Multistage hollow tube-drawing machine

The technology of a hollow extubation machine and a secondary cylinder, which is applied in the direction of a lifting device and the like, can solve the problems of a hoist pulling system that is cumbersome, reduces the efficiency of recovery, and has a lot of preparation work, and achieves improved portability, improved stability, and is easy to move. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

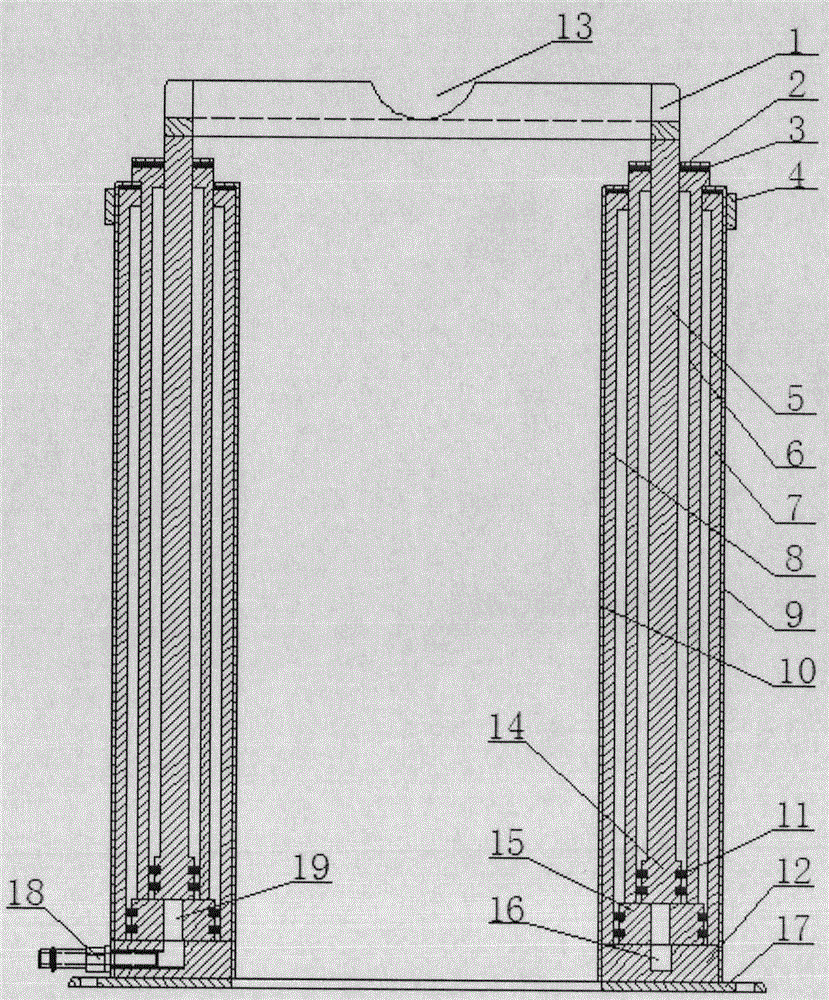

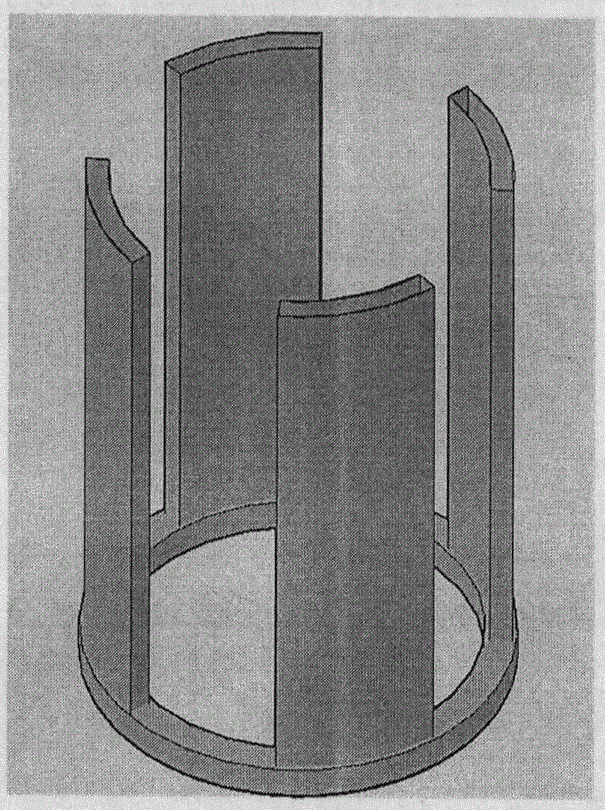

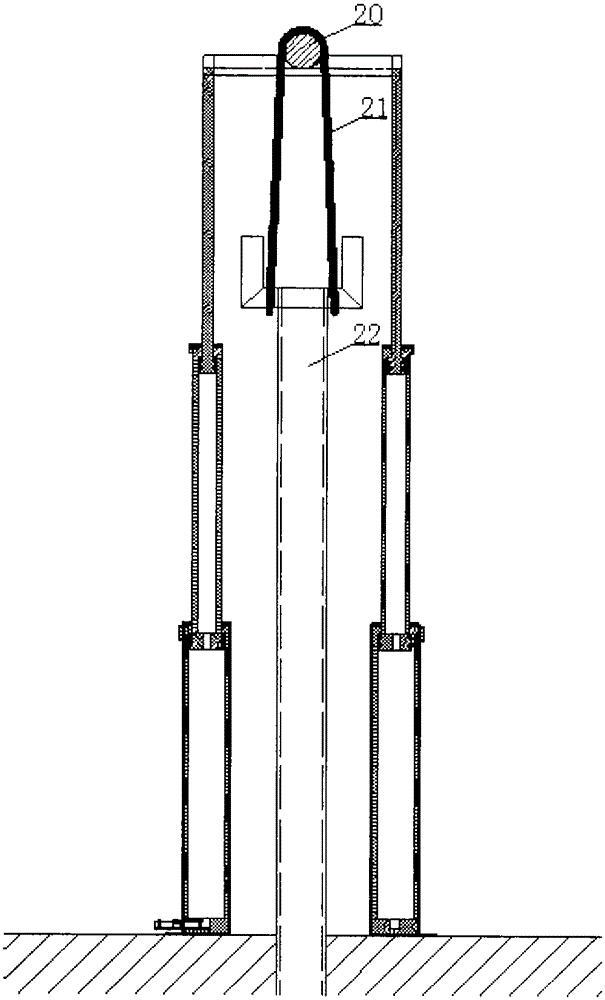

[0019] A multi-stage hollow extubation machine, such as figure 1 As shown, it includes top plate 1, small cover plate 2, gasket 3, outer hoop 4, third-stage cylinder body 5, third-stage cylinder body base 14, second-level cylinder body 6, second-level cylinder body base 15, first-stage cylinder body Outer ring 7, primary cylinder inner ring 8, jacket 9, lining 10, sealing ring 11, primary cylinder base 12, groove 13, main body base 17, oil delivery tank 16, oil delivery hole 19, quick connector 18. An annular cavity is formed between the first-stage cylinder block, the second-stage cylinder block, and the third-stage cylinder block, and is connected with the mobile hydraulic station through the quick joint 18; The oil tank 16 and the oil delivery hole 19 of the secondary cylinder base enter the annular cavity; the outer hoop 4, the outer jacket 9, the inner lining 10, and the main body base 17 maintain the overall stability of the extubation machine. The top plate 1 is a who...

Embodiment 2

