Compact buffering cylinder

A buffer cylinder, a compact technology, applied in the field of buffer cylinders, can solve the problems of large bore diameter and large floor space of the buffer cylinder, and achieve the effect of increasing the force-bearing area of the buffer, good buffering effect, and reducing the bore diameter

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

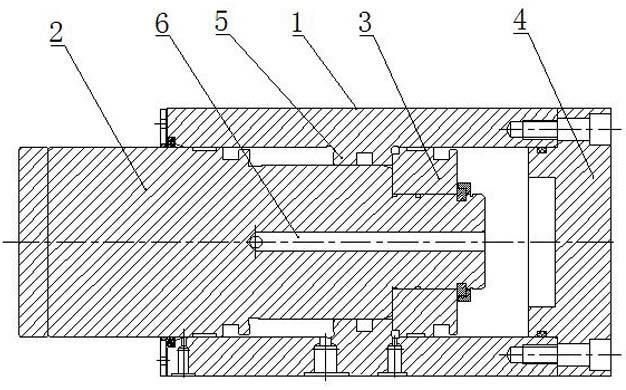

[0007] Such as figure 1 As shown, it includes a cylinder body 1, a piston rod 2, a piston 3, an end cover 4, an isolation ring 5, and a guide channel 6.

[0008] A protruding spacer ring 5 is provided in the middle part of the inner wall of the cylinder body 1, and an end cover 4 is provided at the lower end of the cylinder body 1. The piston rod 2, the spacer ring 5 and the upper part of the cylinder body 1 cooperate to form an upper cylinder structure. , Cooperate with the lower part of the cylinder body 1 to form a lower oil cylinder structure.

[0009] The specific structure is: the piston rod 2 is a stepped cylinder with three sections of cylinders, and the diameters of the stepped cylinders decrease successively. The lower cylinder of piston rod 2 stretches into the lower cavity of cylinder body 1 and is connected and fixed with piston 3, the middle cylinder of piston rod 2 is slidingly fitted with spacer ring, and the upper end cylinder of piston rod 2 is slidingly fit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com