Combined HID electric arc tube

A composite, arc tube technology, applied in the field of arc tubes, can solve the problems affecting the comprehensive pass rate of ceramic arc tubes, not being promoted and popularized, and difficult to package electrodes, etc. Good pressure resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

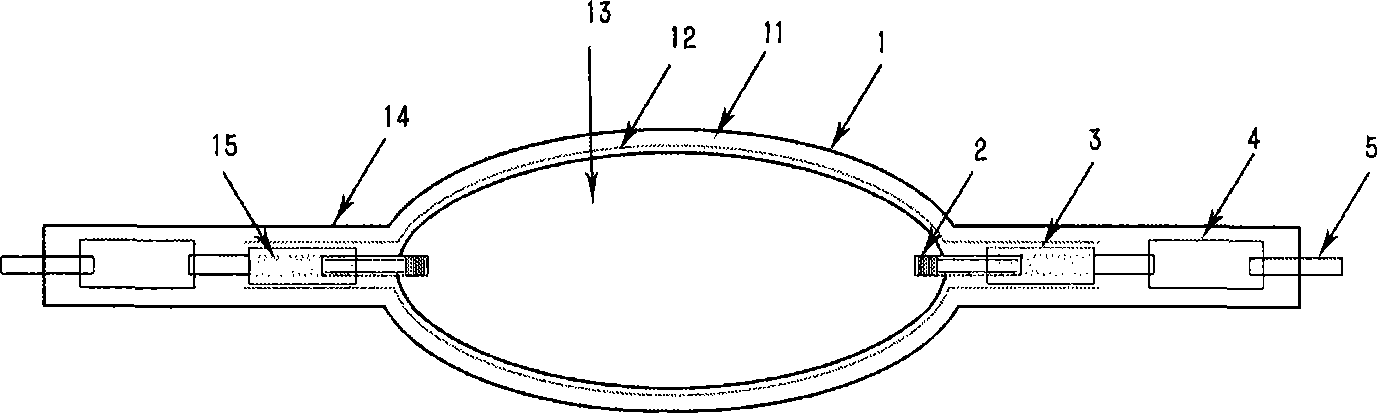

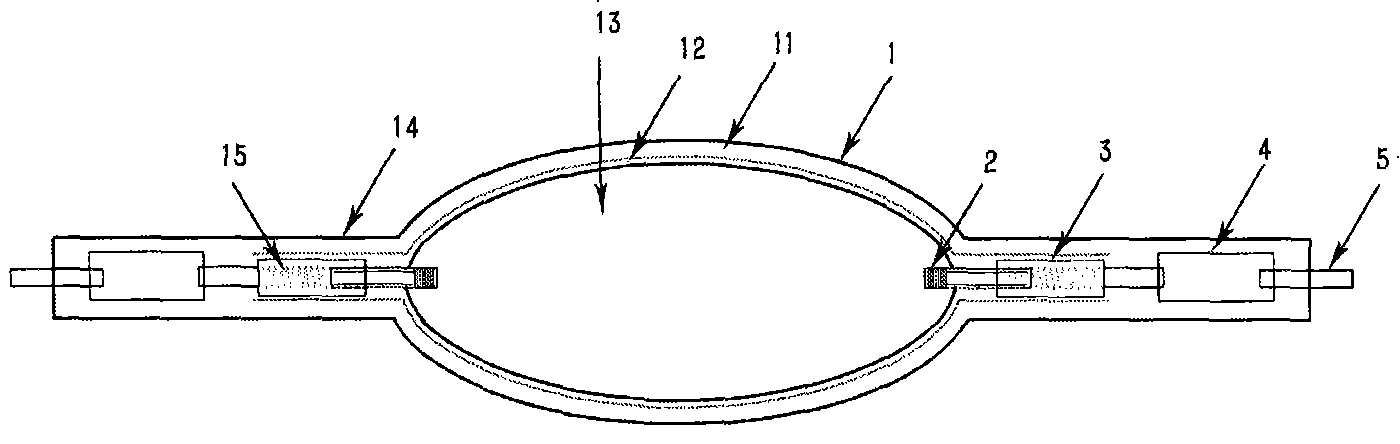

[0020] Hereinafter, the present invention will be specifically described with reference to the accompanying drawings.

[0021] Such as figure 1 As shown, a composite HID arc tube of the present invention has a discharge tube 1, an electrode 2, a molybdenum lead wire 3, a molybdenum foil 4, and a molybdenum outer lead wire 5, and the electrode 2 is arranged in the arc cavity 13 of the discharge tube 1 Inside, the molybdenum lead wire 3, molybdenum foil 4, and molybdenum outer lead wire 5 are connected to the electrode 2 in turn, and are respectively arranged in two lead-out tubes 14 at both ends of the discharge tube 1, wherein the discharge tube 1 is made of fused silica glass or Baykel quartz glass 11 Blown casing, coated with translucent polycrystalline alumina (PCA) 12 to form a composite double-layer shell, two thin and long lead-out tubes 14 are arranged on both sides of the arc cavity 13 of the discharge tube 1, and the lead-out tubes 14, one end of the arc cavity 13 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com