[0022] A multi-stage hollow extubation machine, such as figure 1 As shown, it includes top plate 1, small cover plate 2, gasket 3, outer hoop 4, third-stage cylinder body 5, third-stage cylinder body base 14, second-level cylinder body 6, second-level cylinder body base 15, first-stage cylinder body Outer ring 7, primary cylinder inner ring 8, jacket 9, lining 10, sealing ring 11, primary cylinder base 12, groove 13, main body base 17, oil delivery tank 16, oil delivery hole 19, quick connector 18. An annular cavity is formed between the first-stage cylinder block, the second-stage cylinder block, and the third-stage cylinder block, and is connected with the mobile hydraulic station through the quick joint 18; The oil tank 16 and the oil delivery hole 19 of the secondary cylinder base enter the annular cavity; the outer hoop 4, the outer jacket 9, the inner lining 10, and the main body base 17 maintain the overall stability of the extubation machine. The top plate 1 is a who...

Embodiment 3

[0025] A multi-stage hollow extubation machine, such as figure 1 As shown, it includes top plate 1, small cover plate 2, gasket 3, outer hoop 4, third-stage cylinder body 5, third-stage cylinder body base 14, second-level cylinder body 6, second-level cylinder body base 15, first-stage cylinder body Outer ring 7, primary cylinder inner ring 8, jacket 9, lining 10, sealing ring 11, primary cylinder base 12, groove 13, main body base 17, oil delivery tank 16, oil delivery hole 19, quick connector 18. An annular cavity is formed between the first-stage cylinder block, the second-stage cylinder block, and the third-stage cylinder block, and is connected with the mobile hydraulic station through the quick joint 18; The oil tank 16 and the oil delivery hole 19 of the secondary cylinder base enter the annular cavity; the outer hoop 4, the outer jacket 9, the inner lining 10, and the main body base 17 maintain the overall stability of the extubation machine. The top plate 1 is a who...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com