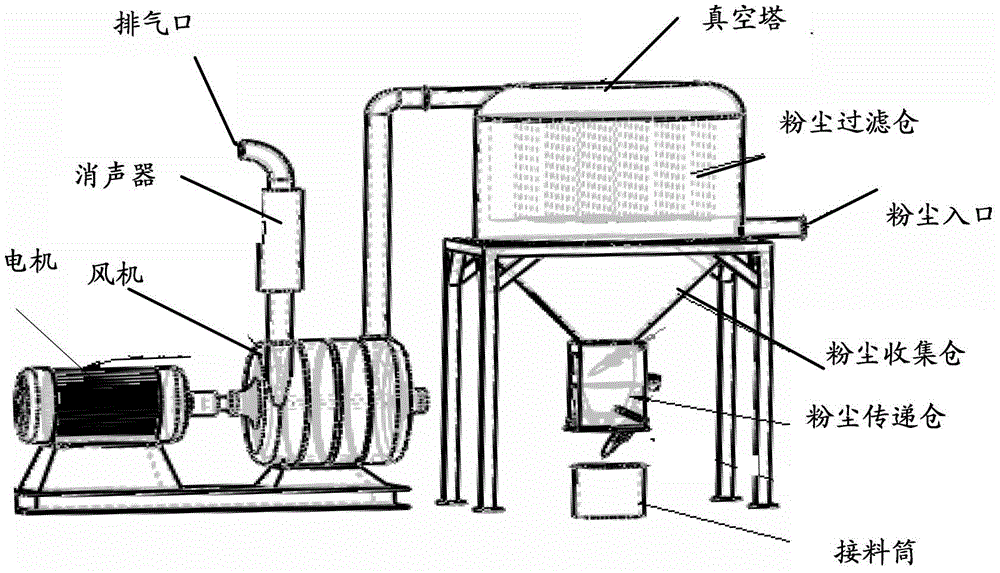

A discharge device and a discharge method

A conversion device and discharge port technology, applied in the direction of maintenance and safety accessories, manufacturing tools, metal processing machinery parts, etc., can solve the problems of energy waste, power source consumption, poor stability, etc., to reduce production costs and save power sources , good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

