Linear motion guide rail engine

A linear motion and engine technology, applied in the direction of machines/engines, mechanical equipment, etc., can solve problems such as enlargement and cylinder sticking, and achieve the effects of eliminating friction loss, increasing height space, and excellent lubrication effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

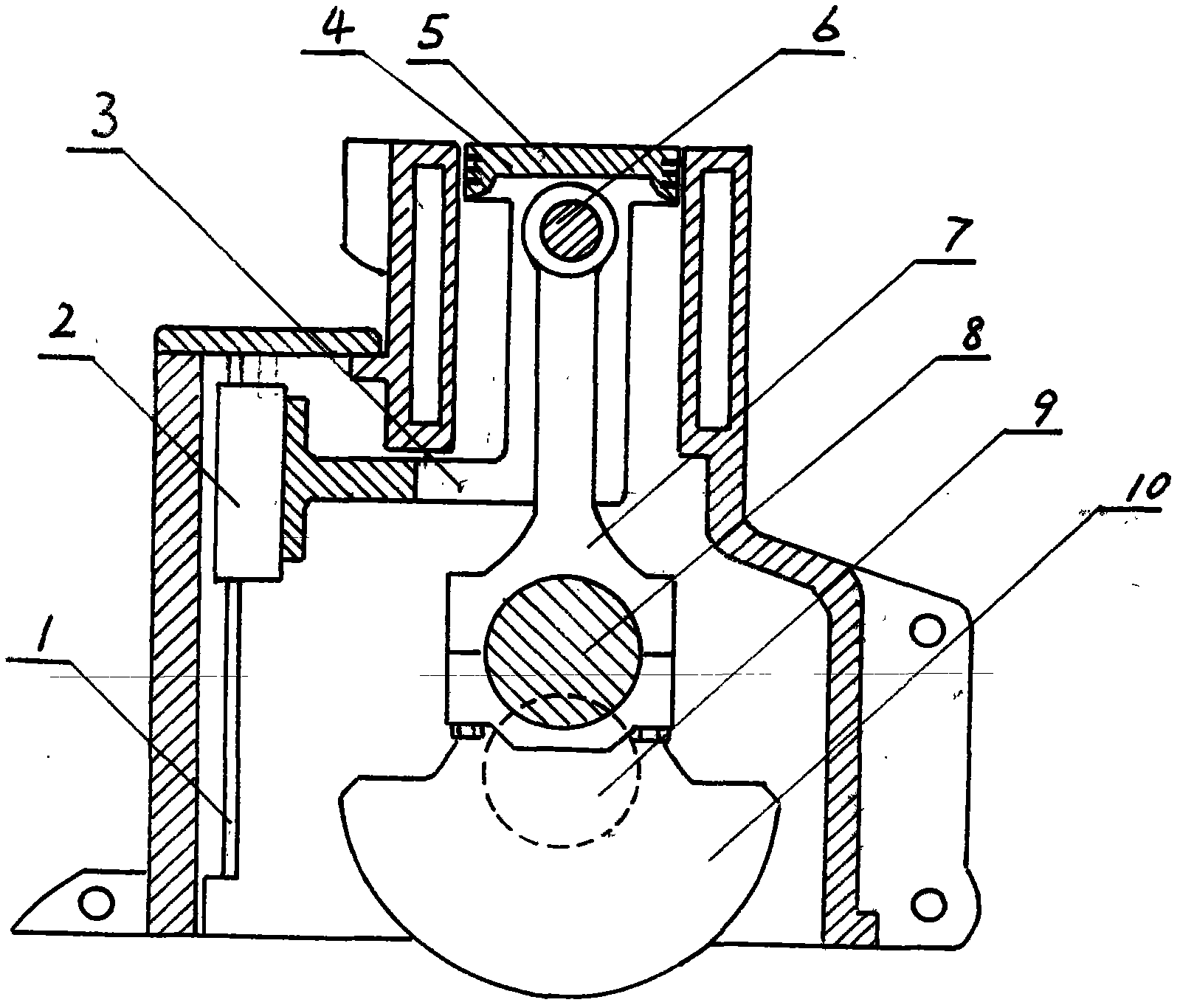

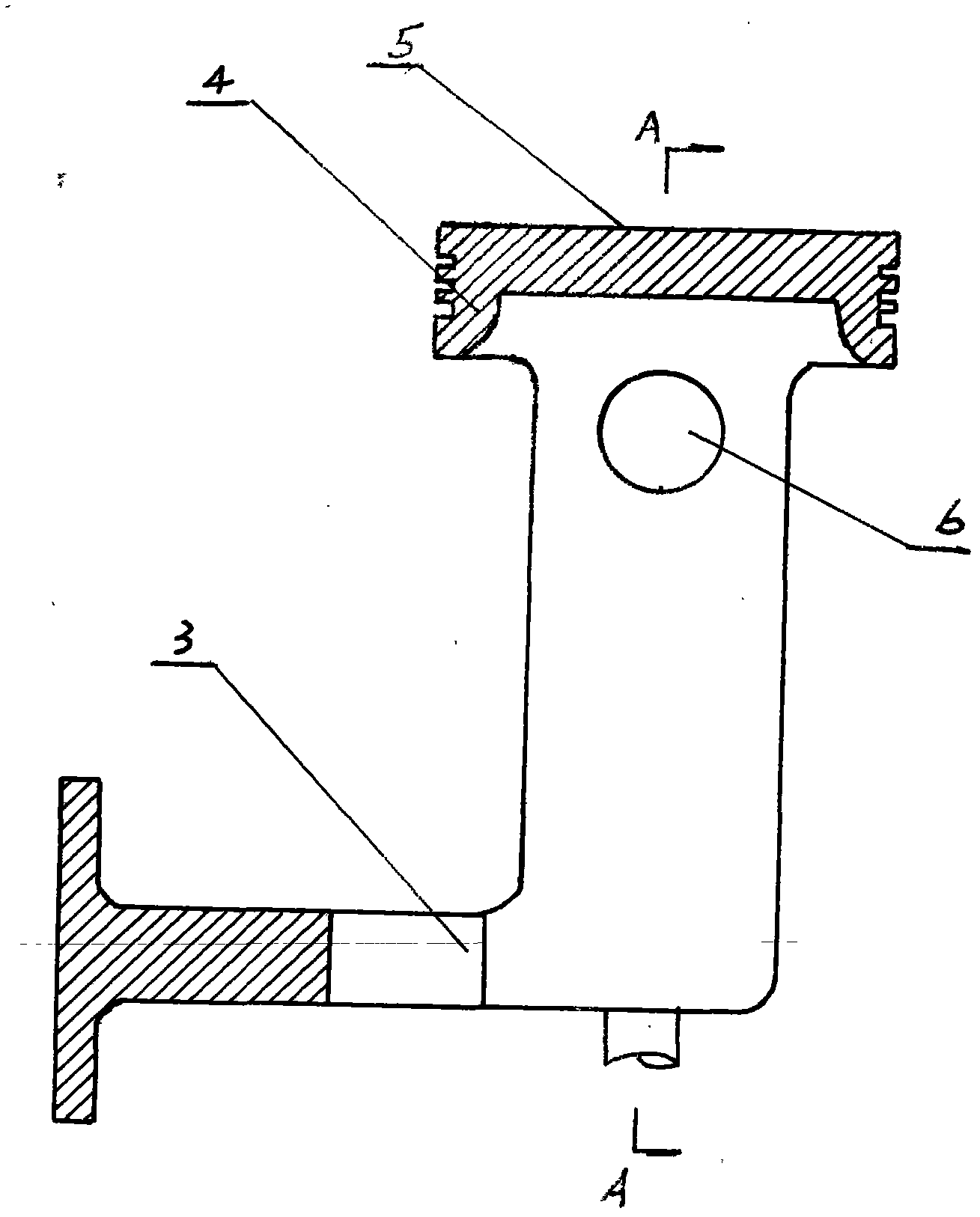

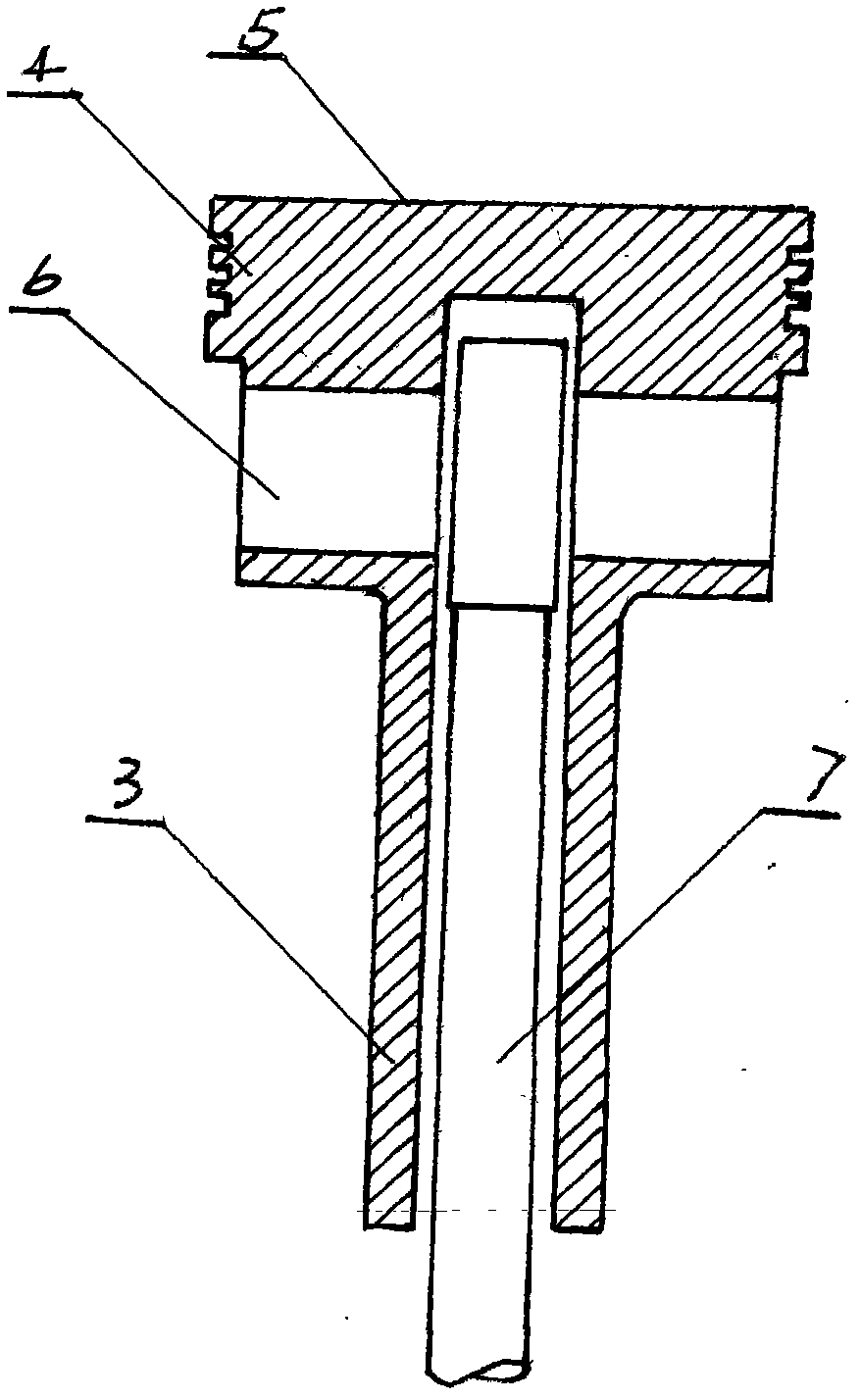

Embodiment 1

[0027] The design and determination of structure, connection mode and structural size are as described in the summary of the invention. Only the cylinder block is an in-line 4-cylinder with a cylinder diameter of 74mm, and the linear motion guide rail is a rolling linear guide rail pair in a rolling linear guide rail.

Embodiment 2

[0029] The design method of structure, connection method and structural size is the same as Example 1, the difference is that the cylinder block is a V-shaped 6-cylinder, the diameter of the cylinder is 74mm, the linear motion guide is a rolling spline pair in the rolling linear guide, and the length of the crankshaft arm is , The piston stroke is increased by 20% on the basis of the original engine crankshaft arm length and piston stroke.

Embodiment 3

[0031] The design and determination of the structure, connection mode, and structural size are the same as in the first embodiment, except that the linear motion guide rail is a linear guide rail in the sliding guide rail. The crankshaft arm length and piston stroke are increased by 30% on the basis of the original engine crankshaft arm length and piston stroke, and the compression ratio is adjusted. The gasoline engine compression ratio is between 6-12, and the diesel engine compression ratio is between 14-22.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com