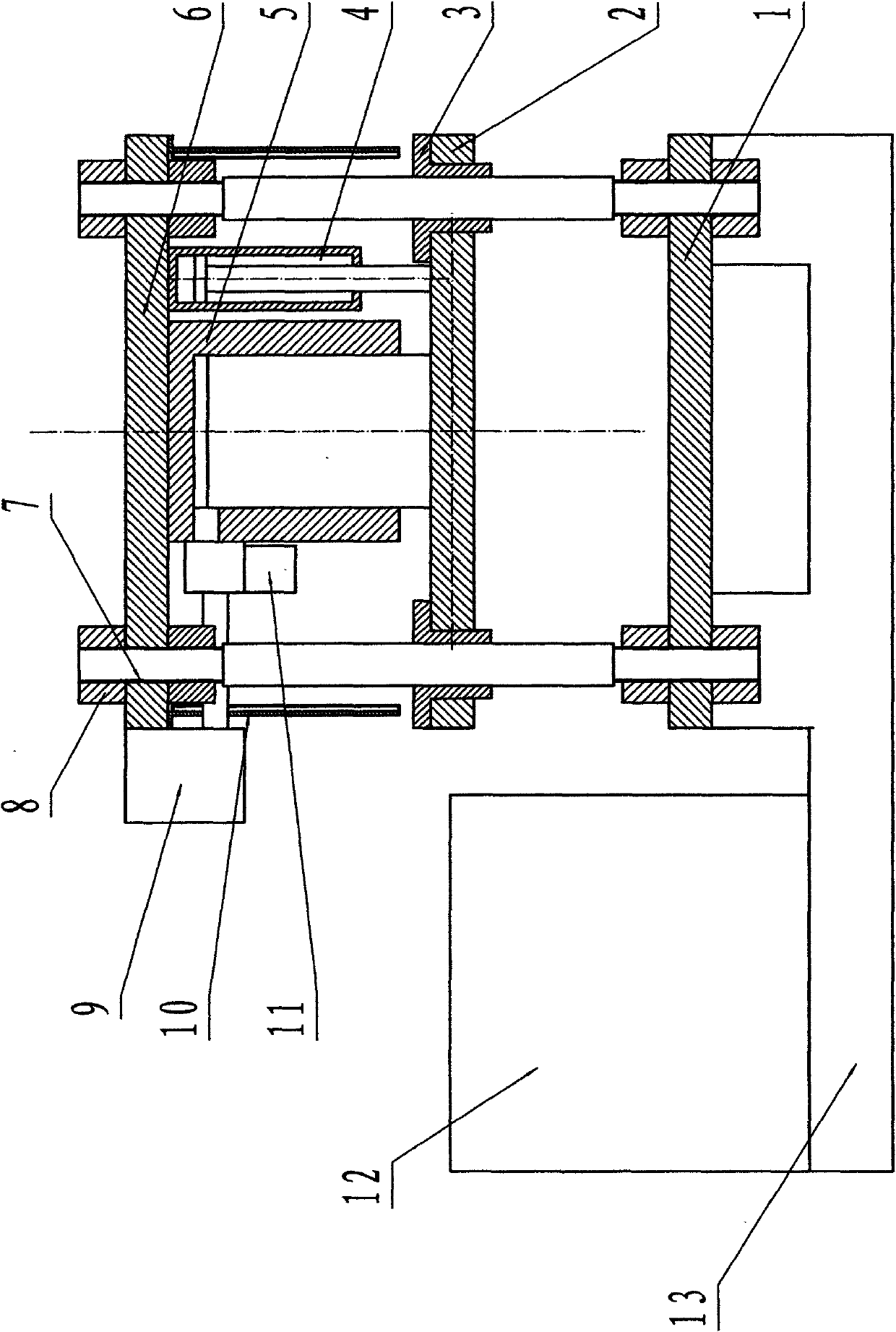

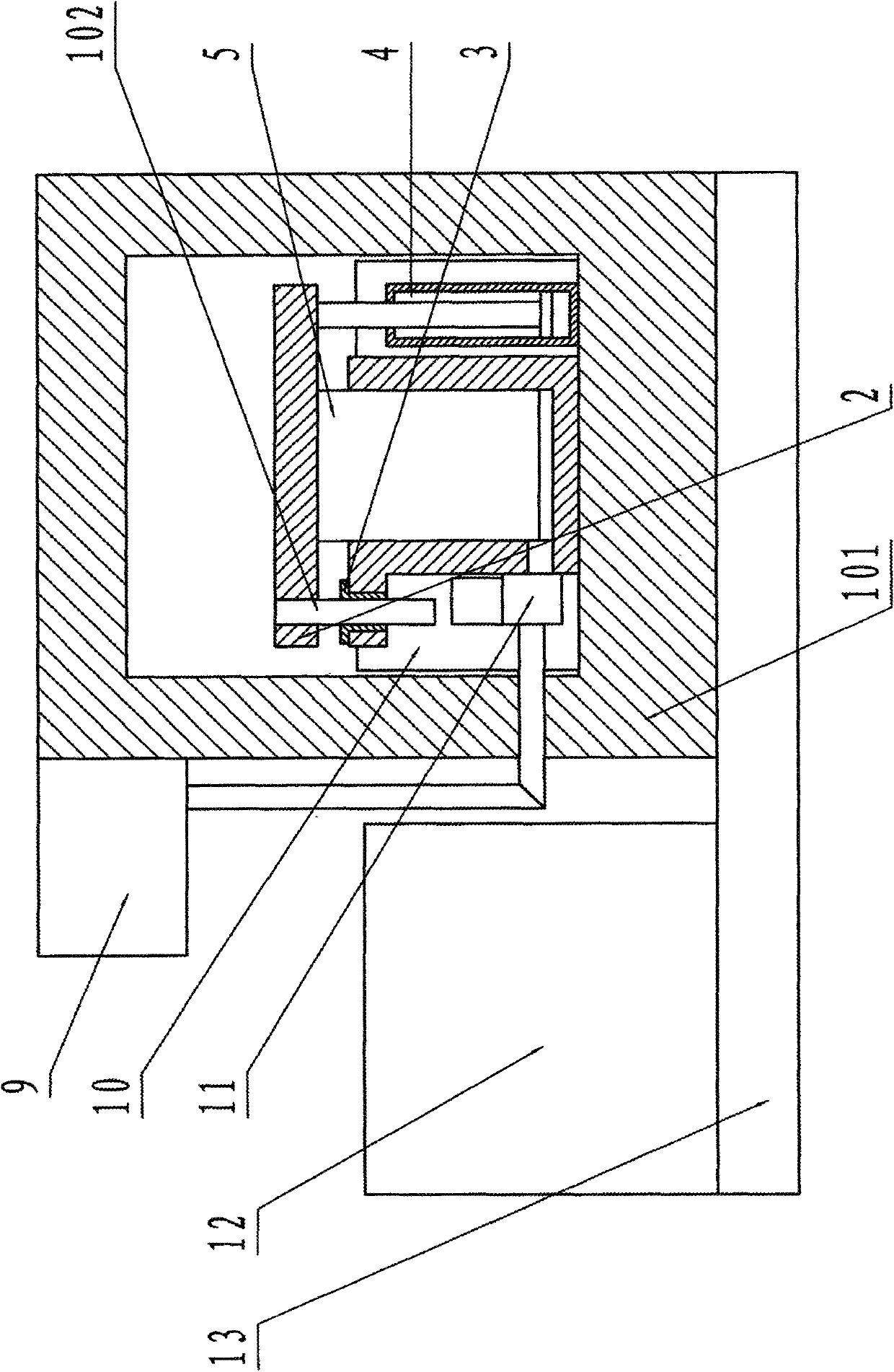

[0022] Embodiments are further described in a preferred manner below in conjunction with the accompanying drawings.

[0023] refer to Figure 1A , the structure consists of 13 parts, 1-lower bottom plate, 2-table slide plate, 3-guide sleeve, 4-small oil cylinder, 5-working oil cylinder, 6-upper top plate, 7-column, 8-nut, 9 -Oil-filled tank, 10-safety protection plate, 11-ultra-high pressure booster, 12-hydraulic station, 13-base. The lower base plate 1 and the upper top plate 6 are fixed into one body through the column 7 with nuts 8 and installed on the lower base plate 1 . The working oil cylinder 5 and the small oil cylinder 4 are fixed on the lower base plate 1, the piston rod of the working oil cylinder 5 and the piston rod of the small oil cylinder 4 are fixed on the slide plate 2 of the workbench, the slide plate 2 of the workbench is fixedly connected with the guide sleeve 3, and can be mounted on the column 7 to move up and down. The ultra-high pressure booster 11 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com