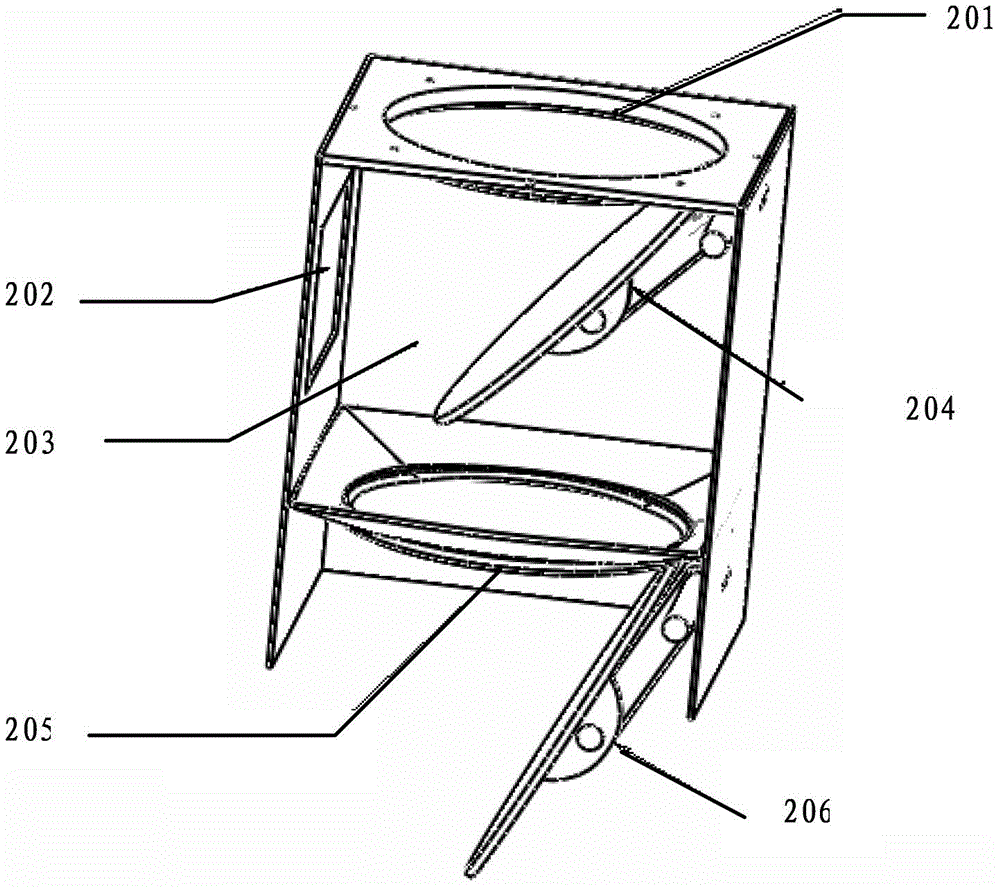

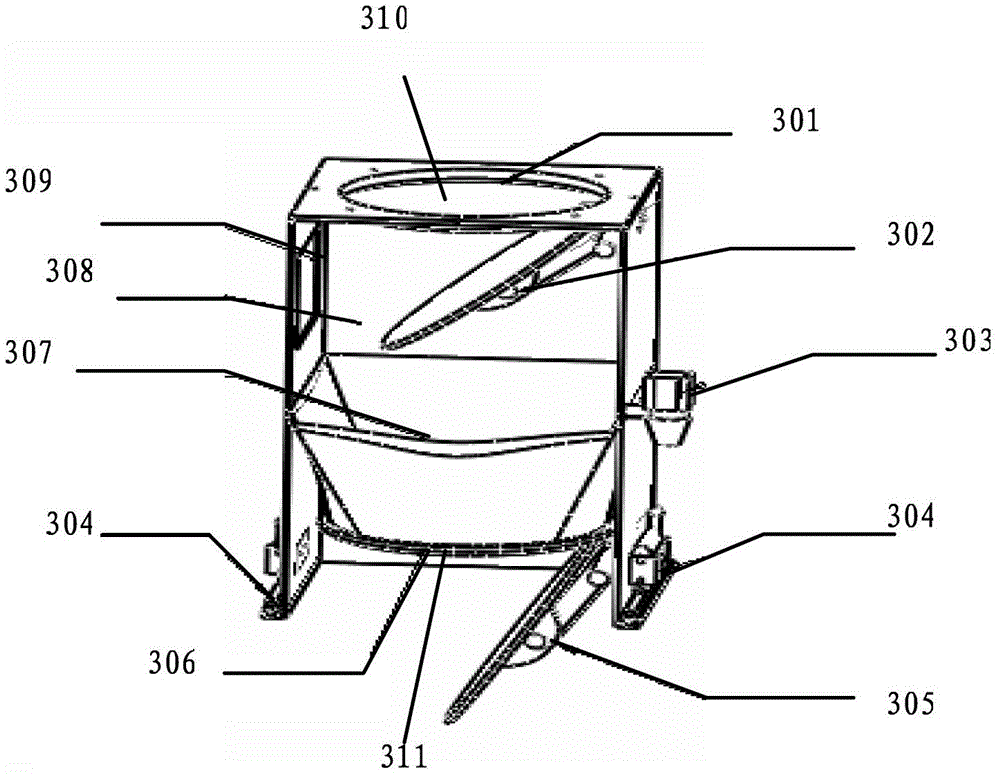

[0020] In view of the problems of serious energy waste, low production efficiency and poor stability of the discharge device in the prior art, the technical solution proposed here in the embodiment of the present invention proposes a temporary pressure adjustment and conversion device. The storage bin and the discharging device including the temporary storage bin ensure that the pressure difference between the upper and lower sides of the baffle is zero before the damper assembly of the discharging device is activated, thus ensuring that the damper does not need to be forcibly opened when it is opened. It will not collide rapidly with the closed ring. At the same time, the air valve drive cylinder only needs to overcome the gravity and rotational friction of the air door baffle to complete its driving task, which can save energy and improve production efficiency. , Good stability.

[0021] The main implementation principles, specific implementation manners and corresponding benef...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com