Electrolytic capacitor and method for manufacturing same

A technology of electrolytic capacitors and capacitors, which is applied in the manufacture of electrolytic capacitors, electrolytic capacitors, solid electrolytic capacitors, etc., to achieve the effects of long life, low ESR, and prevention of degradation of withstand voltage characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

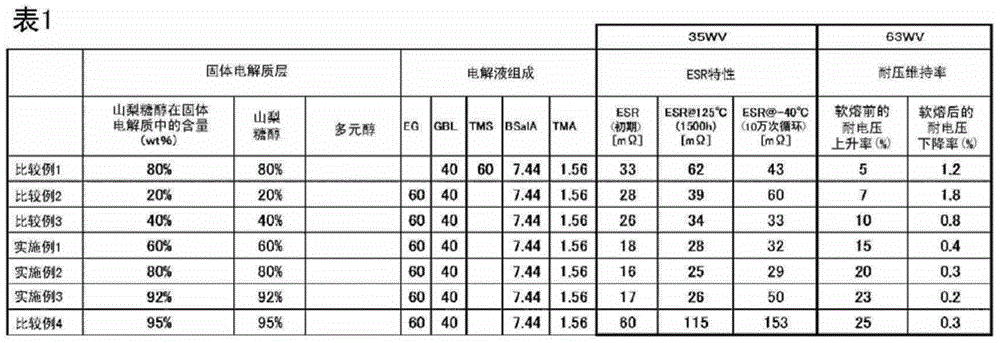

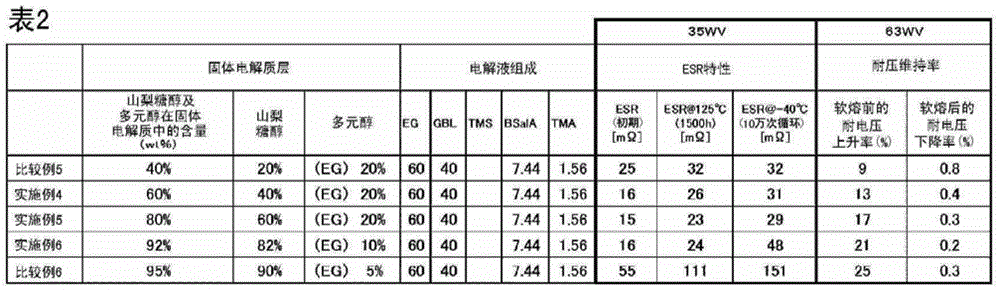

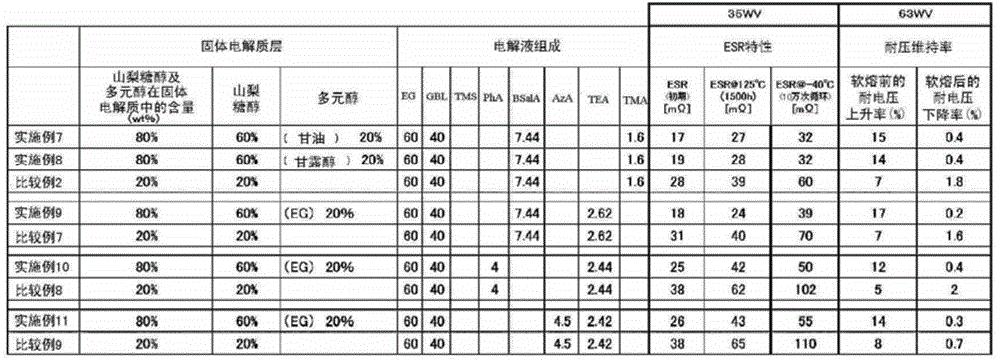

[0056] Next, the present invention will be described in more detail based on Examples and Comparative Examples produced as follows.

[0057] First, an electrode lead-out mechanism is connected to an etched anode foil having an oxide film layer formed on the surface, and an etched cathode foil having a 5V oxide film formed on the surface, and the two electrode foils are separated by cellulose fibers. The separator of the main body was wound to form a capacitor element with an element shape of 6.3φ×6.1L. Then, the capacitor element was immersed in an ammonium dihydrogenphosphate aqueous solution for 40 minutes to carry out repair chemical conversion. Next, immerse in an aqueous solution containing fine particles of PEDOT and a conductive polymer compound dispersion of polystyrenesulfonic acid, sorbitol, or sorbitol and a polyol, lift the capacitor element, and dry it at about 150°C. . Furthermore, the immersion-drying of the capacitor element in the conductive polymer compound...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com